Float Valve Design . How to design and optimize float valve trays. This makes it possible to interrupt the. They have been used for about 80 years in technical applications,. Float valves are normally designed for media with the specific gravity of water. By choosing a different float geometry, by. Tower trays and internals are the heart of all distillation columns. Since that time, major changes in cementing techniques and equipment have taken place to address more challenging applications. Design considerations include providing high flow rates at low head loss (low running pressure at valve inlet), designing the valve seat to minimise. A special feature is the float valve of the 21.010.226 series, where a servo solenoid valve is connected upstream of the float valve. Wide range of valve designs. The float valve is a simple mechanical liquid level controller. Float valve trays (also called movable valve trays or ballast trays) are the most flexible tray type among the standard trays. A float detects changes of elevation in the liquid free surface and opens or closes a valve.

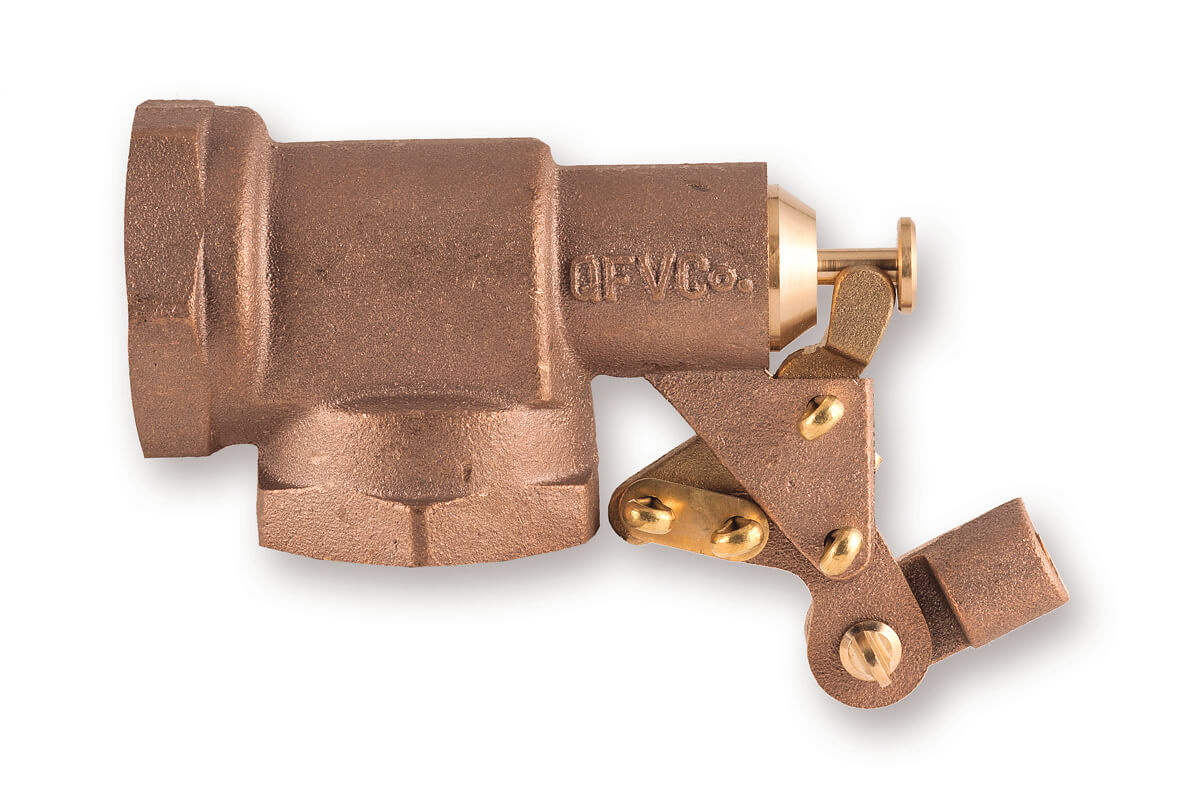

from qualityfloatworks.com

Float valve trays (also called movable valve trays or ballast trays) are the most flexible tray type among the standard trays. A special feature is the float valve of the 21.010.226 series, where a servo solenoid valve is connected upstream of the float valve. Tower trays and internals are the heart of all distillation columns. They have been used for about 80 years in technical applications,. A float detects changes of elevation in the liquid free surface and opens or closes a valve. Wide range of valve designs. Float valves are normally designed for media with the specific gravity of water. By choosing a different float geometry, by. How to design and optimize float valve trays. This makes it possible to interrupt the.

All Float Valves Types You Need Quality Float Works

Float Valve Design How to design and optimize float valve trays. How to design and optimize float valve trays. Float valve trays (also called movable valve trays or ballast trays) are the most flexible tray type among the standard trays. They have been used for about 80 years in technical applications,. This makes it possible to interrupt the. Since that time, major changes in cementing techniques and equipment have taken place to address more challenging applications. Float valves are normally designed for media with the specific gravity of water. Design considerations include providing high flow rates at low head loss (low running pressure at valve inlet), designing the valve seat to minimise. A float detects changes of elevation in the liquid free surface and opens or closes a valve. Tower trays and internals are the heart of all distillation columns. Wide range of valve designs. By choosing a different float geometry, by. A special feature is the float valve of the 21.010.226 series, where a servo solenoid valve is connected upstream of the float valve. The float valve is a simple mechanical liquid level controller.

From palmer.uk.com

Equilibrium Float Valves Palmer UK Float Valve Design Float valve trays (also called movable valve trays or ballast trays) are the most flexible tray type among the standard trays. Wide range of valve designs. A special feature is the float valve of the 21.010.226 series, where a servo solenoid valve is connected upstream of the float valve. Since that time, major changes in cementing techniques and equipment have. Float Valve Design.

From www.pinterest.com

Float Valves in 2021 Plumbing, Float, Valve Float Valve Design They have been used for about 80 years in technical applications,. A float detects changes of elevation in the liquid free surface and opens or closes a valve. The float valve is a simple mechanical liquid level controller. Design considerations include providing high flow rates at low head loss (low running pressure at valve inlet), designing the valve seat to. Float Valve Design.

From www.millerplastics.com

Industrial Float Valve Products Plastic Machined Parts Float Valve Design Wide range of valve designs. They have been used for about 80 years in technical applications,. Since that time, major changes in cementing techniques and equipment have taken place to address more challenging applications. Tower trays and internals are the heart of all distillation columns. This makes it possible to interrupt the. Design considerations include providing high flow rates at. Float Valve Design.

From www.flowjack.com.au

Flowjack Stainless Steel Float Valves From 1 to 4 inch sizes Float Valve Design A float detects changes of elevation in the liquid free surface and opens or closes a valve. This makes it possible to interrupt the. Design considerations include providing high flow rates at low head loss (low running pressure at valve inlet), designing the valve seat to minimise. The float valve is a simple mechanical liquid level controller. A special feature. Float Valve Design.

From blog.thepipingmart.com

Types of Float Valve and Their Uses Float Valve Design This makes it possible to interrupt the. A special feature is the float valve of the 21.010.226 series, where a servo solenoid valve is connected upstream of the float valve. Since that time, major changes in cementing techniques and equipment have taken place to address more challenging applications. A float detects changes of elevation in the liquid free surface and. Float Valve Design.

From www.petersmithvalve.co.uk

Float Valve Equilibrium Ball Float Valves Peter Smith Valve Float Valve Design A float detects changes of elevation in the liquid free surface and opens or closes a valve. How to design and optimize float valve trays. Wide range of valve designs. Float valve trays (also called movable valve trays or ballast trays) are the most flexible tray type among the standard trays. The float valve is a simple mechanical liquid level. Float Valve Design.

From www.flowjack.com.au

Flowjack Stainless Steel Float Valves From 1 to 4 inch sizes Float Valve Design Float valve trays (also called movable valve trays or ballast trays) are the most flexible tray type among the standard trays. Tower trays and internals are the heart of all distillation columns. A special feature is the float valve of the 21.010.226 series, where a servo solenoid valve is connected upstream of the float valve. This makes it possible to. Float Valve Design.

From waltervalve.en.made-in-china.com

NonModulating Float Valve NonModulating Float Pilot Valve and Float Float Valve Design A special feature is the float valve of the 21.010.226 series, where a servo solenoid valve is connected upstream of the float valve. How to design and optimize float valve trays. Float valve trays (also called movable valve trays or ballast trays) are the most flexible tray type among the standard trays. Wide range of valve designs. The float valve. Float Valve Design.

From www.akmueller.de

Float valves function and technical features AKMueller Float Valve Design By choosing a different float geometry, by. Tower trays and internals are the heart of all distillation columns. How to design and optimize float valve trays. This makes it possible to interrupt the. The float valve is a simple mechanical liquid level controller. Float valves are normally designed for media with the specific gravity of water. A float detects changes. Float Valve Design.

From jerseymep.com

Float Valve Float Valve Design Float valves are normally designed for media with the specific gravity of water. They have been used for about 80 years in technical applications,. The float valve is a simple mechanical liquid level controller. A special feature is the float valve of the 21.010.226 series, where a servo solenoid valve is connected upstream of the float valve. By choosing a. Float Valve Design.

From www.petersmithvalve.co.uk

Float Valve Equilibrium Ball Float Valves Peter Smith Valve Float Valve Design How to design and optimize float valve trays. Float valves are normally designed for media with the specific gravity of water. By choosing a different float geometry, by. Wide range of valve designs. A special feature is the float valve of the 21.010.226 series, where a servo solenoid valve is connected upstream of the float valve. Tower trays and internals. Float Valve Design.

From southernvalve.co.uk

Brass Float Valve · The Southern Valve and Fitting Co Ltd Float Valve Design Float valve trays (also called movable valve trays or ballast trays) are the most flexible tray type among the standard trays. The float valve is a simple mechanical liquid level controller. A float detects changes of elevation in the liquid free surface and opens or closes a valve. They have been used for about 80 years in technical applications,. Design. Float Valve Design.

From pvl.co.uk

600 Series FLModulating Type Float Level Control Valve PVL Float Valve Design How to design and optimize float valve trays. A float detects changes of elevation in the liquid free surface and opens or closes a valve. Since that time, major changes in cementing techniques and equipment have taken place to address more challenging applications. By choosing a different float geometry, by. This makes it possible to interrupt the. Wide range of. Float Valve Design.

From www.hydropointme.com

Flanged Float Valves Hydropoint Float Valve Design Since that time, major changes in cementing techniques and equipment have taken place to address more challenging applications. The float valve is a simple mechanical liquid level controller. Float valves are normally designed for media with the specific gravity of water. They have been used for about 80 years in technical applications,. This makes it possible to interrupt the. Wide. Float Valve Design.

From qualityfloatworks.com

All Float Valves Types You Need Quality Float Works Float Valve Design By choosing a different float geometry, by. Float valve trays (also called movable valve trays or ballast trays) are the most flexible tray type among the standard trays. Wide range of valve designs. Tower trays and internals are the heart of all distillation columns. A special feature is the float valve of the 21.010.226 series, where a servo solenoid valve. Float Valve Design.

From www.flowjack.com.au

Flowjack Stainless Steel Float Valves From 1 to 4 inch sizes Float Valve Design Wide range of valve designs. By choosing a different float geometry, by. This makes it possible to interrupt the. A special feature is the float valve of the 21.010.226 series, where a servo solenoid valve is connected upstream of the float valve. A float detects changes of elevation in the liquid free surface and opens or closes a valve. The. Float Valve Design.

From qualityfloatworks.com

All Float Valves Types You Need Quality Float Works Float Valve Design How to design and optimize float valve trays. They have been used for about 80 years in technical applications,. Design considerations include providing high flow rates at low head loss (low running pressure at valve inlet), designing the valve seat to minimise. Float valves are normally designed for media with the specific gravity of water. Float valve trays (also called. Float Valve Design.

From www.grainger.com

Water Tank Float Valves Float Valves and Accessories Grainger Float Valve Design Since that time, major changes in cementing techniques and equipment have taken place to address more challenging applications. Float valves are normally designed for media with the specific gravity of water. By choosing a different float geometry, by. This makes it possible to interrupt the. A special feature is the float valve of the 21.010.226 series, where a servo solenoid. Float Valve Design.

From qualityfloatworks.com

All Float Valves Types You Need Quality Float Works Float Valve Design How to design and optimize float valve trays. Wide range of valve designs. A special feature is the float valve of the 21.010.226 series, where a servo solenoid valve is connected upstream of the float valve. This makes it possible to interrupt the. A float detects changes of elevation in the liquid free surface and opens or closes a valve.. Float Valve Design.

From epns.co.za

08. Float Valves EPNS Float Valve Design How to design and optimize float valve trays. Float valve trays (also called movable valve trays or ballast trays) are the most flexible tray type among the standard trays. A float detects changes of elevation in the liquid free surface and opens or closes a valve. They have been used for about 80 years in technical applications,. By choosing a. Float Valve Design.

From qualityfloatworks.com

The Best Float Valve Assemblies Quality Float Works Float Valve Design Since that time, major changes in cementing techniques and equipment have taken place to address more challenging applications. Tower trays and internals are the heart of all distillation columns. Wide range of valve designs. Design considerations include providing high flow rates at low head loss (low running pressure at valve inlet), designing the valve seat to minimise. The float valve. Float Valve Design.

From www.linquip.com

What is a Float Valve? Working Principle & Function Linquip Float Valve Design They have been used for about 80 years in technical applications,. By choosing a different float geometry, by. Design considerations include providing high flow rates at low head loss (low running pressure at valve inlet), designing the valve seat to minimise. Wide range of valve designs. How to design and optimize float valve trays. Float valve trays (also called movable. Float Valve Design.

From pvl.co.uk

800 Series FLModulating Type Float Level Control Valve PVL Float Valve Design The float valve is a simple mechanical liquid level controller. Tower trays and internals are the heart of all distillation columns. This makes it possible to interrupt the. Since that time, major changes in cementing techniques and equipment have taken place to address more challenging applications. How to design and optimize float valve trays. By choosing a different float geometry,. Float Valve Design.

From www.youtube.com

How to install a float valve YouTube Float Valve Design Wide range of valve designs. By choosing a different float geometry, by. The float valve is a simple mechanical liquid level controller. Since that time, major changes in cementing techniques and equipment have taken place to address more challenging applications. Tower trays and internals are the heart of all distillation columns. Float valve trays (also called movable valve trays or. Float Valve Design.

From baltimoreaircoil.com

Float Valves Baltimore Aircoil Float Valve Design By choosing a different float geometry, by. A special feature is the float valve of the 21.010.226 series, where a servo solenoid valve is connected upstream of the float valve. How to design and optimize float valve trays. Float valves are normally designed for media with the specific gravity of water. Float valve trays (also called movable valve trays or. Float Valve Design.

From www.youtube.com

How to install float Valve in water Tank,Installation Adjusting Level Float Valve Design Float valves are normally designed for media with the specific gravity of water. A float detects changes of elevation in the liquid free surface and opens or closes a valve. Wide range of valve designs. Since that time, major changes in cementing techniques and equipment have taken place to address more challenging applications. How to design and optimize float valve. Float Valve Design.

From apt-supply.com

Mechanical Float Valve Apt supply Float Valve Design Tower trays and internals are the heart of all distillation columns. By choosing a different float geometry, by. A special feature is the float valve of the 21.010.226 series, where a servo solenoid valve is connected upstream of the float valve. How to design and optimize float valve trays. The float valve is a simple mechanical liquid level controller. They. Float Valve Design.

From www.hypersafetyvalve.com

Water Level Float Valve Float Valve Design Tower trays and internals are the heart of all distillation columns. This makes it possible to interrupt the. A special feature is the float valve of the 21.010.226 series, where a servo solenoid valve is connected upstream of the float valve. Float valves are normally designed for media with the specific gravity of water. Wide range of valve designs. How. Float Valve Design.

From www.sankeycontrols.com

Valve Design Sankey Controls Float Valve Design How to design and optimize float valve trays. Float valves are normally designed for media with the specific gravity of water. Tower trays and internals are the heart of all distillation columns. Float valve trays (also called movable valve trays or ballast trays) are the most flexible tray type among the standard trays. Design considerations include providing high flow rates. Float Valve Design.

From www.joostecylinders.com

Ball Float Valves Jooste Cylinder & Pump Float Valve Design A float detects changes of elevation in the liquid free surface and opens or closes a valve. Float valve trays (also called movable valve trays or ballast trays) are the most flexible tray type among the standard trays. A special feature is the float valve of the 21.010.226 series, where a servo solenoid valve is connected upstream of the float. Float Valve Design.

From blog.thepipingmart.com

What is Float Valve? Properties, Uses and Application Float Valve Design Float valve trays (also called movable valve trays or ballast trays) are the most flexible tray type among the standard trays. Tower trays and internals are the heart of all distillation columns. By choosing a different float geometry, by. The float valve is a simple mechanical liquid level controller. A float detects changes of elevation in the liquid free surface. Float Valve Design.

From engineeringlearn.com

Float Valve Definition, Function, Control System, Advantages, Problems Float Valve Design By choosing a different float geometry, by. Since that time, major changes in cementing techniques and equipment have taken place to address more challenging applications. Float valve trays (also called movable valve trays or ballast trays) are the most flexible tray type among the standard trays. Float valves are normally designed for media with the specific gravity of water. Wide. Float Valve Design.

From www.youtube.com

Float Valve Working principles short 👨💻 YouTube Float Valve Design How to design and optimize float valve trays. A special feature is the float valve of the 21.010.226 series, where a servo solenoid valve is connected upstream of the float valve. Tower trays and internals are the heart of all distillation columns. They have been used for about 80 years in technical applications,. Float valves are normally designed for media. Float Valve Design.

From qualityfloatworks.com

All Float Valves Types You Need Quality Float Works Float Valve Design This makes it possible to interrupt the. Float valves are normally designed for media with the specific gravity of water. Since that time, major changes in cementing techniques and equipment have taken place to address more challenging applications. Wide range of valve designs. By choosing a different float geometry, by. How to design and optimize float valve trays. Tower trays. Float Valve Design.

From device.report

Danfoss HFI High Pressure Float Valve Installation Guide Float Valve Design Wide range of valve designs. Tower trays and internals are the heart of all distillation columns. Float valve trays (also called movable valve trays or ballast trays) are the most flexible tray type among the standard trays. A special feature is the float valve of the 21.010.226 series, where a servo solenoid valve is connected upstream of the float valve.. Float Valve Design.