What Kind Of Gas Do You Need For Mig Welding . C2 or 2% carbon dioxide and 98% argon. Gas welding uses a shielding gas to protect the weld from the atmosphere, while flux core welding doesn’t have an external gas but includes flux within the hollow electrode. As an amazon associate i earn from qualifying purchases. For mig welding, use a shielding gas that suits your material. The more common mixtures and gasses are. The shielding gas protects the molten metal from exposure to atmospheric oxygen, hydrogen, and nitrogen, which could. A 75% argon and 25% helium blend is suitable. Mig welding is probably what you picture when you think of welding as it is the most common type of welding process due to being easy to learn and versatile. I recently used this last mixture, when taking my 3g mig welder certification.

from weldguru.com

Mig welding is probably what you picture when you think of welding as it is the most common type of welding process due to being easy to learn and versatile. A 75% argon and 25% helium blend is suitable. For mig welding, use a shielding gas that suits your material. C2 or 2% carbon dioxide and 98% argon. The more common mixtures and gasses are. I recently used this last mixture, when taking my 3g mig welder certification. As an amazon associate i earn from qualifying purchases. Gas welding uses a shielding gas to protect the weld from the atmosphere, while flux core welding doesn’t have an external gas but includes flux within the hollow electrode. The shielding gas protects the molten metal from exposure to atmospheric oxygen, hydrogen, and nitrogen, which could.

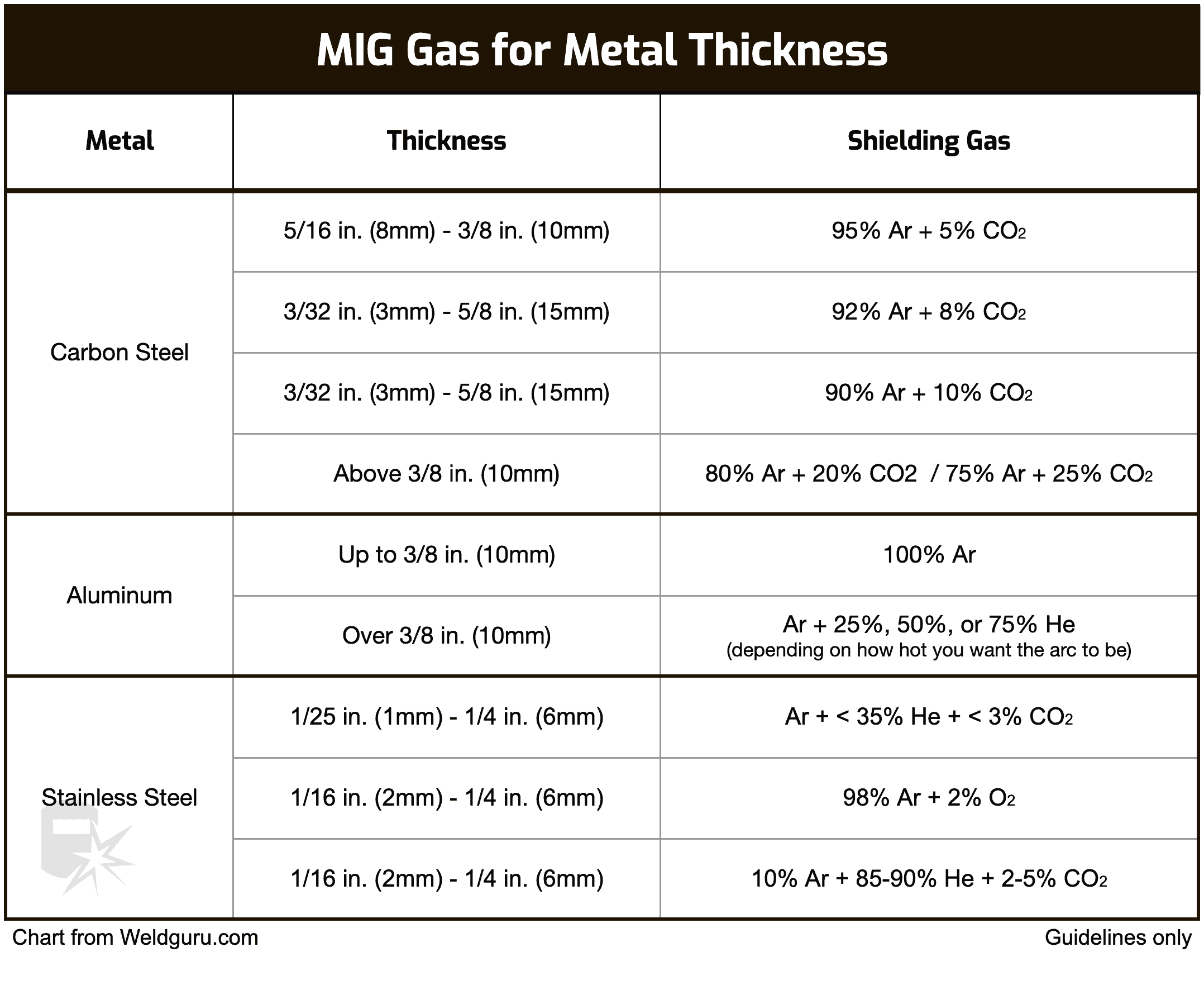

Best Gas for MIG Welding What to Use (with Chart)

What Kind Of Gas Do You Need For Mig Welding C2 or 2% carbon dioxide and 98% argon. As an amazon associate i earn from qualifying purchases. For mig welding, use a shielding gas that suits your material. C2 or 2% carbon dioxide and 98% argon. Gas welding uses a shielding gas to protect the weld from the atmosphere, while flux core welding doesn’t have an external gas but includes flux within the hollow electrode. I recently used this last mixture, when taking my 3g mig welder certification. Mig welding is probably what you picture when you think of welding as it is the most common type of welding process due to being easy to learn and versatile. The more common mixtures and gasses are. A 75% argon and 25% helium blend is suitable. The shielding gas protects the molten metal from exposure to atmospheric oxygen, hydrogen, and nitrogen, which could.

From www.instructables.com

How to Weld MIG Welding 11 Steps (with Pictures) What Kind Of Gas Do You Need For Mig Welding A 75% argon and 25% helium blend is suitable. C2 or 2% carbon dioxide and 98% argon. The shielding gas protects the molten metal from exposure to atmospheric oxygen, hydrogen, and nitrogen, which could. The more common mixtures and gasses are. I recently used this last mixture, when taking my 3g mig welder certification. As an amazon associate i earn. What Kind Of Gas Do You Need For Mig Welding.

From www.mech4study.com

Gas Welding Principle, Working, Equipment, Application, Advantages What Kind Of Gas Do You Need For Mig Welding C2 or 2% carbon dioxide and 98% argon. I recently used this last mixture, when taking my 3g mig welder certification. The more common mixtures and gasses are. For mig welding, use a shielding gas that suits your material. A 75% argon and 25% helium blend is suitable. As an amazon associate i earn from qualifying purchases. Mig welding is. What Kind Of Gas Do You Need For Mig Welding.

From giosztkta.blob.core.windows.net

What Kind Of Tank Do I Need For Mig Welding at Annie Lee blog What Kind Of Gas Do You Need For Mig Welding Mig welding is probably what you picture when you think of welding as it is the most common type of welding process due to being easy to learn and versatile. I recently used this last mixture, when taking my 3g mig welder certification. Gas welding uses a shielding gas to protect the weld from the atmosphere, while flux core welding. What Kind Of Gas Do You Need For Mig Welding.

From www.midiaesportiva.net

How to Use and Operate a MIG Welder midiaesportiva What Kind Of Gas Do You Need For Mig Welding Mig welding is probably what you picture when you think of welding as it is the most common type of welding process due to being easy to learn and versatile. Gas welding uses a shielding gas to protect the weld from the atmosphere, while flux core welding doesn’t have an external gas but includes flux within the hollow electrode. C2. What Kind Of Gas Do You Need For Mig Welding.

From weldguru.com

MIG Welding Gas Pressure Settings (with Charts) What Kind Of Gas Do You Need For Mig Welding The shielding gas protects the molten metal from exposure to atmospheric oxygen, hydrogen, and nitrogen, which could. C2 or 2% carbon dioxide and 98% argon. The more common mixtures and gasses are. A 75% argon and 25% helium blend is suitable. As an amazon associate i earn from qualifying purchases. I recently used this last mixture, when taking my 3g. What Kind Of Gas Do You Need For Mig Welding.

From weldgears.com

Can You MIG Weld Without Gas? (All You Need to Know) Weld Gears What Kind Of Gas Do You Need For Mig Welding For mig welding, use a shielding gas that suits your material. As an amazon associate i earn from qualifying purchases. Gas welding uses a shielding gas to protect the weld from the atmosphere, while flux core welding doesn’t have an external gas but includes flux within the hollow electrode. The shielding gas protects the molten metal from exposure to atmospheric. What Kind Of Gas Do You Need For Mig Welding.

From www.kmart.com

Craftsman MIG 135m Gas/Gasless Wire Feed Welder What Kind Of Gas Do You Need For Mig Welding As an amazon associate i earn from qualifying purchases. The more common mixtures and gasses are. Gas welding uses a shielding gas to protect the weld from the atmosphere, while flux core welding doesn’t have an external gas but includes flux within the hollow electrode. C2 or 2% carbon dioxide and 98% argon. I recently used this last mixture, when. What Kind Of Gas Do You Need For Mig Welding.

From weldguru.com

Best Gas for MIG Welding What to Use (with Chart) What Kind Of Gas Do You Need For Mig Welding Gas welding uses a shielding gas to protect the weld from the atmosphere, while flux core welding doesn’t have an external gas but includes flux within the hollow electrode. A 75% argon and 25% helium blend is suitable. I recently used this last mixture, when taking my 3g mig welder certification. Mig welding is probably what you picture when you. What Kind Of Gas Do You Need For Mig Welding.

From makemoneywelding.com

Explained Best MIG Welding Shielding Gas To Use What Kind Of Gas Do You Need For Mig Welding The more common mixtures and gasses are. A 75% argon and 25% helium blend is suitable. Mig welding is probably what you picture when you think of welding as it is the most common type of welding process due to being easy to learn and versatile. I recently used this last mixture, when taking my 3g mig welder certification. C2. What Kind Of Gas Do You Need For Mig Welding.

From itstillruns.com

How to Set the Gas on an MIG Welder It Still Runs What Kind Of Gas Do You Need For Mig Welding C2 or 2% carbon dioxide and 98% argon. For mig welding, use a shielding gas that suits your material. I recently used this last mixture, when taking my 3g mig welder certification. Gas welding uses a shielding gas to protect the weld from the atmosphere, while flux core welding doesn’t have an external gas but includes flux within the hollow. What Kind Of Gas Do You Need For Mig Welding.

From www.youtube.com

Aluminum MIG Welding YouTube What Kind Of Gas Do You Need For Mig Welding As an amazon associate i earn from qualifying purchases. Mig welding is probably what you picture when you think of welding as it is the most common type of welding process due to being easy to learn and versatile. A 75% argon and 25% helium blend is suitable. C2 or 2% carbon dioxide and 98% argon. For mig welding, use. What Kind Of Gas Do You Need For Mig Welding.

From giosztkta.blob.core.windows.net

What Kind Of Tank Do I Need For Mig Welding at Annie Lee blog What Kind Of Gas Do You Need For Mig Welding C2 or 2% carbon dioxide and 98% argon. The shielding gas protects the molten metal from exposure to atmospheric oxygen, hydrogen, and nitrogen, which could. Mig welding is probably what you picture when you think of welding as it is the most common type of welding process due to being easy to learn and versatile. As an amazon associate i. What Kind Of Gas Do You Need For Mig Welding.

From thetoolreviews.com

Do You Need Gas for Mig Welding? The Tool Reviews What Kind Of Gas Do You Need For Mig Welding Gas welding uses a shielding gas to protect the weld from the atmosphere, while flux core welding doesn’t have an external gas but includes flux within the hollow electrode. The more common mixtures and gasses are. C2 or 2% carbon dioxide and 98% argon. For mig welding, use a shielding gas that suits your material. A 75% argon and 25%. What Kind Of Gas Do You Need For Mig Welding.

From www.jlcatj.gob.mx

Gmaw Welding Online Discounted, Save 56 jlcatj.gob.mx What Kind Of Gas Do You Need For Mig Welding As an amazon associate i earn from qualifying purchases. Mig welding is probably what you picture when you think of welding as it is the most common type of welding process due to being easy to learn and versatile. C2 or 2% carbon dioxide and 98% argon. The shielding gas protects the molten metal from exposure to atmospheric oxygen, hydrogen,. What Kind Of Gas Do You Need For Mig Welding.

From weldguru.com

Best Gas for MIG Welding What to Use (with Chart) What Kind Of Gas Do You Need For Mig Welding The shielding gas protects the molten metal from exposure to atmospheric oxygen, hydrogen, and nitrogen, which could. A 75% argon and 25% helium blend is suitable. For mig welding, use a shielding gas that suits your material. I recently used this last mixture, when taking my 3g mig welder certification. Mig welding is probably what you picture when you think. What Kind Of Gas Do You Need For Mig Welding.

From www.youtube.com

🔥 MIG Welding Stainless Steel YouTube What Kind Of Gas Do You Need For Mig Welding The more common mixtures and gasses are. C2 or 2% carbon dioxide and 98% argon. Gas welding uses a shielding gas to protect the weld from the atmosphere, while flux core welding doesn’t have an external gas but includes flux within the hollow electrode. As an amazon associate i earn from qualifying purchases. I recently used this last mixture, when. What Kind Of Gas Do You Need For Mig Welding.

From www.walmart.com

FCInert Gas Welding Hose, Tig Welding Connection Hose, Tig Mig, 5/8 What Kind Of Gas Do You Need For Mig Welding Mig welding is probably what you picture when you think of welding as it is the most common type of welding process due to being easy to learn and versatile. The shielding gas protects the molten metal from exposure to atmospheric oxygen, hydrogen, and nitrogen, which could. C2 or 2% carbon dioxide and 98% argon. As an amazon associate i. What Kind Of Gas Do You Need For Mig Welding.

From fyolbqnmj.blob.core.windows.net

Components Of Mig Welding at Steven Delaughter blog What Kind Of Gas Do You Need For Mig Welding I recently used this last mixture, when taking my 3g mig welder certification. Gas welding uses a shielding gas to protect the weld from the atmosphere, while flux core welding doesn’t have an external gas but includes flux within the hollow electrode. The shielding gas protects the molten metal from exposure to atmospheric oxygen, hydrogen, and nitrogen, which could. A. What Kind Of Gas Do You Need For Mig Welding.

From giosztkta.blob.core.windows.net

What Kind Of Tank Do I Need For Mig Welding at Annie Lee blog What Kind Of Gas Do You Need For Mig Welding C2 or 2% carbon dioxide and 98% argon. The shielding gas protects the molten metal from exposure to atmospheric oxygen, hydrogen, and nitrogen, which could. Mig welding is probably what you picture when you think of welding as it is the most common type of welding process due to being easy to learn and versatile. As an amazon associate i. What Kind Of Gas Do You Need For Mig Welding.

From gowelding.org

MIG Welding Gases Choices and Options for Most Metals What Kind Of Gas Do You Need For Mig Welding As an amazon associate i earn from qualifying purchases. A 75% argon and 25% helium blend is suitable. The shielding gas protects the molten metal from exposure to atmospheric oxygen, hydrogen, and nitrogen, which could. For mig welding, use a shielding gas that suits your material. C2 or 2% carbon dioxide and 98% argon. I recently used this last mixture,. What Kind Of Gas Do You Need For Mig Welding.

From www.welding.com.au

MIG Welding Essentials Gas vs Gasless WIA What Kind Of Gas Do You Need For Mig Welding The more common mixtures and gasses are. C2 or 2% carbon dioxide and 98% argon. Gas welding uses a shielding gas to protect the weld from the atmosphere, while flux core welding doesn’t have an external gas but includes flux within the hollow electrode. A 75% argon and 25% helium blend is suitable. For mig welding, use a shielding gas. What Kind Of Gas Do You Need For Mig Welding.

From www.youtube.com

MIG WELDING WITH AND WITHOUT GAS WHAT WELDS LOOK LIKE IF YOU RUN OUT What Kind Of Gas Do You Need For Mig Welding As an amazon associate i earn from qualifying purchases. For mig welding, use a shielding gas that suits your material. A 75% argon and 25% helium blend is suitable. The more common mixtures and gasses are. The shielding gas protects the molten metal from exposure to atmospheric oxygen, hydrogen, and nitrogen, which could. C2 or 2% carbon dioxide and 98%. What Kind Of Gas Do You Need For Mig Welding.

From www.hollyfab.com

Common Welding Methods What Kind Of Gas Do You Need For Mig Welding As an amazon associate i earn from qualifying purchases. Mig welding is probably what you picture when you think of welding as it is the most common type of welding process due to being easy to learn and versatile. For mig welding, use a shielding gas that suits your material. Gas welding uses a shielding gas to protect the weld. What Kind Of Gas Do You Need For Mig Welding.

From diagramlistrenverses.z14.web.core.windows.net

Types Of Welding Process With Diagram What Kind Of Gas Do You Need For Mig Welding A 75% argon and 25% helium blend is suitable. The shielding gas protects the molten metal from exposure to atmospheric oxygen, hydrogen, and nitrogen, which could. As an amazon associate i earn from qualifying purchases. I recently used this last mixture, when taking my 3g mig welder certification. Mig welding is probably what you picture when you think of welding. What Kind Of Gas Do You Need For Mig Welding.

From www.familyhandyman.com

Here's What You Need to Know About MIG Welding Pros, Cons, Cost and What Kind Of Gas Do You Need For Mig Welding Gas welding uses a shielding gas to protect the weld from the atmosphere, while flux core welding doesn’t have an external gas but includes flux within the hollow electrode. The more common mixtures and gasses are. Mig welding is probably what you picture when you think of welding as it is the most common type of welding process due to. What Kind Of Gas Do You Need For Mig Welding.

From www.technoxmachine.com

MIG vs TIG Welding Types, Materials, and Applications A Guide What Kind Of Gas Do You Need For Mig Welding C2 or 2% carbon dioxide and 98% argon. As an amazon associate i earn from qualifying purchases. The shielding gas protects the molten metal from exposure to atmospheric oxygen, hydrogen, and nitrogen, which could. Mig welding is probably what you picture when you think of welding as it is the most common type of welding process due to being easy. What Kind Of Gas Do You Need For Mig Welding.

From exovybpej.blob.core.windows.net

Welding Amp Chart Mig at Merri Bauer blog What Kind Of Gas Do You Need For Mig Welding Gas welding uses a shielding gas to protect the weld from the atmosphere, while flux core welding doesn’t have an external gas but includes flux within the hollow electrode. The shielding gas protects the molten metal from exposure to atmospheric oxygen, hydrogen, and nitrogen, which could. The more common mixtures and gasses are. For mig welding, use a shielding gas. What Kind Of Gas Do You Need For Mig Welding.

From weldguru.com

What Gas Should You Use for TIG Welding? (with Chart) What Kind Of Gas Do You Need For Mig Welding As an amazon associate i earn from qualifying purchases. The shielding gas protects the molten metal from exposure to atmospheric oxygen, hydrogen, and nitrogen, which could. A 75% argon and 25% helium blend is suitable. Gas welding uses a shielding gas to protect the weld from the atmosphere, while flux core welding doesn’t have an external gas but includes flux. What Kind Of Gas Do You Need For Mig Welding.

From www.youtube.com

How to Setup a MIG Welding Machine to Weld with ER70S6 Wire Quick What Kind Of Gas Do You Need For Mig Welding I recently used this last mixture, when taking my 3g mig welder certification. A 75% argon and 25% helium blend is suitable. For mig welding, use a shielding gas that suits your material. Gas welding uses a shielding gas to protect the weld from the atmosphere, while flux core welding doesn’t have an external gas but includes flux within the. What Kind Of Gas Do You Need For Mig Welding.

From www.instructables.com

Basics of MIG Welding 17 Steps (with Pictures) Instructables What Kind Of Gas Do You Need For Mig Welding C2 or 2% carbon dioxide and 98% argon. The shielding gas protects the molten metal from exposure to atmospheric oxygen, hydrogen, and nitrogen, which could. Gas welding uses a shielding gas to protect the weld from the atmosphere, while flux core welding doesn’t have an external gas but includes flux within the hollow electrode. I recently used this last mixture,. What Kind Of Gas Do You Need For Mig Welding.

From gearheadworkspace.com

Intro to MIG Welding Class Gearhead Workspace What Kind Of Gas Do You Need For Mig Welding The more common mixtures and gasses are. The shielding gas protects the molten metal from exposure to atmospheric oxygen, hydrogen, and nitrogen, which could. Mig welding is probably what you picture when you think of welding as it is the most common type of welding process due to being easy to learn and versatile. A 75% argon and 25% helium. What Kind Of Gas Do You Need For Mig Welding.

From hxefqlzys.blob.core.windows.net

How To Set Up A Mig Welding Machine at Judith Alford blog What Kind Of Gas Do You Need For Mig Welding C2 or 2% carbon dioxide and 98% argon. The more common mixtures and gasses are. The shielding gas protects the molten metal from exposure to atmospheric oxygen, hydrogen, and nitrogen, which could. A 75% argon and 25% helium blend is suitable. Gas welding uses a shielding gas to protect the weld from the atmosphere, while flux core welding doesn’t have. What Kind Of Gas Do You Need For Mig Welding.

From www.thoughtco.com

What Is a MIG Welder and How Does It Work? What Kind Of Gas Do You Need For Mig Welding Gas welding uses a shielding gas to protect the weld from the atmosphere, while flux core welding doesn’t have an external gas but includes flux within the hollow electrode. C2 or 2% carbon dioxide and 98% argon. The shielding gas protects the molten metal from exposure to atmospheric oxygen, hydrogen, and nitrogen, which could. I recently used this last mixture,. What Kind Of Gas Do You Need For Mig Welding.

From weldguru.com

What is GMAW (MIG Welding) & How Does it Work? Weld Guru What Kind Of Gas Do You Need For Mig Welding I recently used this last mixture, when taking my 3g mig welder certification. The shielding gas protects the molten metal from exposure to atmospheric oxygen, hydrogen, and nitrogen, which could. For mig welding, use a shielding gas that suits your material. A 75% argon and 25% helium blend is suitable. The more common mixtures and gasses are. Gas welding uses. What Kind Of Gas Do You Need For Mig Welding.

From www.youtube.com

Mig Welding Gas Setup Made Simple YouTube What Kind Of Gas Do You Need For Mig Welding I recently used this last mixture, when taking my 3g mig welder certification. A 75% argon and 25% helium blend is suitable. For mig welding, use a shielding gas that suits your material. As an amazon associate i earn from qualifying purchases. C2 or 2% carbon dioxide and 98% argon. The more common mixtures and gasses are. Mig welding is. What Kind Of Gas Do You Need For Mig Welding.