Plastic Defects . Learn about the most common defects in plastic molding, such as splay, sink, contamination, and delamination, and how to prevent them with quality engineering processes. The causes of defects may involve mold design, mold materials, tolerances, product materials, injection molding processes, etc. This article will introduce in detail. Learn how to prevent and troubleshoot common plastic injection molding defects such as flow lines, burn marks, warping, air pockets, sink. Molding defects refer to undesirable irregularities, flaws, or imperfections that occur during the process of molding materials, such. Learn about the common injection molding defects and their causes, such as flow lines, sink marks, weld lines, burn marks, discoloration, delamination, and flash.

from www.vem-tooling.com

Learn about the most common defects in plastic molding, such as splay, sink, contamination, and delamination, and how to prevent them with quality engineering processes. Molding defects refer to undesirable irregularities, flaws, or imperfections that occur during the process of molding materials, such. Learn about the common injection molding defects and their causes, such as flow lines, sink marks, weld lines, burn marks, discoloration, delamination, and flash. This article will introduce in detail. The causes of defects may involve mold design, mold materials, tolerances, product materials, injection molding processes, etc. Learn how to prevent and troubleshoot common plastic injection molding defects such as flow lines, burn marks, warping, air pockets, sink.

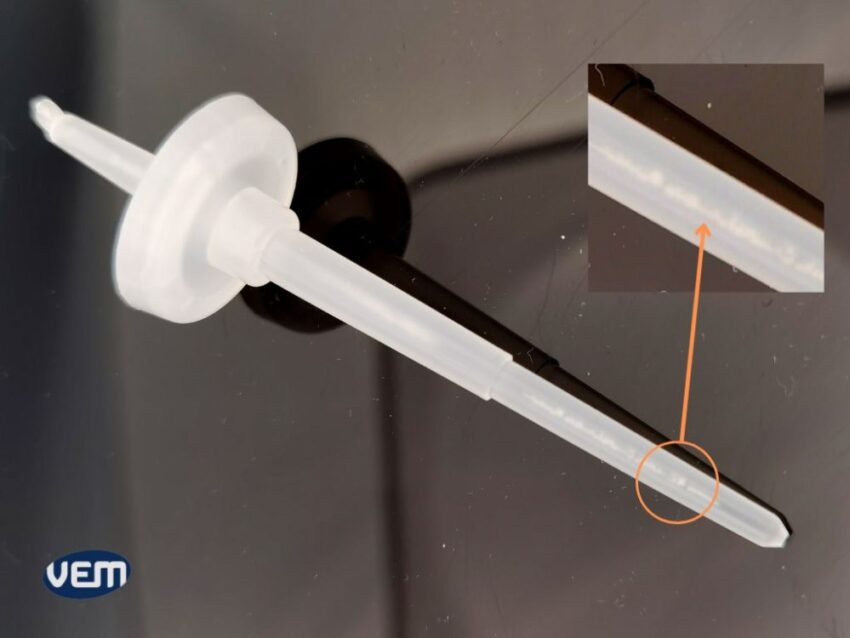

Vacuum Voids

Plastic Defects Learn about the most common defects in plastic molding, such as splay, sink, contamination, and delamination, and how to prevent them with quality engineering processes. The causes of defects may involve mold design, mold materials, tolerances, product materials, injection molding processes, etc. Learn about the most common defects in plastic molding, such as splay, sink, contamination, and delamination, and how to prevent them with quality engineering processes. This article will introduce in detail. Molding defects refer to undesirable irregularities, flaws, or imperfections that occur during the process of molding materials, such. Learn how to prevent and troubleshoot common plastic injection molding defects such as flow lines, burn marks, warping, air pockets, sink. Learn about the common injection molding defects and their causes, such as flow lines, sink marks, weld lines, burn marks, discoloration, delamination, and flash.

From es.easylockware.com

Possible Causes Of Molding Defects Of Plastic Food Containers Plastic Defects Learn about the most common defects in plastic molding, such as splay, sink, contamination, and delamination, and how to prevent them with quality engineering processes. Molding defects refer to undesirable irregularities, flaws, or imperfections that occur during the process of molding materials, such. The causes of defects may involve mold design, mold materials, tolerances, product materials, injection molding processes, etc.. Plastic Defects.

From www.smlease.com

What are Injection Molding Defects and How to Control Them? SMLease Plastic Defects Learn how to prevent and troubleshoot common plastic injection molding defects such as flow lines, burn marks, warping, air pockets, sink. Learn about the most common defects in plastic molding, such as splay, sink, contamination, and delamination, and how to prevent them with quality engineering processes. Learn about the common injection molding defects and their causes, such as flow lines,. Plastic Defects.

From ims-tex.com

The Most Common Injection Molding Defects Causes & Solutions Plastic Defects This article will introduce in detail. Learn about the most common defects in plastic molding, such as splay, sink, contamination, and delamination, and how to prevent them with quality engineering processes. Molding defects refer to undesirable irregularities, flaws, or imperfections that occur during the process of molding materials, such. Learn how to prevent and troubleshoot common plastic injection molding defects. Plastic Defects.

From sealectplastics.com

The Top 5 Plastic Injection Molding Defects (and How to Solve Them) Plastic Defects Learn how to prevent and troubleshoot common plastic injection molding defects such as flow lines, burn marks, warping, air pockets, sink. The causes of defects may involve mold design, mold materials, tolerances, product materials, injection molding processes, etc. Learn about the most common defects in plastic molding, such as splay, sink, contamination, and delamination, and how to prevent them with. Plastic Defects.

From www.csmolding.com

Common Plastic Injection Molding Defects and Solutions A Comprehensive Plastic Defects Learn about the most common defects in plastic molding, such as splay, sink, contamination, and delamination, and how to prevent them with quality engineering processes. Molding defects refer to undesirable irregularities, flaws, or imperfections that occur during the process of molding materials, such. Learn about the common injection molding defects and their causes, such as flow lines, sink marks, weld. Plastic Defects.

From www.mdpi.com

Applied Sciences Free FullText DualKernelBased Aggregated Plastic Defects Learn about the most common defects in plastic molding, such as splay, sink, contamination, and delamination, and how to prevent them with quality engineering processes. Molding defects refer to undesirable irregularities, flaws, or imperfections that occur during the process of molding materials, such. The causes of defects may involve mold design, mold materials, tolerances, product materials, injection molding processes, etc.. Plastic Defects.

From slidetodoc.com

DEFECT IN PLASTIC INJECTION MOULDING PROCESS DEFECT IN Plastic Defects This article will introduce in detail. Molding defects refer to undesirable irregularities, flaws, or imperfections that occur during the process of molding materials, such. Learn about the most common defects in plastic molding, such as splay, sink, contamination, and delamination, and how to prevent them with quality engineering processes. Learn about the common injection molding defects and their causes, such. Plastic Defects.

From slidetodoc.com

DEFECT IN PLASTIC INJECTION MOULDING PROCESS DEFECT IN Plastic Defects Learn about the most common defects in plastic molding, such as splay, sink, contamination, and delamination, and how to prevent them with quality engineering processes. The causes of defects may involve mold design, mold materials, tolerances, product materials, injection molding processes, etc. Learn about the common injection molding defects and their causes, such as flow lines, sink marks, weld lines,. Plastic Defects.

From www.vem-tooling.com

Vacuum Voids Plastic Defects Learn about the most common defects in plastic molding, such as splay, sink, contamination, and delamination, and how to prevent them with quality engineering processes. The causes of defects may involve mold design, mold materials, tolerances, product materials, injection molding processes, etc. This article will introduce in detail. Learn how to prevent and troubleshoot common plastic injection molding defects such. Plastic Defects.

From www.easylockware.com

Top 10 Injection Molding Defects Of Plastic Products Part 2 Plastic Defects Learn how to prevent and troubleshoot common plastic injection molding defects such as flow lines, burn marks, warping, air pockets, sink. Learn about the common injection molding defects and their causes, such as flow lines, sink marks, weld lines, burn marks, discoloration, delamination, and flash. The causes of defects may involve mold design, mold materials, tolerances, product materials, injection molding. Plastic Defects.

From www.plasticmoulds.net

Troubleshooting Product Defects In Injection Moldingflash,short Shot Plastic Defects The causes of defects may involve mold design, mold materials, tolerances, product materials, injection molding processes, etc. Learn about the most common defects in plastic molding, such as splay, sink, contamination, and delamination, and how to prevent them with quality engineering processes. Molding defects refer to undesirable irregularities, flaws, or imperfections that occur during the process of molding materials, such.. Plastic Defects.

From www.pioneerplastics.com

Injection Molding Defects and How to Avoid Them Plastic Defects The causes of defects may involve mold design, mold materials, tolerances, product materials, injection molding processes, etc. Learn about the most common defects in plastic molding, such as splay, sink, contamination, and delamination, and how to prevent them with quality engineering processes. This article will introduce in detail. Molding defects refer to undesirable irregularities, flaws, or imperfections that occur during. Plastic Defects.

From www.chessplastics.co.uk

News Chess Plastics Plastic Defects Learn how to prevent and troubleshoot common plastic injection molding defects such as flow lines, burn marks, warping, air pockets, sink. The causes of defects may involve mold design, mold materials, tolerances, product materials, injection molding processes, etc. Molding defects refer to undesirable irregularities, flaws, or imperfections that occur during the process of molding materials, such. Learn about the most. Plastic Defects.

From www.slideshare.net

PLASTIC DEFECTS Plastic Defects Learn about the common injection molding defects and their causes, such as flow lines, sink marks, weld lines, burn marks, discoloration, delamination, and flash. Learn about the most common defects in plastic molding, such as splay, sink, contamination, and delamination, and how to prevent them with quality engineering processes. The causes of defects may involve mold design, mold materials, tolerances,. Plastic Defects.

From www.vem-tooling.com

Clear Plastic Injection Molding Plastic Defects Learn about the common injection molding defects and their causes, such as flow lines, sink marks, weld lines, burn marks, discoloration, delamination, and flash. Learn how to prevent and troubleshoot common plastic injection molding defects such as flow lines, burn marks, warping, air pockets, sink. The causes of defects may involve mold design, mold materials, tolerances, product materials, injection molding. Plastic Defects.

From www.vrogue.co

How To Identifying Common Injection Molded Part Defec vrogue.co Plastic Defects This article will introduce in detail. Learn how to prevent and troubleshoot common plastic injection molding defects such as flow lines, burn marks, warping, air pockets, sink. Learn about the most common defects in plastic molding, such as splay, sink, contamination, and delamination, and how to prevent them with quality engineering processes. Learn about the common injection molding defects and. Plastic Defects.

From www.elastron.com

11 Injection Molding Defects and Troubleshooting Elastron TPE Plastic Defects Learn about the common injection molding defects and their causes, such as flow lines, sink marks, weld lines, burn marks, discoloration, delamination, and flash. Learn about the most common defects in plastic molding, such as splay, sink, contamination, and delamination, and how to prevent them with quality engineering processes. This article will introduce in detail. The causes of defects may. Plastic Defects.

From www.echosupply.com

Injection Molding Basics Common Surface Defects Echo Supply Plastic Defects The causes of defects may involve mold design, mold materials, tolerances, product materials, injection molding processes, etc. Molding defects refer to undesirable irregularities, flaws, or imperfections that occur during the process of molding materials, such. Learn about the most common defects in plastic molding, such as splay, sink, contamination, and delamination, and how to prevent them with quality engineering processes.. Plastic Defects.

From www.slideserve.com

PPT DEFECT IN PLASTIC INJECTION MOULDING PROCESS PowerPoint Plastic Defects The causes of defects may involve mold design, mold materials, tolerances, product materials, injection molding processes, etc. Learn how to prevent and troubleshoot common plastic injection molding defects such as flow lines, burn marks, warping, air pockets, sink. Learn about the most common defects in plastic molding, such as splay, sink, contamination, and delamination, and how to prevent them with. Plastic Defects.

From www.bennettplastics.com

Plastic Injection Molding Defects & How to Prevent Them Plastic Defects Learn how to prevent and troubleshoot common plastic injection molding defects such as flow lines, burn marks, warping, air pockets, sink. This article will introduce in detail. Learn about the most common defects in plastic molding, such as splay, sink, contamination, and delamination, and how to prevent them with quality engineering processes. The causes of defects may involve mold design,. Plastic Defects.

From hitopindustrial.com

Splay in Injection Molding Causes, Prevention & Solutions Plastic Defects This article will introduce in detail. Learn how to prevent and troubleshoot common plastic injection molding defects such as flow lines, burn marks, warping, air pockets, sink. Learn about the common injection molding defects and their causes, such as flow lines, sink marks, weld lines, burn marks, discoloration, delamination, and flash. Learn about the most common defects in plastic molding,. Plastic Defects.

From makenica.com

Preventing Voids, Bubbles, and other part defects in injection molding Plastic Defects Molding defects refer to undesirable irregularities, flaws, or imperfections that occur during the process of molding materials, such. Learn about the most common defects in plastic molding, such as splay, sink, contamination, and delamination, and how to prevent them with quality engineering processes. Learn about the common injection molding defects and their causes, such as flow lines, sink marks, weld. Plastic Defects.

From www.fastradius.com

7 Injection Molding Defects and How to Avoid Plastic Defects Molding defects refer to undesirable irregularities, flaws, or imperfections that occur during the process of molding materials, such. The causes of defects may involve mold design, mold materials, tolerances, product materials, injection molding processes, etc. Learn how to prevent and troubleshoot common plastic injection molding defects such as flow lines, burn marks, warping, air pockets, sink. Learn about the common. Plastic Defects.

From www.vem-tooling.com

Vacuum Voids Plastic Defects The causes of defects may involve mold design, mold materials, tolerances, product materials, injection molding processes, etc. Molding defects refer to undesirable irregularities, flaws, or imperfections that occur during the process of molding materials, such. Learn about the most common defects in plastic molding, such as splay, sink, contamination, and delamination, and how to prevent them with quality engineering processes.. Plastic Defects.

From www.injectionmould.org

Common Plastic Injection Molding Defects Plastic Defects The causes of defects may involve mold design, mold materials, tolerances, product materials, injection molding processes, etc. This article will introduce in detail. Molding defects refer to undesirable irregularities, flaws, or imperfections that occur during the process of molding materials, such. Learn about the most common defects in plastic molding, such as splay, sink, contamination, and delamination, and how to. Plastic Defects.

From www.vem-tooling.com

Plastic Warpage in Injection Molding Plastic Defects The causes of defects may involve mold design, mold materials, tolerances, product materials, injection molding processes, etc. Learn about the most common defects in plastic molding, such as splay, sink, contamination, and delamination, and how to prevent them with quality engineering processes. Learn how to prevent and troubleshoot common plastic injection molding defects such as flow lines, burn marks, warping,. Plastic Defects.

From www.alamy.com

Defects of plastic. Polarised light micrograph showing the defects of a Plastic Defects Learn about the most common defects in plastic molding, such as splay, sink, contamination, and delamination, and how to prevent them with quality engineering processes. This article will introduce in detail. Molding defects refer to undesirable irregularities, flaws, or imperfections that occur during the process of molding materials, such. The causes of defects may involve mold design, mold materials, tolerances,. Plastic Defects.

From weldingblos.netlify.app

Projection Welding Defects Plastic Defects This article will introduce in detail. Learn about the common injection molding defects and their causes, such as flow lines, sink marks, weld lines, burn marks, discoloration, delamination, and flash. Molding defects refer to undesirable irregularities, flaws, or imperfections that occur during the process of molding materials, such. The causes of defects may involve mold design, mold materials, tolerances, product. Plastic Defects.

From www.ulprospector.com

Plastic defects avoiding common injectionmolding issues Plastic Defects This article will introduce in detail. Learn about the common injection molding defects and their causes, such as flow lines, sink marks, weld lines, burn marks, discoloration, delamination, and flash. Learn how to prevent and troubleshoot common plastic injection molding defects such as flow lines, burn marks, warping, air pockets, sink. Molding defects refer to undesirable irregularities, flaws, or imperfections. Plastic Defects.

From www.reddit.com

Fixing small scratches on interior plastic. AutoDetailing Plastic Defects Learn how to prevent and troubleshoot common plastic injection molding defects such as flow lines, burn marks, warping, air pockets, sink. The causes of defects may involve mold design, mold materials, tolerances, product materials, injection molding processes, etc. This article will introduce in detail. Learn about the common injection molding defects and their causes, such as flow lines, sink marks,. Plastic Defects.

From sybridge.com

7 Injection Molding Defects and How to Avoid Plastic Defects Learn how to prevent and troubleshoot common plastic injection molding defects such as flow lines, burn marks, warping, air pockets, sink. Molding defects refer to undesirable irregularities, flaws, or imperfections that occur during the process of molding materials, such. The causes of defects may involve mold design, mold materials, tolerances, product materials, injection molding processes, etc. Learn about the common. Plastic Defects.

From info.rodongroup.com

Scary Plastic Part Defects and How to Avoid Them The Rodon Group® Plastic Defects This article will introduce in detail. The causes of defects may involve mold design, mold materials, tolerances, product materials, injection molding processes, etc. Learn about the most common defects in plastic molding, such as splay, sink, contamination, and delamination, and how to prevent them with quality engineering processes. Learn about the common injection molding defects and their causes, such as. Plastic Defects.

From sybridge.com

7 Injection Molding Defects and How to Avoid Plastic Defects This article will introduce in detail. Learn how to prevent and troubleshoot common plastic injection molding defects such as flow lines, burn marks, warping, air pockets, sink. Learn about the common injection molding defects and their causes, such as flow lines, sink marks, weld lines, burn marks, discoloration, delamination, and flash. Learn about the most common defects in plastic molding,. Plastic Defects.

From mavink.com

Plastic Defects In Injection Molding Plastic Defects Learn how to prevent and troubleshoot common plastic injection molding defects such as flow lines, burn marks, warping, air pockets, sink. The causes of defects may involve mold design, mold materials, tolerances, product materials, injection molding processes, etc. This article will introduce in detail. Molding defects refer to undesirable irregularities, flaws, or imperfections that occur during the process of molding. Plastic Defects.

From www.shutterstock.com

Defect Grunge Rubber Stamp On White Background, Vector Illustration Plastic Defects Learn about the common injection molding defects and their causes, such as flow lines, sink marks, weld lines, burn marks, discoloration, delamination, and flash. This article will introduce in detail. Learn how to prevent and troubleshoot common plastic injection molding defects such as flow lines, burn marks, warping, air pockets, sink. The causes of defects may involve mold design, mold. Plastic Defects.