Baffle Tray Definition . There are five major types of tray column; Their major disadvantage is fouling,. Bubble cap tray, sieve deck tray, dual flow tray, valve tray and baffle tray. For a baffle tray column the gas flows upwards through the baffle openings and in doing so contacts the liquid showering. A tray is a circular disc, or part of, fixed in a distillation column of a chemical plant and which provides a platform for an ascending vapour. A baffle system consists of plates or barriers in a tank or vessel to direct the flow of fluids, reducing turbulence and. Bellow is discussed each type. They have open areas approaching 50% where a high efficiency. Baffle trays are trays of low fouling potential, with low efficiency. Suitable in highly fouling services where efficiency and turndown are not concerns. Proper tray or baffle design can lead to shorter columns, and potentially small heat exchanger volume for the same service.

from lob-gmbh.de

Baffle trays are trays of low fouling potential, with low efficiency. A baffle system consists of plates or barriers in a tank or vessel to direct the flow of fluids, reducing turbulence and. Bellow is discussed each type. Suitable in highly fouling services where efficiency and turndown are not concerns. Their major disadvantage is fouling,. Bubble cap tray, sieve deck tray, dual flow tray, valve tray and baffle tray. A tray is a circular disc, or part of, fixed in a distillation column of a chemical plant and which provides a platform for an ascending vapour. There are five major types of tray column; They have open areas approaching 50% where a high efficiency. Proper tray or baffle design can lead to shorter columns, and potentially small heat exchanger volume for the same service.

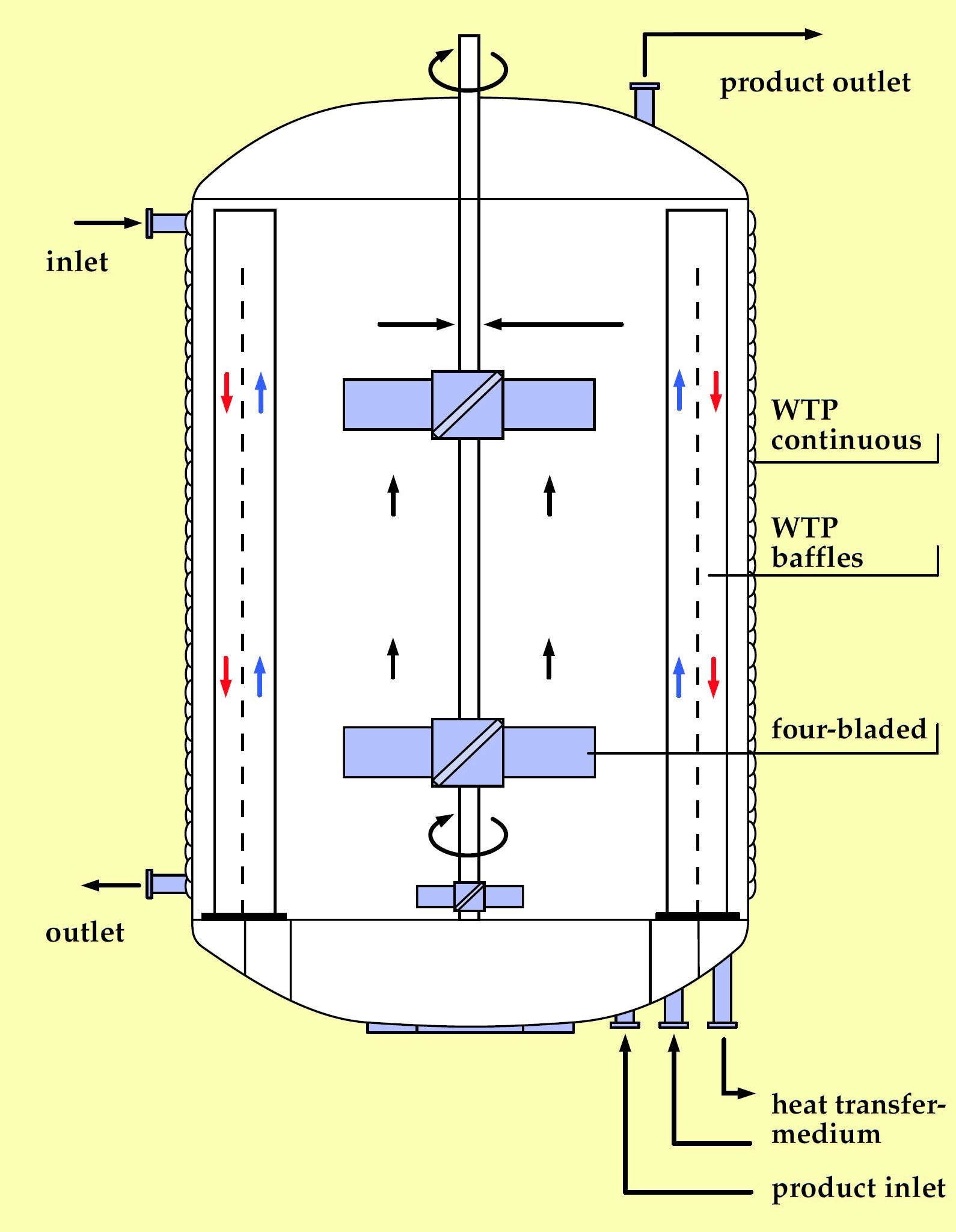

Baffles with WTPSystem® for perfect temperature LOB

Baffle Tray Definition A tray is a circular disc, or part of, fixed in a distillation column of a chemical plant and which provides a platform for an ascending vapour. Bubble cap tray, sieve deck tray, dual flow tray, valve tray and baffle tray. A tray is a circular disc, or part of, fixed in a distillation column of a chemical plant and which provides a platform for an ascending vapour. They have open areas approaching 50% where a high efficiency. Bellow is discussed each type. A baffle system consists of plates or barriers in a tank or vessel to direct the flow of fluids, reducing turbulence and. For a baffle tray column the gas flows upwards through the baffle openings and in doing so contacts the liquid showering. There are five major types of tray column; Suitable in highly fouling services where efficiency and turndown are not concerns. Baffle trays are trays of low fouling potential, with low efficiency. Their major disadvantage is fouling,. Proper tray or baffle design can lead to shorter columns, and potentially small heat exchanger volume for the same service.

From www.sulzer.com

Dual flow and baffle trays Sulzer Baffle Tray Definition Their major disadvantage is fouling,. Proper tray or baffle design can lead to shorter columns, and potentially small heat exchanger volume for the same service. Bubble cap tray, sieve deck tray, dual flow tray, valve tray and baffle tray. Suitable in highly fouling services where efficiency and turndown are not concerns. Bellow is discussed each type. They have open areas. Baffle Tray Definition.

From www.slideserve.com

PPT EXTRACTION and SUGAR INDUSTRY APPLICATIONS PowerPoint Baffle Tray Definition Bellow is discussed each type. A tray is a circular disc, or part of, fixed in a distillation column of a chemical plant and which provides a platform for an ascending vapour. For a baffle tray column the gas flows upwards through the baffle openings and in doing so contacts the liquid showering. There are five major types of tray. Baffle Tray Definition.

From pellet-stove-parts-4less.com

Traeger Heat Baffle and Drip Tray Assembly Kit for 22 Series Pellet Gr Baffle Tray Definition Their major disadvantage is fouling,. Bubble cap tray, sieve deck tray, dual flow tray, valve tray and baffle tray. Baffle trays are trays of low fouling potential, with low efficiency. A tray is a circular disc, or part of, fixed in a distillation column of a chemical plant and which provides a platform for an ascending vapour. Proper tray or. Baffle Tray Definition.

From allthingsnuclear.org

Indian Point’s Baffling Bolts Union of Concerned Scientists Baffle Tray Definition For a baffle tray column the gas flows upwards through the baffle openings and in doing so contacts the liquid showering. A tray is a circular disc, or part of, fixed in a distillation column of a chemical plant and which provides a platform for an ascending vapour. Bubble cap tray, sieve deck tray, dual flow tray, valve tray and. Baffle Tray Definition.

From www.scribd.com

Baffle Tray PDF Baffle Tray Definition Bubble cap tray, sieve deck tray, dual flow tray, valve tray and baffle tray. Proper tray or baffle design can lead to shorter columns, and potentially small heat exchanger volume for the same service. Baffle trays are trays of low fouling potential, with low efficiency. A baffle system consists of plates or barriers in a tank or vessel to direct. Baffle Tray Definition.

From amacs.com

What Are Trays and How Are They Used in Process Plants? AMACS Baffle Tray Definition Proper tray or baffle design can lead to shorter columns, and potentially small heat exchanger volume for the same service. They have open areas approaching 50% where a high efficiency. Bellow is discussed each type. Suitable in highly fouling services where efficiency and turndown are not concerns. A baffle system consists of plates or barriers in a tank or vessel. Baffle Tray Definition.

From www.pinterest.com

What are baffles? And do you need them for your construction project Baffle Tray Definition Suitable in highly fouling services where efficiency and turndown are not concerns. Proper tray or baffle design can lead to shorter columns, and potentially small heat exchanger volume for the same service. Bellow is discussed each type. They have open areas approaching 50% where a high efficiency. Baffle trays are trays of low fouling potential, with low efficiency. A tray. Baffle Tray Definition.

From tungaloy.com

Heat exchangers Baffle plate Industries Tungaloy Corporation Baffle Tray Definition A tray is a circular disc, or part of, fixed in a distillation column of a chemical plant and which provides a platform for an ascending vapour. Bellow is discussed each type. Bubble cap tray, sieve deck tray, dual flow tray, valve tray and baffle tray. Their major disadvantage is fouling,. They have open areas approaching 50% where a high. Baffle Tray Definition.

From newzelindustries.com

Baffle Plates Manufacturers Perforated Baffle Plates Exporters Baffle Tray Definition A tray is a circular disc, or part of, fixed in a distillation column of a chemical plant and which provides a platform for an ascending vapour. There are five major types of tray column; They have open areas approaching 50% where a high efficiency. Bellow is discussed each type. Baffle trays are trays of low fouling potential, with low. Baffle Tray Definition.

From chempedia.info

Baffle Trays Big Chemical Encyclopedia Baffle Tray Definition A tray is a circular disc, or part of, fixed in a distillation column of a chemical plant and which provides a platform for an ascending vapour. There are five major types of tray column; They have open areas approaching 50% where a high efficiency. For a baffle tray column the gas flows upwards through the baffle openings and in. Baffle Tray Definition.

From hxerajawx.blob.core.windows.net

Baffle Definition In Science at Michael Huffman blog Baffle Tray Definition Proper tray or baffle design can lead to shorter columns, and potentially small heat exchanger volume for the same service. A baffle system consists of plates or barriers in a tank or vessel to direct the flow of fluids, reducing turbulence and. A tray is a circular disc, or part of, fixed in a distillation column of a chemical plant. Baffle Tray Definition.

From www.walmart.com

Davy Crockett Grease Drip Tray Baffle, 2 Piece Open Flame Technology Baffle Tray Definition Bellow is discussed each type. Suitable in highly fouling services where efficiency and turndown are not concerns. For a baffle tray column the gas flows upwards through the baffle openings and in doing so contacts the liquid showering. Baffle trays are trays of low fouling potential, with low efficiency. A tray is a circular disc, or part of, fixed in. Baffle Tray Definition.

From www.sulzer.com

Dual flow and baffle trays Sulzer Baffle Tray Definition Bellow is discussed each type. A tray is a circular disc, or part of, fixed in a distillation column of a chemical plant and which provides a platform for an ascending vapour. Their major disadvantage is fouling,. They have open areas approaching 50% where a high efficiency. Bubble cap tray, sieve deck tray, dual flow tray, valve tray and baffle. Baffle Tray Definition.

From mungfali.com

Septic Tank Baffle Wall Baffle Tray Definition There are five major types of tray column; For a baffle tray column the gas flows upwards through the baffle openings and in doing so contacts the liquid showering. They have open areas approaching 50% where a high efficiency. Suitable in highly fouling services where efficiency and turndown are not concerns. Bellow is discussed each type. A baffle system consists. Baffle Tray Definition.

From ssmperformanceparts.com.au

IAG Performance Baffle, Windage Tray and Oil Pick Up WRX/STI SSM Baffle Tray Definition Their major disadvantage is fouling,. Bellow is discussed each type. Baffle trays are trays of low fouling potential, with low efficiency. For a baffle tray column the gas flows upwards through the baffle openings and in doing so contacts the liquid showering. A baffle system consists of plates or barriers in a tank or vessel to direct the flow of. Baffle Tray Definition.

From globalforgingsupply.com

Baffle plates Baffle Tray Definition Bellow is discussed each type. There are five major types of tray column; Baffle trays are trays of low fouling potential, with low efficiency. Proper tray or baffle design can lead to shorter columns, and potentially small heat exchanger volume for the same service. A tray is a circular disc, or part of, fixed in a distillation column of a. Baffle Tray Definition.

From chemglass.com

CG1971X PTFE BAFFLE, REACTION VESSEL, BENCHTOP, INSERTABLE Baffle Tray Definition A tray is a circular disc, or part of, fixed in a distillation column of a chemical plant and which provides a platform for an ascending vapour. Baffle trays are trays of low fouling potential, with low efficiency. There are five major types of tray column; They have open areas approaching 50% where a high efficiency. Their major disadvantage is. Baffle Tray Definition.

From www.youtube.com

Baffles in the Sump of a Column Demonstration YouTube Baffle Tray Definition A baffle system consists of plates or barriers in a tank or vessel to direct the flow of fluids, reducing turbulence and. Bubble cap tray, sieve deck tray, dual flow tray, valve tray and baffle tray. Baffle trays are trays of low fouling potential, with low efficiency. A tray is a circular disc, or part of, fixed in a distillation. Baffle Tray Definition.

From docs.oracle.com

Servicing the Air Baffle (CRU) Baffle Tray Definition Bubble cap tray, sieve deck tray, dual flow tray, valve tray and baffle tray. There are five major types of tray column; A baffle system consists of plates or barriers in a tank or vessel to direct the flow of fluids, reducing turbulence and. They have open areas approaching 50% where a high efficiency. For a baffle tray column the. Baffle Tray Definition.

From www.walmart.com

Heat Baffle And Drip Tray Assembly Kit For 34 Series Pellet Grills By Baffle Tray Definition They have open areas approaching 50% where a high efficiency. Baffle trays are trays of low fouling potential, with low efficiency. Bubble cap tray, sieve deck tray, dual flow tray, valve tray and baffle tray. For a baffle tray column the gas flows upwards through the baffle openings and in doing so contacts the liquid showering. A baffle system consists. Baffle Tray Definition.

From www.gtisoln.com

Fractionation Trays gtisolutions Baffle Tray Definition Proper tray or baffle design can lead to shorter columns, and potentially small heat exchanger volume for the same service. A baffle system consists of plates or barriers in a tank or vessel to direct the flow of fluids, reducing turbulence and. Baffle trays are trays of low fouling potential, with low efficiency. Bellow is discussed each type. Bubble cap. Baffle Tray Definition.

From chempedia.info

Baffle tray columns Big Chemical Encyclopedia Baffle Tray Definition Bubble cap tray, sieve deck tray, dual flow tray, valve tray and baffle tray. A tray is a circular disc, or part of, fixed in a distillation column of a chemical plant and which provides a platform for an ascending vapour. Suitable in highly fouling services where efficiency and turndown are not concerns. For a baffle tray column the gas. Baffle Tray Definition.

From chempedia.info

Baffle Trays Big Chemical Encyclopedia Baffle Tray Definition There are five major types of tray column; Bubble cap tray, sieve deck tray, dual flow tray, valve tray and baffle tray. A baffle system consists of plates or barriers in a tank or vessel to direct the flow of fluids, reducing turbulence and. Their major disadvantage is fouling,. Bellow is discussed each type. Proper tray or baffle design can. Baffle Tray Definition.

From www.researchgate.net

Entrance B (1) with baffle and metal tray (2) fitted as an Baffle Tray Definition They have open areas approaching 50% where a high efficiency. Their major disadvantage is fouling,. Suitable in highly fouling services where efficiency and turndown are not concerns. For a baffle tray column the gas flows upwards through the baffle openings and in doing so contacts the liquid showering. A baffle system consists of plates or barriers in a tank or. Baffle Tray Definition.

From www.researchgate.net

Definition sketch of a vertically tankbottomed baffle Download Baffle Tray Definition Bubble cap tray, sieve deck tray, dual flow tray, valve tray and baffle tray. Suitable in highly fouling services where efficiency and turndown are not concerns. Baffle trays are trays of low fouling potential, with low efficiency. A tray is a circular disc, or part of, fixed in a distillation column of a chemical plant and which provides a platform. Baffle Tray Definition.

From www.mapesausa.com

Side to Side Baffle and Disc and Donut Trays MAPESA Baffle Tray Definition A baffle system consists of plates or barriers in a tank or vessel to direct the flow of fluids, reducing turbulence and. Bubble cap tray, sieve deck tray, dual flow tray, valve tray and baffle tray. Their major disadvantage is fouling,. Bellow is discussed each type. For a baffle tray column the gas flows upwards through the baffle openings and. Baffle Tray Definition.

From www.reddit.com

Should my new baffle and tray look like this? r/Traeger Baffle Tray Definition They have open areas approaching 50% where a high efficiency. A baffle system consists of plates or barriers in a tank or vessel to direct the flow of fluids, reducing turbulence and. For a baffle tray column the gas flows upwards through the baffle openings and in doing so contacts the liquid showering. Their major disadvantage is fouling,. Baffle trays. Baffle Tray Definition.

From www.webstaurantstore.com

AccuTemp AT2A25522 Baffle Locking Grease Tray Assembly for AccuSteam Baffle Tray Definition Bubble cap tray, sieve deck tray, dual flow tray, valve tray and baffle tray. There are five major types of tray column; Their major disadvantage is fouling,. Bellow is discussed each type. Suitable in highly fouling services where efficiency and turndown are not concerns. A baffle system consists of plates or barriers in a tank or vessel to direct the. Baffle Tray Definition.

From www.youtube.com

Vapor/Liquid Flow in a Baffle Column Demonstration YouTube Baffle Tray Definition Bellow is discussed each type. A tray is a circular disc, or part of, fixed in a distillation column of a chemical plant and which provides a platform for an ascending vapour. They have open areas approaching 50% where a high efficiency. There are five major types of tray column; Proper tray or baffle design can lead to shorter columns,. Baffle Tray Definition.

From lob-gmbh.de

Baffles with WTPSystem® for perfect temperature LOB Baffle Tray Definition Bubble cap tray, sieve deck tray, dual flow tray, valve tray and baffle tray. Their major disadvantage is fouling,. Suitable in highly fouling services where efficiency and turndown are not concerns. For a baffle tray column the gas flows upwards through the baffle openings and in doing so contacts the liquid showering. Proper tray or baffle design can lead to. Baffle Tray Definition.

From www.cascadegerman.com

Windage Baffle Tray, 4 Cylinder Cascade German Parts Baffle Tray Definition Bellow is discussed each type. Their major disadvantage is fouling,. They have open areas approaching 50% where a high efficiency. Suitable in highly fouling services where efficiency and turndown are not concerns. A tray is a circular disc, or part of, fixed in a distillation column of a chemical plant and which provides a platform for an ascending vapour. Bubble. Baffle Tray Definition.

From www.minisport.com

Gearbox baffle tray Mini Gearbox Mini Sport Baffle Tray Definition Baffle trays are trays of low fouling potential, with low efficiency. Suitable in highly fouling services where efficiency and turndown are not concerns. A baffle system consists of plates or barriers in a tank or vessel to direct the flow of fluids, reducing turbulence and. There are five major types of tray column; They have open areas approaching 50% where. Baffle Tray Definition.

From theowanne.com

Baffle Types Theo Wanne Baffle Tray Definition A baffle system consists of plates or barriers in a tank or vessel to direct the flow of fluids, reducing turbulence and. Bellow is discussed each type. Baffle trays are trays of low fouling potential, with low efficiency. They have open areas approaching 50% where a high efficiency. Their major disadvantage is fouling,. For a baffle tray column the gas. Baffle Tray Definition.

From tracomfrp.com

Benefits of Baffle Plates Baffle Tray Definition They have open areas approaching 50% where a high efficiency. There are five major types of tray column; Bellow is discussed each type. Baffle trays are trays of low fouling potential, with low efficiency. Proper tray or baffle design can lead to shorter columns, and potentially small heat exchanger volume for the same service. Their major disadvantage is fouling,. Suitable. Baffle Tray Definition.

From ipgparts.com

OEM Windage Tray Baffle Fits Honda Integra B18c B18c1 B18c5 GSR IPGparts Baffle Tray Definition Their major disadvantage is fouling,. A tray is a circular disc, or part of, fixed in a distillation column of a chemical plant and which provides a platform for an ascending vapour. There are five major types of tray column; For a baffle tray column the gas flows upwards through the baffle openings and in doing so contacts the liquid. Baffle Tray Definition.