Equipment Vibration . vibration measurement is a method used to identify oscillating movements in industrial machinery and components. excessive vibrations on rotating equipment like pumps, gearboxes, turbines and compressors are a clear sign that the equipment is. learn about the 15 most common mechanical vibration problems and their symptoms. Other effects of vibration include safety issues and diminished working conditions. vibration analysis is the process of measuring and analyzing your asset vibration patterns. Modern vibration sensors and analytic tools can identify faults at an early stage when problems are still easy to repair. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned downtime. Identify the issue and find solutions to avoid costly repairs and downtime. When measured and analyzed properly, however, vibration can play an important role in preventive maintenance programs. vibration can accelerate machine wear, consume excess power, and cause equipment to be taken out of service, resulting in unplanned downtime. machine vibration is a normal, and typically unavoidable, result of moving and rotating parts, often caused by standard manufacturing and.

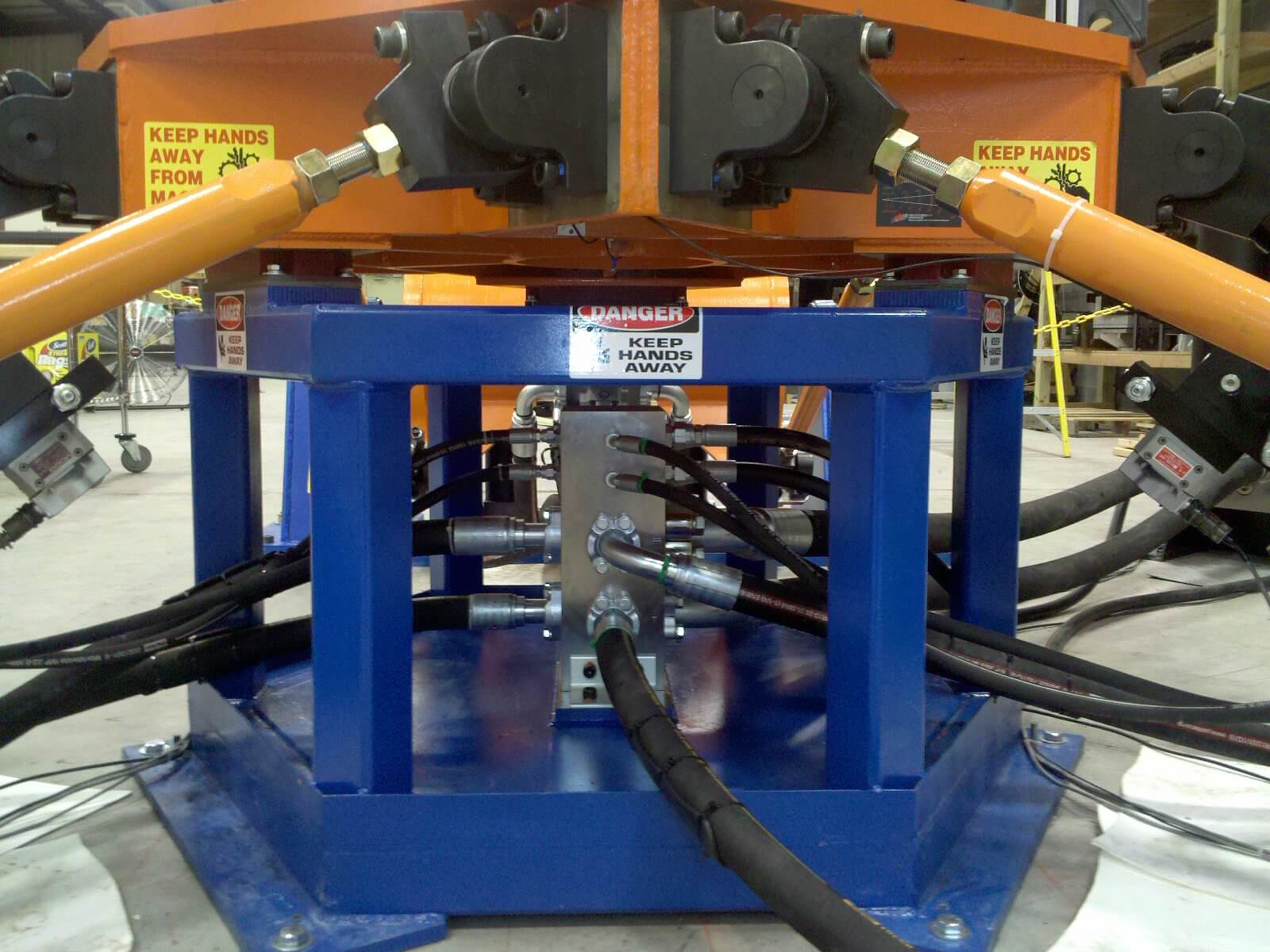

from www.linkeng.com

learn about the 15 most common mechanical vibration problems and their symptoms. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned downtime. vibration analysis is the process of measuring and analyzing your asset vibration patterns. vibration can accelerate machine wear, consume excess power, and cause equipment to be taken out of service, resulting in unplanned downtime. Identify the issue and find solutions to avoid costly repairs and downtime. Other effects of vibration include safety issues and diminished working conditions. machine vibration is a normal, and typically unavoidable, result of moving and rotating parts, often caused by standard manufacturing and. excessive vibrations on rotating equipment like pumps, gearboxes, turbines and compressors are a clear sign that the equipment is. When measured and analyzed properly, however, vibration can play an important role in preventive maintenance programs. Modern vibration sensors and analytic tools can identify faults at an early stage when problems are still easy to repair.

Exciter 3D Three Degrees of Freedom Vibration Test System Link

Equipment Vibration Modern vibration sensors and analytic tools can identify faults at an early stage when problems are still easy to repair. vibration can accelerate machine wear, consume excess power, and cause equipment to be taken out of service, resulting in unplanned downtime. vibration analysis is the process of measuring and analyzing your asset vibration patterns. learn about the 15 most common mechanical vibration problems and their symptoms. Other effects of vibration include safety issues and diminished working conditions. excessive vibrations on rotating equipment like pumps, gearboxes, turbines and compressors are a clear sign that the equipment is. When measured and analyzed properly, however, vibration can play an important role in preventive maintenance programs. machine vibration is a normal, and typically unavoidable, result of moving and rotating parts, often caused by standard manufacturing and. Modern vibration sensors and analytic tools can identify faults at an early stage when problems are still easy to repair. Identify the issue and find solutions to avoid costly repairs and downtime. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned downtime. vibration measurement is a method used to identify oscillating movements in industrial machinery and components.

From www.fluke.com

Vibration Monitoring System Fluke 3562 Screening Vibration Sensor Equipment Vibration Other effects of vibration include safety issues and diminished working conditions. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned downtime. vibration measurement is a method used to identify oscillating movements in industrial machinery and components. Modern vibration sensors and analytic tools can identify faults at an early stage when problems are still easy to. Equipment Vibration.

From www.fluke.com

Vibration Monitoring System Fluke 3562 Screening Vibration Sensor Equipment Vibration excessive vibrations on rotating equipment like pumps, gearboxes, turbines and compressors are a clear sign that the equipment is. Modern vibration sensors and analytic tools can identify faults at an early stage when problems are still easy to repair. machine vibration is a normal, and typically unavoidable, result of moving and rotating parts, often caused by standard manufacturing. Equipment Vibration.

From www.labvibrationtest.com

Vibration Test Machine 1000kg.f Sine Force Meet IEC, MILSTD Standards Equipment Vibration Modern vibration sensors and analytic tools can identify faults at an early stage when problems are still easy to repair. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned downtime. excessive vibrations on rotating equipment like pumps, gearboxes, turbines and compressors are a clear sign that the equipment is. vibration analysis is the process. Equipment Vibration.

From www.aciacoustical.com

Vibration Equipment ACI Acoustical Consultants Inc. Equipment Vibration vibration can accelerate machine wear, consume excess power, and cause equipment to be taken out of service, resulting in unplanned downtime. excessive vibrations on rotating equipment like pumps, gearboxes, turbines and compressors are a clear sign that the equipment is. learn about the 15 most common mechanical vibration problems and their symptoms. vibration analysis is the. Equipment Vibration.

From svibtech.net

handheld vibration Analyzer Svib Blog Equipment Vibration vibration can accelerate machine wear, consume excess power, and cause equipment to be taken out of service, resulting in unplanned downtime. machine vibration is a normal, and typically unavoidable, result of moving and rotating parts, often caused by standard manufacturing and. Other effects of vibration include safety issues and diminished working conditions. When measured and analyzed properly, however,. Equipment Vibration.

From www.fluke.com

Top 5 Industrial Vibration Sensor Applications Fluke Equipment Vibration learn about the 15 most common mechanical vibration problems and their symptoms. When measured and analyzed properly, however, vibration can play an important role in preventive maintenance programs. Modern vibration sensors and analytic tools can identify faults at an early stage when problems are still easy to repair. excessive vibrations on rotating equipment like pumps, gearboxes, turbines and. Equipment Vibration.

From www.fluke-infrared.com

Understanding Vibration Monitoring and Analysis Fluke Equipment Vibration Modern vibration sensors and analytic tools can identify faults at an early stage when problems are still easy to repair. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned downtime. Other effects of vibration include safety issues and diminished working conditions. Identify the issue and find solutions to avoid costly repairs and downtime. machine vibration. Equipment Vibration.

From aisys.com.my

MR3000C Vibration & Motion Measurement System Absolute Equipment Vibration excessive vibrations on rotating equipment like pumps, gearboxes, turbines and compressors are a clear sign that the equipment is. learn about the 15 most common mechanical vibration problems and their symptoms. Modern vibration sensors and analytic tools can identify faults at an early stage when problems are still easy to repair. Identify the issue and find solutions to. Equipment Vibration.

From brotechnologyx.com

What Is A Vibration Monitoring System and Why Do You Need One? Equipment Vibration vibration analysis is the process of measuring and analyzing your asset vibration patterns. When measured and analyzed properly, however, vibration can play an important role in preventive maintenance programs. Modern vibration sensors and analytic tools can identify faults at an early stage when problems are still easy to repair. learn about the 15 most common mechanical vibration problems. Equipment Vibration.

From www.aerospacetestinginternational.com

More realistic vibration testing Aerospace Testing International Equipment Vibration vibration analysis is the process of measuring and analyzing your asset vibration patterns. When measured and analyzed properly, however, vibration can play an important role in preventive maintenance programs. Identify the issue and find solutions to avoid costly repairs and downtime. machine vibration is a normal, and typically unavoidable, result of moving and rotating parts, often caused by. Equipment Vibration.

From www.vibrationtestmachine.com

Vibration Test Machine , Vibration Test System With 17 Years Experience Equipment Vibration machine vibration is a normal, and typically unavoidable, result of moving and rotating parts, often caused by standard manufacturing and. Identify the issue and find solutions to avoid costly repairs and downtime. vibration measurement is a method used to identify oscillating movements in industrial machinery and components. It’s a proven, highly effective way to extend asset lifespan and. Equipment Vibration.

From nttinc.com

What is Vibration Analysis in Mechanical Maintenance? NTT Training Equipment Vibration machine vibration is a normal, and typically unavoidable, result of moving and rotating parts, often caused by standard manufacturing and. Other effects of vibration include safety issues and diminished working conditions. vibration analysis is the process of measuring and analyzing your asset vibration patterns. Modern vibration sensors and analytic tools can identify faults at an early stage when. Equipment Vibration.

From www.desolutions.com

Choosing A Vibration Test Lab Product Reliability Testing Equipment Vibration learn about the 15 most common mechanical vibration problems and their symptoms. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned downtime. vibration can accelerate machine wear, consume excess power, and cause equipment to be taken out of service, resulting in unplanned downtime. excessive vibrations on rotating equipment like pumps, gearboxes, turbines and. Equipment Vibration.

From falcon-professionals.com

FMF009 Vibration Analysis for Rotating Equipment Equipment Vibration vibration can accelerate machine wear, consume excess power, and cause equipment to be taken out of service, resulting in unplanned downtime. Modern vibration sensors and analytic tools can identify faults at an early stage when problems are still easy to repair. vibration analysis is the process of measuring and analyzing your asset vibration patterns. machine vibration is. Equipment Vibration.

From www.fluke.com

Improve Motor Health Vibration Testing Fluke Equipment Vibration learn about the 15 most common mechanical vibration problems and their symptoms. Identify the issue and find solutions to avoid costly repairs and downtime. vibration can accelerate machine wear, consume excess power, and cause equipment to be taken out of service, resulting in unplanned downtime. machine vibration is a normal, and typically unavoidable, result of moving and. Equipment Vibration.

From www.pcne.eu

Portable multifunction vibration screening tool Handheld Fluke® 805 FC Equipment Vibration excessive vibrations on rotating equipment like pumps, gearboxes, turbines and compressors are a clear sign that the equipment is. learn about the 15 most common mechanical vibration problems and their symptoms. Identify the issue and find solutions to avoid costly repairs and downtime. vibration analysis is the process of measuring and analyzing your asset vibration patterns. Modern. Equipment Vibration.

From www.youtube.com

What is Vibration Analysis? A Quick Introduction and Key Benefits to Equipment Vibration It’s a proven, highly effective way to extend asset lifespan and reduce unplanned downtime. vibration can accelerate machine wear, consume excess power, and cause equipment to be taken out of service, resulting in unplanned downtime. excessive vibrations on rotating equipment like pumps, gearboxes, turbines and compressors are a clear sign that the equipment is. learn about the. Equipment Vibration.

From www.rasmech.com

Equipment Vibration Analysis (An All Inclusive Guide) RasMech Equipment Vibration vibration measurement is a method used to identify oscillating movements in industrial machinery and components. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned downtime. Modern vibration sensors and analytic tools can identify faults at an early stage when problems are still easy to repair. vibration analysis is the process of measuring and analyzing. Equipment Vibration.

From www.cembhofmann.co.uk

N600 Vibration Monitoring Instrument Cemb Hofmann UK Equipment Vibration When measured and analyzed properly, however, vibration can play an important role in preventive maintenance programs. vibration measurement is a method used to identify oscillating movements in industrial machinery and components. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned downtime. vibration analysis is the process of measuring and analyzing your asset vibration patterns.. Equipment Vibration.

From www.youtube.com

How to Measure Vibration with the Fluke 810 Vibration Tester YouTube Equipment Vibration vibration can accelerate machine wear, consume excess power, and cause equipment to be taken out of service, resulting in unplanned downtime. vibration measurement is a method used to identify oscillating movements in industrial machinery and components. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned downtime. Modern vibration sensors and analytic tools can identify. Equipment Vibration.

From www.pumpsandsystems.com

Smart Vibration Tools Bridge the Gap Between Technicians & Experts Equipment Vibration machine vibration is a normal, and typically unavoidable, result of moving and rotating parts, often caused by standard manufacturing and. excessive vibrations on rotating equipment like pumps, gearboxes, turbines and compressors are a clear sign that the equipment is. vibration can accelerate machine wear, consume excess power, and cause equipment to be taken out of service, resulting. Equipment Vibration.

From www.theedgesearch.com

3 Essential Benefits of Vibration Monitoring Equipment Equipment Vibration Other effects of vibration include safety issues and diminished working conditions. vibration analysis is the process of measuring and analyzing your asset vibration patterns. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned downtime. learn about the 15 most common mechanical vibration problems and their symptoms. machine vibration is a normal, and typically. Equipment Vibration.

From control.com

Mechanical Vibration Switches Introduction to Machine Vibration Equipment Vibration vibration measurement is a method used to identify oscillating movements in industrial machinery and components. Modern vibration sensors and analytic tools can identify faults at an early stage when problems are still easy to repair. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned downtime. Identify the issue and find solutions to avoid costly repairs. Equipment Vibration.

From www.reliableplant.com

How to Use Vibration Analysis to Identify Equipment Problems Equipment Vibration vibration can accelerate machine wear, consume excess power, and cause equipment to be taken out of service, resulting in unplanned downtime. Identify the issue and find solutions to avoid costly repairs and downtime. vibration measurement is a method used to identify oscillating movements in industrial machinery and components. machine vibration is a normal, and typically unavoidable, result. Equipment Vibration.

From www.fluke.com

Improve uptime with new vibration analysis tools Fluke Equipment Vibration When measured and analyzed properly, however, vibration can play an important role in preventive maintenance programs. learn about the 15 most common mechanical vibration problems and their symptoms. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned downtime. Other effects of vibration include safety issues and diminished working conditions. Identify the issue and find solutions. Equipment Vibration.

From www.vibrationtestmachine.com

3 Axis XYZ Vibration Testing Equipment , Vibration Testing Services Equipment Vibration Identify the issue and find solutions to avoid costly repairs and downtime. vibration measurement is a method used to identify oscillating movements in industrial machinery and components. Other effects of vibration include safety issues and diminished working conditions. excessive vibrations on rotating equipment like pumps, gearboxes, turbines and compressors are a clear sign that the equipment is. Modern. Equipment Vibration.

From www.reliableplant.com

Vibration Analysis Explained Reliable Plant Equipment Vibration When measured and analyzed properly, however, vibration can play an important role in preventive maintenance programs. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned downtime. vibration can accelerate machine wear, consume excess power, and cause equipment to be taken out of service, resulting in unplanned downtime. learn about the 15 most common mechanical. Equipment Vibration.

From www.stress.com

Equipment Vibration Monitoring Stress Engineering Services, Inc Equipment Vibration vibration analysis is the process of measuring and analyzing your asset vibration patterns. vibration measurement is a method used to identify oscillating movements in industrial machinery and components. excessive vibrations on rotating equipment like pumps, gearboxes, turbines and compressors are a clear sign that the equipment is. Identify the issue and find solutions to avoid costly repairs. Equipment Vibration.

From www.lansmont.com

Model 1000 Vibration Test System Lansmont Corporation Equipment Vibration Identify the issue and find solutions to avoid costly repairs and downtime. vibration measurement is a method used to identify oscillating movements in industrial machinery and components. When measured and analyzed properly, however, vibration can play an important role in preventive maintenance programs. vibration analysis is the process of measuring and analyzing your asset vibration patterns. Modern vibration. Equipment Vibration.

From www.desolutions.com

Vibration Testing Services Three Axis ED Shakers Equipment Vibration learn about the 15 most common mechanical vibration problems and their symptoms. vibration can accelerate machine wear, consume excess power, and cause equipment to be taken out of service, resulting in unplanned downtime. machine vibration is a normal, and typically unavoidable, result of moving and rotating parts, often caused by standard manufacturing and. It’s a proven, highly. Equipment Vibration.

From www.desolutions.com

Vibration Testing Services Three Axis ED Shakers Equipment Vibration excessive vibrations on rotating equipment like pumps, gearboxes, turbines and compressors are a clear sign that the equipment is. vibration analysis is the process of measuring and analyzing your asset vibration patterns. Modern vibration sensors and analytic tools can identify faults at an early stage when problems are still easy to repair. It’s a proven, highly effective way. Equipment Vibration.

From www.etssolution-asia.com

Vibration Testing Equipment Services Singapore Equipment Vibration vibration can accelerate machine wear, consume excess power, and cause equipment to be taken out of service, resulting in unplanned downtime. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned downtime. learn about the 15 most common mechanical vibration problems and their symptoms. vibration measurement is a method used to identify oscillating movements. Equipment Vibration.

From www.desolutions.com

Choosing a Vibration Test Lab Part I Delserro Engineering Solutions Equipment Vibration excessive vibrations on rotating equipment like pumps, gearboxes, turbines and compressors are a clear sign that the equipment is. Modern vibration sensors and analytic tools can identify faults at an early stage when problems are still easy to repair. vibration analysis is the process of measuring and analyzing your asset vibration patterns. vibration can accelerate machine wear,. Equipment Vibration.

From www.desolutions.com

Three Axis Vibration Testing Delserro Engineering Solutions Equipment Vibration learn about the 15 most common mechanical vibration problems and their symptoms. Modern vibration sensors and analytic tools can identify faults at an early stage when problems are still easy to repair. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned downtime. vibration can accelerate machine wear, consume excess power, and cause equipment to. Equipment Vibration.

From www.linkeng.com

Exciter 3D Three Degrees of Freedom Vibration Test System Link Equipment Vibration Modern vibration sensors and analytic tools can identify faults at an early stage when problems are still easy to repair. When measured and analyzed properly, however, vibration can play an important role in preventive maintenance programs. vibration measurement is a method used to identify oscillating movements in industrial machinery and components. excessive vibrations on rotating equipment like pumps,. Equipment Vibration.