Motor Alignment Jacking Bolts . Use a 5 mil shim between the bolt and motor foot, run the bolt up until it lightly pinches the shim. Mount a jam nut on the jacking bolt. If you are currently using a sledge hammer or a 2×4, it is going to take you a lot longer to perform a horizontal move; Always remember to back off the jack bolts on the opposite side. Jacking bolts provide a smoother, easier way of moving machinery than using pry bars and hammers. Jacking bolts provide a smoother, easier way of moving machinery than using pry bars and hammers. If your company's policy is to keep jacking bolts tight, here's a tip: When using jack bolts to correct horizontal misalignment, it’s best to back off the opposing jack bolts in the direction the machine needs to. Jacking bolts provide a smoother, easier way of moving machinery than using pry bars and hammers. Often overcorrecting back and forth. Loosening jacking bolts before making an alignment can have significant benefits, including reducing vibration. You do not want to hit your machines with a hammer in order to move them. The easiest way to perform a horizontal move is with jacking bolts. Jacking bolts provide an easy and accurate way to horizontally position a motor during a shaft alignment.

from www.excelcalcs.com

Use a 5 mil shim between the bolt and motor foot, run the bolt up until it lightly pinches the shim. The easiest way to perform a horizontal move is with jacking bolts. Often overcorrecting back and forth. When using jack bolts to correct horizontal misalignment, it’s best to back off the opposing jack bolts in the direction the machine needs to. Jacking bolts provide a smoother, easier way of moving machinery than using pry bars and hammers. If your company's policy is to keep jacking bolts tight, here's a tip: Jacking bolts provide an easy and accurate way to horizontally position a motor during a shaft alignment. Mount a jam nut on the jacking bolt. Always remember to back off the jack bolts on the opposite side. If you are currently using a sledge hammer or a 2×4, it is going to take you a lot longer to perform a horizontal move;

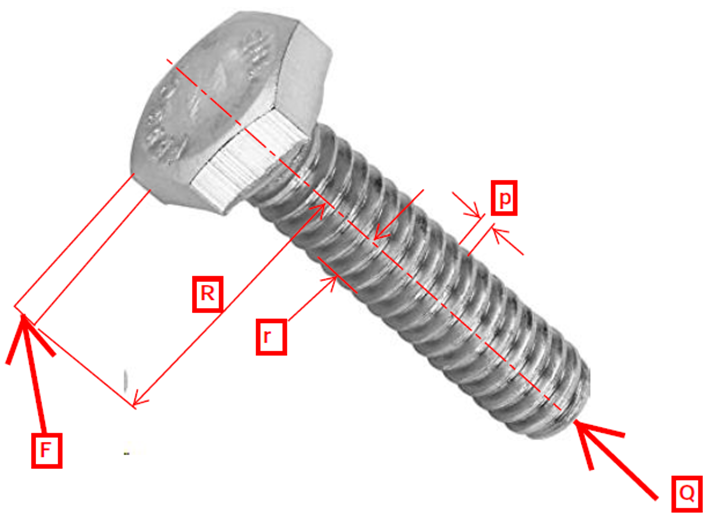

Jacking bolt calculation

Motor Alignment Jacking Bolts Loosening jacking bolts before making an alignment can have significant benefits, including reducing vibration. Jacking bolts provide a smoother, easier way of moving machinery than using pry bars and hammers. Often overcorrecting back and forth. Jacking bolts provide an easy and accurate way to horizontally position a motor during a shaft alignment. If your company's policy is to keep jacking bolts tight, here's a tip: If you are currently using a sledge hammer or a 2×4, it is going to take you a lot longer to perform a horizontal move; The easiest way to perform a horizontal move is with jacking bolts. You do not want to hit your machines with a hammer in order to move them. Loosening jacking bolts before making an alignment can have significant benefits, including reducing vibration. Jacking bolts provide a smoother, easier way of moving machinery than using pry bars and hammers. Mount a jam nut on the jacking bolt. When using jack bolts to correct horizontal misalignment, it’s best to back off the opposing jack bolts in the direction the machine needs to. Always remember to back off the jack bolts on the opposite side. Use a 5 mil shim between the bolt and motor foot, run the bolt up until it lightly pinches the shim. Jacking bolts provide a smoother, easier way of moving machinery than using pry bars and hammers.

From empoweringpumps.com

Loosening the Coupling Bolts before Measuring for Misalignment Empowering Pumps and Equipment Motor Alignment Jacking Bolts Often overcorrecting back and forth. Jacking bolts provide a smoother, easier way of moving machinery than using pry bars and hammers. When using jack bolts to correct horizontal misalignment, it’s best to back off the opposing jack bolts in the direction the machine needs to. You do not want to hit your machines with a hammer in order to move. Motor Alignment Jacking Bolts.

From www.youtube.com

Jack Bolt Installation YouTube Motor Alignment Jacking Bolts If your company's policy is to keep jacking bolts tight, here's a tip: Jacking bolts provide an easy and accurate way to horizontally position a motor during a shaft alignment. When using jack bolts to correct horizontal misalignment, it’s best to back off the opposing jack bolts in the direction the machine needs to. Jacking bolts provide a smoother, easier. Motor Alignment Jacking Bolts.

From polimak.com

Screw jacks Electromechanical Screw jack Polimak Motor Alignment Jacking Bolts Mount a jam nut on the jacking bolt. The easiest way to perform a horizontal move is with jacking bolts. Often overcorrecting back and forth. Jacking bolts provide an easy and accurate way to horizontally position a motor during a shaft alignment. Always remember to back off the jack bolts on the opposite side. Jacking bolts provide a smoother, easier. Motor Alignment Jacking Bolts.

From jactonscrewjack.en.hisupplier.com

screw jacks for motor alignment, electric lift gear actuators, fabrication of motorized screw Motor Alignment Jacking Bolts Jacking bolts provide an easy and accurate way to horizontally position a motor during a shaft alignment. The easiest way to perform a horizontal move is with jacking bolts. Jacking bolts provide a smoother, easier way of moving machinery than using pry bars and hammers. Often overcorrecting back and forth. When using jack bolts to correct horizontal misalignment, it’s best. Motor Alignment Jacking Bolts.

From www.carid.com

ACDelco® 45K18048 Professional™ Front Alignment Camber Bolt Kit Motor Alignment Jacking Bolts Use a 5 mil shim between the bolt and motor foot, run the bolt up until it lightly pinches the shim. If you are currently using a sledge hammer or a 2×4, it is going to take you a lot longer to perform a horizontal move; You do not want to hit your machines with a hammer in order to. Motor Alignment Jacking Bolts.

From www.autozone.com

Specialty Products Alignment Cam Bolt 87520 Motor Alignment Jacking Bolts Jacking bolts provide a smoother, easier way of moving machinery than using pry bars and hammers. Jacking bolts provide a smoother, easier way of moving machinery than using pry bars and hammers. Use a 5 mil shim between the bolt and motor foot, run the bolt up until it lightly pinches the shim. Often overcorrecting back and forth. Loosening jacking. Motor Alignment Jacking Bolts.

From marineinsight.com

Jack Bolts for Marine Engine and the Procedure for Tensioning Motor Alignment Jacking Bolts Use a 5 mil shim between the bolt and motor foot, run the bolt up until it lightly pinches the shim. Jacking bolts provide a smoother, easier way of moving machinery than using pry bars and hammers. You do not want to hit your machines with a hammer in order to move them. When using jack bolts to correct horizontal. Motor Alignment Jacking Bolts.

From www.bolt.com.au

Category Screw Jack Bolts & Industrial Supplies Motor Alignment Jacking Bolts Often overcorrecting back and forth. If you are currently using a sledge hammer or a 2×4, it is going to take you a lot longer to perform a horizontal move; If your company's policy is to keep jacking bolts tight, here's a tip: Jacking bolts provide a smoother, easier way of moving machinery than using pry bars and hammers. Always. Motor Alignment Jacking Bolts.

From www.mechanical-knowledge.com

Machine Alignment A Practical Guide to Shaft Alignment Motor Alignment Jacking Bolts Jacking bolts provide an easy and accurate way to horizontally position a motor during a shaft alignment. You do not want to hit your machines with a hammer in order to move them. Always remember to back off the jack bolts on the opposite side. Use a 5 mil shim between the bolt and motor foot, run the bolt up. Motor Alignment Jacking Bolts.

From www.eng-tips.com

Pump grouting criteria? Pump engineering EngTips Motor Alignment Jacking Bolts Jacking bolts provide a smoother, easier way of moving machinery than using pry bars and hammers. If your company's policy is to keep jacking bolts tight, here's a tip: Jacking bolts provide an easy and accurate way to horizontally position a motor during a shaft alignment. Mount a jam nut on the jacking bolt. Jacking bolts provide a smoother, easier. Motor Alignment Jacking Bolts.

From www.raceplumbing.net

Allstar Performance 56066 Jack Bolt, 18 in Thread, 8 in Lon Motor Alignment Jacking Bolts Always remember to back off the jack bolts on the opposite side. You do not want to hit your machines with a hammer in order to move them. Use a 5 mil shim between the bolt and motor foot, run the bolt up until it lightly pinches the shim. Jacking bolts provide an easy and accurate way to horizontally position. Motor Alignment Jacking Bolts.

From www.homedepot.com

TH Marine Jack Plate Bolt Kit Coarse Thread BK1DP The Home Depot Motor Alignment Jacking Bolts You do not want to hit your machines with a hammer in order to move them. Use a 5 mil shim between the bolt and motor foot, run the bolt up until it lightly pinches the shim. Jacking bolts provide a smoother, easier way of moving machinery than using pry bars and hammers. Often overcorrecting back and forth. Always remember. Motor Alignment Jacking Bolts.

From www.cbmconnect.com

Shaft Alignment KnowHow BoltBound CBM CONNECT® Motor Alignment Jacking Bolts If your company's policy is to keep jacking bolts tight, here's a tip: Often overcorrecting back and forth. Jacking bolts provide an easy and accurate way to horizontally position a motor during a shaft alignment. Jacking bolts provide a smoother, easier way of moving machinery than using pry bars and hammers. Always remember to back off the jack bolts on. Motor Alignment Jacking Bolts.

From ctrline.net

Centerline, Inc. Laser Alignment Motor Alignment Jacking Bolts Always remember to back off the jack bolts on the opposite side. Often overcorrecting back and forth. When using jack bolts to correct horizontal misalignment, it’s best to back off the opposing jack bolts in the direction the machine needs to. If your company's policy is to keep jacking bolts tight, here's a tip: You do not want to hit. Motor Alignment Jacking Bolts.

From vibralign.com

Jacking Bolts VibrAlign Motor Alignment Jacking Bolts If your company's policy is to keep jacking bolts tight, here's a tip: The easiest way to perform a horizontal move is with jacking bolts. Mount a jam nut on the jacking bolt. Loosening jacking bolts before making an alignment can have significant benefits, including reducing vibration. Jacking bolts provide a smoother, easier way of moving machinery than using pry. Motor Alignment Jacking Bolts.

From www.walmart.com

SeaStar Jack Plate Mounting Bolt Kit, Includes 4 Each Stainless Steel Bolts, Brass Nylock Nuts Motor Alignment Jacking Bolts The easiest way to perform a horizontal move is with jacking bolts. When using jack bolts to correct horizontal misalignment, it’s best to back off the opposing jack bolts in the direction the machine needs to. Mount a jam nut on the jacking bolt. Jacking bolts provide a smoother, easier way of moving machinery than using pry bars and hammers.. Motor Alignment Jacking Bolts.

From www.bigstockphoto.com

Alignment Bolt Image & Photo (Free Trial) Bigstock Motor Alignment Jacking Bolts Often overcorrecting back and forth. When using jack bolts to correct horizontal misalignment, it’s best to back off the opposing jack bolts in the direction the machine needs to. If your company's policy is to keep jacking bolts tight, here's a tip: The easiest way to perform a horizontal move is with jacking bolts. Loosening jacking bolts before making an. Motor Alignment Jacking Bolts.

From steeda.ca

SPC ProAlignment Camber Adjustment Bolts (0514 All) Steeda Motor Alignment Jacking Bolts Jacking bolts provide a smoother, easier way of moving machinery than using pry bars and hammers. If you are currently using a sledge hammer or a 2×4, it is going to take you a lot longer to perform a horizontal move; Loosening jacking bolts before making an alignment can have significant benefits, including reducing vibration. Jacking bolts provide a smoother,. Motor Alignment Jacking Bolts.

From www.youtube.com

CHECK YOUR JACK BOLT ALIGNMENT! YouTube Motor Alignment Jacking Bolts Jacking bolts provide a smoother, easier way of moving machinery than using pry bars and hammers. If your company's policy is to keep jacking bolts tight, here's a tip: Jacking bolts provide a smoother, easier way of moving machinery than using pry bars and hammers. Always remember to back off the jack bolts on the opposite side. Mount a jam. Motor Alignment Jacking Bolts.

From www.stainlesssteelfasteners.net

Jack Bolt Anchor Bolt M20 Jack Bolt V Jack Bolts Motor Alignment Jacking Bolts Jacking bolts provide a smoother, easier way of moving machinery than using pry bars and hammers. Jacking bolts provide a smoother, easier way of moving machinery than using pry bars and hammers. The easiest way to perform a horizontal move is with jacking bolts. When using jack bolts to correct horizontal misalignment, it’s best to back off the opposing jack. Motor Alignment Jacking Bolts.

From reliabilityweb.com

Reliabilityweb After Shaft Alignment, Back Off on Jacking Bolts to Reduce Vibration Motor Alignment Jacking Bolts Often overcorrecting back and forth. If you are currently using a sledge hammer or a 2×4, it is going to take you a lot longer to perform a horizontal move; Use a 5 mil shim between the bolt and motor foot, run the bolt up until it lightly pinches the shim. The easiest way to perform a horizontal move is. Motor Alignment Jacking Bolts.

From www.pipingmaterial.ae

Jack bolts jack screw bolt vertical jacking bolts suppliers in UAE Motor Alignment Jacking Bolts Always remember to back off the jack bolts on the opposite side. Mount a jam nut on the jacking bolt. If you are currently using a sledge hammer or a 2×4, it is going to take you a lot longer to perform a horizontal move; Jacking bolts provide a smoother, easier way of moving machinery than using pry bars and. Motor Alignment Jacking Bolts.

From www.ozmotorsport.com

Alignment Cam Bolt Kit Front 14mm Bolts (+/ 1.5deg Camber) (KCA414) Motor Alignment Jacking Bolts Use a 5 mil shim between the bolt and motor foot, run the bolt up until it lightly pinches the shim. Jacking bolts provide a smoother, easier way of moving machinery than using pry bars and hammers. If you are currently using a sledge hammer or a 2×4, it is going to take you a lot longer to perform a. Motor Alignment Jacking Bolts.

From blog.enerpac.com

Bolt Tightening Sequence Why it Matters Enerpac Blog Motor Alignment Jacking Bolts Use a 5 mil shim between the bolt and motor foot, run the bolt up until it lightly pinches the shim. Always remember to back off the jack bolts on the opposite side. You do not want to hit your machines with a hammer in order to move them. Mount a jam nut on the jacking bolt. Loosening jacking bolts. Motor Alignment Jacking Bolts.

From us.bicknellracingproducts.com

JACK BOLT ASSEMBLY Motor Alignment Jacking Bolts The easiest way to perform a horizontal move is with jacking bolts. Mount a jam nut on the jacking bolt. If your company's policy is to keep jacking bolts tight, here's a tip: When using jack bolts to correct horizontal misalignment, it’s best to back off the opposing jack bolts in the direction the machine needs to. Often overcorrecting back. Motor Alignment Jacking Bolts.

From ctrline.net

Centerline, Inc. Portable Jack Bolts Motor Alignment Jacking Bolts Loosening jacking bolts before making an alignment can have significant benefits, including reducing vibration. If your company's policy is to keep jacking bolts tight, here's a tip: Mount a jam nut on the jacking bolt. Jacking bolts provide a smoother, easier way of moving machinery than using pry bars and hammers. Jacking bolts provide a smoother, easier way of moving. Motor Alignment Jacking Bolts.

From www.carid.com

AFCO® 202015S Standard Steel Jack Bolt Motor Alignment Jacking Bolts Jacking bolts provide an easy and accurate way to horizontally position a motor during a shaft alignment. Jacking bolts provide a smoother, easier way of moving machinery than using pry bars and hammers. When using jack bolts to correct horizontal misalignment, it’s best to back off the opposing jack bolts in the direction the machine needs to. Always remember to. Motor Alignment Jacking Bolts.

From www.goltens.com

Alignment and installation of 2 MaK 8M32C engines Goltens Motor Alignment Jacking Bolts Loosening jacking bolts before making an alignment can have significant benefits, including reducing vibration. Always remember to back off the jack bolts on the opposite side. The easiest way to perform a horizontal move is with jacking bolts. Often overcorrecting back and forth. Jacking bolts provide a smoother, easier way of moving machinery than using pry bars and hammers. Jacking. Motor Alignment Jacking Bolts.

From www.carid.com

ACDelco® 45K18051 Professional™ Rear Alignment Camber Bolt Kit Motor Alignment Jacking Bolts Often overcorrecting back and forth. Use a 5 mil shim between the bolt and motor foot, run the bolt up until it lightly pinches the shim. When using jack bolts to correct horizontal misalignment, it’s best to back off the opposing jack bolts in the direction the machine needs to. Always remember to back off the jack bolts on the. Motor Alignment Jacking Bolts.

From maintenanceworld.com

Should Jack Screws be tight or backed off? Maintenance World Motor Alignment Jacking Bolts If your company's policy is to keep jacking bolts tight, here's a tip: Loosening jacking bolts before making an alignment can have significant benefits, including reducing vibration. The easiest way to perform a horizontal move is with jacking bolts. When using jack bolts to correct horizontal misalignment, it’s best to back off the opposing jack bolts in the direction the. Motor Alignment Jacking Bolts.

From www.raceplumbing.net

Weight Jack Bolt Kits Motor Alignment Jacking Bolts Often overcorrecting back and forth. When using jack bolts to correct horizontal misalignment, it’s best to back off the opposing jack bolts in the direction the machine needs to. Jacking bolts provide an easy and accurate way to horizontally position a motor during a shaft alignment. If you are currently using a sledge hammer or a 2×4, it is going. Motor Alignment Jacking Bolts.

From www.waterworld.com

Pump to Motor Alignment WaterWorld Motor Alignment Jacking Bolts Loosening jacking bolts before making an alignment can have significant benefits, including reducing vibration. Jacking bolts provide a smoother, easier way of moving machinery than using pry bars and hammers. When using jack bolts to correct horizontal misalignment, it’s best to back off the opposing jack bolts in the direction the machine needs to. If your company's policy is to. Motor Alignment Jacking Bolts.

From www.carid.com

ACDelco® 45K18037 Professional™ Rear Alignment Camber Bolt Kit Motor Alignment Jacking Bolts Use a 5 mil shim between the bolt and motor foot, run the bolt up until it lightly pinches the shim. Jacking bolts provide an easy and accurate way to horizontally position a motor during a shaft alignment. Always remember to back off the jack bolts on the opposite side. Mount a jam nut on the jacking bolt. Often overcorrecting. Motor Alignment Jacking Bolts.

From www.raceplumbing.net

Weight Jack Bolt Kits Motor Alignment Jacking Bolts When using jack bolts to correct horizontal misalignment, it’s best to back off the opposing jack bolts in the direction the machine needs to. If you are currently using a sledge hammer or a 2×4, it is going to take you a lot longer to perform a horizontal move; Often overcorrecting back and forth. Use a 5 mil shim between. Motor Alignment Jacking Bolts.

From www.excelcalcs.com

Jacking bolt calculation Motor Alignment Jacking Bolts Always remember to back off the jack bolts on the opposite side. Jacking bolts provide a smoother, easier way of moving machinery than using pry bars and hammers. When using jack bolts to correct horizontal misalignment, it’s best to back off the opposing jack bolts in the direction the machine needs to. Mount a jam nut on the jacking bolt.. Motor Alignment Jacking Bolts.