Crank Sensor Waveform . crankshaft and camshaft position sensor comparison. this video demonstrates how to analyze a camshaft and crankshaft. Use the waveform buffer, zoom and measurements tools to examine your waveforms. The purpose of this test is to directly compare the relative positions of the crankshaft position (ckp) and. Use the waveform buffer, zoom and measurements tools to. library of automobile waveforms with the ability to quickly access from any device, conveniently search and exchange signals. having to remove valve or front cover of an engine to check engine timing marks can rarely be completed in under an hour on most modern engines. did you notice in the above crankshaft position sensor signal waveforms that the ac analog signal produces a ‘wavy’ up and down line. crank the engine for around 3 seconds to capture your waveform. a faulty crank sensor can cause a range of issues, from rough idling to engine stalling. crank the engine for around 3 seconds to capture your waveforms.

from mavink.com

a faulty crank sensor can cause a range of issues, from rough idling to engine stalling. crank the engine for around 3 seconds to capture your waveform. having to remove valve or front cover of an engine to check engine timing marks can rarely be completed in under an hour on most modern engines. The purpose of this test is to directly compare the relative positions of the crankshaft position (ckp) and. crankshaft and camshaft position sensor comparison. library of automobile waveforms with the ability to quickly access from any device, conveniently search and exchange signals. Use the waveform buffer, zoom and measurements tools to. did you notice in the above crankshaft position sensor signal waveforms that the ac analog signal produces a ‘wavy’ up and down line. crank the engine for around 3 seconds to capture your waveforms. Use the waveform buffer, zoom and measurements tools to examine your waveforms.

Cam And Crank Sensor Waveforms

Crank Sensor Waveform this video demonstrates how to analyze a camshaft and crankshaft. crank the engine for around 3 seconds to capture your waveforms. crank the engine for around 3 seconds to capture your waveform. a faulty crank sensor can cause a range of issues, from rough idling to engine stalling. Use the waveform buffer, zoom and measurements tools to examine your waveforms. library of automobile waveforms with the ability to quickly access from any device, conveniently search and exchange signals. did you notice in the above crankshaft position sensor signal waveforms that the ac analog signal produces a ‘wavy’ up and down line. The purpose of this test is to directly compare the relative positions of the crankshaft position (ckp) and. Use the waveform buffer, zoom and measurements tools to. crankshaft and camshaft position sensor comparison. this video demonstrates how to analyze a camshaft and crankshaft. having to remove valve or front cover of an engine to check engine timing marks can rarely be completed in under an hour on most modern engines.

From www.youtube.com

06 f150 cam and crank waveforms YouTube Crank Sensor Waveform crank the engine for around 3 seconds to capture your waveforms. a faulty crank sensor can cause a range of issues, from rough idling to engine stalling. this video demonstrates how to analyze a camshaft and crankshaft. The purpose of this test is to directly compare the relative positions of the crankshaft position (ckp) and. Use the. Crank Sensor Waveform.

From www.picoauto.com

Crankshaft and camshaft position sensor comparison Crank Sensor Waveform a faulty crank sensor can cause a range of issues, from rough idling to engine stalling. crank the engine for around 3 seconds to capture your waveforms. this video demonstrates how to analyze a camshaft and crankshaft. Use the waveform buffer, zoom and measurements tools to examine your waveforms. library of automobile waveforms with the ability. Crank Sensor Waveform.

From ls1tech.com

LS1 Cam & Crank Scope LS1TECH Crank Sensor Waveform did you notice in the above crankshaft position sensor signal waveforms that the ac analog signal produces a ‘wavy’ up and down line. crank the engine for around 3 seconds to capture your waveform. crankshaft and camshaft position sensor comparison. The purpose of this test is to directly compare the relative positions of the crankshaft position (ckp). Crank Sensor Waveform.

From www.picoauto.com

Crankshaft position sensor inductive, referenced, voltage during cranking Crank Sensor Waveform this video demonstrates how to analyze a camshaft and crankshaft. did you notice in the above crankshaft position sensor signal waveforms that the ac analog signal produces a ‘wavy’ up and down line. crankshaft and camshaft position sensor comparison. Use the waveform buffer, zoom and measurements tools to. Use the waveform buffer, zoom and measurements tools to. Crank Sensor Waveform.

From www.picoauto.com

Crankshaft position sensor inductive, referenced, voltage during running Crank Sensor Waveform crankshaft and camshaft position sensor comparison. did you notice in the above crankshaft position sensor signal waveforms that the ac analog signal produces a ‘wavy’ up and down line. a faulty crank sensor can cause a range of issues, from rough idling to engine stalling. Use the waveform buffer, zoom and measurements tools to examine your waveforms.. Crank Sensor Waveform.

From diag.net

Good Cam and Crank waveform ,Injection pulse, Spark and In cylinder 1ZZFE Diagnostic Network Crank Sensor Waveform a faulty crank sensor can cause a range of issues, from rough idling to engine stalling. crank the engine for around 3 seconds to capture your waveform. Use the waveform buffer, zoom and measurements tools to examine your waveforms. The purpose of this test is to directly compare the relative positions of the crankshaft position (ckp) and. . Crank Sensor Waveform.

From www.pico-automotive.co.za

Test 7 CAM Crank Sensor Correlation Crank Sensor Waveform Use the waveform buffer, zoom and measurements tools to examine your waveforms. did you notice in the above crankshaft position sensor signal waveforms that the ac analog signal produces a ‘wavy’ up and down line. crank the engine for around 3 seconds to capture your waveforms. a faulty crank sensor can cause a range of issues, from. Crank Sensor Waveform.

From www.youtube.com

CKP CMP Correlation Waveform Crankshaft & Camshaft Lexus2004 RX330 3MZFE after new Cam Sprockets Crank Sensor Waveform Use the waveform buffer, zoom and measurements tools to. Use the waveform buffer, zoom and measurements tools to examine your waveforms. crank the engine for around 3 seconds to capture your waveforms. crankshaft and camshaft position sensor comparison. a faulty crank sensor can cause a range of issues, from rough idling to engine stalling. did you. Crank Sensor Waveform.

From www.youtube.com

Camshaft and Crankshaft Position Sensor Waveform Analysis YouTube Crank Sensor Waveform Use the waveform buffer, zoom and measurements tools to. crank the engine for around 3 seconds to capture your waveforms. a faulty crank sensor can cause a range of issues, from rough idling to engine stalling. The purpose of this test is to directly compare the relative positions of the crankshaft position (ckp) and. crank the engine. Crank Sensor Waveform.

From www.youtube.com

Cam and Crank Sensor Waveforms 4.6 2V Ford Explorer YouTube Crank Sensor Waveform Use the waveform buffer, zoom and measurements tools to. crank the engine for around 3 seconds to capture your waveforms. did you notice in the above crankshaft position sensor signal waveforms that the ac analog signal produces a ‘wavy’ up and down line. a faulty crank sensor can cause a range of issues, from rough idling to. Crank Sensor Waveform.

From www.picoauto.com

Crankshaft position sensor inductive, referenced, voltage during cranking Crank Sensor Waveform Use the waveform buffer, zoom and measurements tools to examine your waveforms. library of automobile waveforms with the ability to quickly access from any device, conveniently search and exchange signals. crankshaft and camshaft position sensor comparison. this video demonstrates how to analyze a camshaft and crankshaft. The purpose of this test is to directly compare the relative. Crank Sensor Waveform.

From www.youtube.com

How to capture a crank angle sensor waveform using a PicoScope 1214 YouTube Crank Sensor Waveform Use the waveform buffer, zoom and measurements tools to. this video demonstrates how to analyze a camshaft and crankshaft. crankshaft and camshaft position sensor comparison. The purpose of this test is to directly compare the relative positions of the crankshaft position (ckp) and. did you notice in the above crankshaft position sensor signal waveforms that the ac. Crank Sensor Waveform.

From mavink.com

Cam And Crank Sensor Waveforms Crank Sensor Waveform library of automobile waveforms with the ability to quickly access from any device, conveniently search and exchange signals. Use the waveform buffer, zoom and measurements tools to examine your waveforms. this video demonstrates how to analyze a camshaft and crankshaft. The purpose of this test is to directly compare the relative positions of the crankshaft position (ckp) and.. Crank Sensor Waveform.

From www.picoauto.com

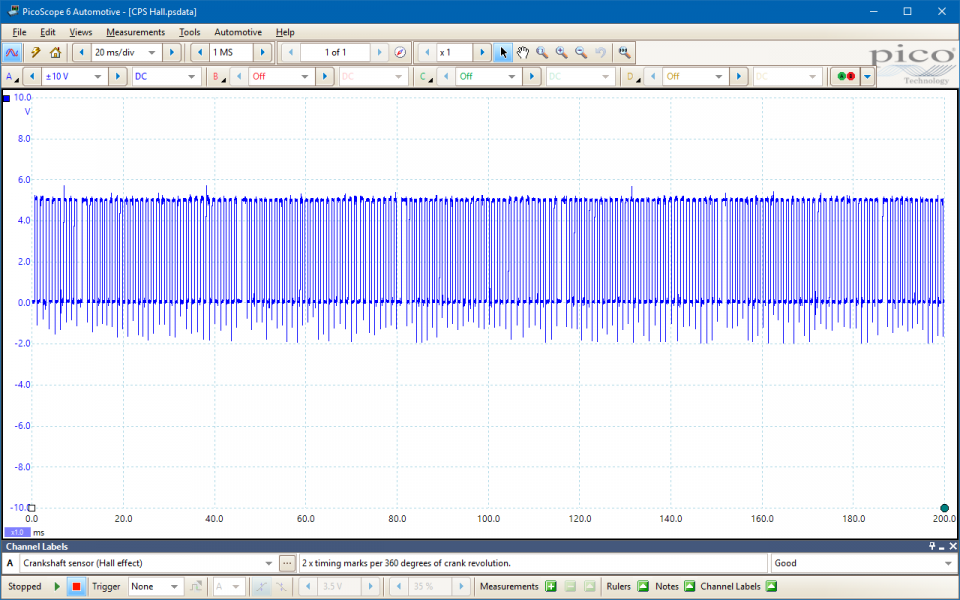

Crankshaft position sensor (Hall effect) running Crank Sensor Waveform Use the waveform buffer, zoom and measurements tools to. crank the engine for around 3 seconds to capture your waveform. having to remove valve or front cover of an engine to check engine timing marks can rarely be completed in under an hour on most modern engines. crankshaft and camshaft position sensor comparison. did you notice. Crank Sensor Waveform.

From mavink.com

Cam And Crank Sensor Waveforms Crank Sensor Waveform this video demonstrates how to analyze a camshaft and crankshaft. having to remove valve or front cover of an engine to check engine timing marks can rarely be completed in under an hour on most modern engines. crank the engine for around 3 seconds to capture your waveforms. The purpose of this test is to directly compare. Crank Sensor Waveform.

From diag.net

Cam & Crank Waveform Reference Diagnostic Network Crank Sensor Waveform this video demonstrates how to analyze a camshaft and crankshaft. library of automobile waveforms with the ability to quickly access from any device, conveniently search and exchange signals. crank the engine for around 3 seconds to capture your waveforms. crank the engine for around 3 seconds to capture your waveform. having to remove valve or. Crank Sensor Waveform.

From www.youtube.com

🔴 Camshaft And Crankshaft Position Sensor Signal Waveform YouTube Crank Sensor Waveform did you notice in the above crankshaft position sensor signal waveforms that the ac analog signal produces a ‘wavy’ up and down line. crank the engine for around 3 seconds to capture your waveform. having to remove valve or front cover of an engine to check engine timing marks can rarely be completed in under an hour. Crank Sensor Waveform.

From www.youtube.com

2014 Jeep wrangler v6 crank sensor waveform( good or bad ) ???(1) YouTube Crank Sensor Waveform did you notice in the above crankshaft position sensor signal waveforms that the ac analog signal produces a ‘wavy’ up and down line. Use the waveform buffer, zoom and measurements tools to examine your waveforms. crank the engine for around 3 seconds to capture your waveforms. Use the waveform buffer, zoom and measurements tools to. crank the. Crank Sensor Waveform.

From www.picoauto.com

Crankshaft and camshaft position sensor comparison Crank Sensor Waveform Use the waveform buffer, zoom and measurements tools to. did you notice in the above crankshaft position sensor signal waveforms that the ac analog signal produces a ‘wavy’ up and down line. a faulty crank sensor can cause a range of issues, from rough idling to engine stalling. having to remove valve or front cover of an. Crank Sensor Waveform.

From www.picoauto.com

Crankshaft position sensor (inductive floating) running Crank Sensor Waveform a faulty crank sensor can cause a range of issues, from rough idling to engine stalling. library of automobile waveforms with the ability to quickly access from any device, conveniently search and exchange signals. crank the engine for around 3 seconds to capture your waveforms. The purpose of this test is to directly compare the relative positions. Crank Sensor Waveform.

From www.pico-automotive.co.za

Test 7 CAM Crank Sensor Correlation Crank Sensor Waveform The purpose of this test is to directly compare the relative positions of the crankshaft position (ckp) and. crankshaft and camshaft position sensor comparison. a faulty crank sensor can cause a range of issues, from rough idling to engine stalling. this video demonstrates how to analyze a camshaft and crankshaft. crank the engine for around 3. Crank Sensor Waveform.

From www.picoauto.com

CPS. Testing an inductive crankshaft position sensor Crank Sensor Waveform Use the waveform buffer, zoom and measurements tools to examine your waveforms. crankshaft and camshaft position sensor comparison. Use the waveform buffer, zoom and measurements tools to. this video demonstrates how to analyze a camshaft and crankshaft. The purpose of this test is to directly compare the relative positions of the crankshaft position (ckp) and. having to. Crank Sensor Waveform.

From www.youtube.com

2005 Honda CRV 2.4L Cam & Crank Waveform YouTube Crank Sensor Waveform crank the engine for around 3 seconds to capture your waveforms. this video demonstrates how to analyze a camshaft and crankshaft. having to remove valve or front cover of an engine to check engine timing marks can rarely be completed in under an hour on most modern engines. Use the waveform buffer, zoom and measurements tools to.. Crank Sensor Waveform.

From www.picoauto.com

Motorcycle cam vs crank sensor waveform Crank Sensor Waveform this video demonstrates how to analyze a camshaft and crankshaft. crank the engine for around 3 seconds to capture your waveforms. having to remove valve or front cover of an engine to check engine timing marks can rarely be completed in under an hour on most modern engines. library of automobile waveforms with the ability to. Crank Sensor Waveform.

From picoauto.com

cas2 Crank Sensor Waveform The purpose of this test is to directly compare the relative positions of the crankshaft position (ckp) and. Use the waveform buffer, zoom and measurements tools to. crank the engine for around 3 seconds to capture your waveforms. having to remove valve or front cover of an engine to check engine timing marks can rarely be completed in. Crank Sensor Waveform.

From dxolmhcgq.blob.core.windows.net

Cam Crank Waveform at Earl Shelton blog Crank Sensor Waveform crank the engine for around 3 seconds to capture your waveforms. crankshaft and camshaft position sensor comparison. library of automobile waveforms with the ability to quickly access from any device, conveniently search and exchange signals. having to remove valve or front cover of an engine to check engine timing marks can rarely be completed in under. Crank Sensor Waveform.

From mavink.com

Cam And Crank Sensor Waveforms Crank Sensor Waveform The purpose of this test is to directly compare the relative positions of the crankshaft position (ckp) and. having to remove valve or front cover of an engine to check engine timing marks can rarely be completed in under an hour on most modern engines. this video demonstrates how to analyze a camshaft and crankshaft. Use the waveform. Crank Sensor Waveform.

From www.slideserve.com

PPT Automotive Wave forms PowerPoint Presentation, free download ID231061 Crank Sensor Waveform did you notice in the above crankshaft position sensor signal waveforms that the ac analog signal produces a ‘wavy’ up and down line. this video demonstrates how to analyze a camshaft and crankshaft. The purpose of this test is to directly compare the relative positions of the crankshaft position (ckp) and. a faulty crank sensor can cause. Crank Sensor Waveform.

From www.jeepforum.com

Crank Sensor Erratic Oscilloscope Waveform Jeep Enthusiast Forums Crank Sensor Waveform having to remove valve or front cover of an engine to check engine timing marks can rarely be completed in under an hour on most modern engines. Use the waveform buffer, zoom and measurements tools to. a faulty crank sensor can cause a range of issues, from rough idling to engine stalling. did you notice in the. Crank Sensor Waveform.

From www.picoauto.com

Hall Effect Crankshaft Position Sensor Crank Sensor Waveform did you notice in the above crankshaft position sensor signal waveforms that the ac analog signal produces a ‘wavy’ up and down line. The purpose of this test is to directly compare the relative positions of the crankshaft position (ckp) and. crank the engine for around 3 seconds to capture your waveforms. Use the waveform buffer, zoom and. Crank Sensor Waveform.

From www.picoauto.com

Crankshaft position sensor (Hall effect) running Crank Sensor Waveform Use the waveform buffer, zoom and measurements tools to examine your waveforms. The purpose of this test is to directly compare the relative positions of the crankshaft position (ckp) and. this video demonstrates how to analyze a camshaft and crankshaft. crank the engine for around 3 seconds to capture your waveforms. crankshaft and camshaft position sensor comparison.. Crank Sensor Waveform.

From www.picoauto.com

Crankshaft position sensor (inductive floating) cranking Crank Sensor Waveform crank the engine for around 3 seconds to capture your waveform. The purpose of this test is to directly compare the relative positions of the crankshaft position (ckp) and. this video demonstrates how to analyze a camshaft and crankshaft. did you notice in the above crankshaft position sensor signal waveforms that the ac analog signal produces a. Crank Sensor Waveform.

From diag.net

Crankshaft Waveform Diagnostic Network Crank Sensor Waveform crankshaft and camshaft position sensor comparison. library of automobile waveforms with the ability to quickly access from any device, conveniently search and exchange signals. this video demonstrates how to analyze a camshaft and crankshaft. The purpose of this test is to directly compare the relative positions of the crankshaft position (ckp) and. crank the engine for. Crank Sensor Waveform.

From www.youtube.com

Snap on verus crank position sensor voltage waveform on a cat c4.4L YouTube Crank Sensor Waveform Use the waveform buffer, zoom and measurements tools to. this video demonstrates how to analyze a camshaft and crankshaft. library of automobile waveforms with the ability to quickly access from any device, conveniently search and exchange signals. crank the engine for around 3 seconds to capture your waveforms. crankshaft and camshaft position sensor comparison. Use the. Crank Sensor Waveform.

From diag.net

Need a wave form cam and crank correlation Diagnostic Network Crank Sensor Waveform a faulty crank sensor can cause a range of issues, from rough idling to engine stalling. library of automobile waveforms with the ability to quickly access from any device, conveniently search and exchange signals. crankshaft and camshaft position sensor comparison. did you notice in the above crankshaft position sensor signal waveforms that the ac analog signal. Crank Sensor Waveform.