Tip Distance For Mig Welding . For example, you would choose a 0.023” contact tip for a 0.023” wire. Mig welding is more tolerant of minor surface. Why is clean metal essential? The material needs to be clean to get a good weld; Manufacturers recommend that you match the size of the contact tip to the size of the wire. I know miller has a photo in their gmaw book, i. Typically, maintaining a consistent electrode extension of around ¼ to ⅜ inch (6 to 10 mm) is recommended for most mig welding applications. The distance the electrode wire protrudes from the contact tip of the mig gun. Remove any grease or oil before using abrasives. Finding the right stickout length. How do i know which sized contact tip to select for my mig welder? Does anyone know the proper tip to cup distance for mig short circuit and spray arc. This distance is called electrode stickout. There’s one more critical factor to your wire feed speed:

from americantorchtip.com

Manufacturers recommend that you match the size of the contact tip to the size of the wire. There’s one more critical factor to your wire feed speed: This distance is called electrode stickout. Why is clean metal essential? Mig welding is more tolerant of minor surface. The material needs to be clean to get a good weld; Remove any grease or oil before using abrasives. For example, you would choose a 0.023” contact tip for a 0.023” wire. Typically, maintaining a consistent electrode extension of around ¼ to ⅜ inch (6 to 10 mm) is recommended for most mig welding applications. I know miller has a photo in their gmaw book, i.

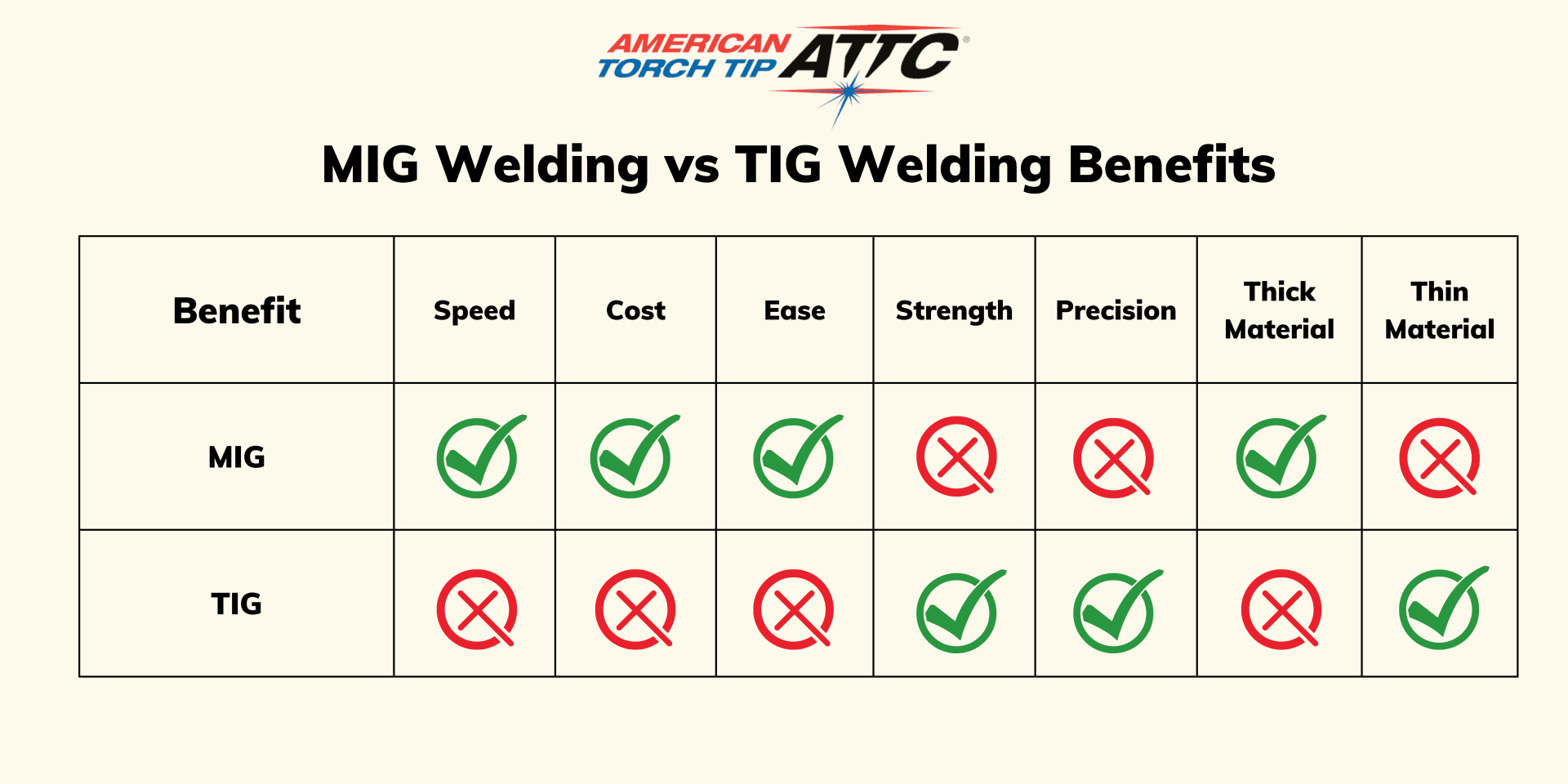

MIG vs TIG Welding Why a MIG Welder is More Efficient

Tip Distance For Mig Welding The material needs to be clean to get a good weld; Typically, maintaining a consistent electrode extension of around ¼ to ⅜ inch (6 to 10 mm) is recommended for most mig welding applications. Remove any grease or oil before using abrasives. Why is clean metal essential? The material needs to be clean to get a good weld; Mig welding is more tolerant of minor surface. How do i know which sized contact tip to select for my mig welder? This distance is called electrode stickout. For example, you would choose a 0.023” contact tip for a 0.023” wire. Manufacturers recommend that you match the size of the contact tip to the size of the wire. I know miller has a photo in their gmaw book, i. Finding the right stickout length. The distance the electrode wire protrudes from the contact tip of the mig gun. There’s one more critical factor to your wire feed speed: Does anyone know the proper tip to cup distance for mig short circuit and spray arc.

From www.weldingcity.com

Bernard MIG Welding Gun Contact Tip 4200 Tip Distance For Mig Welding Mig welding is more tolerant of minor surface. Typically, maintaining a consistent electrode extension of around ¼ to ⅜ inch (6 to 10 mm) is recommended for most mig welding applications. For example, you would choose a 0.023” contact tip for a 0.023” wire. The material needs to be clean to get a good weld; Why is clean metal essential?. Tip Distance For Mig Welding.

From www.weldingtipsandtricks.com

Mig Welding Techniques flat, horizontal, overhead, vertical Tip Distance For Mig Welding This distance is called electrode stickout. The material needs to be clean to get a good weld; For example, you would choose a 0.023” contact tip for a 0.023” wire. There’s one more critical factor to your wire feed speed: Why is clean metal essential? Mig welding is more tolerant of minor surface. Manufacturers recommend that you match the size. Tip Distance For Mig Welding.

From makemoneywelding.com

Important MIG Welder Settings You Need to Know (with Chart) Tip Distance For Mig Welding The material needs to be clean to get a good weld; I know miller has a photo in their gmaw book, i. Finding the right stickout length. Typically, maintaining a consistent electrode extension of around ¼ to ⅜ inch (6 to 10 mm) is recommended for most mig welding applications. Remove any grease or oil before using abrasives. For example,. Tip Distance For Mig Welding.

From www.walmart.com

MIG Tip 1mm Welding Contact Tips for 24KD MIG Welding Brass Pack of 3 Tip Distance For Mig Welding This distance is called electrode stickout. Finding the right stickout length. For example, you would choose a 0.023” contact tip for a 0.023” wire. Typically, maintaining a consistent electrode extension of around ¼ to ⅜ inch (6 to 10 mm) is recommended for most mig welding applications. I know miller has a photo in their gmaw book, i. Why is. Tip Distance For Mig Welding.

From www.weldingtipsandtricks.com

Mig Welding Uphill 3f Tee joint Tip Distance For Mig Welding For example, you would choose a 0.023” contact tip for a 0.023” wire. The distance the electrode wire protrudes from the contact tip of the mig gun. Does anyone know the proper tip to cup distance for mig short circuit and spray arc. Finding the right stickout length. How do i know which sized contact tip to select for my. Tip Distance For Mig Welding.

From sharkind.com

10 PK Mig Welder Contact Tip (Standard) Lincoln Tip Size .030 Tip Distance For Mig Welding Typically, maintaining a consistent electrode extension of around ¼ to ⅜ inch (6 to 10 mm) is recommended for most mig welding applications. Mig welding is more tolerant of minor surface. Manufacturers recommend that you match the size of the contact tip to the size of the wire. For example, you would choose a 0.023” contact tip for a 0.023”. Tip Distance For Mig Welding.

From fsmdirect.com

Welding Quality Variable with Recessed Contact Tip Tip Distance For Mig Welding Why is clean metal essential? For example, you would choose a 0.023” contact tip for a 0.023” wire. Manufacturers recommend that you match the size of the contact tip to the size of the wire. Typically, maintaining a consistent electrode extension of around ¼ to ⅜ inch (6 to 10 mm) is recommended for most mig welding applications. Remove any. Tip Distance For Mig Welding.

From www.amazon.com

Mig Welding Contact Tips .035"(0.9mm) for Lincoln Magnum Pro 250/350 Tip Distance For Mig Welding Remove any grease or oil before using abrasives. Typically, maintaining a consistent electrode extension of around ¼ to ⅜ inch (6 to 10 mm) is recommended for most mig welding applications. Mig welding is more tolerant of minor surface. For example, you would choose a 0.023” contact tip for a 0.023” wire. This distance is called electrode stickout. Manufacturers recommend. Tip Distance For Mig Welding.

From www.electroweld.com.au

Genuine Binzel M8 MIG Welding Contact Tip, 1.2mm 10 Pack Best Tip Distance For Mig Welding Typically, maintaining a consistent electrode extension of around ¼ to ⅜ inch (6 to 10 mm) is recommended for most mig welding applications. Remove any grease or oil before using abrasives. Manufacturers recommend that you match the size of the contact tip to the size of the wire. I know miller has a photo in their gmaw book, i. Mig. Tip Distance For Mig Welding.

From www.instructables.com

Beginning to MIG Weld 11 Steps Instructables Tip Distance For Mig Welding This distance is called electrode stickout. Mig welding is more tolerant of minor surface. Manufacturers recommend that you match the size of the contact tip to the size of the wire. There’s one more critical factor to your wire feed speed: Why is clean metal essential? How do i know which sized contact tip to select for my mig welder?. Tip Distance For Mig Welding.

From elgawelding.com

What Are Stickout, Electrode Extension and ContactTipToWork Distance Tip Distance For Mig Welding Typically, maintaining a consistent electrode extension of around ¼ to ⅜ inch (6 to 10 mm) is recommended for most mig welding applications. The distance the electrode wire protrudes from the contact tip of the mig gun. How do i know which sized contact tip to select for my mig welder? Why is clean metal essential? There’s one more critical. Tip Distance For Mig Welding.

From weldersadvice.com

025 Mig Welder Contact Tip Everything You Need to Know Tip Distance For Mig Welding I know miller has a photo in their gmaw book, i. The material needs to be clean to get a good weld; Why is clean metal essential? This distance is called electrode stickout. How do i know which sized contact tip to select for my mig welder? For example, you would choose a 0.023” contact tip for a 0.023” wire.. Tip Distance For Mig Welding.

From weldingtroop.com

MIG Welding Contact Tip Thread Size Chart And Users Guide Tip Distance For Mig Welding Finding the right stickout length. This distance is called electrode stickout. Remove any grease or oil before using abrasives. There’s one more critical factor to your wire feed speed: Manufacturers recommend that you match the size of the contact tip to the size of the wire. I know miller has a photo in their gmaw book, i. The distance the. Tip Distance For Mig Welding.

From www.hampdon.com.au

Binzel MIG Contact Tips for ALUMINIUM 0.9mm 100 pack M8 x 10mm x 0.9mm Tip Distance For Mig Welding This distance is called electrode stickout. How do i know which sized contact tip to select for my mig welder? Typically, maintaining a consistent electrode extension of around ¼ to ⅜ inch (6 to 10 mm) is recommended for most mig welding applications. Manufacturers recommend that you match the size of the contact tip to the size of the wire.. Tip Distance For Mig Welding.

From www.walmart.com

MIG Tip 0.8mm Welding Contact Tips for 15AK MIG Welding Brass Pack of Tip Distance For Mig Welding Typically, maintaining a consistent electrode extension of around ¼ to ⅜ inch (6 to 10 mm) is recommended for most mig welding applications. How do i know which sized contact tip to select for my mig welder? The material needs to be clean to get a good weld; Finding the right stickout length. Does anyone know the proper tip to. Tip Distance For Mig Welding.

From itstillruns.com

How to Set the Gas on an MIG Welder It Still Runs Tip Distance For Mig Welding Mig welding is more tolerant of minor surface. For example, you would choose a 0.023” contact tip for a 0.023” wire. This distance is called electrode stickout. There’s one more critical factor to your wire feed speed: The distance the electrode wire protrudes from the contact tip of the mig gun. Does anyone know the proper tip to cup distance. Tip Distance For Mig Welding.

From www.sip-group.com

SIP 1.0mm 15 M6 MIG Welding Tip SIP Industrial Products Official site Tip Distance For Mig Welding Remove any grease or oil before using abrasives. The distance the electrode wire protrudes from the contact tip of the mig gun. I know miller has a photo in their gmaw book, i. The material needs to be clean to get a good weld; Typically, maintaining a consistent electrode extension of around ¼ to ⅜ inch (6 to 10 mm). Tip Distance For Mig Welding.

From www.colegiosantainescampestre.edu.co

MIG Welding Contact Tip Thread Size Chart And Users Guide, 59 OFF Tip Distance For Mig Welding There’s one more critical factor to your wire feed speed: How do i know which sized contact tip to select for my mig welder? Does anyone know the proper tip to cup distance for mig short circuit and spray arc. The distance the electrode wire protrudes from the contact tip of the mig gun. I know miller has a photo. Tip Distance For Mig Welding.

From www.walmart.com

MIG Tip 0.8mm Welding Contact Tips for 15AK MIG Welding Brass Pack of 5 Tip Distance For Mig Welding Finding the right stickout length. The material needs to be clean to get a good weld; Why is clean metal essential? I know miller has a photo in their gmaw book, i. For example, you would choose a 0.023” contact tip for a 0.023” wire. Does anyone know the proper tip to cup distance for mig short circuit and spray. Tip Distance For Mig Welding.

From xpressmobilewelding.com

Welding Tips and Tricks of MIG Welding Tip Distance For Mig Welding Remove any grease or oil before using abrasives. There’s one more critical factor to your wire feed speed: The material needs to be clean to get a good weld; I know miller has a photo in their gmaw book, i. Manufacturers recommend that you match the size of the contact tip to the size of the wire. Typically, maintaining a. Tip Distance For Mig Welding.

From www.hollyfab.com

Common Welding Methods Tip Distance For Mig Welding The distance the electrode wire protrudes from the contact tip of the mig gun. Does anyone know the proper tip to cup distance for mig short circuit and spray arc. The material needs to be clean to get a good weld; Why is clean metal essential? How do i know which sized contact tip to select for my mig welder?. Tip Distance For Mig Welding.

From www.alibaba.com

Tokinarc Contact Tips For Mig Welding Spare Parts Weld Gun Accessory Tip Distance For Mig Welding For example, you would choose a 0.023” contact tip for a 0.023” wire. Manufacturers recommend that you match the size of the contact tip to the size of the wire. How do i know which sized contact tip to select for my mig welder? Remove any grease or oil before using abrasives. I know miller has a photo in their. Tip Distance For Mig Welding.

From www.mig-welding.co.uk

Arc Welding Faults Examples of Speed, Arc Length, and Current Problems Tip Distance For Mig Welding Why is clean metal essential? The material needs to be clean to get a good weld; There’s one more critical factor to your wire feed speed: This distance is called electrode stickout. How do i know which sized contact tip to select for my mig welder? Finding the right stickout length. Does anyone know the proper tip to cup distance. Tip Distance For Mig Welding.

From www.walmart.com

Uxcell 1mm for 24KD Brass MIG Welding Contact Tips Pack of 3 Tip Distance For Mig Welding Remove any grease or oil before using abrasives. Does anyone know the proper tip to cup distance for mig short circuit and spray arc. The material needs to be clean to get a good weld; Mig welding is more tolerant of minor surface. Typically, maintaining a consistent electrode extension of around ¼ to ⅜ inch (6 to 10 mm) is. Tip Distance For Mig Welding.

From www.wcwelding.com

MIG Wire Types Tip Distance For Mig Welding Typically, maintaining a consistent electrode extension of around ¼ to ⅜ inch (6 to 10 mm) is recommended for most mig welding applications. How do i know which sized contact tip to select for my mig welder? For example, you would choose a 0.023” contact tip for a 0.023” wire. I know miller has a photo in their gmaw book,. Tip Distance For Mig Welding.

From americantorchtip.com

MIG vs TIG Welding Why a MIG Welder is More Efficient Tip Distance For Mig Welding The distance the electrode wire protrudes from the contact tip of the mig gun. For example, you would choose a 0.023” contact tip for a 0.023” wire. The material needs to be clean to get a good weld; Finding the right stickout length. There’s one more critical factor to your wire feed speed: How do i know which sized contact. Tip Distance For Mig Welding.

From www.technoxmachine.com

MIG vs TIG Welding Types, Materials, and Applications A Guide Tip Distance For Mig Welding For example, you would choose a 0.023” contact tip for a 0.023” wire. Why is clean metal essential? The distance the electrode wire protrudes from the contact tip of the mig gun. The material needs to be clean to get a good weld; Mig welding is more tolerant of minor surface. I know miller has a photo in their gmaw. Tip Distance For Mig Welding.

From weldingtorchapes.com

Japanese Type Contact tips Panasonic CuCrZr /Copper MIG Welding Contact Tip Distance For Mig Welding This distance is called electrode stickout. I know miller has a photo in their gmaw book, i. Typically, maintaining a consistent electrode extension of around ¼ to ⅜ inch (6 to 10 mm) is recommended for most mig welding applications. Remove any grease or oil before using abrasives. The material needs to be clean to get a good weld; There’s. Tip Distance For Mig Welding.

From dynaweld.com.au

7 common welding issues + welding tips and tricks Tip Distance For Mig Welding There’s one more critical factor to your wire feed speed: For example, you would choose a 0.023” contact tip for a 0.023” wire. I know miller has a photo in their gmaw book, i. Finding the right stickout length. This distance is called electrode stickout. Typically, maintaining a consistent electrode extension of around ¼ to ⅜ inch (6 to 10. Tip Distance For Mig Welding.

From www.thefabricator.com

Troubleshooting MIG starts with components of welding gun Tip Distance For Mig Welding Mig welding is more tolerant of minor surface. Remove any grease or oil before using abrasives. I know miller has a photo in their gmaw book, i. Why is clean metal essential? Manufacturers recommend that you match the size of the contact tip to the size of the wire. Does anyone know the proper tip to cup distance for mig. Tip Distance For Mig Welding.

From www.lazada.com.ph

5pcs Mig Nozzle Tip Tig Welding Tip Welding Accessories Nozzles MIG Tip Distance For Mig Welding Typically, maintaining a consistent electrode extension of around ¼ to ⅜ inch (6 to 10 mm) is recommended for most mig welding applications. Mig welding is more tolerant of minor surface. The material needs to be clean to get a good weld; How do i know which sized contact tip to select for my mig welder? Finding the right stickout. Tip Distance For Mig Welding.

From www.cwbgroup.org

How is Argon Used in MIG Welding and how do MIG and MAG Welding Differ Tip Distance For Mig Welding The material needs to be clean to get a good weld; Manufacturers recommend that you match the size of the contact tip to the size of the wire. Mig welding is more tolerant of minor surface. I know miller has a photo in their gmaw book, i. Remove any grease or oil before using abrasives. Finding the right stickout length.. Tip Distance For Mig Welding.

From weldingtorchapes.com

Contact tip 1.2 mm CE certification copper material contact tips for Tip Distance For Mig Welding There’s one more critical factor to your wire feed speed: Finding the right stickout length. I know miller has a photo in their gmaw book, i. Typically, maintaining a consistent electrode extension of around ¼ to ⅜ inch (6 to 10 mm) is recommended for most mig welding applications. Does anyone know the proper tip to cup distance for mig. Tip Distance For Mig Welding.

From weldguru.com

MIG Welder Settings Explained (with Chart) Weld Guru Tip Distance For Mig Welding Mig welding is more tolerant of minor surface. I know miller has a photo in their gmaw book, i. Does anyone know the proper tip to cup distance for mig short circuit and spray arc. Remove any grease or oil before using abrasives. Finding the right stickout length. This distance is called electrode stickout. The distance the electrode wire protrudes. Tip Distance For Mig Welding.

From weldguru.com

MIG vs TIG Welding The Main Differences Weld Guru Tip Distance For Mig Welding How do i know which sized contact tip to select for my mig welder? The distance the electrode wire protrudes from the contact tip of the mig gun. Typically, maintaining a consistent electrode extension of around ¼ to ⅜ inch (6 to 10 mm) is recommended for most mig welding applications. There’s one more critical factor to your wire feed. Tip Distance For Mig Welding.