Ultrasound Transducer Backing Material . In this paper, a new composite for ultrasonic attenuation backing has been successfully fabricated from porous epoxy. In contrast, a transducer for which a backing material with a low acoustic impedance is used has a high sensitivity, while the time. Backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. Generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high thermal expansion coefficient, low. Selection of the proper backing material for a piezoelectric polymer ultrasonic transducer demands careful design. In this study, the backing material located in the bodies of ultrasonic transducers was investigated in terms of hardness values in order to find the.

from www.mdpi.com

In this paper, a new composite for ultrasonic attenuation backing has been successfully fabricated from porous epoxy. Backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. In contrast, a transducer for which a backing material with a low acoustic impedance is used has a high sensitivity, while the time. Generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high thermal expansion coefficient, low. In this study, the backing material located in the bodies of ultrasonic transducers was investigated in terms of hardness values in order to find the. Selection of the proper backing material for a piezoelectric polymer ultrasonic transducer demands careful design.

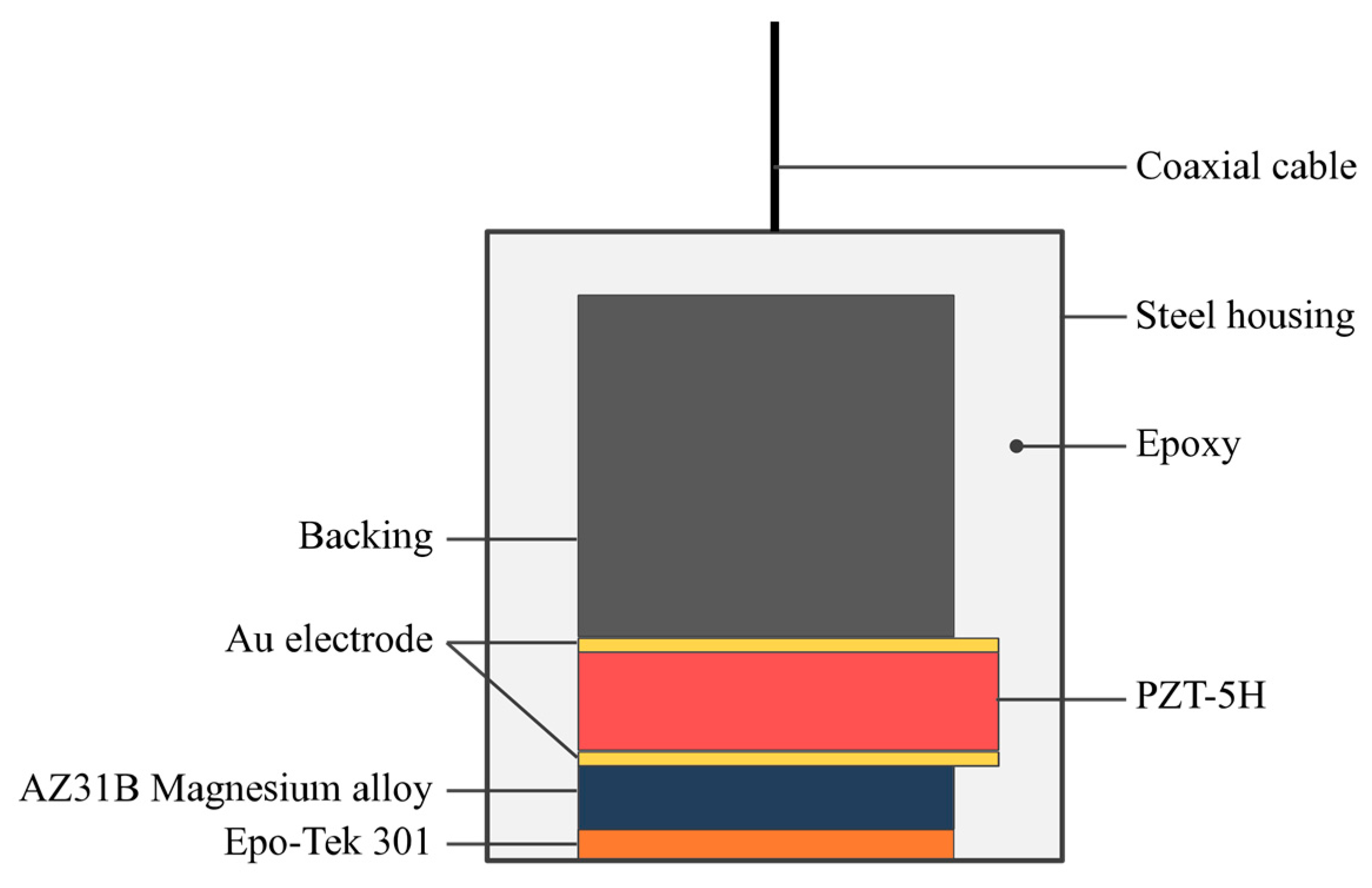

Sensors Free FullText Magnesium Alloy Matching Layer for High

Ultrasound Transducer Backing Material In this paper, a new composite for ultrasonic attenuation backing has been successfully fabricated from porous epoxy. Backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. Selection of the proper backing material for a piezoelectric polymer ultrasonic transducer demands careful design. Generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high thermal expansion coefficient, low. In this study, the backing material located in the bodies of ultrasonic transducers was investigated in terms of hardness values in order to find the. In this paper, a new composite for ultrasonic attenuation backing has been successfully fabricated from porous epoxy. In contrast, a transducer for which a backing material with a low acoustic impedance is used has a high sensitivity, while the time.

From www.researchgate.net

Sketch of fabricated ultrasonic transducers with backing materials from Ultrasound Transducer Backing Material Selection of the proper backing material for a piezoelectric polymer ultrasonic transducer demands careful design. In contrast, a transducer for which a backing material with a low acoustic impedance is used has a high sensitivity, while the time. In this study, the backing material located in the bodies of ultrasonic transducers was investigated in terms of hardness values in order. Ultrasound Transducer Backing Material.

From www.researchgate.net

(PDF) Preparation of polyvinyl acetate composite as a new backing Ultrasound Transducer Backing Material In this paper, a new composite for ultrasonic attenuation backing has been successfully fabricated from porous epoxy. Backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. In this study, the backing material located in the bodies of ultrasonic transducers was investigated in terms of hardness values in order to find the. Selection of the proper backing. Ultrasound Transducer Backing Material.

From mavink.com

Parts Of Ultrasound Transducer Ultrasound Transducer Backing Material In this paper, a new composite for ultrasonic attenuation backing has been successfully fabricated from porous epoxy. Selection of the proper backing material for a piezoelectric polymer ultrasonic transducer demands careful design. Backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. In this study, the backing material located in the bodies of ultrasonic transducers was investigated. Ultrasound Transducer Backing Material.

From www.mdpi.com

Biosensors Free FullText A BackingLayerShared Miniature Dual Ultrasound Transducer Backing Material In this study, the backing material located in the bodies of ultrasonic transducers was investigated in terms of hardness values in order to find the. In contrast, a transducer for which a backing material with a low acoustic impedance is used has a high sensitivity, while the time. Backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer. Ultrasound Transducer Backing Material.

From onscale.com

The advantages of using composite piezoelectric transducers for medical Ultrasound Transducer Backing Material Backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. Generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high thermal expansion coefficient, low. In contrast, a transducer for which a backing material with a low acoustic impedance is used has a high sensitivity, while the time. In this. Ultrasound Transducer Backing Material.

From www.uscultrasound.com

Ultrasound Transducer Single Crystal Technology Ultrasound Transducer Backing Material In contrast, a transducer for which a backing material with a low acoustic impedance is used has a high sensitivity, while the time. Backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. Selection of the proper backing material for a piezoelectric polymer ultrasonic transducer demands careful design. Generally, an ideal thermal expansion material for the optoacoustic. Ultrasound Transducer Backing Material.

From www.researchgate.net

Components of an ultrasound transducer Download Scientific Diagram Ultrasound Transducer Backing Material In contrast, a transducer for which a backing material with a low acoustic impedance is used has a high sensitivity, while the time. Generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high thermal expansion coefficient, low. Selection of the proper backing material for a piezoelectric polymer ultrasonic transducer demands careful design.. Ultrasound Transducer Backing Material.

From informacionpublica.svet.gob.gt

ULTRASOUND TRANSDUCER informacionpublica.svet.gob.gt Ultrasound Transducer Backing Material Selection of the proper backing material for a piezoelectric polymer ultrasonic transducer demands careful design. In this paper, a new composite for ultrasonic attenuation backing has been successfully fabricated from porous epoxy. In this study, the backing material located in the bodies of ultrasonic transducers was investigated in terms of hardness values in order to find the. Generally, an ideal. Ultrasound Transducer Backing Material.

From doctorlib.info

Sonography Principles, Techniques, and Instrumentation Lange Review Ultrasound Transducer Backing Material Generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high thermal expansion coefficient, low. In this study, the backing material located in the bodies of ultrasonic transducers was investigated in terms of hardness values in order to find the. Backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design.. Ultrasound Transducer Backing Material.

From www.mdpi.com

Sensors Free FullText Ultrasonic Transducer for NonDestructive Ultrasound Transducer Backing Material In this study, the backing material located in the bodies of ultrasonic transducers was investigated in terms of hardness values in order to find the. Selection of the proper backing material for a piezoelectric polymer ultrasonic transducer demands careful design. Generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high thermal expansion. Ultrasound Transducer Backing Material.

From www.mdpi.com

Sensors Free FullText Thermal Ablation and HighResolution Imaging Ultrasound Transducer Backing Material Backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. In this paper, a new composite for ultrasonic attenuation backing has been successfully fabricated from porous epoxy. Generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high thermal expansion coefficient, low. In contrast, a transducer for which a backing. Ultrasound Transducer Backing Material.

From www.researchgate.net

The key steps involved in the fabrication of the transparent ultrasound Ultrasound Transducer Backing Material Backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. Generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high thermal expansion coefficient, low. In this study, the backing material located in the bodies of ultrasonic transducers was investigated in terms of hardness values in order to find the.. Ultrasound Transducer Backing Material.

From www.ptemasters.com

Download Ultrasound Transducer Backing Material In this study, the backing material located in the bodies of ultrasonic transducers was investigated in terms of hardness values in order to find the. Generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high thermal expansion coefficient, low. In contrast, a transducer for which a backing material with a low acoustic. Ultrasound Transducer Backing Material.

From www.mdpi.com

Micromachines Free FullText Particle Swarm Optimization Algorithm Ultrasound Transducer Backing Material In contrast, a transducer for which a backing material with a low acoustic impedance is used has a high sensitivity, while the time. Selection of the proper backing material for a piezoelectric polymer ultrasonic transducer demands careful design. Generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high thermal expansion coefficient, low.. Ultrasound Transducer Backing Material.

From www.mdpi.com

Coatings Free FullText Preparation of ZnO Piezoelectric ThinFilm Ultrasound Transducer Backing Material In this study, the backing material located in the bodies of ultrasonic transducers was investigated in terms of hardness values in order to find the. In contrast, a transducer for which a backing material with a low acoustic impedance is used has a high sensitivity, while the time. Selection of the proper backing material for a piezoelectric polymer ultrasonic transducer. Ultrasound Transducer Backing Material.

From www.mdpi.com

Sensors Free FullText Magnesium Alloy Matching Layer for High Ultrasound Transducer Backing Material In this study, the backing material located in the bodies of ultrasonic transducers was investigated in terms of hardness values in order to find the. Selection of the proper backing material for a piezoelectric polymer ultrasonic transducer demands careful design. In contrast, a transducer for which a backing material with a low acoustic impedance is used has a high sensitivity,. Ultrasound Transducer Backing Material.

From www.mdpi.com

Sensors Free FullText FPCB as an Acoustic Matching Layer for 1D Ultrasound Transducer Backing Material In this paper, a new composite for ultrasonic attenuation backing has been successfully fabricated from porous epoxy. In contrast, a transducer for which a backing material with a low acoustic impedance is used has a high sensitivity, while the time. Backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. In this study, the backing material located. Ultrasound Transducer Backing Material.

From www.comsol.fr

Using Simulation to Study Ultrasound Focusing for Clinical Applications Ultrasound Transducer Backing Material Selection of the proper backing material for a piezoelectric polymer ultrasonic transducer demands careful design. Backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. In contrast, a transducer for which a backing material with a low acoustic impedance is used has a high sensitivity, while the time. In this paper, a new composite for ultrasonic attenuation. Ultrasound Transducer Backing Material.

From www.nibib.nih.gov

Ultrasound Ultrasound Transducer Backing Material In this paper, a new composite for ultrasonic attenuation backing has been successfully fabricated from porous epoxy. Generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high thermal expansion coefficient, low. Backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. Selection of the proper backing material for a. Ultrasound Transducer Backing Material.

From techblog.ctgclean.com

Ultrasonics Transducers Hardware CTG Technical Blog Ultrasound Transducer Backing Material Generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high thermal expansion coefficient, low. Backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. In this study, the backing material located in the bodies of ultrasonic transducers was investigated in terms of hardness values in order to find the.. Ultrasound Transducer Backing Material.

From www.appli-tec.com

The Use of Specialty Materials in Ultrasound Probes AppliTec Ultrasound Transducer Backing Material Generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high thermal expansion coefficient, low. Selection of the proper backing material for a piezoelectric polymer ultrasonic transducer demands careful design. In this paper, a new composite for ultrasonic attenuation backing has been successfully fabricated from porous epoxy. In this study, the backing material. Ultrasound Transducer Backing Material.

From www.researchgate.net

Sketch of fabricated ultrasonic transducers with backing materials from Ultrasound Transducer Backing Material Generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high thermal expansion coefficient, low. In this study, the backing material located in the bodies of ultrasonic transducers was investigated in terms of hardness values in order to find the. Selection of the proper backing material for a piezoelectric polymer ultrasonic transducer demands. Ultrasound Transducer Backing Material.

From www.mdpi.com

Sensors Free FullText A SphericallyShaped PZT Thin Film Ultrasound Transducer Backing Material Selection of the proper backing material for a piezoelectric polymer ultrasonic transducer demands careful design. In contrast, a transducer for which a backing material with a low acoustic impedance is used has a high sensitivity, while the time. In this study, the backing material located in the bodies of ultrasonic transducers was investigated in terms of hardness values in order. Ultrasound Transducer Backing Material.

From slideplayer.com

Ultrasound Transducers ppt download Ultrasound Transducer Backing Material Generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high thermal expansion coefficient, low. Selection of the proper backing material for a piezoelectric polymer ultrasonic transducer demands careful design. In this study, the backing material located in the bodies of ultrasonic transducers was investigated in terms of hardness values in order to. Ultrasound Transducer Backing Material.

From feaforall.com

Piezoelectric Transducer Simulation with OnScale Ultrasonic Sensor Ultrasound Transducer Backing Material In this study, the backing material located in the bodies of ultrasonic transducers was investigated in terms of hardness values in order to find the. Selection of the proper backing material for a piezoelectric polymer ultrasonic transducer demands careful design. In contrast, a transducer for which a backing material with a low acoustic impedance is used has a high sensitivity,. Ultrasound Transducer Backing Material.

From akicare.en.made-in-china.com

Mindray 75L38ha New Linear Array Sensor Ultrasound Probe Ultrasonic Ultrasound Transducer Backing Material In contrast, a transducer for which a backing material with a low acoustic impedance is used has a high sensitivity, while the time. Backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. Selection of the proper backing material for a piezoelectric polymer ultrasonic transducer demands careful design. In this paper, a new composite for ultrasonic attenuation. Ultrasound Transducer Backing Material.

From www.radiologystar.com

Ultrasound Transducer radiologystar Ultrasound Transducer Backing Material In this study, the backing material located in the bodies of ultrasonic transducers was investigated in terms of hardness values in order to find the. In contrast, a transducer for which a backing material with a low acoustic impedance is used has a high sensitivity, while the time. Selection of the proper backing material for a piezoelectric polymer ultrasonic transducer. Ultrasound Transducer Backing Material.

From www.medicaldevicecables.com

Reusable Medical Transducer Probe / External Ultrasound Transducer With Ultrasound Transducer Backing Material Generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high thermal expansion coefficient, low. Selection of the proper backing material for a piezoelectric polymer ultrasonic transducer demands careful design. Backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. In contrast, a transducer for which a backing material with. Ultrasound Transducer Backing Material.

From www.animalia-life.club

Ultrasound Piezoelectric Transducer Ultrasound Transducer Backing Material Backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. In this study, the backing material located in the bodies of ultrasonic transducers was investigated in terms of hardness values in order to find the. Selection of the proper backing material for a piezoelectric polymer ultrasonic transducer demands careful design. In this paper, a new composite for. Ultrasound Transducer Backing Material.

From www.mdpi.com

Sensors Free FullText Design and Fabrication of DoubleFocused Ultrasound Transducer Backing Material Generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high thermal expansion coefficient, low. In this study, the backing material located in the bodies of ultrasonic transducers was investigated in terms of hardness values in order to find the. In contrast, a transducer for which a backing material with a low acoustic. Ultrasound Transducer Backing Material.

From www.researchgate.net

(PDF) Influence of backing and matching layers in ultrasound transducer Ultrasound Transducer Backing Material Selection of the proper backing material for a piezoelectric polymer ultrasonic transducer demands careful design. In contrast, a transducer for which a backing material with a low acoustic impedance is used has a high sensitivity, while the time. In this study, the backing material located in the bodies of ultrasonic transducers was investigated in terms of hardness values in order. Ultrasound Transducer Backing Material.

From www.disposablespo2sensor.com

Goldway Fetal Monitor Ultrasound Transducer Probe 5 Pin Connector TPU Ultrasound Transducer Backing Material Backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. In this paper, a new composite for ultrasonic attenuation backing has been successfully fabricated from porous epoxy. Selection of the proper backing material for a piezoelectric polymer ultrasonic transducer demands careful design. In contrast, a transducer for which a backing material with a low acoustic impedance is. Ultrasound Transducer Backing Material.

From www.researchgate.net

Comparison between tradition external transducer with backing material Ultrasound Transducer Backing Material Generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high thermal expansion coefficient, low. In this study, the backing material located in the bodies of ultrasonic transducers was investigated in terms of hardness values in order to find the. In contrast, a transducer for which a backing material with a low acoustic. Ultrasound Transducer Backing Material.

From informacionpublica.svet.gob.gt

Ultrasound Transducer Backing Material informacionpublica.svet.gob.gt Ultrasound Transducer Backing Material In contrast, a transducer for which a backing material with a low acoustic impedance is used has a high sensitivity, while the time. In this paper, a new composite for ultrasonic attenuation backing has been successfully fabricated from porous epoxy. Generally, an ideal thermal expansion material for the optoacoustic transducer is the polydimethylsiloxane (pdms) because of its high thermal expansion. Ultrasound Transducer Backing Material.

From www.slideserve.com

PPT Ultrasound PowerPoint Presentation, free download ID1105836 Ultrasound Transducer Backing Material In this paper, a new composite for ultrasonic attenuation backing has been successfully fabricated from porous epoxy. In this study, the backing material located in the bodies of ultrasonic transducers was investigated in terms of hardness values in order to find the. Backing materials with tailored acoustic properties are beneficial for miniaturized ultrasonic transducer design. In contrast, a transducer for. Ultrasound Transducer Backing Material.