Dc Motors Efficiency . Bldc motors offer high efficiency, controllability, and starting torque, but are typically more expensive. Losses occur during conversion of electrical energy into mechanical energy in electrical motor. Dc motors have lower efficiency but high controllability and starting torque. Efficiency of a dc motor. These losses and conversion of energy in the motor is known as the power stages of a dc motor which is shown in the below diagram. Electrical motor efficiency when shaft output is. Most electric motors are designed to run at 50% to 100% of rated load. Efficiencies and power stages in dc motors. This guide covers efficiency and losses of dc machines (motor and generator) which include copper, core, brush, mechanical (friction and windage), and stray losses. Explanation of power stages and different efficiencies in the motor Maximum efficiency is usually near 75% of rated load. This guide covers dc motor efficiency and losses, such as copper, core, brush, mechanical (friction and windage), and stray losses. The efficiency of a dc motor is defined as the ratio of output power to the input power. Ac motors have higher efficiency but lower controllability and starting torque.

from electricalworkbook.com

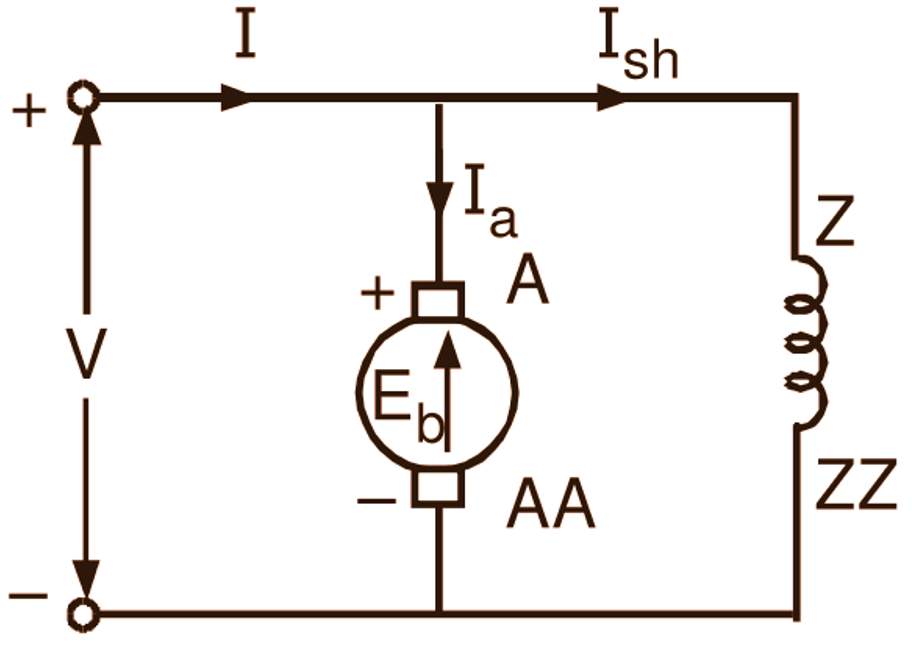

This guide covers dc motor efficiency and losses, such as copper, core, brush, mechanical (friction and windage), and stray losses. Most electric motors are designed to run at 50% to 100% of rated load. Electrical motor efficiency when shaft output is. Efficiencies and power stages in dc motors. Explanation of power stages and different efficiencies in the motor The efficiency of a dc motor is defined as the ratio of output power to the input power. Dc motors have lower efficiency but high controllability and starting torque. Ac motors have higher efficiency but lower controllability and starting torque. Losses occur during conversion of electrical energy into mechanical energy in electrical motor. These losses and conversion of energy in the motor is known as the power stages of a dc motor which is shown in the below diagram.

Efficiency of DC Motor ElectricalWorkbook

Dc Motors Efficiency Losses occur during conversion of electrical energy into mechanical energy in electrical motor. Dc motors have lower efficiency but high controllability and starting torque. Losses occur during conversion of electrical energy into mechanical energy in electrical motor. This guide covers efficiency and losses of dc machines (motor and generator) which include copper, core, brush, mechanical (friction and windage), and stray losses. Most electric motors are designed to run at 50% to 100% of rated load. Efficiency of a dc motor. Explanation of power stages and different efficiencies in the motor Maximum efficiency is usually near 75% of rated load. The efficiency of a dc motor is defined as the ratio of output power to the input power. These losses and conversion of energy in the motor is known as the power stages of a dc motor which is shown in the below diagram. Ac motors have higher efficiency but lower controllability and starting torque. Electrical motor efficiency when shaft output is. Efficiencies and power stages in dc motors. Bldc motors offer high efficiency, controllability, and starting torque, but are typically more expensive. This guide covers dc motor efficiency and losses, such as copper, core, brush, mechanical (friction and windage), and stray losses.

From www.researchgate.net

Typical AC/DC and DC/DC conversion efficiency curves Download Scientific Diagram Dc Motors Efficiency Most electric motors are designed to run at 50% to 100% of rated load. Losses occur during conversion of electrical energy into mechanical energy in electrical motor. Efficiency of a dc motor. Maximum efficiency is usually near 75% of rated load. Ac motors have higher efficiency but lower controllability and starting torque. Efficiencies and power stages in dc motors. This. Dc Motors Efficiency.

From www.researchgate.net

Efficiency characteristic for DC supply of the universal motor. Download Scientific Diagram Dc Motors Efficiency Efficiency of a dc motor. The efficiency of a dc motor is defined as the ratio of output power to the input power. Bldc motors offer high efficiency, controllability, and starting torque, but are typically more expensive. Maximum efficiency is usually near 75% of rated load. Electrical motor efficiency when shaft output is. Explanation of power stages and different efficiencies. Dc Motors Efficiency.

From electricalworkbook.com

Efficiency of DC Motor ElectricalWorkbook Dc Motors Efficiency Ac motors have higher efficiency but lower controllability and starting torque. Losses occur during conversion of electrical energy into mechanical energy in electrical motor. Most electric motors are designed to run at 50% to 100% of rated load. Dc motors have lower efficiency but high controllability and starting torque. Bldc motors offer high efficiency, controllability, and starting torque, but are. Dc Motors Efficiency.

From medium.com

Get to know your DC motor how to read a datasheet luosrobotics Medium Dc Motors Efficiency These losses and conversion of energy in the motor is known as the power stages of a dc motor which is shown in the below diagram. Explanation of power stages and different efficiencies in the motor Efficiency of a dc motor. Most electric motors are designed to run at 50% to 100% of rated load. Dc motors have lower efficiency. Dc Motors Efficiency.

From webmotor.org

Dc Motor Efficiency Calculation Dc Motors Efficiency Explanation of power stages and different efficiencies in the motor Efficiencies and power stages in dc motors. Losses occur during conversion of electrical energy into mechanical energy in electrical motor. Ac motors have higher efficiency but lower controllability and starting torque. Bldc motors offer high efficiency, controllability, and starting torque, but are typically more expensive. Efficiency of a dc motor.. Dc Motors Efficiency.

From electricalworkbook.com

Efficiency of DC Motor ElectricalWorkbook Dc Motors Efficiency Maximum efficiency is usually near 75% of rated load. Explanation of power stages and different efficiencies in the motor Dc motors have lower efficiency but high controllability and starting torque. Efficiency of a dc motor. This guide covers efficiency and losses of dc machines (motor and generator) which include copper, core, brush, mechanical (friction and windage), and stray losses. Electrical. Dc Motors Efficiency.

From www.youtube.com

19 DC Motor DC motor efficiency calculation YouTube Dc Motors Efficiency Losses occur during conversion of electrical energy into mechanical energy in electrical motor. Electrical motor efficiency when shaft output is. These losses and conversion of energy in the motor is known as the power stages of a dc motor which is shown in the below diagram. Ac motors have higher efficiency but lower controllability and starting torque. The efficiency of. Dc Motors Efficiency.

From www.youtube.com

Losses and Efficiency of DC Motors [Year 2] YouTube Dc Motors Efficiency This guide covers efficiency and losses of dc machines (motor and generator) which include copper, core, brush, mechanical (friction and windage), and stray losses. Dc motors have lower efficiency but high controllability and starting torque. Most electric motors are designed to run at 50% to 100% of rated load. Explanation of power stages and different efficiencies in the motor Efficiencies. Dc Motors Efficiency.

From www.youtube.com

condition for maximum efficiency of dc generator efficiency of dc generator dc motor in Dc Motors Efficiency Ac motors have higher efficiency but lower controllability and starting torque. These losses and conversion of energy in the motor is known as the power stages of a dc motor which is shown in the below diagram. This guide covers efficiency and losses of dc machines (motor and generator) which include copper, core, brush, mechanical (friction and windage), and stray. Dc Motors Efficiency.

From haipernews.com

How To Calculate Efficiency Dc Motor Haiper Dc Motors Efficiency Ac motors have higher efficiency but lower controllability and starting torque. Efficiencies and power stages in dc motors. The efficiency of a dc motor is defined as the ratio of output power to the input power. Bldc motors offer high efficiency, controllability, and starting torque, but are typically more expensive. Losses occur during conversion of electrical energy into mechanical energy. Dc Motors Efficiency.

From electricalworkbook.com

Efficiency of DC Motor ElectricalWorkbook Dc Motors Efficiency These losses and conversion of energy in the motor is known as the power stages of a dc motor which is shown in the below diagram. Dc motors have lower efficiency but high controllability and starting torque. Most electric motors are designed to run at 50% to 100% of rated load. Maximum efficiency is usually near 75% of rated load.. Dc Motors Efficiency.

From www.duncansonelectric.com

Duncanson Electric Co » ELECTRICAL BASICS Part 1 DC Dc Motors Efficiency Most electric motors are designed to run at 50% to 100% of rated load. Efficiencies and power stages in dc motors. Maximum efficiency is usually near 75% of rated load. The efficiency of a dc motor is defined as the ratio of output power to the input power. Dc motors have lower efficiency but high controllability and starting torque. This. Dc Motors Efficiency.

From www.youtube.com

DC Motor Efficiency at a given operating point YouTube Dc Motors Efficiency The efficiency of a dc motor is defined as the ratio of output power to the input power. Efficiency of a dc motor. Bldc motors offer high efficiency, controllability, and starting torque, but are typically more expensive. Dc motors have lower efficiency but high controllability and starting torque. Ac motors have higher efficiency but lower controllability and starting torque. Most. Dc Motors Efficiency.

From studylib.net

Efficiency DC Motor Dc Motors Efficiency Explanation of power stages and different efficiencies in the motor Dc motors have lower efficiency but high controllability and starting torque. Bldc motors offer high efficiency, controllability, and starting torque, but are typically more expensive. The efficiency of a dc motor is defined as the ratio of output power to the input power. Maximum efficiency is usually near 75% of. Dc Motors Efficiency.

From www.linquip.com

DC Motor Efficiency Calculation Formula & Equation Linquip Dc Motors Efficiency Most electric motors are designed to run at 50% to 100% of rated load. Efficiencies and power stages in dc motors. The efficiency of a dc motor is defined as the ratio of output power to the input power. Ac motors have higher efficiency but lower controllability and starting torque. Bldc motors offer high efficiency, controllability, and starting torque, but. Dc Motors Efficiency.

From www.linquip.com

Efficiency of Electric Motor (Formula & Diagram) Linquip Dc Motors Efficiency Electrical motor efficiency when shaft output is. Losses occur during conversion of electrical energy into mechanical energy in electrical motor. Explanation of power stages and different efficiencies in the motor Efficiencies and power stages in dc motors. This guide covers efficiency and losses of dc machines (motor and generator) which include copper, core, brush, mechanical (friction and windage), and stray. Dc Motors Efficiency.

From electricalworkbook.com

Efficiency of DC Motor ElectricalWorkbook Dc Motors Efficiency Maximum efficiency is usually near 75% of rated load. These losses and conversion of energy in the motor is known as the power stages of a dc motor which is shown in the below diagram. This guide covers dc motor efficiency and losses, such as copper, core, brush, mechanical (friction and windage), and stray losses. Dc motors have lower efficiency. Dc Motors Efficiency.

From webmotor.org

Dc Motor Efficiency Calculation Dc Motors Efficiency Electrical motor efficiency when shaft output is. Dc motors have lower efficiency but high controllability and starting torque. This guide covers dc motor efficiency and losses, such as copper, core, brush, mechanical (friction and windage), and stray losses. Most electric motors are designed to run at 50% to 100% of rated load. Losses occur during conversion of electrical energy into. Dc Motors Efficiency.

From webmotor.org

Dc Motor Efficiency Calculation Dc Motors Efficiency The efficiency of a dc motor is defined as the ratio of output power to the input power. Efficiency of a dc motor. Most electric motors are designed to run at 50% to 100% of rated load. Electrical motor efficiency when shaft output is. Dc motors have lower efficiency but high controllability and starting torque. Ac motors have higher efficiency. Dc Motors Efficiency.

From x-engineer.org

EV design electric motor Dc Motors Efficiency Efficiencies and power stages in dc motors. Maximum efficiency is usually near 75% of rated load. Losses occur during conversion of electrical energy into mechanical energy in electrical motor. Most electric motors are designed to run at 50% to 100% of rated load. These losses and conversion of energy in the motor is known as the power stages of a. Dc Motors Efficiency.

From electronics.stackexchange.com

DC motor and power Electrical Engineering Stack Exchange Dc Motors Efficiency Bldc motors offer high efficiency, controllability, and starting torque, but are typically more expensive. Electrical motor efficiency when shaft output is. Maximum efficiency is usually near 75% of rated load. These losses and conversion of energy in the motor is known as the power stages of a dc motor which is shown in the below diagram. Losses occur during conversion. Dc Motors Efficiency.

From webmotor.org

Bldc Motor Efficiency Calculation Dc Motors Efficiency Efficiency of a dc motor. Explanation of power stages and different efficiencies in the motor Losses occur during conversion of electrical energy into mechanical energy in electrical motor. This guide covers efficiency and losses of dc machines (motor and generator) which include copper, core, brush, mechanical (friction and windage), and stray losses. This guide covers dc motor efficiency and losses,. Dc Motors Efficiency.

From islproducts.com

How To Read DC Motor & Gear Motor Performance Curves Dc Motors Efficiency Bldc motors offer high efficiency, controllability, and starting torque, but are typically more expensive. Electrical motor efficiency when shaft output is. This guide covers dc motor efficiency and losses, such as copper, core, brush, mechanical (friction and windage), and stray losses. These losses and conversion of energy in the motor is known as the power stages of a dc motor. Dc Motors Efficiency.

From webmotor.org

How To Calculate The Motor Efficiency Dc Motors Efficiency These losses and conversion of energy in the motor is known as the power stages of a dc motor which is shown in the below diagram. Dc motors have lower efficiency but high controllability and starting torque. Most electric motors are designed to run at 50% to 100% of rated load. Efficiencies and power stages in dc motors. This guide. Dc Motors Efficiency.

From webmotor.org

Dc Motor Efficiency Calculation Dc Motors Efficiency This guide covers efficiency and losses of dc machines (motor and generator) which include copper, core, brush, mechanical (friction and windage), and stray losses. Most electric motors are designed to run at 50% to 100% of rated load. Dc motors have lower efficiency but high controllability and starting torque. Efficiencies and power stages in dc motors. Efficiency of a dc. Dc Motors Efficiency.

From www.electricaltechnology.org

What is Motor Efficiency and How to improve it? 8 Steps Dc Motors Efficiency Maximum efficiency is usually near 75% of rated load. The efficiency of a dc motor is defined as the ratio of output power to the input power. These losses and conversion of energy in the motor is known as the power stages of a dc motor which is shown in the below diagram. Ac motors have higher efficiency but lower. Dc Motors Efficiency.

From www.pololu.com

Pololu Brushed DC motor performance curves. Dc Motors Efficiency These losses and conversion of energy in the motor is known as the power stages of a dc motor which is shown in the below diagram. The efficiency of a dc motor is defined as the ratio of output power to the input power. Efficiencies and power stages in dc motors. Most electric motors are designed to run at 50%. Dc Motors Efficiency.

From www.scribd.com

DC Motor Efficiency Calculation Formula Amp Equation PDF Electric Motor Power (Physics) Dc Motors Efficiency Efficiency of a dc motor. This guide covers dc motor efficiency and losses, such as copper, core, brush, mechanical (friction and windage), and stray losses. Most electric motors are designed to run at 50% to 100% of rated load. Losses occur during conversion of electrical energy into mechanical energy in electrical motor. Ac motors have higher efficiency but lower controllability. Dc Motors Efficiency.

From electronics.stackexchange.com

DC motor efficiency Electrical Engineering Stack Exchange Dc Motors Efficiency These losses and conversion of energy in the motor is known as the power stages of a dc motor which is shown in the below diagram. Efficiency of a dc motor. This guide covers efficiency and losses of dc machines (motor and generator) which include copper, core, brush, mechanical (friction and windage), and stray losses. Maximum efficiency is usually near. Dc Motors Efficiency.

From blog.republicmanufacturing.com

Motor Efficiency & Ratings Explained Republic Manufacturing Blog Dc Motors Efficiency Dc motors have lower efficiency but high controllability and starting torque. Maximum efficiency is usually near 75% of rated load. Electrical motor efficiency when shaft output is. These losses and conversion of energy in the motor is known as the power stages of a dc motor which is shown in the below diagram. The efficiency of a dc motor is. Dc Motors Efficiency.

From www.electrical4u.net

3 Phase Motor Efficiency Formula & DC motor Efficiency Calculation Electrical4u Dc Motors Efficiency Efficiencies and power stages in dc motors. This guide covers dc motor efficiency and losses, such as copper, core, brush, mechanical (friction and windage), and stray losses. Bldc motors offer high efficiency, controllability, and starting torque, but are typically more expensive. Ac motors have higher efficiency but lower controllability and starting torque. Maximum efficiency is usually near 75% of rated. Dc Motors Efficiency.

From www.youtube.com

20 DC Motor Numerical DC motor efficiency calculation YouTube Dc Motors Efficiency The efficiency of a dc motor is defined as the ratio of output power to the input power. Electrical motor efficiency when shaft output is. These losses and conversion of energy in the motor is known as the power stages of a dc motor which is shown in the below diagram. Maximum efficiency is usually near 75% of rated load.. Dc Motors Efficiency.

From islproducts.com

How To Read DC Motor & Gear Motor Performance Curves Dc Motors Efficiency Most electric motors are designed to run at 50% to 100% of rated load. Electrical motor efficiency when shaft output is. These losses and conversion of energy in the motor is known as the power stages of a dc motor which is shown in the below diagram. This guide covers efficiency and losses of dc machines (motor and generator) which. Dc Motors Efficiency.

From www.youtube.com

Efficiency of DC Motor YouTube Dc Motors Efficiency These losses and conversion of energy in the motor is known as the power stages of a dc motor which is shown in the below diagram. Efficiency of a dc motor. This guide covers dc motor efficiency and losses, such as copper, core, brush, mechanical (friction and windage), and stray losses. Most electric motors are designed to run at 50%. Dc Motors Efficiency.

From electronics.stackexchange.com

efficiency Practical Approach for getting maximum Power from a DC motor Electrical Dc Motors Efficiency Efficiency of a dc motor. Bldc motors offer high efficiency, controllability, and starting torque, but are typically more expensive. This guide covers efficiency and losses of dc machines (motor and generator) which include copper, core, brush, mechanical (friction and windage), and stray losses. This guide covers dc motor efficiency and losses, such as copper, core, brush, mechanical (friction and windage),. Dc Motors Efficiency.