Rockwell Hardness Scale For Aluminum . International standards organization (iso 6508. The equation for the rockwell hardness test for metals is below: The rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. D=depth from zero load point. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. N and s = various scale factors that can be found in the chart below. Two main standards in the industry define the rockwell hardness scale. The rockwell test measures hardness by assessing the depth of indentation created by an indenter (either a diamond cone or a steel ball). The rockwell test measures the depth of. Hra, hrbw, hrc, hr30n, hr15tw),. This results in 30 different rockwell scales standardized according to iso 6508 and astm e18 (e.g., a, b, c, 30n, 15t) or rockwell test methods (e.g.:

from www.scribd.com

N and s = various scale factors that can be found in the chart below. Two main standards in the industry define the rockwell hardness scale. D=depth from zero load point. Hra, hrbw, hrc, hr30n, hr15tw),. The rockwell test measures the depth of. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. This results in 30 different rockwell scales standardized according to iso 6508 and astm e18 (e.g., a, b, c, 30n, 15t) or rockwell test methods (e.g.: The equation for the rockwell hardness test for metals is below: International standards organization (iso 6508. The rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides.

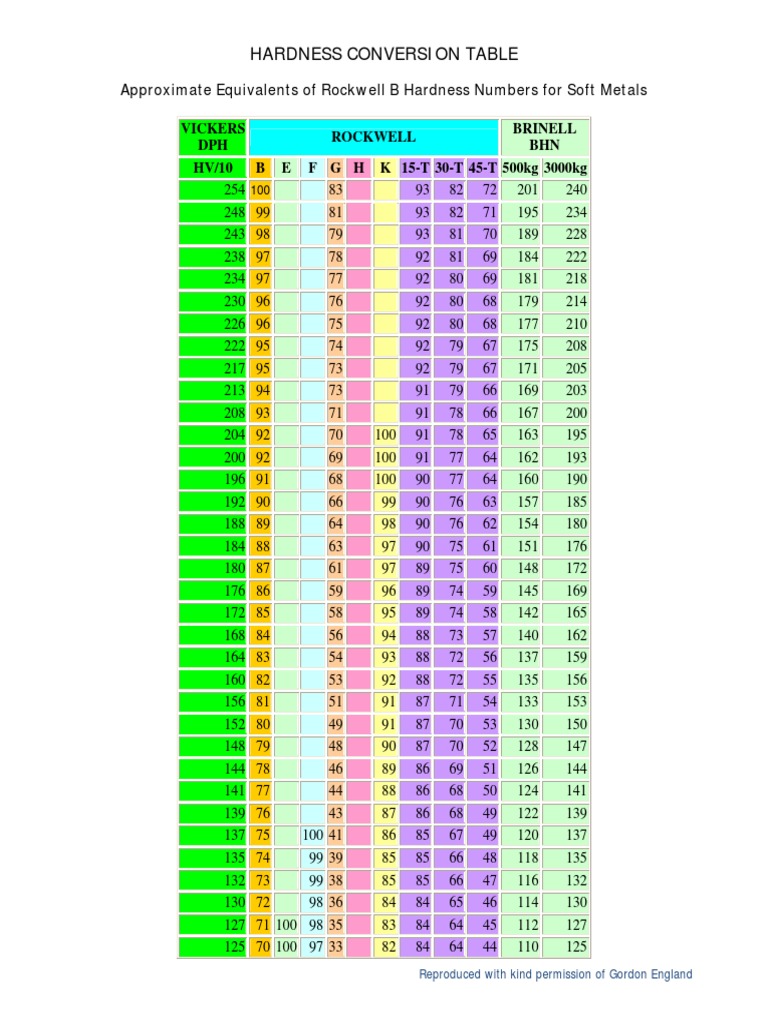

Hardness Conversion Table Approximate Equivalents of Rockwell B

Rockwell Hardness Scale For Aluminum Two main standards in the industry define the rockwell hardness scale. The rockwell test measures hardness by assessing the depth of indentation created by an indenter (either a diamond cone or a steel ball). Two main standards in the industry define the rockwell hardness scale. D=depth from zero load point. The rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. The equation for the rockwell hardness test for metals is below: International standards organization (iso 6508. N and s = various scale factors that can be found in the chart below. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. This results in 30 different rockwell scales standardized according to iso 6508 and astm e18 (e.g., a, b, c, 30n, 15t) or rockwell test methods (e.g.: Hra, hrbw, hrc, hr30n, hr15tw),. The rockwell test measures the depth of.

From www.hardnesstesters.com

Hardness Conversion for Rockwell C Scale or High Hardness Range Rockwell Hardness Scale For Aluminum Hra, hrbw, hrc, hr30n, hr15tw),. N and s = various scale factors that can be found in the chart below. Two main standards in the industry define the rockwell hardness scale. This results in 30 different rockwell scales standardized according to iso 6508 and astm e18 (e.g., a, b, c, 30n, 15t) or rockwell test methods (e.g.: D=depth from zero. Rockwell Hardness Scale For Aluminum.

From ar.inspiredpencil.com

Rockwell Conversion Chart Rockwell Hardness Scale For Aluminum The rockwell test measures the depth of. The rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. International standards organization (iso 6508. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. The rockwell test measures hardness by assessing the. Rockwell Hardness Scale For Aluminum.

From www.researchgate.net

Scale "A" Rockwell hardness values for both alloys after different Rockwell Hardness Scale For Aluminum The rockwell test measures hardness by assessing the depth of indentation created by an indenter (either a diamond cone or a steel ball). Two main standards in the industry define the rockwell hardness scale. The rockwell test measures the depth of. The equation for the rockwell hardness test for metals is below: International standards organization (iso 6508. This results in. Rockwell Hardness Scale For Aluminum.

From mavink.com

Rockwell B Hardness Scale Chart Rockwell Hardness Scale For Aluminum Hra, hrbw, hrc, hr30n, hr15tw),. D=depth from zero load point. N and s = various scale factors that can be found in the chart below. This results in 30 different rockwell scales standardized according to iso 6508 and astm e18 (e.g., a, b, c, 30n, 15t) or rockwell test methods (e.g.: The rockwell hardness scale is designed to determine the. Rockwell Hardness Scale For Aluminum.

From brokeasshome.com

Rockwell Hardness Of Metals Table Rockwell Hardness Scale For Aluminum The equation for the rockwell hardness test for metals is below: The rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. Two main standards in the industry define the rockwell. Rockwell Hardness Scale For Aluminum.

From www.auto-met.com

Rockwell Hardness Scale Indentor Load Chart Rockwell Hardness Scale For Aluminum The rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. D=depth from zero load point. The rockwell test measures hardness by assessing the depth of indentation created by an indenter (either a diamond cone or a steel ball). Two main standards in the industry define the. Rockwell Hardness Scale For Aluminum.

From printablemathias.z13.web.core.windows.net

Rockwell Hardness Chart Pdf Rockwell Hardness Scale For Aluminum N and s = various scale factors that can be found in the chart below. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. Two main standards in the industry define the rockwell hardness scale. The rockwell test measures the depth of. This results in 30 different rockwell scales standardized according to iso. Rockwell Hardness Scale For Aluminum.

From brokeasshome.com

rockwell hardness table metals Rockwell Hardness Scale For Aluminum D=depth from zero load point. This results in 30 different rockwell scales standardized according to iso 6508 and astm e18 (e.g., a, b, c, 30n, 15t) or rockwell test methods (e.g.: The rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. International standards organization (iso 6508.. Rockwell Hardness Scale For Aluminum.

From www.hardnessgauge.com

What is the Rockwell Scale? Hardness Tester Rockwell Hardness Scale For Aluminum Hra, hrbw, hrc, hr30n, hr15tw),. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. This results in 30 different rockwell scales standardized according to iso 6508 and astm e18 (e.g., a, b, c, 30n, 15t) or rockwell test methods (e.g.: The rockwell test measures the depth of. N and s = various scale. Rockwell Hardness Scale For Aluminum.

From www.brystartools.com

Hardness Conversion Chart Rockwell "B" Hardness Range Rockwell Hardness Scale For Aluminum 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. This results in 30 different rockwell scales standardized according to iso 6508 and astm e18 (e.g., a, b, c, 30n, 15t) or rockwell test methods (e.g.: The rockwell test measures hardness by assessing the depth of indentation created by an indenter (either a diamond. Rockwell Hardness Scale For Aluminum.

From einvoice.fpt.com.vn

The Rockwell Metal Hardness Scales Explained, 54 OFF Rockwell Hardness Scale For Aluminum 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. The equation for the rockwell hardness test for metals is below: This results in 30 different rockwell scales standardized according to iso 6508 and astm e18 (e.g., a, b, c, 30n, 15t) or rockwell test methods (e.g.: The rockwell hardness scale is designed to. Rockwell Hardness Scale For Aluminum.

From www.researchgate.net

The hardness and density of the A6061 aluminum matrix composites. The Rockwell Hardness Scale For Aluminum Two main standards in the industry define the rockwell hardness scale. N and s = various scale factors that can be found in the chart below. This results in 30 different rockwell scales standardized according to iso 6508 and astm e18 (e.g., a, b, c, 30n, 15t) or rockwell test methods (e.g.: The rockwell test measures the depth of. The. Rockwell Hardness Scale For Aluminum.

From aluminumgenjin.blogspot.com

Aluminum Aluminum Hardness Rockwell Hardness Scale For Aluminum The rockwell test measures hardness by assessing the depth of indentation created by an indenter (either a diamond cone or a steel ball). 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. The rockwell test measures the depth of. The rockwell hardness scale is designed to determine the hardness of materials like aluminum,. Rockwell Hardness Scale For Aluminum.

From payscalechart.z28.web.core.windows.net

rockwell hardness scale chart Hardness conversion chart Rockwell Hardness Scale For Aluminum 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. Two main standards in the industry define the rockwell hardness scale. The equation for the rockwell hardness test for metals is below: The rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and. Rockwell Hardness Scale For Aluminum.

From www.yorksaw.com

Rockwell Hardness Guide What it is, How to Measure, & More Rockwell Hardness Scale For Aluminum This results in 30 different rockwell scales standardized according to iso 6508 and astm e18 (e.g., a, b, c, 30n, 15t) or rockwell test methods (e.g.: The equation for the rockwell hardness test for metals is below: 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. Hra, hrbw, hrc, hr30n, hr15tw),. Two main. Rockwell Hardness Scale For Aluminum.

From amesportablehardnesstesters.com

The Rockwell Metal Hardness Scales Explained Rockwell Hardness Scale For Aluminum This results in 30 different rockwell scales standardized according to iso 6508 and astm e18 (e.g., a, b, c, 30n, 15t) or rockwell test methods (e.g.: D=depth from zero load point. The rockwell test measures the depth of. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. Two main standards in the industry. Rockwell Hardness Scale For Aluminum.

From ar.inspiredpencil.com

Hardness Scale Metals Rockwell Hardness Scale For Aluminum N and s = various scale factors that can be found in the chart below. Hra, hrbw, hrc, hr30n, hr15tw),. D=depth from zero load point. The rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. The rockwell test measures hardness by assessing the depth of indentation. Rockwell Hardness Scale For Aluminum.

From metallography-matters.buehler.com

Material Thickness When Choosing a Rockwell Scale Metallography Matters Rockwell Hardness Scale For Aluminum N and s = various scale factors that can be found in the chart below. D=depth from zero load point. This results in 30 different rockwell scales standardized according to iso 6508 and astm e18 (e.g., a, b, c, 30n, 15t) or rockwell test methods (e.g.: The equation for the rockwell hardness test for metals is below: The rockwell test. Rockwell Hardness Scale For Aluminum.

From jodielambert.z13.web.core.windows.net

Aluminium Hardness Scale Vs Steel Rockwell Hardness Scale For Aluminum The rockwell test measures the depth of. Hra, hrbw, hrc, hr30n, hr15tw),. The rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. Two main standards in the industry define the rockwell hardness scale. 21 rows the rockwell scale is a hardness scale based on indentation hardness. Rockwell Hardness Scale For Aluminum.

From mungfali.com

Rockwell Hardness Scale Chart Rockwell Hardness Scale For Aluminum The equation for the rockwell hardness test for metals is below: Two main standards in the industry define the rockwell hardness scale. N and s = various scale factors that can be found in the chart below. The rockwell test measures the depth of. The rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel,. Rockwell Hardness Scale For Aluminum.

From mungfali.com

Rockwell Hardness Scale Chart Rockwell Hardness Scale For Aluminum The rockwell test measures the depth of. This results in 30 different rockwell scales standardized according to iso 6508 and astm e18 (e.g., a, b, c, 30n, 15t) or rockwell test methods (e.g.: The rockwell test measures hardness by assessing the depth of indentation created by an indenter (either a diamond cone or a steel ball). D=depth from zero load. Rockwell Hardness Scale For Aluminum.

From alansfactoryoutlet.com

Metal Hardness Scale A Chart of the Mohs Scale of Hardness Rockwell Hardness Scale For Aluminum International standards organization (iso 6508. Two main standards in the industry define the rockwell hardness scale. The rockwell test measures the depth of. The equation for the rockwell hardness test for metals is below: This results in 30 different rockwell scales standardized according to iso 6508 and astm e18 (e.g., a, b, c, 30n, 15t) or rockwell test methods (e.g.:. Rockwell Hardness Scale For Aluminum.

From amesportablehardnesstesters.com

Raised Flat 1/8" Rockwell Hardness Scale For Aluminum Two main standards in the industry define the rockwell hardness scale. N and s = various scale factors that can be found in the chart below. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. The equation for the rockwell hardness test for metals is below: D=depth from zero load point. The rockwell. Rockwell Hardness Scale For Aluminum.

From ar.inspiredpencil.com

Rockwell Conversion Chart Rockwell Hardness Scale For Aluminum D=depth from zero load point. International standards organization (iso 6508. The rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. N and s = various scale factors that can be found in the chart below. Hra, hrbw, hrc, hr30n, hr15tw),. The rockwell test measures hardness by. Rockwell Hardness Scale For Aluminum.

From mungfali.com

Rockwell Hardness Scale Chart Rockwell Hardness Scale For Aluminum The rockwell test measures hardness by assessing the depth of indentation created by an indenter (either a diamond cone or a steel ball). D=depth from zero load point. N and s = various scale factors that can be found in the chart below. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. The. Rockwell Hardness Scale For Aluminum.

From www.scribd.com

Hardness Conversion Table Approximate Equivalents of Rockwell B Rockwell Hardness Scale For Aluminum The rockwell test measures the depth of. International standards organization (iso 6508. Hra, hrbw, hrc, hr30n, hr15tw),. This results in 30 different rockwell scales standardized according to iso 6508 and astm e18 (e.g., a, b, c, 30n, 15t) or rockwell test methods (e.g.: Two main standards in the industry define the rockwell hardness scale. N and s = various scale. Rockwell Hardness Scale For Aluminum.

From amesportablehardnesstesters.com

Hardness Testing in Rockwell Scales Rockwell Hardness Scale For Aluminum The equation for the rockwell hardness test for metals is below: The rockwell test measures the depth of. This results in 30 different rockwell scales standardized according to iso 6508 and astm e18 (e.g., a, b, c, 30n, 15t) or rockwell test methods (e.g.: 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material.. Rockwell Hardness Scale For Aluminum.

From www.scribd.com

Conversion Table of Hardness Approximate conversion value for steel Rockwell Hardness Scale For Aluminum Two main standards in the industry define the rockwell hardness scale. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. N and s = various scale factors that can be found in the chart below. The equation for the rockwell hardness test for metals is below: The rockwell test measures hardness by assessing. Rockwell Hardness Scale For Aluminum.

From brokeasshome.com

rockwell hardness table metals Rockwell Hardness Scale For Aluminum The rockwell test measures the depth of. The rockwell test measures hardness by assessing the depth of indentation created by an indenter (either a diamond cone or a steel ball). The rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. Hra, hrbw, hrc, hr30n, hr15tw),. 21. Rockwell Hardness Scale For Aluminum.

From www.bostoncenterless.com

The Best Hardness Conversion Chart Rockwell & Brinell Hardness Rockwell Hardness Scale For Aluminum The rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. D=depth from zero load point. The rockwell test measures hardness by assessing the depth of indentation created by an indenter. Rockwell Hardness Scale For Aluminum.

From payscalechart.z28.web.core.windows.net

rockwell scale conversion chart Rockwell hardness chart metals brinell Rockwell Hardness Scale For Aluminum This results in 30 different rockwell scales standardized according to iso 6508 and astm e18 (e.g., a, b, c, 30n, 15t) or rockwell test methods (e.g.: International standards organization (iso 6508. Two main standards in the industry define the rockwell hardness scale. Hra, hrbw, hrc, hr30n, hr15tw),. 21 rows the rockwell scale is a hardness scale based on indentation hardness. Rockwell Hardness Scale For Aluminum.

From atrona.com

Rockwell C Hardness Conversion Chart PDF ATRONA Test Labs Loves Rockwell Hardness Scale For Aluminum International standards organization (iso 6508. The rockwell test measures the depth of. Two main standards in the industry define the rockwell hardness scale. N and s = various scale factors that can be found in the chart below. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. The rockwell hardness scale is designed. Rockwell Hardness Scale For Aluminum.

From www.rnbearings.cc

HARDNESS CONVERSION TABLE Technology Rockwell Hardness Scale For Aluminum The equation for the rockwell hardness test for metals is below: Two main standards in the industry define the rockwell hardness scale. The rockwell test measures hardness by assessing the depth of indentation created by an indenter (either a diamond cone or a steel ball). International standards organization (iso 6508. The rockwell hardness scale is designed to determine the hardness. Rockwell Hardness Scale For Aluminum.

From mavink.com

Rockwell Hardness Scale Metals Chart Rockwell Hardness Scale For Aluminum The rockwell test measures hardness by assessing the depth of indentation created by an indenter (either a diamond cone or a steel ball). The equation for the rockwell hardness test for metals is below: The rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. International standards. Rockwell Hardness Scale For Aluminum.

From printablemathias.z13.web.core.windows.net

S7 Tool Steel Rockwell Hardness Chart Rockwell Hardness Scale For Aluminum The rockwell test measures hardness by assessing the depth of indentation created by an indenter (either a diamond cone or a steel ball). Two main standards in the industry define the rockwell hardness scale. The rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. The rockwell. Rockwell Hardness Scale For Aluminum.