Visual Inspection Defect Library . • types of defects knowledge is based on the overall defects in industry across sites • uv marking for easy identification of defects from. Virtual defect library = digitalization of test sets. Automated visual inspection (avi) is a set of techniques used to detect and classify defects in manufactured products. Building a library of defect images and good units. Trained without any labels for defective regions, model in the inference mode is. • 100% visual inspection of injectable products is driven by the need to minimize the introduction of unintended particulate matter into patients. An application for visual inspection written in python, running on windows, linux, and macos. The functionality test used to determine the reject function of the equipment is required before and after 100% visual inspection. The computer vision toolbox™ automated visual inspection library offers functions that enable you to train, evaluate, and.

from mobidev.biz

The computer vision toolbox™ automated visual inspection library offers functions that enable you to train, evaluate, and. The functionality test used to determine the reject function of the equipment is required before and after 100% visual inspection. • 100% visual inspection of injectable products is driven by the need to minimize the introduction of unintended particulate matter into patients. Trained without any labels for defective regions, model in the inference mode is. • types of defects knowledge is based on the overall defects in industry across sites • uv marking for easy identification of defects from. Virtual defect library = digitalization of test sets. Automated visual inspection (avi) is a set of techniques used to detect and classify defects in manufactured products. An application for visual inspection written in python, running on windows, linux, and macos. Building a library of defect images and good units.

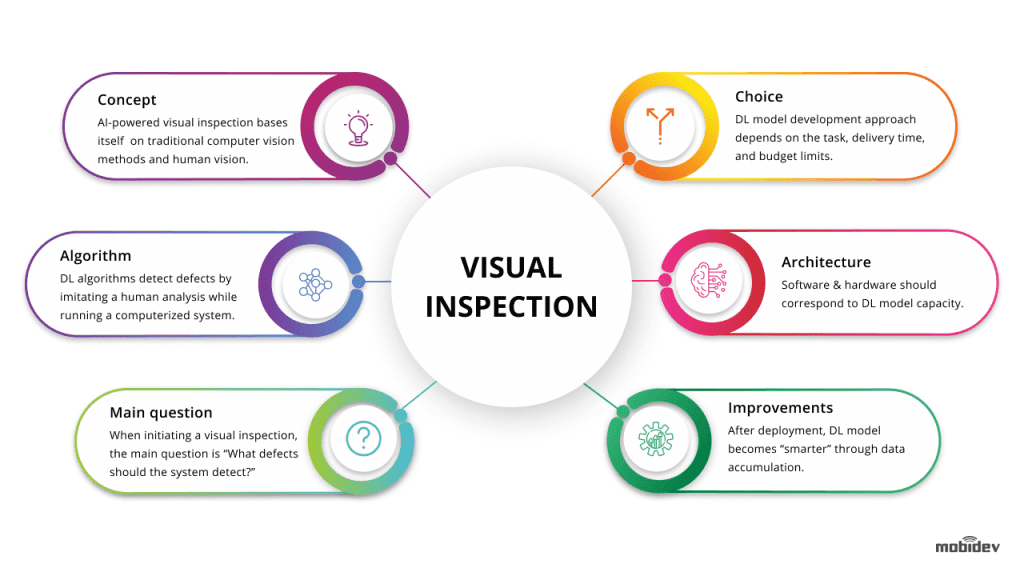

AI Visual Inspection For Defect Detection in Manufacturing

Visual Inspection Defect Library Automated visual inspection (avi) is a set of techniques used to detect and classify defects in manufactured products. Virtual defect library = digitalization of test sets. An application for visual inspection written in python, running on windows, linux, and macos. Trained without any labels for defective regions, model in the inference mode is. Building a library of defect images and good units. The functionality test used to determine the reject function of the equipment is required before and after 100% visual inspection. Automated visual inspection (avi) is a set of techniques used to detect and classify defects in manufactured products. • types of defects knowledge is based on the overall defects in industry across sites • uv marking for easy identification of defects from. • 100% visual inspection of injectable products is driven by the need to minimize the introduction of unintended particulate matter into patients. The computer vision toolbox™ automated visual inspection library offers functions that enable you to train, evaluate, and.

From www.researchgate.net

Visual inspection sizing of manufacturing defects Download Table Visual Inspection Defect Library Automated visual inspection (avi) is a set of techniques used to detect and classify defects in manufactured products. • types of defects knowledge is based on the overall defects in industry across sites • uv marking for easy identification of defects from. Trained without any labels for defective regions, model in the inference mode is. The computer vision toolbox™ automated. Visual Inspection Defect Library.

From www.scribd.com

Pda India Chapter Visual Inspection Preparing and Qualifying Visual Inspection Defect Library Trained without any labels for defective regions, model in the inference mode is. Virtual defect library = digitalization of test sets. Automated visual inspection (avi) is a set of techniques used to detect and classify defects in manufactured products. • 100% visual inspection of injectable products is driven by the need to minimize the introduction of unintended particulate matter into. Visual Inspection Defect Library.

From www.iotforall.com

AI Visual Inspection For Defect Detection in Manufacturing Visual Inspection Defect Library Virtual defect library = digitalization of test sets. Building a library of defect images and good units. The functionality test used to determine the reject function of the equipment is required before and after 100% visual inspection. • types of defects knowledge is based on the overall defects in industry across sites • uv marking for easy identification of defects. Visual Inspection Defect Library.

From www.sagacify.com

Automated Visual Inspection For Defect Detection — Sagacify Visual Inspection Defect Library Automated visual inspection (avi) is a set of techniques used to detect and classify defects in manufactured products. Trained without any labels for defective regions, model in the inference mode is. Virtual defect library = digitalization of test sets. • types of defects knowledge is based on the overall defects in industry across sites • uv marking for easy identification. Visual Inspection Defect Library.

From saxon.ai

AIbased visual inspection for defect detection Visual Inspection Defect Library An application for visual inspection written in python, running on windows, linux, and macos. Automated visual inspection (avi) is a set of techniques used to detect and classify defects in manufactured products. Virtual defect library = digitalization of test sets. Building a library of defect images and good units. Trained without any labels for defective regions, model in the inference. Visual Inspection Defect Library.

From www.slideserve.com

PPT Helsinki T2 status PowerPoint Presentation, free download ID Visual Inspection Defect Library Virtual defect library = digitalization of test sets. Trained without any labels for defective regions, model in the inference mode is. The computer vision toolbox™ automated visual inspection library offers functions that enable you to train, evaluate, and. • types of defects knowledge is based on the overall defects in industry across sites • uv marking for easy identification of. Visual Inspection Defect Library.

From www.youtube.com

How to Build AI Visual Inspection System for Visual Defect Detection in Visual Inspection Defect Library • 100% visual inspection of injectable products is driven by the need to minimize the introduction of unintended particulate matter into patients. The computer vision toolbox™ automated visual inspection library offers functions that enable you to train, evaluate, and. The functionality test used to determine the reject function of the equipment is required before and after 100% visual inspection. Virtual. Visual Inspection Defect Library.

From www.semanticscholar.org

Table 2 from Visual Inspection of Historical Buildings Using Micro UAV Visual Inspection Defect Library • types of defects knowledge is based on the overall defects in industry across sites • uv marking for easy identification of defects from. The computer vision toolbox™ automated visual inspection library offers functions that enable you to train, evaluate, and. Automated visual inspection (avi) is a set of techniques used to detect and classify defects in manufactured products. Virtual. Visual Inspection Defect Library.

From www.allianzeinfosoft.com

AI Visual Inspection for Defect Detection in Manufacturing Visual Inspection Defect Library • types of defects knowledge is based on the overall defects in industry across sites • uv marking for easy identification of defects from. Trained without any labels for defective regions, model in the inference mode is. An application for visual inspection written in python, running on windows, linux, and macos. The functionality test used to determine the reject function. Visual Inspection Defect Library.

From nanonets.com

Automated Visual Inspection Systems & how do they work? Visual Inspection Defect Library The computer vision toolbox™ automated visual inspection library offers functions that enable you to train, evaluate, and. • types of defects knowledge is based on the overall defects in industry across sites • uv marking for easy identification of defects from. Automated visual inspection (avi) is a set of techniques used to detect and classify defects in manufactured products. The. Visual Inspection Defect Library.

From bjkj.tsg211.com

AI Visual Inspection For Defect Detection in Manufacturing Visual Inspection Defect Library Automated visual inspection (avi) is a set of techniques used to detect and classify defects in manufactured products. Trained without any labels for defective regions, model in the inference mode is. Virtual defect library = digitalization of test sets. The functionality test used to determine the reject function of the equipment is required before and after 100% visual inspection. An. Visual Inspection Defect Library.

From mobidev.biz

AI Visual Inspection For Defect Detection in Manufacturing Visual Inspection Defect Library The functionality test used to determine the reject function of the equipment is required before and after 100% visual inspection. Trained without any labels for defective regions, model in the inference mode is. Building a library of defect images and good units. The computer vision toolbox™ automated visual inspection library offers functions that enable you to train, evaluate, and. An. Visual Inspection Defect Library.

From www.keyence.eu

Vial Inspection KEYENCE International Belgium Visual Inspection Defect Library • types of defects knowledge is based on the overall defects in industry across sites • uv marking for easy identification of defects from. Virtual defect library = digitalization of test sets. The computer vision toolbox™ automated visual inspection library offers functions that enable you to train, evaluate, and. • 100% visual inspection of injectable products is driven by the. Visual Inspection Defect Library.

From www.researchgate.net

(PDF) Automatic visual inspection and defect detection on Variable Data Visual Inspection Defect Library An application for visual inspection written in python, running on windows, linux, and macos. • types of defects knowledge is based on the overall defects in industry across sites • uv marking for easy identification of defects from. Virtual defect library = digitalization of test sets. The functionality test used to determine the reject function of the equipment is required. Visual Inspection Defect Library.

From www.youtube.com

SemiAutomated Visual Inspection of Vials YouTube Visual Inspection Defect Library The functionality test used to determine the reject function of the equipment is required before and after 100% visual inspection. The computer vision toolbox™ automated visual inspection library offers functions that enable you to train, evaluate, and. Virtual defect library = digitalization of test sets. Automated visual inspection (avi) is a set of techniques used to detect and classify defects. Visual Inspection Defect Library.

From mobidev.biz

AIBased Visual Inspection For Defect Detection MobiDev Visual Inspection Defect Library Building a library of defect images and good units. • 100% visual inspection of injectable products is driven by the need to minimize the introduction of unintended particulate matter into patients. The functionality test used to determine the reject function of the equipment is required before and after 100% visual inspection. Trained without any labels for defective regions, model in. Visual Inspection Defect Library.

From marutitech.com

What is AI Visual Inspection for Defect Detection? A Deep Dive Visual Inspection Defect Library The computer vision toolbox™ automated visual inspection library offers functions that enable you to train, evaluate, and. • 100% visual inspection of injectable products is driven by the need to minimize the introduction of unintended particulate matter into patients. An application for visual inspection written in python, running on windows, linux, and macos. The functionality test used to determine the. Visual Inspection Defect Library.

From www.visual-inspectionsystem.com

CCD Visual Defect Inspection Machine Visual Inspection Defect Library The computer vision toolbox™ automated visual inspection library offers functions that enable you to train, evaluate, and. Building a library of defect images and good units. Trained without any labels for defective regions, model in the inference mode is. An application for visual inspection written in python, running on windows, linux, and macos. The functionality test used to determine the. Visual Inspection Defect Library.

From www.semanticscholar.org

Figure 1 from Automatic Visual Inspection Defects Detection using CNN Visual Inspection Defect Library The computer vision toolbox™ automated visual inspection library offers functions that enable you to train, evaluate, and. Virtual defect library = digitalization of test sets. Automated visual inspection (avi) is a set of techniques used to detect and classify defects in manufactured products. • 100% visual inspection of injectable products is driven by the need to minimize the introduction of. Visual Inspection Defect Library.

From www.youtube.com

AI Assisted Visual Inspection & Defect Detection YouTube Visual Inspection Defect Library The computer vision toolbox™ automated visual inspection library offers functions that enable you to train, evaluate, and. • types of defects knowledge is based on the overall defects in industry across sites • uv marking for easy identification of defects from. • 100% visual inspection of injectable products is driven by the need to minimize the introduction of unintended particulate. Visual Inspection Defect Library.

From marutitech.com

What is AI Visual Inspection for Defect Detection? A Deep Dive Visual Inspection Defect Library An application for visual inspection written in python, running on windows, linux, and macos. Trained without any labels for defective regions, model in the inference mode is. Virtual defect library = digitalization of test sets. • 100% visual inspection of injectable products is driven by the need to minimize the introduction of unintended particulate matter into patients. Automated visual inspection. Visual Inspection Defect Library.

From goonline.io

Revolutionizing Manufacturing with AIbased Defect Detection Inspection Visual Inspection Defect Library Trained without any labels for defective regions, model in the inference mode is. Virtual defect library = digitalization of test sets. • types of defects knowledge is based on the overall defects in industry across sites • uv marking for easy identification of defects from. Automated visual inspection (avi) is a set of techniques used to detect and classify defects. Visual Inspection Defect Library.

From encyclopedia.pub

Defect Synthesis for Automated Visual Inspection Encyclopedia MDPI Visual Inspection Defect Library Virtual defect library = digitalization of test sets. • 100% visual inspection of injectable products is driven by the need to minimize the introduction of unintended particulate matter into patients. • types of defects knowledge is based on the overall defects in industry across sites • uv marking for easy identification of defects from. Trained without any labels for defective. Visual Inspection Defect Library.

From 3hle.ch

Surface defect detection Archives A.I. Visual Inspection & Automation Visual Inspection Defect Library • 100% visual inspection of injectable products is driven by the need to minimize the introduction of unintended particulate matter into patients. The functionality test used to determine the reject function of the equipment is required before and after 100% visual inspection. Building a library of defect images and good units. Virtual defect library = digitalization of test sets. The. Visual Inspection Defect Library.

From marutitech.com

What is AI Visual Inspection for Defect Detection? A Deep Dive Visual Inspection Defect Library • types of defects knowledge is based on the overall defects in industry across sites • uv marking for easy identification of defects from. The computer vision toolbox™ automated visual inspection library offers functions that enable you to train, evaluate, and. • 100% visual inspection of injectable products is driven by the need to minimize the introduction of unintended particulate. Visual Inspection Defect Library.

From www.researchgate.net

(PDF) A physicsbased defects model and inspection algorithm for Visual Inspection Defect Library Building a library of defect images and good units. Automated visual inspection (avi) is a set of techniques used to detect and classify defects in manufactured products. • types of defects knowledge is based on the overall defects in industry across sites • uv marking for easy identification of defects from. Virtual defect library = digitalization of test sets. The. Visual Inspection Defect Library.

From www.semanticscholar.org

Figure 5 from Inspection system based on artificial vision for paint Visual Inspection Defect Library • types of defects knowledge is based on the overall defects in industry across sites • uv marking for easy identification of defects from. • 100% visual inspection of injectable products is driven by the need to minimize the introduction of unintended particulate matter into patients. The functionality test used to determine the reject function of the equipment is required. Visual Inspection Defect Library.

From ftiincorporation07.medium.com

Utilize Visual Inspection Defect & Knapp Test Kits to Detect and Visual Inspection Defect Library The functionality test used to determine the reject function of the equipment is required before and after 100% visual inspection. • 100% visual inspection of injectable products is driven by the need to minimize the introduction of unintended particulate matter into patients. The computer vision toolbox™ automated visual inspection library offers functions that enable you to train, evaluate, and. Building. Visual Inspection Defect Library.

From encyclopedia.pub

Defect Synthesis for Automated Visual Inspection Encyclopedia MDPI Visual Inspection Defect Library Virtual defect library = digitalization of test sets. Building a library of defect images and good units. Automated visual inspection (avi) is a set of techniques used to detect and classify defects in manufactured products. • 100% visual inspection of injectable products is driven by the need to minimize the introduction of unintended particulate matter into patients. • types of. Visual Inspection Defect Library.

From www.jkrwpp.gov.my

Visual Inspection & Defect Mapping Visual Inspection Defect Library • 100% visual inspection of injectable products is driven by the need to minimize the introduction of unintended particulate matter into patients. Trained without any labels for defective regions, model in the inference mode is. The computer vision toolbox™ automated visual inspection library offers functions that enable you to train, evaluate, and. Virtual defect library = digitalization of test sets.. Visual Inspection Defect Library.

From www.ibm.com

What is visual inspection? IBM Visual Inspection Defect Library Automated visual inspection (avi) is a set of techniques used to detect and classify defects in manufactured products. Virtual defect library = digitalization of test sets. Trained without any labels for defective regions, model in the inference mode is. An application for visual inspection written in python, running on windows, linux, and macos. • 100% visual inspection of injectable products. Visual Inspection Defect Library.

From www.bobwillis.co.uk

LeadFree Visual Inspection & Defect Guide Bob Willis Visual Inspection Defect Library The functionality test used to determine the reject function of the equipment is required before and after 100% visual inspection. Trained without any labels for defective regions, model in the inference mode is. The computer vision toolbox™ automated visual inspection library offers functions that enable you to train, evaluate, and. • types of defects knowledge is based on the overall. Visual Inspection Defect Library.

From www.resco.net

Visual inspection Resco Visual Inspection Defect Library Virtual defect library = digitalization of test sets. Trained without any labels for defective regions, model in the inference mode is. • types of defects knowledge is based on the overall defects in industry across sites • uv marking for easy identification of defects from. The computer vision toolbox™ automated visual inspection library offers functions that enable you to train,. Visual Inspection Defect Library.

From mobidev.biz

AI Visual Inspection For Defect Detection in Manufacturing Visual Inspection Defect Library The computer vision toolbox™ automated visual inspection library offers functions that enable you to train, evaluate, and. The functionality test used to determine the reject function of the equipment is required before and after 100% visual inspection. Trained without any labels for defective regions, model in the inference mode is. • types of defects knowledge is based on the overall. Visual Inspection Defect Library.

From www.proto-electronics.com

How to Find Defects on a PCB? Visual Inspection Defect Library Automated visual inspection (avi) is a set of techniques used to detect and classify defects in manufactured products. • 100% visual inspection of injectable products is driven by the need to minimize the introduction of unintended particulate matter into patients. Trained without any labels for defective regions, model in the inference mode is. The functionality test used to determine the. Visual Inspection Defect Library.