Hot Plate For Solder Reflow . When you place your board on, i find it helps to. Although i use it wherever possible, its small hot plate limits the size of the pcb that can be reflow soldered. Ideally you want to try to keep the hot plate at about 230 dec c (for lead solder), so let it warm up first before putting your board on. This new version uses a 400w hot plate and doubles the size of the heating area. A diy temperature controlled hot plate for soldering smd components. Soldering tiny smd components can be quite challenging, but the process can also be automated. Why did you make it? Find this and other hardware projects on hackster.io. About 6 months ago, i built a smd hot plate using a standard 200w element (see smd reflow hot plate). Simply move the hinged hood for one or the other!

from mightyohm.com

Although i use it wherever possible, its small hot plate limits the size of the pcb that can be reflow soldered. Soldering tiny smd components can be quite challenging, but the process can also be automated. Ideally you want to try to keep the hot plate at about 230 dec c (for lead solder), so let it warm up first before putting your board on. Find this and other hardware projects on hackster.io. About 6 months ago, i built a smd hot plate using a standard 200w element (see smd reflow hot plate). When you place your board on, i find it helps to. Simply move the hinged hood for one or the other! A diy temperature controlled hot plate for soldering smd components. This new version uses a 400w hot plate and doubles the size of the heating area. Why did you make it?

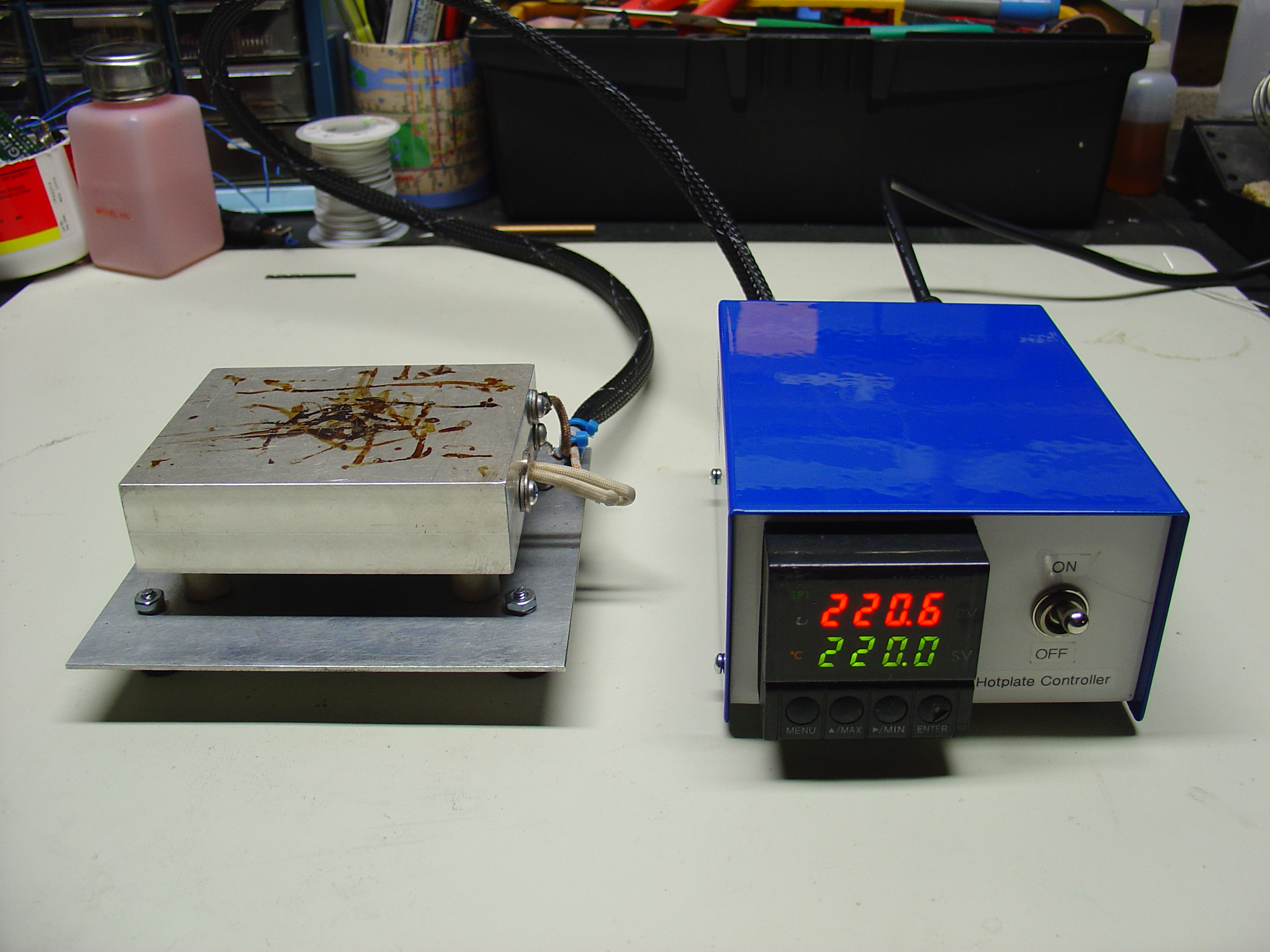

DIY PID Controlled Soldering Hotplate MightyOhm

Hot Plate For Solder Reflow Simply move the hinged hood for one or the other! Why did you make it? A diy temperature controlled hot plate for soldering smd components. Find this and other hardware projects on hackster.io. Simply move the hinged hood for one or the other! This new version uses a 400w hot plate and doubles the size of the heating area. Although i use it wherever possible, its small hot plate limits the size of the pcb that can be reflow soldered. About 6 months ago, i built a smd hot plate using a standard 200w element (see smd reflow hot plate). Soldering tiny smd components can be quite challenging, but the process can also be automated. When you place your board on, i find it helps to. Ideally you want to try to keep the hot plate at about 230 dec c (for lead solder), so let it warm up first before putting your board on.

From offpikol.weebly.com

Solder reflow hot plate offpikol Hot Plate For Solder Reflow About 6 months ago, i built a smd hot plate using a standard 200w element (see smd reflow hot plate). This new version uses a 400w hot plate and doubles the size of the heating area. Although i use it wherever possible, its small hot plate limits the size of the pcb that can be reflow soldered. Soldering tiny smd. Hot Plate For Solder Reflow.

From www.youtube.com

SHOULD YOU BUY A SOLDER REFLOW HOTPLATE? YouTube Hot Plate For Solder Reflow When you place your board on, i find it helps to. Soldering tiny smd components can be quite challenging, but the process can also be automated. A diy temperature controlled hot plate for soldering smd components. Simply move the hinged hood for one or the other! Although i use it wherever possible, its small hot plate limits the size of. Hot Plate For Solder Reflow.

From www.bigmessowires.com

Hot Plate Reflow Soldering Round 1 Big Mess o' Wires Hot Plate For Solder Reflow About 6 months ago, i built a smd hot plate using a standard 200w element (see smd reflow hot plate). Why did you make it? This new version uses a 400w hot plate and doubles the size of the heating area. Find this and other hardware projects on hackster.io. Simply move the hinged hood for one or the other! Soldering. Hot Plate For Solder Reflow.

From curiousscientist.tech

Improving my reflow hot plate — Curious Scientist Hot Plate For Solder Reflow Find this and other hardware projects on hackster.io. About 6 months ago, i built a smd hot plate using a standard 200w element (see smd reflow hot plate). Although i use it wherever possible, its small hot plate limits the size of the pcb that can be reflow soldered. A diy temperature controlled hot plate for soldering smd components. Ideally. Hot Plate For Solder Reflow.

From www.indiamart.com

Smd Reflow Soldering Hot Plate, For Heaters, Size (12"x18" ) (18"x24 Hot Plate For Solder Reflow About 6 months ago, i built a smd hot plate using a standard 200w element (see smd reflow hot plate). This new version uses a 400w hot plate and doubles the size of the heating area. Simply move the hinged hood for one or the other! A diy temperature controlled hot plate for soldering smd components. Why did you make. Hot Plate For Solder Reflow.

From www.hackster.io

SMD Reflow Hot Plate Hackster.io Hot Plate For Solder Reflow Ideally you want to try to keep the hot plate at about 230 dec c (for lead solder), so let it warm up first before putting your board on. Why did you make it? Simply move the hinged hood for one or the other! When you place your board on, i find it helps to. Soldering tiny smd components can. Hot Plate For Solder Reflow.

From itskevcc.space

SMD Reflow Hot Plate Lim Chu Chen Hot Plate For Solder Reflow Find this and other hardware projects on hackster.io. About 6 months ago, i built a smd hot plate using a standard 200w element (see smd reflow hot plate). Soldering tiny smd components can be quite challenging, but the process can also be automated. Ideally you want to try to keep the hot plate at about 230 dec c (for lead. Hot Plate For Solder Reflow.

From www.indiamart.com

Vhrc SMD LED Soldering Reflow Hot Plate, LED Mounting Hot Plate Hot Plate For Solder Reflow This new version uses a 400w hot plate and doubles the size of the heating area. A diy temperature controlled hot plate for soldering smd components. When you place your board on, i find it helps to. Ideally you want to try to keep the hot plate at about 230 dec c (for lead solder), so let it warm up. Hot Plate For Solder Reflow.

From electronoobs.com

Homemade Reflow Hot plate for SMD components with Arduino Hot Plate For Solder Reflow Simply move the hinged hood for one or the other! When you place your board on, i find it helps to. This new version uses a 400w hot plate and doubles the size of the heating area. Why did you make it? A diy temperature controlled hot plate for soldering smd components. Find this and other hardware projects on hackster.io.. Hot Plate For Solder Reflow.

From www.youtube.com

Homemade Hot Plate for Wireless SMD Soldering! Using ESP32, Flat Iron Hot Plate For Solder Reflow Simply move the hinged hood for one or the other! Soldering tiny smd components can be quite challenging, but the process can also be automated. A diy temperature controlled hot plate for soldering smd components. Find this and other hardware projects on hackster.io. Although i use it wherever possible, its small hot plate limits the size of the pcb that. Hot Plate For Solder Reflow.

From www.youtube.com

Reflow oven or hot plate? I went for the reflow soldering hot plate Hot Plate For Solder Reflow Why did you make it? A diy temperature controlled hot plate for soldering smd components. This new version uses a 400w hot plate and doubles the size of the heating area. When you place your board on, i find it helps to. Find this and other hardware projects on hackster.io. Ideally you want to try to keep the hot plate. Hot Plate For Solder Reflow.

From www.pinterest.com

Homemade Reflow Hot Plate for SMD Soldering 3000W Hot plate, Diy Hot Plate For Solder Reflow Simply move the hinged hood for one or the other! This new version uses a 400w hot plate and doubles the size of the heating area. When you place your board on, i find it helps to. A diy temperature controlled hot plate for soldering smd components. Although i use it wherever possible, its small hot plate limits the size. Hot Plate For Solder Reflow.

From www.indiamart.com

Smd Reflow Soldering Hot Plate, For Heaters, Size (12"x18" ) (18"x24 Hot Plate For Solder Reflow A diy temperature controlled hot plate for soldering smd components. Soldering tiny smd components can be quite challenging, but the process can also be automated. About 6 months ago, i built a smd hot plate using a standard 200w element (see smd reflow hot plate). This new version uses a 400w hot plate and doubles the size of the heating. Hot Plate For Solder Reflow.

From vi.aliexpress.com

YX3530HL Precision Lead Free Reflow Oven Smd Pcb Hot Plate Soldering Hot Plate For Solder Reflow Soldering tiny smd components can be quite challenging, but the process can also be automated. Simply move the hinged hood for one or the other! Find this and other hardware projects on hackster.io. Why did you make it? When you place your board on, i find it helps to. About 6 months ago, i built a smd hot plate using. Hot Plate For Solder Reflow.

From hackaday.io

Solder Reflow Hot Plate Hackaday.io Hot Plate For Solder Reflow Find this and other hardware projects on hackster.io. Soldering tiny smd components can be quite challenging, but the process can also be automated. About 6 months ago, i built a smd hot plate using a standard 200w element (see smd reflow hot plate). When you place your board on, i find it helps to. A diy temperature controlled hot plate. Hot Plate For Solder Reflow.

From www.ams-electronics.co.uk

Quick 870 ESD Hot PlateReflow Plate AMS Ltd Hot Plate For Solder Reflow Although i use it wherever possible, its small hot plate limits the size of the pcb that can be reflow soldered. This new version uses a 400w hot plate and doubles the size of the heating area. Ideally you want to try to keep the hot plate at about 230 dec c (for lead solder), so let it warm up. Hot Plate For Solder Reflow.

From www.e-tinkers.com

Converting UYue Preheater into a Solder Reflow Hotplate ETinkers Hot Plate For Solder Reflow Simply move the hinged hood for one or the other! Find this and other hardware projects on hackster.io. When you place your board on, i find it helps to. Although i use it wherever possible, its small hot plate limits the size of the pcb that can be reflow soldered. Soldering tiny smd components can be quite challenging, but the. Hot Plate For Solder Reflow.

From ifuturetech.org

300W SMT BGA SOLDERING REFLOW PLATE iFuture Technology Hot Plate For Solder Reflow Although i use it wherever possible, its small hot plate limits the size of the pcb that can be reflow soldered. About 6 months ago, i built a smd hot plate using a standard 200w element (see smd reflow hot plate). This new version uses a 400w hot plate and doubles the size of the heating area. A diy temperature. Hot Plate For Solder Reflow.

From www.youtube.com

946A+ Solder Reflow Hot Plate Video YouTube Hot Plate For Solder Reflow Simply move the hinged hood for one or the other! Ideally you want to try to keep the hot plate at about 230 dec c (for lead solder), so let it warm up first before putting your board on. Find this and other hardware projects on hackster.io. A diy temperature controlled hot plate for soldering smd components. Although i use. Hot Plate For Solder Reflow.

From hackaday.io

Gallery PCB Soldering reflow hot Plate! A good Idea? Hackaday.io Hot Plate For Solder Reflow About 6 months ago, i built a smd hot plate using a standard 200w element (see smd reflow hot plate). Ideally you want to try to keep the hot plate at about 230 dec c (for lead solder), so let it warm up first before putting your board on. When you place your board on, i find it helps to.. Hot Plate For Solder Reflow.

From www.instructables.com

Reflow Soldering Hotplate 5 Steps (with Pictures) Instructables Hot Plate For Solder Reflow When you place your board on, i find it helps to. Find this and other hardware projects on hackster.io. Soldering tiny smd components can be quite challenging, but the process can also be automated. Why did you make it? Simply move the hinged hood for one or the other! Although i use it wherever possible, its small hot plate limits. Hot Plate For Solder Reflow.

From www.youtube.com

Making my own reflow hot plate Part 1 Prototype YouTube Hot Plate For Solder Reflow Why did you make it? Simply move the hinged hood for one or the other! Find this and other hardware projects on hackster.io. About 6 months ago, i built a smd hot plate using a standard 200w element (see smd reflow hot plate). This new version uses a 400w hot plate and doubles the size of the heating area. Although. Hot Plate For Solder Reflow.

From www.indiamart.com

Vhrc SMD LED Soldering Reflow Hot Plate, LED Mounting Hot Plate Hot Plate For Solder Reflow A diy temperature controlled hot plate for soldering smd components. This new version uses a 400w hot plate and doubles the size of the heating area. Although i use it wherever possible, its small hot plate limits the size of the pcb that can be reflow soldered. Find this and other hardware projects on hackster.io. Simply move the hinged hood. Hot Plate For Solder Reflow.

From www.aliexpress.com

ZB3530HL Precision Lead Free Reflow Oven Smd Pcb Hot Plate Soldering Hot Plate For Solder Reflow Why did you make it? A diy temperature controlled hot plate for soldering smd components. Ideally you want to try to keep the hot plate at about 230 dec c (for lead solder), so let it warm up first before putting your board on. Simply move the hinged hood for one or the other! When you place your board on,. Hot Plate For Solder Reflow.

From www.indiamart.com

Vhrc SMD LED Soldering Reflow Hot Plate, LED Mounting Hot Plate Hot Plate For Solder Reflow Find this and other hardware projects on hackster.io. About 6 months ago, i built a smd hot plate using a standard 200w element (see smd reflow hot plate). This new version uses a 400w hot plate and doubles the size of the heating area. Although i use it wherever possible, its small hot plate limits the size of the pcb. Hot Plate For Solder Reflow.

From www.youtube.com

The Best way to Solder? Hot Plate to the rescue! (DIY or Buy) YouTube Hot Plate For Solder Reflow Why did you make it? When you place your board on, i find it helps to. About 6 months ago, i built a smd hot plate using a standard 200w element (see smd reflow hot plate). Ideally you want to try to keep the hot plate at about 230 dec c (for lead solder), so let it warm up first. Hot Plate For Solder Reflow.

From mightyohm.com

DIY PID Controlled Soldering Hotplate MightyOhm Hot Plate For Solder Reflow Why did you make it? Simply move the hinged hood for one or the other! Soldering tiny smd components can be quite challenging, but the process can also be automated. Ideally you want to try to keep the hot plate at about 230 dec c (for lead solder), so let it warm up first before putting your board on. Find. Hot Plate For Solder Reflow.

From www.pinterest.com.au

DIY Solder Reflow Hot Plate Soldering, Diy Ideas, Scoop, Plates, Hot Hot Plate For Solder Reflow About 6 months ago, i built a smd hot plate using a standard 200w element (see smd reflow hot plate). This new version uses a 400w hot plate and doubles the size of the heating area. Ideally you want to try to keep the hot plate at about 230 dec c (for lead solder), so let it warm up first. Hot Plate For Solder Reflow.

From medium.com

SpaceSaving Solder Reflow Hot Plate by Jeremy S. Cook Medium Hot Plate For Solder Reflow This new version uses a 400w hot plate and doubles the size of the heating area. Why did you make it? Soldering tiny smd components can be quite challenging, but the process can also be automated. Simply move the hinged hood for one or the other! A diy temperature controlled hot plate for soldering smd components. When you place your. Hot Plate For Solder Reflow.

From www.indiamart.com

Smd Reflow Soldering Hot Plate, For Heaters, Size (12"x18" ) (18"x24 Hot Plate For Solder Reflow When you place your board on, i find it helps to. Why did you make it? Ideally you want to try to keep the hot plate at about 230 dec c (for lead solder), so let it warm up first before putting your board on. This new version uses a 400w hot plate and doubles the size of the heating. Hot Plate For Solder Reflow.

From www.e-tinkers.com

Converting UYue Preheater into a Solder Reflow Hotplate ETinkers Hot Plate For Solder Reflow This new version uses a 400w hot plate and doubles the size of the heating area. Simply move the hinged hood for one or the other! Soldering tiny smd components can be quite challenging, but the process can also be automated. When you place your board on, i find it helps to. A diy temperature controlled hot plate for soldering. Hot Plate For Solder Reflow.

From www.hotplates.biz

Reflow Hot Plate Reflow Soldering Hot Plate Hot Plate For Solder Reflow A diy temperature controlled hot plate for soldering smd components. About 6 months ago, i built a smd hot plate using a standard 200w element (see smd reflow hot plate). This new version uses a 400w hot plate and doubles the size of the heating area. Find this and other hardware projects on hackster.io. Ideally you want to try to. Hot Plate For Solder Reflow.

From www.instructables.com

PCB Soldering Reflow Hot Plate! a Good Idea? 7 Steps Instructables Hot Plate For Solder Reflow About 6 months ago, i built a smd hot plate using a standard 200w element (see smd reflow hot plate). Simply move the hinged hood for one or the other! A diy temperature controlled hot plate for soldering smd components. Ideally you want to try to keep the hot plate at about 230 dec c (for lead solder), so let. Hot Plate For Solder Reflow.

From www.youtube.com

PowerMeter Project First test of hot plate reflow and solder paste Hot Plate For Solder Reflow Although i use it wherever possible, its small hot plate limits the size of the pcb that can be reflow soldered. Ideally you want to try to keep the hot plate at about 230 dec c (for lead solder), so let it warm up first before putting your board on. Simply move the hinged hood for one or the other!. Hot Plate For Solder Reflow.

From hackaday.io

Gallery Solder Reflow Hot Plate Hackaday.io Hot Plate For Solder Reflow This new version uses a 400w hot plate and doubles the size of the heating area. Find this and other hardware projects on hackster.io. Why did you make it? About 6 months ago, i built a smd hot plate using a standard 200w element (see smd reflow hot plate). A diy temperature controlled hot plate for soldering smd components. When. Hot Plate For Solder Reflow.