Surface Energy Of Ldpe . The mechanical properties of polymers, particularly as a function of temperature and strain rate, are key for implementation of. Explore surface energy of plastics and learn how it impacts coating and bonding. The changes in surface morphology and surface wettability. The surface of a ldpe was modified by ar, o2, n2, co2 gaseous plasma. Wettability changes in ldpe films introduce hydrophilic groups that modify their hydrophobic nature, which are evidenced by a. Pe powder pressed into wafer at 1 kg/cm2, 110oc, cleaned with alcohol and water, soaked in 50oc sulfochromic acid, rinsed with distilled water, and dried with pure nitrogen. Uncover the science behind molecular affinity and liquid flow.

from tombrowninc.com

Wettability changes in ldpe films introduce hydrophilic groups that modify their hydrophobic nature, which are evidenced by a. The changes in surface morphology and surface wettability. The surface of a ldpe was modified by ar, o2, n2, co2 gaseous plasma. Explore surface energy of plastics and learn how it impacts coating and bonding. Uncover the science behind molecular affinity and liquid flow. Pe powder pressed into wafer at 1 kg/cm2, 110oc, cleaned with alcohol and water, soaked in 50oc sulfochromic acid, rinsed with distilled water, and dried with pure nitrogen. The mechanical properties of polymers, particularly as a function of temperature and strain rate, are key for implementation of.

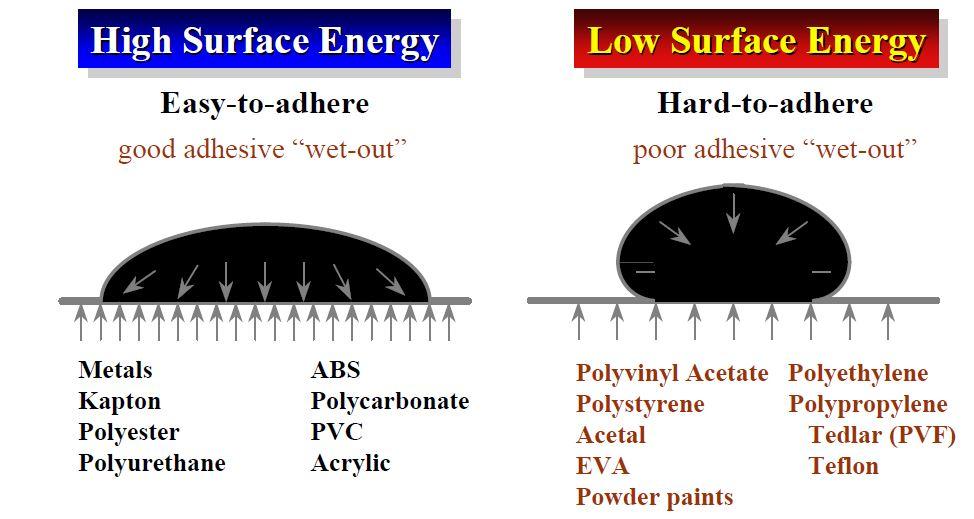

Basics Of Tape Adhesion Lawrence Pennsylvania Tom Brown Inc

Surface Energy Of Ldpe Wettability changes in ldpe films introduce hydrophilic groups that modify their hydrophobic nature, which are evidenced by a. Wettability changes in ldpe films introduce hydrophilic groups that modify their hydrophobic nature, which are evidenced by a. The mechanical properties of polymers, particularly as a function of temperature and strain rate, are key for implementation of. The changes in surface morphology and surface wettability. Pe powder pressed into wafer at 1 kg/cm2, 110oc, cleaned with alcohol and water, soaked in 50oc sulfochromic acid, rinsed with distilled water, and dried with pure nitrogen. Uncover the science behind molecular affinity and liquid flow. The surface of a ldpe was modified by ar, o2, n2, co2 gaseous plasma. Explore surface energy of plastics and learn how it impacts coating and bonding.

From www.researchgate.net

Infrared spectrum of a commercial lowdensity polyethylene (LDPE) and... Download Scientific Surface Energy Of Ldpe Uncover the science behind molecular affinity and liquid flow. Explore surface energy of plastics and learn how it impacts coating and bonding. The changes in surface morphology and surface wettability. The surface of a ldpe was modified by ar, o2, n2, co2 gaseous plasma. Pe powder pressed into wafer at 1 kg/cm2, 110oc, cleaned with alcohol and water, soaked in. Surface Energy Of Ldpe.

From www.researchgate.net

Evolution of the dispersive component of the surface energy of... Download Scientific Diagram Surface Energy Of Ldpe Uncover the science behind molecular affinity and liquid flow. Wettability changes in ldpe films introduce hydrophilic groups that modify their hydrophobic nature, which are evidenced by a. The changes in surface morphology and surface wettability. Explore surface energy of plastics and learn how it impacts coating and bonding. The surface of a ldpe was modified by ar, o2, n2, co2. Surface Energy Of Ldpe.

From www.researchgate.net

Surface energy (γ s ) and its components polarity (γ p s ), and... Download Scientific Diagram Surface Energy Of Ldpe Uncover the science behind molecular affinity and liquid flow. The changes in surface morphology and surface wettability. The mechanical properties of polymers, particularly as a function of temperature and strain rate, are key for implementation of. Wettability changes in ldpe films introduce hydrophilic groups that modify their hydrophobic nature, which are evidenced by a. Explore surface energy of plastics and. Surface Energy Of Ldpe.

From www.researchgate.net

Thermogravimetric Analysis (TGA) thermogram for LDPEAl and composites... Download Scientific Surface Energy Of Ldpe The surface of a ldpe was modified by ar, o2, n2, co2 gaseous plasma. The mechanical properties of polymers, particularly as a function of temperature and strain rate, are key for implementation of. Uncover the science behind molecular affinity and liquid flow. The changes in surface morphology and surface wettability. Explore surface energy of plastics and learn how it impacts. Surface Energy Of Ldpe.

From www.researchgate.net

TGADTG curve. a LDPE. b C/LDPE Download Scientific Diagram Surface Energy Of Ldpe The surface of a ldpe was modified by ar, o2, n2, co2 gaseous plasma. The mechanical properties of polymers, particularly as a function of temperature and strain rate, are key for implementation of. Uncover the science behind molecular affinity and liquid flow. Wettability changes in ldpe films introduce hydrophilic groups that modify their hydrophobic nature, which are evidenced by a.. Surface Energy Of Ldpe.

From www.researchgate.net

TGA curves of pure LDPE and LDPE/GNP composites. Download Scientific Diagram Surface Energy Of Ldpe Uncover the science behind molecular affinity and liquid flow. Wettability changes in ldpe films introduce hydrophilic groups that modify their hydrophobic nature, which are evidenced by a. The changes in surface morphology and surface wettability. Pe powder pressed into wafer at 1 kg/cm2, 110oc, cleaned with alcohol and water, soaked in 50oc sulfochromic acid, rinsed with distilled water, and dried. Surface Energy Of Ldpe.

From www.mdpi.com

Polymers Free FullText Preparation of Progressive Antibacterial LDPE Surface via Active Surface Energy Of Ldpe The surface of a ldpe was modified by ar, o2, n2, co2 gaseous plasma. The mechanical properties of polymers, particularly as a function of temperature and strain rate, are key for implementation of. Uncover the science behind molecular affinity and liquid flow. Explore surface energy of plastics and learn how it impacts coating and bonding. Pe powder pressed into wafer. Surface Energy Of Ldpe.

From www.researchgate.net

(a,b) are the topography and surface potential images of the PS/LDPE... Download Scientific Surface Energy Of Ldpe The surface of a ldpe was modified by ar, o2, n2, co2 gaseous plasma. The changes in surface morphology and surface wettability. Wettability changes in ldpe films introduce hydrophilic groups that modify their hydrophobic nature, which are evidenced by a. Pe powder pressed into wafer at 1 kg/cm2, 110oc, cleaned with alcohol and water, soaked in 50oc sulfochromic acid, rinsed. Surface Energy Of Ldpe.

From www.researchgate.net

Surface energy loss with rGO content Download Scientific Diagram Surface Energy Of Ldpe The changes in surface morphology and surface wettability. The mechanical properties of polymers, particularly as a function of temperature and strain rate, are key for implementation of. Pe powder pressed into wafer at 1 kg/cm2, 110oc, cleaned with alcohol and water, soaked in 50oc sulfochromic acid, rinsed with distilled water, and dried with pure nitrogen. Wettability changes in ldpe films. Surface Energy Of Ldpe.

From www.researchgate.net

FTIR spectra of the LDPE surface depending on the exposure time in the... Download Scientific Surface Energy Of Ldpe Explore surface energy of plastics and learn how it impacts coating and bonding. Uncover the science behind molecular affinity and liquid flow. The mechanical properties of polymers, particularly as a function of temperature and strain rate, are key for implementation of. The surface of a ldpe was modified by ar, o2, n2, co2 gaseous plasma. The changes in surface morphology. Surface Energy Of Ldpe.

From www.researchgate.net

TGA curves of the materials a PP and LDPE waste; b LDPE/PP blends... Download Scientific Diagram Surface Energy Of Ldpe The mechanical properties of polymers, particularly as a function of temperature and strain rate, are key for implementation of. Uncover the science behind molecular affinity and liquid flow. The surface of a ldpe was modified by ar, o2, n2, co2 gaseous plasma. Explore surface energy of plastics and learn how it impacts coating and bonding. The changes in surface morphology. Surface Energy Of Ldpe.

From www.researchgate.net

Tensile strengths of the PP (a), HDPE (b), LDPE (c), and LLDPE (d)... Download Scientific Diagram Surface Energy Of Ldpe Explore surface energy of plastics and learn how it impacts coating and bonding. Pe powder pressed into wafer at 1 kg/cm2, 110oc, cleaned with alcohol and water, soaked in 50oc sulfochromic acid, rinsed with distilled water, and dried with pure nitrogen. Wettability changes in ldpe films introduce hydrophilic groups that modify their hydrophobic nature, which are evidenced by a. The. Surface Energy Of Ldpe.

From www.vem-tooling.com

LDPE Versus HDPE Surface Energy Of Ldpe The surface of a ldpe was modified by ar, o2, n2, co2 gaseous plasma. Explore surface energy of plastics and learn how it impacts coating and bonding. The mechanical properties of polymers, particularly as a function of temperature and strain rate, are key for implementation of. The changes in surface morphology and surface wettability. Pe powder pressed into wafer at. Surface Energy Of Ldpe.

From www.researchgate.net

Plasmaassisted surface modification processes (a) sputtering (b)... Download Scientific Diagram Surface Energy Of Ldpe Pe powder pressed into wafer at 1 kg/cm2, 110oc, cleaned with alcohol and water, soaked in 50oc sulfochromic acid, rinsed with distilled water, and dried with pure nitrogen. The changes in surface morphology and surface wettability. Explore surface energy of plastics and learn how it impacts coating and bonding. Wettability changes in ldpe films introduce hydrophilic groups that modify their. Surface Energy Of Ldpe.

From www.researchgate.net

Mechanical properties of the PS and LDPE sample. (a)... Download Scientific Diagram Surface Energy Of Ldpe The mechanical properties of polymers, particularly as a function of temperature and strain rate, are key for implementation of. The changes in surface morphology and surface wettability. Explore surface energy of plastics and learn how it impacts coating and bonding. Uncover the science behind molecular affinity and liquid flow. The surface of a ldpe was modified by ar, o2, n2,. Surface Energy Of Ldpe.

From www.researchgate.net

Mechanical property of LDPE sample mapped at different frequencies.... Download Scientific Diagram Surface Energy Of Ldpe The changes in surface morphology and surface wettability. The mechanical properties of polymers, particularly as a function of temperature and strain rate, are key for implementation of. Wettability changes in ldpe films introduce hydrophilic groups that modify their hydrophobic nature, which are evidenced by a. Uncover the science behind molecular affinity and liquid flow. Explore surface energy of plastics and. Surface Energy Of Ldpe.

From www.researchgate.net

SEM micrographs showing surface of LDPE, LDPE+20 TPS, and LDPE+20... Download Scientific Diagram Surface Energy Of Ldpe The mechanical properties of polymers, particularly as a function of temperature and strain rate, are key for implementation of. The changes in surface morphology and surface wettability. Explore surface energy of plastics and learn how it impacts coating and bonding. Uncover the science behind molecular affinity and liquid flow. Wettability changes in ldpe films introduce hydrophilic groups that modify their. Surface Energy Of Ldpe.

From www.researchgate.net

SEM images of (a) surface of neat LDPE, (b) surface of LDPE10CAT, (c)... Download Scientific Surface Energy Of Ldpe Pe powder pressed into wafer at 1 kg/cm2, 110oc, cleaned with alcohol and water, soaked in 50oc sulfochromic acid, rinsed with distilled water, and dried with pure nitrogen. The changes in surface morphology and surface wettability. Uncover the science behind molecular affinity and liquid flow. The surface of a ldpe was modified by ar, o2, n2, co2 gaseous plasma. The. Surface Energy Of Ldpe.

From www.researchgate.net

Surface morphology of (a) LDPE/LLDPE blend (80/20), (b) LDPE/LLDPE... Download Scientific Diagram Surface Energy Of Ldpe The surface of a ldpe was modified by ar, o2, n2, co2 gaseous plasma. Uncover the science behind molecular affinity and liquid flow. Explore surface energy of plastics and learn how it impacts coating and bonding. The mechanical properties of polymers, particularly as a function of temperature and strain rate, are key for implementation of. Pe powder pressed into wafer. Surface Energy Of Ldpe.

From www.researchgate.net

FTIR spectra of pure LDPE (a), zeolite/LDPE with... Download Scientific Diagram Surface Energy Of Ldpe Wettability changes in ldpe films introduce hydrophilic groups that modify their hydrophobic nature, which are evidenced by a. The surface of a ldpe was modified by ar, o2, n2, co2 gaseous plasma. Uncover the science behind molecular affinity and liquid flow. Explore surface energy of plastics and learn how it impacts coating and bonding. Pe powder pressed into wafer at. Surface Energy Of Ldpe.

From www.geeksforgeeks.org

Surface Energy Definition, Formula, Unit & Numericals Surface Energy Of Ldpe Uncover the science behind molecular affinity and liquid flow. The changes in surface morphology and surface wettability. Pe powder pressed into wafer at 1 kg/cm2, 110oc, cleaned with alcohol and water, soaked in 50oc sulfochromic acid, rinsed with distilled water, and dried with pure nitrogen. Wettability changes in ldpe films introduce hydrophilic groups that modify their hydrophobic nature, which are. Surface Energy Of Ldpe.

From www.researchgate.net

Activation energy and mechanism of LDPE obtained by... Download Table Surface Energy Of Ldpe Uncover the science behind molecular affinity and liquid flow. Explore surface energy of plastics and learn how it impacts coating and bonding. Pe powder pressed into wafer at 1 kg/cm2, 110oc, cleaned with alcohol and water, soaked in 50oc sulfochromic acid, rinsed with distilled water, and dried with pure nitrogen. The surface of a ldpe was modified by ar, o2,. Surface Energy Of Ldpe.

From tombrowninc.com

Basics Of Tape Adhesion Lawrence Pennsylvania Tom Brown Inc Surface Energy Of Ldpe Uncover the science behind molecular affinity and liquid flow. The surface of a ldpe was modified by ar, o2, n2, co2 gaseous plasma. Pe powder pressed into wafer at 1 kg/cm2, 110oc, cleaned with alcohol and water, soaked in 50oc sulfochromic acid, rinsed with distilled water, and dried with pure nitrogen. Wettability changes in ldpe films introduce hydrophilic groups that. Surface Energy Of Ldpe.

From wiki.zero-emissions.at

Low density polyethylene (LDPE) Efficiency Finder Surface Energy Of Ldpe Explore surface energy of plastics and learn how it impacts coating and bonding. The changes in surface morphology and surface wettability. Wettability changes in ldpe films introduce hydrophilic groups that modify their hydrophobic nature, which are evidenced by a. Uncover the science behind molecular affinity and liquid flow. The surface of a ldpe was modified by ar, o2, n2, co2. Surface Energy Of Ldpe.

From www.researchgate.net

Mechanical properties of LDPE and LDPE composites Download Table Surface Energy Of Ldpe Wettability changes in ldpe films introduce hydrophilic groups that modify their hydrophobic nature, which are evidenced by a. The mechanical properties of polymers, particularly as a function of temperature and strain rate, are key for implementation of. Pe powder pressed into wafer at 1 kg/cm2, 110oc, cleaned with alcohol and water, soaked in 50oc sulfochromic acid, rinsed with distilled water,. Surface Energy Of Ldpe.

From uk.onlinelabels.com

Surface Energy and Labels The Unscientific Guide Surface Energy Of Ldpe The mechanical properties of polymers, particularly as a function of temperature and strain rate, are key for implementation of. The changes in surface morphology and surface wettability. Explore surface energy of plastics and learn how it impacts coating and bonding. The surface of a ldpe was modified by ar, o2, n2, co2 gaseous plasma. Pe powder pressed into wafer at. Surface Energy Of Ldpe.

From www.researchgate.net

SEM micrographs showing surface of a, b LDPE and c, d LDPE_40TPS before... Download Scientific Surface Energy Of Ldpe Wettability changes in ldpe films introduce hydrophilic groups that modify their hydrophobic nature, which are evidenced by a. The mechanical properties of polymers, particularly as a function of temperature and strain rate, are key for implementation of. Explore surface energy of plastics and learn how it impacts coating and bonding. The changes in surface morphology and surface wettability. The surface. Surface Energy Of Ldpe.

From www.researchgate.net

TGA curves of neat LDPE, its and the... Download Scientific Diagram Surface Energy Of Ldpe The mechanical properties of polymers, particularly as a function of temperature and strain rate, are key for implementation of. Wettability changes in ldpe films introduce hydrophilic groups that modify their hydrophobic nature, which are evidenced by a. Explore surface energy of plastics and learn how it impacts coating and bonding. Pe powder pressed into wafer at 1 kg/cm2, 110oc, cleaned. Surface Energy Of Ldpe.

From www.researchgate.net

SEM analysis of LDPE biodegradation at different resolutions (500×,... Download Scientific Diagram Surface Energy Of Ldpe Wettability changes in ldpe films introduce hydrophilic groups that modify their hydrophobic nature, which are evidenced by a. Explore surface energy of plastics and learn how it impacts coating and bonding. The changes in surface morphology and surface wettability. The mechanical properties of polymers, particularly as a function of temperature and strain rate, are key for implementation of. The surface. Surface Energy Of Ldpe.

From www.researchgate.net

Infrared spectrum of frost water on the (a) surface of LDPE and PVC... Download Scientific Diagram Surface Energy Of Ldpe Uncover the science behind molecular affinity and liquid flow. The changes in surface morphology and surface wettability. Pe powder pressed into wafer at 1 kg/cm2, 110oc, cleaned with alcohol and water, soaked in 50oc sulfochromic acid, rinsed with distilled water, and dried with pure nitrogen. The mechanical properties of polymers, particularly as a function of temperature and strain rate, are. Surface Energy Of Ldpe.

From redmin.com

LDPE (Low Density Polyethylene) Redmin Surface Energy Of Ldpe The changes in surface morphology and surface wettability. The surface of a ldpe was modified by ar, o2, n2, co2 gaseous plasma. Explore surface energy of plastics and learn how it impacts coating and bonding. Uncover the science behind molecular affinity and liquid flow. The mechanical properties of polymers, particularly as a function of temperature and strain rate, are key. Surface Energy Of Ldpe.

From www.researchgate.net

SEM micrographs images of tensile fracture surface for pure LDPE,... Download Scientific Diagram Surface Energy Of Ldpe The mechanical properties of polymers, particularly as a function of temperature and strain rate, are key for implementation of. Wettability changes in ldpe films introduce hydrophilic groups that modify their hydrophobic nature, which are evidenced by a. Pe powder pressed into wafer at 1 kg/cm2, 110oc, cleaned with alcohol and water, soaked in 50oc sulfochromic acid, rinsed with distilled water,. Surface Energy Of Ldpe.

From www.researchgate.net

SEM micrographs showing surface of LDPE, LDPE+20 TPS, and LDPE+20... Download Scientific Diagram Surface Energy Of Ldpe Wettability changes in ldpe films introduce hydrophilic groups that modify their hydrophobic nature, which are evidenced by a. Explore surface energy of plastics and learn how it impacts coating and bonding. The surface of a ldpe was modified by ar, o2, n2, co2 gaseous plasma. The mechanical properties of polymers, particularly as a function of temperature and strain rate, are. Surface Energy Of Ldpe.

From www.jarp.nl

Dyne pens non toxic » JARP Surface Energy Of Ldpe Uncover the science behind molecular affinity and liquid flow. The surface of a ldpe was modified by ar, o2, n2, co2 gaseous plasma. The mechanical properties of polymers, particularly as a function of temperature and strain rate, are key for implementation of. The changes in surface morphology and surface wettability. Explore surface energy of plastics and learn how it impacts. Surface Energy Of Ldpe.

From www.researchgate.net

Surface roughness parameters of plasmatreated LDPE obtained from 10 μ... Download Scientific Surface Energy Of Ldpe The mechanical properties of polymers, particularly as a function of temperature and strain rate, are key for implementation of. Explore surface energy of plastics and learn how it impacts coating and bonding. The surface of a ldpe was modified by ar, o2, n2, co2 gaseous plasma. The changes in surface morphology and surface wettability. Uncover the science behind molecular affinity. Surface Energy Of Ldpe.