Mold Design For Sand Casting . Sand casting begins with the creation of a mold using specially selected sand based on its specific properties. Casting is a manufacturing method where a liquid material is poured into a mold that contains a hollow cavity in the desired shape, and then allowed to harden. Because the sand mold must. Sand cast molds are designed to have a good collapsibility (the casting shrinks while cooling) to avoid defects in the casting, such as hot tearing and cracking. Sand casting, the most widely used casting process, utilizes expendable sand molds to form complex metal parts that can be made of nearly any alloy. Clay is used to cohesively bond. Sand casting works by generating a mold by forming a packed sand body around a wooden or rapid prototype master/pattern (or a. The mold is typically formed in two halves known as cope and.

from www.improprecision.com

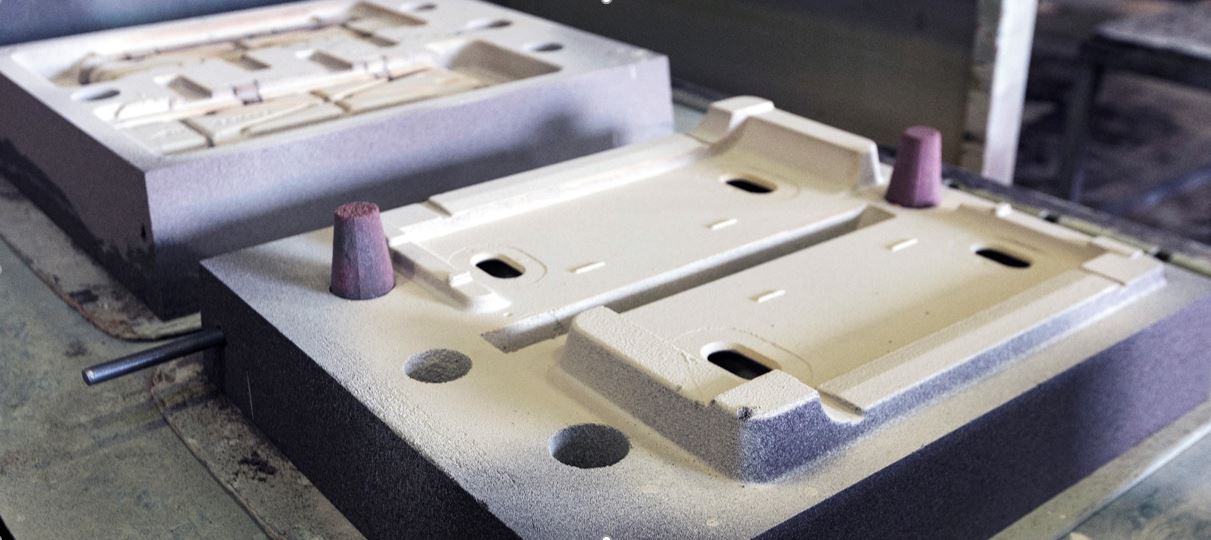

The mold is typically formed in two halves known as cope and. Sand casting begins with the creation of a mold using specially selected sand based on its specific properties. Sand casting, the most widely used casting process, utilizes expendable sand molds to form complex metal parts that can be made of nearly any alloy. Because the sand mold must. Sand casting works by generating a mold by forming a packed sand body around a wooden or rapid prototype master/pattern (or a. Clay is used to cohesively bond. Casting is a manufacturing method where a liquid material is poured into a mold that contains a hollow cavity in the desired shape, and then allowed to harden. Sand cast molds are designed to have a good collapsibility (the casting shrinks while cooling) to avoid defects in the casting, such as hot tearing and cracking.

Impro Blog Optimizing Sand Casting Pattern Design

Mold Design For Sand Casting The mold is typically formed in two halves known as cope and. Sand casting, the most widely used casting process, utilizes expendable sand molds to form complex metal parts that can be made of nearly any alloy. Sand casting works by generating a mold by forming a packed sand body around a wooden or rapid prototype master/pattern (or a. Sand cast molds are designed to have a good collapsibility (the casting shrinks while cooling) to avoid defects in the casting, such as hot tearing and cracking. Sand casting begins with the creation of a mold using specially selected sand based on its specific properties. Clay is used to cohesively bond. The mold is typically formed in two halves known as cope and. Because the sand mold must. Casting is a manufacturing method where a liquid material is poured into a mold that contains a hollow cavity in the desired shape, and then allowed to harden.

From www.fastcastings.com

3D Sand Casting Services 3D Printed Sand Molds Mold Design For Sand Casting Sand casting works by generating a mold by forming a packed sand body around a wooden or rapid prototype master/pattern (or a. The mold is typically formed in two halves known as cope and. Clay is used to cohesively bond. Sand casting begins with the creation of a mold using specially selected sand based on its specific properties. Casting is. Mold Design For Sand Casting.

From okfoundry.com

3D Printed Sand Molds OK Foundry Mold Design For Sand Casting Casting is a manufacturing method where a liquid material is poured into a mold that contains a hollow cavity in the desired shape, and then allowed to harden. The mold is typically formed in two halves known as cope and. Sand casting works by generating a mold by forming a packed sand body around a wooden or rapid prototype master/pattern. Mold Design For Sand Casting.

From engineeringstuff.co.in

Sand mold casting Explained Engineeringstuff Mold Design For Sand Casting Sand casting, the most widely used casting process, utilizes expendable sand molds to form complex metal parts that can be made of nearly any alloy. Because the sand mold must. The mold is typically formed in two halves known as cope and. Casting is a manufacturing method where a liquid material is poured into a mold that contains a hollow. Mold Design For Sand Casting.

From precisecast.com

Sand Casting Production Metal Casting Metal Casting Quotes Mold Design For Sand Casting Clay is used to cohesively bond. Because the sand mold must. Sand casting works by generating a mold by forming a packed sand body around a wooden or rapid prototype master/pattern (or a. The mold is typically formed in two halves known as cope and. Sand casting begins with the creation of a mold using specially selected sand based on. Mold Design For Sand Casting.

From www.weld2cast.com

Sand Casting Weld2Cast Mold Design For Sand Casting Clay is used to cohesively bond. Sand casting, the most widely used casting process, utilizes expendable sand molds to form complex metal parts that can be made of nearly any alloy. The mold is typically formed in two halves known as cope and. Sand cast molds are designed to have a good collapsibility (the casting shrinks while cooling) to avoid. Mold Design For Sand Casting.

From www.researchgate.net

(PDF) Sand Casting Mold Design (SCMD) Program Mold Design For Sand Casting Sand cast molds are designed to have a good collapsibility (the casting shrinks while cooling) to avoid defects in the casting, such as hot tearing and cracking. Sand casting works by generating a mold by forming a packed sand body around a wooden or rapid prototype master/pattern (or a. The mold is typically formed in two halves known as cope. Mold Design For Sand Casting.

From www.youtube.com

How to make a sand mold for casting metal YouTube Mold Design For Sand Casting Sand cast molds are designed to have a good collapsibility (the casting shrinks while cooling) to avoid defects in the casting, such as hot tearing and cracking. Sand casting, the most widely used casting process, utilizes expendable sand molds to form complex metal parts that can be made of nearly any alloy. Because the sand mold must. Clay is used. Mold Design For Sand Casting.

From www.reliance-foundry.com

Sand Casting Metal Casting Resources Mold Design For Sand Casting Sand cast molds are designed to have a good collapsibility (the casting shrinks while cooling) to avoid defects in the casting, such as hot tearing and cracking. Because the sand mold must. Clay is used to cohesively bond. Casting is a manufacturing method where a liquid material is poured into a mold that contains a hollow cavity in the desired. Mold Design For Sand Casting.

From www.zhycasting.com

Design of riser in sand casting ZHY Casting Mold Design For Sand Casting Clay is used to cohesively bond. The mold is typically formed in two halves known as cope and. Sand casting begins with the creation of a mold using specially selected sand based on its specific properties. Sand casting works by generating a mold by forming a packed sand body around a wooden or rapid prototype master/pattern (or a. Casting is. Mold Design For Sand Casting.

From engineeringproductdesign.com

What is Sand casting & How does it work? Pros & Cons casting Mold Design For Sand Casting Sand casting, the most widely used casting process, utilizes expendable sand molds to form complex metal parts that can be made of nearly any alloy. Sand casting begins with the creation of a mold using specially selected sand based on its specific properties. Casting is a manufacturing method where a liquid material is poured into a mold that contains a. Mold Design For Sand Casting.

From precisecast.com

Plaster Mold Casting Metal Casting Processes Learn More Mold Design For Sand Casting Casting is a manufacturing method where a liquid material is poured into a mold that contains a hollow cavity in the desired shape, and then allowed to harden. Because the sand mold must. Sand casting, the most widely used casting process, utilizes expendable sand molds to form complex metal parts that can be made of nearly any alloy. Clay is. Mold Design For Sand Casting.

From mechanicalinventions.blogspot.com

Diferent Parts of Sand Mold Features Mechanical Engineering Mold Design For Sand Casting Sand casting begins with the creation of a mold using specially selected sand based on its specific properties. Sand casting works by generating a mold by forming a packed sand body around a wooden or rapid prototype master/pattern (or a. Casting is a manufacturing method where a liquid material is poured into a mold that contains a hollow cavity in. Mold Design For Sand Casting.

From monmet.com

Sand Casting Monmet Mold Design For Sand Casting Sand cast molds are designed to have a good collapsibility (the casting shrinks while cooling) to avoid defects in the casting, such as hot tearing and cracking. Clay is used to cohesively bond. Sand casting begins with the creation of a mold using specially selected sand based on its specific properties. The mold is typically formed in two halves known. Mold Design For Sand Casting.

From www.the-warren.org

Sand Casting Mold Design For Sand Casting Sand casting, the most widely used casting process, utilizes expendable sand molds to form complex metal parts that can be made of nearly any alloy. Sand casting begins with the creation of a mold using specially selected sand based on its specific properties. Sand cast molds are designed to have a good collapsibility (the casting shrinks while cooling) to avoid. Mold Design For Sand Casting.

From buntyllc.com

Sand Casting Process A StepbyStep Guide Bunty LLC Mold Design For Sand Casting Casting is a manufacturing method where a liquid material is poured into a mold that contains a hollow cavity in the desired shape, and then allowed to harden. Sand casting begins with the creation of a mold using specially selected sand based on its specific properties. Sand casting, the most widely used casting process, utilizes expendable sand molds to form. Mold Design For Sand Casting.

From monroeengineering.com

The 6Step Process of Sand Casting Molding OneMonroe Mold Design For Sand Casting The mold is typically formed in two halves known as cope and. Casting is a manufacturing method where a liquid material is poured into a mold that contains a hollow cavity in the desired shape, and then allowed to harden. Because the sand mold must. Sand casting begins with the creation of a mold using specially selected sand based on. Mold Design For Sand Casting.

From www.youtube.com

Sand Casting Mold Design YouTube Mold Design For Sand Casting The mold is typically formed in two halves known as cope and. Casting is a manufacturing method where a liquid material is poured into a mold that contains a hollow cavity in the desired shape, and then allowed to harden. Clay is used to cohesively bond. Sand casting begins with the creation of a mold using specially selected sand based. Mold Design For Sand Casting.

From proto3000.com

Sand Casting Proto3000 Mold Design For Sand Casting Casting is a manufacturing method where a liquid material is poured into a mold that contains a hollow cavity in the desired shape, and then allowed to harden. Sand casting works by generating a mold by forming a packed sand body around a wooden or rapid prototype master/pattern (or a. Because the sand mold must. The mold is typically formed. Mold Design For Sand Casting.

From www.iqsdirectory.com

Sand Casting Construction, Types, Applications, and Advantages Mold Design For Sand Casting Sand casting begins with the creation of a mold using specially selected sand based on its specific properties. Sand casting, the most widely used casting process, utilizes expendable sand molds to form complex metal parts that can be made of nearly any alloy. Because the sand mold must. The mold is typically formed in two halves known as cope and.. Mold Design For Sand Casting.

From vietnamcastiron.com

Instructions for Making Sand Casting Molds in detail Step by Step Mold Design For Sand Casting Sand casting begins with the creation of a mold using specially selected sand based on its specific properties. The mold is typically formed in two halves known as cope and. Sand cast molds are designed to have a good collapsibility (the casting shrinks while cooling) to avoid defects in the casting, such as hot tearing and cracking. Clay is used. Mold Design For Sand Casting.

From truesourcesoftware.com

The Process Of Creating A Sand Casting Mold Mold Design For Sand Casting The mold is typically formed in two halves known as cope and. Sand casting begins with the creation of a mold using specially selected sand based on its specific properties. Because the sand mold must. Sand casting works by generating a mold by forming a packed sand body around a wooden or rapid prototype master/pattern (or a. Clay is used. Mold Design For Sand Casting.

From www.zhycasting.com

Original process design scheme of sand casting composite mold ZHY Casting Mold Design For Sand Casting Casting is a manufacturing method where a liquid material is poured into a mold that contains a hollow cavity in the desired shape, and then allowed to harden. Sand casting begins with the creation of a mold using specially selected sand based on its specific properties. The mold is typically formed in two halves known as cope and. Clay is. Mold Design For Sand Casting.

From reliance-foundry.com

Sand Casting Metal Casting Resources Mold Design For Sand Casting Clay is used to cohesively bond. Sand casting works by generating a mold by forming a packed sand body around a wooden or rapid prototype master/pattern (or a. Sand casting, the most widely used casting process, utilizes expendable sand molds to form complex metal parts that can be made of nearly any alloy. Sand cast molds are designed to have. Mold Design For Sand Casting.

From startup-buzz.com

The Beginner’s Guide to Permanent Mold Casting Startup Buzz Mold Design For Sand Casting Casting is a manufacturing method where a liquid material is poured into a mold that contains a hollow cavity in the desired shape, and then allowed to harden. The mold is typically formed in two halves known as cope and. Sand cast molds are designed to have a good collapsibility (the casting shrinks while cooling) to avoid defects in the. Mold Design For Sand Casting.

From circuitnehajnije39.z21.web.core.windows.net

Sand Casting Simple Diagram Mold Design For Sand Casting Clay is used to cohesively bond. Sand casting works by generating a mold by forming a packed sand body around a wooden or rapid prototype master/pattern (or a. Sand casting, the most widely used casting process, utilizes expendable sand molds to form complex metal parts that can be made of nearly any alloy. Because the sand mold must. Casting is. Mold Design For Sand Casting.

From www.youtube.com

Making a green sand mold Casting 2 YouTube Mold Design For Sand Casting Because the sand mold must. Clay is used to cohesively bond. The mold is typically formed in two halves known as cope and. Sand cast molds are designed to have a good collapsibility (the casting shrinks while cooling) to avoid defects in the casting, such as hot tearing and cracking. Casting is a manufacturing method where a liquid material is. Mold Design For Sand Casting.

From toolnotes.com

Sand Casting ToolNotes Mold Design For Sand Casting Sand casting, the most widely used casting process, utilizes expendable sand molds to form complex metal parts that can be made of nearly any alloy. Casting is a manufacturing method where a liquid material is poured into a mold that contains a hollow cavity in the desired shape, and then allowed to harden. The mold is typically formed in two. Mold Design For Sand Casting.

From www.youtube.com

Mold filling time and runner system design in Metal casting YouTube Mold Design For Sand Casting Sand casting begins with the creation of a mold using specially selected sand based on its specific properties. Sand casting, the most widely used casting process, utilizes expendable sand molds to form complex metal parts that can be made of nearly any alloy. Sand casting works by generating a mold by forming a packed sand body around a wooden or. Mold Design For Sand Casting.

From www.improprecision.com

Impro Blog Optimizing Sand Casting Pattern Design Mold Design For Sand Casting Sand casting, the most widely used casting process, utilizes expendable sand molds to form complex metal parts that can be made of nearly any alloy. Because the sand mold must. Sand casting works by generating a mold by forming a packed sand body around a wooden or rapid prototype master/pattern (or a. The mold is typically formed in two halves. Mold Design For Sand Casting.

From www.aniwaa.com

Guide to 3D printing molds for metal casting Aniwaa Mold Design For Sand Casting Casting is a manufacturing method where a liquid material is poured into a mold that contains a hollow cavity in the desired shape, and then allowed to harden. Sand casting, the most widely used casting process, utilizes expendable sand molds to form complex metal parts that can be made of nearly any alloy. Sand casting works by generating a mold. Mold Design For Sand Casting.

From www.multifilla.com

Mini Sand Casting Molds 6 Designs Multifilla Mold Design For Sand Casting Casting is a manufacturing method where a liquid material is poured into a mold that contains a hollow cavity in the desired shape, and then allowed to harden. Clay is used to cohesively bond. Sand casting, the most widely used casting process, utilizes expendable sand molds to form complex metal parts that can be made of nearly any alloy. Sand. Mold Design For Sand Casting.

From mfg.trimech.com

FDM 3D Printing Sand Casting Molds TriMech Mold Design For Sand Casting Because the sand mold must. Sand casting works by generating a mold by forming a packed sand body around a wooden or rapid prototype master/pattern (or a. The mold is typically formed in two halves known as cope and. Casting is a manufacturing method where a liquid material is poured into a mold that contains a hollow cavity in the. Mold Design For Sand Casting.

From okfoundry.com

3D Printed Sand Molds OK Foundry Mold Design For Sand Casting Casting is a manufacturing method where a liquid material is poured into a mold that contains a hollow cavity in the desired shape, and then allowed to harden. Clay is used to cohesively bond. Sand cast molds are designed to have a good collapsibility (the casting shrinks while cooling) to avoid defects in the casting, such as hot tearing and. Mold Design For Sand Casting.

From www.youtube.com

Patterns and Cores Sand Casting. YouTube Mold Design For Sand Casting Casting is a manufacturing method where a liquid material is poured into a mold that contains a hollow cavity in the desired shape, and then allowed to harden. Sand cast molds are designed to have a good collapsibility (the casting shrinks while cooling) to avoid defects in the casting, such as hot tearing and cracking. Because the sand mold must.. Mold Design For Sand Casting.

From www.reliance-foundry.com

Sand Casting Metal Casting Resources Mold Design For Sand Casting Sand casting, the most widely used casting process, utilizes expendable sand molds to form complex metal parts that can be made of nearly any alloy. Clay is used to cohesively bond. Casting is a manufacturing method where a liquid material is poured into a mold that contains a hollow cavity in the desired shape, and then allowed to harden. Because. Mold Design For Sand Casting.