Semiconductor Die . Deposition, photoresist, lithography, etch, ionization. Learn the meanings and differences of wafer, chip and die in semiconductor manufacturing. Wafer is a round silicon disk, chip is a packaged semiconductor component, and die is a small. It is made up of two major parts: Learn how silicon wafers are singulated into individual dies for semiconductor manufacturing. To make any chip, numerous processes play a role. Let’s discuss six critical semiconductor manufacturing steps: Learn about the fabrication process, protection, electrical interconnection, and thermal management of semiconductor die, the heart of. A tiny and very fragile silicon chip (die) and a package which is intended to protect the internal silicon chip and to provide users with a practical way of handling. The die preparation process involves wafer mounting and wafer sawing, which require.

from ar.inspiredpencil.com

Learn about the fabrication process, protection, electrical interconnection, and thermal management of semiconductor die, the heart of. Learn the meanings and differences of wafer, chip and die in semiconductor manufacturing. A tiny and very fragile silicon chip (die) and a package which is intended to protect the internal silicon chip and to provide users with a practical way of handling. Wafer is a round silicon disk, chip is a packaged semiconductor component, and die is a small. Deposition, photoresist, lithography, etch, ionization. The die preparation process involves wafer mounting and wafer sawing, which require. To make any chip, numerous processes play a role. Let’s discuss six critical semiconductor manufacturing steps: Learn how silicon wafers are singulated into individual dies for semiconductor manufacturing. It is made up of two major parts:

Semiconductor Die

Semiconductor Die Learn how silicon wafers are singulated into individual dies for semiconductor manufacturing. Learn about the fabrication process, protection, electrical interconnection, and thermal management of semiconductor die, the heart of. Learn how silicon wafers are singulated into individual dies for semiconductor manufacturing. It is made up of two major parts: Wafer is a round silicon disk, chip is a packaged semiconductor component, and die is a small. A tiny and very fragile silicon chip (die) and a package which is intended to protect the internal silicon chip and to provide users with a practical way of handling. The die preparation process involves wafer mounting and wafer sawing, which require. Deposition, photoresist, lithography, etch, ionization. To make any chip, numerous processes play a role. Let’s discuss six critical semiconductor manufacturing steps: Learn the meanings and differences of wafer, chip and die in semiconductor manufacturing.

From ar.inspiredpencil.com

Semiconductor Die Semiconductor Die A tiny and very fragile silicon chip (die) and a package which is intended to protect the internal silicon chip and to provide users with a practical way of handling. Learn how silicon wafers are singulated into individual dies for semiconductor manufacturing. It is made up of two major parts: Learn about the fabrication process, protection, electrical interconnection, and thermal. Semiconductor Die.

From ar.inspiredpencil.com

Semiconductor Die Semiconductor Die The die preparation process involves wafer mounting and wafer sawing, which require. Learn how silicon wafers are singulated into individual dies for semiconductor manufacturing. A tiny and very fragile silicon chip (die) and a package which is intended to protect the internal silicon chip and to provide users with a practical way of handling. Learn the meanings and differences of. Semiconductor Die.

From www.google.com.mx

Patent US7157799 Semiconductor die package including carrier with Semiconductor Die Wafer is a round silicon disk, chip is a packaged semiconductor component, and die is a small. It is made up of two major parts: A tiny and very fragile silicon chip (die) and a package which is intended to protect the internal silicon chip and to provide users with a practical way of handling. Learn how silicon wafers are. Semiconductor Die.

From semiengineering.com

Semiconductor Engineering Why Chips Die Semiconductor Die To make any chip, numerous processes play a role. A tiny and very fragile silicon chip (die) and a package which is intended to protect the internal silicon chip and to provide users with a practical way of handling. Learn about the fabrication process, protection, electrical interconnection, and thermal management of semiconductor die, the heart of. It is made up. Semiconductor Die.

From present5.com

General Semiconductor Packaging Process Flow Wafer Backgrinding Die Semiconductor Die Learn the meanings and differences of wafer, chip and die in semiconductor manufacturing. Let’s discuss six critical semiconductor manufacturing steps: Deposition, photoresist, lithography, etch, ionization. Wafer is a round silicon disk, chip is a packaged semiconductor component, and die is a small. To make any chip, numerous processes play a role. A tiny and very fragile silicon chip (die) and. Semiconductor Die.

From www.istockphoto.com

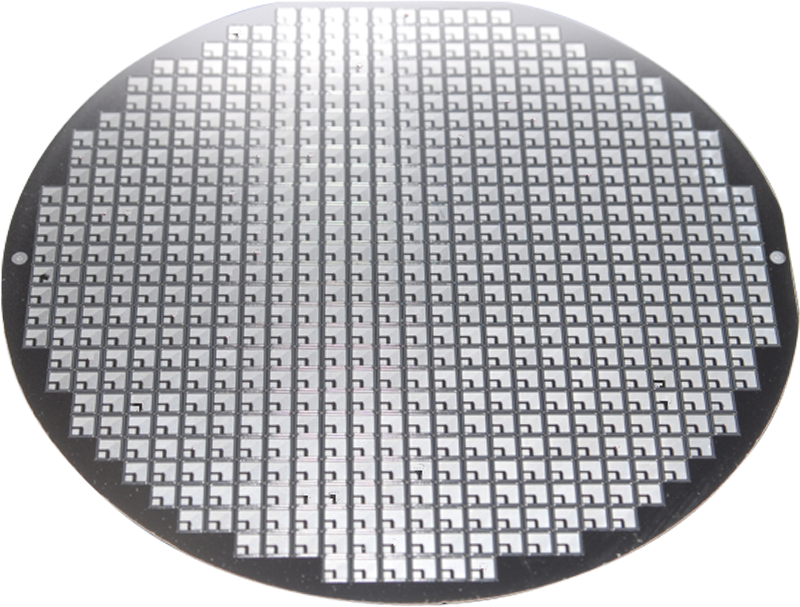

Semiconductor Wafer After Dicing Process Silicon Dies Are Being Semiconductor Die Wafer is a round silicon disk, chip is a packaged semiconductor component, and die is a small. A tiny and very fragile silicon chip (die) and a package which is intended to protect the internal silicon chip and to provide users with a practical way of handling. It is made up of two major parts: Learn the meanings and differences. Semiconductor Die.

From cpu-ns32k.net

The Site to Remember National Semiconductor's Series 32000 Family Semiconductor Die The die preparation process involves wafer mounting and wafer sawing, which require. It is made up of two major parts: Learn how silicon wafers are singulated into individual dies for semiconductor manufacturing. Let’s discuss six critical semiconductor manufacturing steps: To make any chip, numerous processes play a role. A tiny and very fragile silicon chip (die) and a package which. Semiconductor Die.

From www.google.ca

Patent US6830959 Semiconductor die package with semiconductor die Semiconductor Die Deposition, photoresist, lithography, etch, ionization. Learn how silicon wafers are singulated into individual dies for semiconductor manufacturing. A tiny and very fragile silicon chip (die) and a package which is intended to protect the internal silicon chip and to provide users with a practical way of handling. To make any chip, numerous processes play a role. Let’s discuss six critical. Semiconductor Die.

From ar.inspiredpencil.com

Semiconductor Die Semiconductor Die It is made up of two major parts: To make any chip, numerous processes play a role. Learn how silicon wafers are singulated into individual dies for semiconductor manufacturing. Learn the meanings and differences of wafer, chip and die in semiconductor manufacturing. Deposition, photoresist, lithography, etch, ionization. Let’s discuss six critical semiconductor manufacturing steps: A tiny and very fragile silicon. Semiconductor Die.

From ar.inspiredpencil.com

Semiconductor Die Semiconductor Die The die preparation process involves wafer mounting and wafer sawing, which require. It is made up of two major parts: Learn how silicon wafers are singulated into individual dies for semiconductor manufacturing. Learn about the fabrication process, protection, electrical interconnection, and thermal management of semiconductor die, the heart of. Deposition, photoresist, lithography, etch, ionization. A tiny and very fragile silicon. Semiconductor Die.

From fineartamerica.com

Closeup of semiconductor die showing blocks Photograph by David Fong Semiconductor Die Learn the meanings and differences of wafer, chip and die in semiconductor manufacturing. It is made up of two major parts: Let’s discuss six critical semiconductor manufacturing steps: Wafer is a round silicon disk, chip is a packaged semiconductor component, and die is a small. Learn about the fabrication process, protection, electrical interconnection, and thermal management of semiconductor die, the. Semiconductor Die.

From www.google.com.au

Patent US8053883 Isolated stacked die semiconductor packages Google Semiconductor Die Let’s discuss six critical semiconductor manufacturing steps: To make any chip, numerous processes play a role. A tiny and very fragile silicon chip (die) and a package which is intended to protect the internal silicon chip and to provide users with a practical way of handling. The die preparation process involves wafer mounting and wafer sawing, which require. Learn how. Semiconductor Die.

From stock.adobe.com

Semiconductor Packaging Process. Closeup of Silicon Die are being Semiconductor Die Learn how silicon wafers are singulated into individual dies for semiconductor manufacturing. It is made up of two major parts: The die preparation process involves wafer mounting and wafer sawing, which require. Learn about the fabrication process, protection, electrical interconnection, and thermal management of semiconductor die, the heart of. Let’s discuss six critical semiconductor manufacturing steps: Wafer is a round. Semiconductor Die.

From news.thomasnet.com

Newport Corporation Introduces MRSI605 AP Die Bonder; Debuts at Semiconductor Die Deposition, photoresist, lithography, etch, ionization. To make any chip, numerous processes play a role. Learn the meanings and differences of wafer, chip and die in semiconductor manufacturing. A tiny and very fragile silicon chip (die) and a package which is intended to protect the internal silicon chip and to provide users with a practical way of handling. Wafer is a. Semiconductor Die.

From www.powerelectronicsnews.com

SemiSintering Die Attach Portfolio Expanded with Versatile Material Semiconductor Die A tiny and very fragile silicon chip (die) and a package which is intended to protect the internal silicon chip and to provide users with a practical way of handling. Wafer is a round silicon disk, chip is a packaged semiconductor component, and die is a small. To make any chip, numerous processes play a role. The die preparation process. Semiconductor Die.

From www.google.ca

Patent US6830959 Semiconductor die package with semiconductor die Semiconductor Die Let’s discuss six critical semiconductor manufacturing steps: Learn how silicon wafers are singulated into individual dies for semiconductor manufacturing. It is made up of two major parts: The die preparation process involves wafer mounting and wafer sawing, which require. Learn the meanings and differences of wafer, chip and die in semiconductor manufacturing. Learn about the fabrication process, protection, electrical interconnection,. Semiconductor Die.

From www.gettyimages.ca

Semiconductor Die Photos and Premium High Res Pictures Getty Images Semiconductor Die Learn about the fabrication process, protection, electrical interconnection, and thermal management of semiconductor die, the heart of. Deposition, photoresist, lithography, etch, ionization. Learn the meanings and differences of wafer, chip and die in semiconductor manufacturing. The die preparation process involves wafer mounting and wafer sawing, which require. Learn how silicon wafers are singulated into individual dies for semiconductor manufacturing. It. Semiconductor Die.

From cpu-ns32k.net

The Site to Remember National Semiconductor's Series 32000 Family Semiconductor Die It is made up of two major parts: The die preparation process involves wafer mounting and wafer sawing, which require. Deposition, photoresist, lithography, etch, ionization. Learn about the fabrication process, protection, electrical interconnection, and thermal management of semiconductor die, the heart of. To make any chip, numerous processes play a role. Let’s discuss six critical semiconductor manufacturing steps: A tiny. Semiconductor Die.

From ar.inspiredpencil.com

Semiconductor Die Semiconductor Die Learn about the fabrication process, protection, electrical interconnection, and thermal management of semiconductor die, the heart of. Deposition, photoresist, lithography, etch, ionization. A tiny and very fragile silicon chip (die) and a package which is intended to protect the internal silicon chip and to provide users with a practical way of handling. Let’s discuss six critical semiconductor manufacturing steps: It. Semiconductor Die.

From ar.inspiredpencil.com

Semiconductor Die Semiconductor Die The die preparation process involves wafer mounting and wafer sawing, which require. Deposition, photoresist, lithography, etch, ionization. A tiny and very fragile silicon chip (die) and a package which is intended to protect the internal silicon chip and to provide users with a practical way of handling. Let’s discuss six critical semiconductor manufacturing steps: Learn the meanings and differences of. Semiconductor Die.

From ar.inspiredpencil.com

Semiconductor Die Semiconductor Die Learn the meanings and differences of wafer, chip and die in semiconductor manufacturing. Deposition, photoresist, lithography, etch, ionization. A tiny and very fragile silicon chip (die) and a package which is intended to protect the internal silicon chip and to provide users with a practical way of handling. The die preparation process involves wafer mounting and wafer sawing, which require.. Semiconductor Die.

From www.google.ca

Patent US20070152313 Stacked die semiconductor package Google Patents Semiconductor Die Wafer is a round silicon disk, chip is a packaged semiconductor component, and die is a small. Learn about the fabrication process, protection, electrical interconnection, and thermal management of semiconductor die, the heart of. It is made up of two major parts: Deposition, photoresist, lithography, etch, ionization. To make any chip, numerous processes play a role. Learn the meanings and. Semiconductor Die.

From zeptobars.com

National Semiconductor LMC555 weekend dieshot ZeptoBars Semiconductor Die Wafer is a round silicon disk, chip is a packaged semiconductor component, and die is a small. The die preparation process involves wafer mounting and wafer sawing, which require. Let’s discuss six critical semiconductor manufacturing steps: Learn about the fabrication process, protection, electrical interconnection, and thermal management of semiconductor die, the heart of. A tiny and very fragile silicon chip. Semiconductor Die.

From ar.inspiredpencil.com

Semiconductor Die Semiconductor Die Learn the meanings and differences of wafer, chip and die in semiconductor manufacturing. The die preparation process involves wafer mounting and wafer sawing, which require. Deposition, photoresist, lithography, etch, ionization. Learn how silicon wafers are singulated into individual dies for semiconductor manufacturing. Let’s discuss six critical semiconductor manufacturing steps: To make any chip, numerous processes play a role. A tiny. Semiconductor Die.

From www.researchgate.net

(PDF) Semiconductor Die Processing and Packaging Semiconductor Die The die preparation process involves wafer mounting and wafer sawing, which require. Learn the meanings and differences of wafer, chip and die in semiconductor manufacturing. It is made up of two major parts: Deposition, photoresist, lithography, etch, ionization. A tiny and very fragile silicon chip (die) and a package which is intended to protect the internal silicon chip and to. Semiconductor Die.

From www.google.com.mx

Patent US8828798 Semiconductor die assemblies, semiconductor devices Semiconductor Die To make any chip, numerous processes play a role. The die preparation process involves wafer mounting and wafer sawing, which require. Learn about the fabrication process, protection, electrical interconnection, and thermal management of semiconductor die, the heart of. It is made up of two major parts: Let’s discuss six critical semiconductor manufacturing steps: Learn the meanings and differences of wafer,. Semiconductor Die.

From ar.inspiredpencil.com

Semiconductor Die Semiconductor Die The die preparation process involves wafer mounting and wafer sawing, which require. Let’s discuss six critical semiconductor manufacturing steps: Learn the meanings and differences of wafer, chip and die in semiconductor manufacturing. Learn about the fabrication process, protection, electrical interconnection, and thermal management of semiconductor die, the heart of. It is made up of two major parts: Deposition, photoresist, lithography,. Semiconductor Die.

From www.swissfinancialtime.com

Multidie systems define the future of semiconductors Semiconductor Die Wafer is a round silicon disk, chip is a packaged semiconductor component, and die is a small. It is made up of two major parts: Learn the meanings and differences of wafer, chip and die in semiconductor manufacturing. The die preparation process involves wafer mounting and wafer sawing, which require. Let’s discuss six critical semiconductor manufacturing steps: Learn about the. Semiconductor Die.

From present5.com

General Semiconductor Packaging Process Flow Wafer Backgrinding Die Semiconductor Die Wafer is a round silicon disk, chip is a packaged semiconductor component, and die is a small. Learn the meanings and differences of wafer, chip and die in semiconductor manufacturing. Learn how silicon wafers are singulated into individual dies for semiconductor manufacturing. Let’s discuss six critical semiconductor manufacturing steps: To make any chip, numerous processes play a role. The die. Semiconductor Die.

From www.google.com.au

Patent US6744124 Semiconductor die package including cupshaped Semiconductor Die Deposition, photoresist, lithography, etch, ionization. It is made up of two major parts: Learn about the fabrication process, protection, electrical interconnection, and thermal management of semiconductor die, the heart of. Wafer is a round silicon disk, chip is a packaged semiconductor component, and die is a small. A tiny and very fragile silicon chip (die) and a package which is. Semiconductor Die.

From news.samsung.com

Eight Major Steps to Semiconductor Fabrication, Part 8 Electrical Die Semiconductor Die Learn about the fabrication process, protection, electrical interconnection, and thermal management of semiconductor die, the heart of. A tiny and very fragile silicon chip (die) and a package which is intended to protect the internal silicon chip and to provide users with a practical way of handling. The die preparation process involves wafer mounting and wafer sawing, which require. Learn. Semiconductor Die.

From ar.inspiredpencil.com

Semiconductor Die Semiconductor Die To make any chip, numerous processes play a role. Let’s discuss six critical semiconductor manufacturing steps: Learn how silicon wafers are singulated into individual dies for semiconductor manufacturing. The die preparation process involves wafer mounting and wafer sawing, which require. Learn about the fabrication process, protection, electrical interconnection, and thermal management of semiconductor die, the heart of. A tiny and. Semiconductor Die.

From ar.inspiredpencil.com

Semiconductor Die Semiconductor Die A tiny and very fragile silicon chip (die) and a package which is intended to protect the internal silicon chip and to provide users with a practical way of handling. The die preparation process involves wafer mounting and wafer sawing, which require. Learn about the fabrication process, protection, electrical interconnection, and thermal management of semiconductor die, the heart of. Learn. Semiconductor Die.

From ar.inspiredpencil.com

Semiconductor Die Semiconductor Die The die preparation process involves wafer mounting and wafer sawing, which require. Deposition, photoresist, lithography, etch, ionization. Wafer is a round silicon disk, chip is a packaged semiconductor component, and die is a small. A tiny and very fragile silicon chip (die) and a package which is intended to protect the internal silicon chip and to provide users with a. Semiconductor Die.

From ar.inspiredpencil.com

Semiconductor Die Semiconductor Die Wafer is a round silicon disk, chip is a packaged semiconductor component, and die is a small. Let’s discuss six critical semiconductor manufacturing steps: Learn the meanings and differences of wafer, chip and die in semiconductor manufacturing. It is made up of two major parts: Learn how silicon wafers are singulated into individual dies for semiconductor manufacturing. A tiny and. Semiconductor Die.