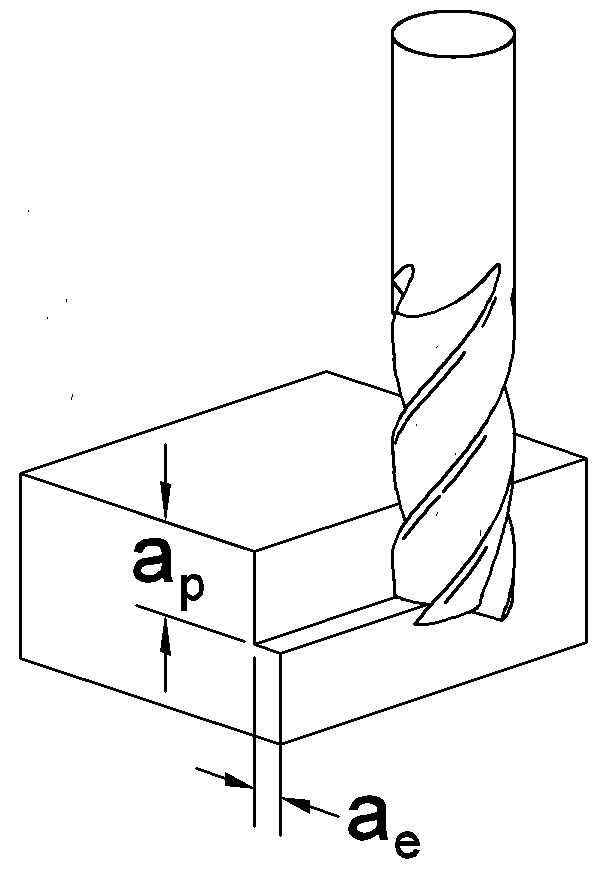

End Mill Width Of Cut . Finish cuts typically require reduced feed rates. All cutting data are target values. The axial cutting depth should be generally reduced to around 70% of the edge length. A typical end mill removes material from the side and along its end face. End mills, htpm, speeds and feeds, slotting and side cutting, metric. Machine rigidity and chip evacuation should also be. Find out the definitions, examples, and tips for radial and axial depth of cut, and access a free webinar on hem. Feed to be reduced by approximately 50% if loc (length of cut) is over. Hence, there is a depth and a width of cut, and these parameters are generally known as axial depth. Learn how to choose the right depth of cut for peripheral and slotting milling operations, and how to apply high efficiency milling (hem) strategies for improved productivity and tool life. Full slotting with an end mill is a demanding operation.

from toolnotes.com

The axial cutting depth should be generally reduced to around 70% of the edge length. Full slotting with an end mill is a demanding operation. End mills, htpm, speeds and feeds, slotting and side cutting, metric. Machine rigidity and chip evacuation should also be. All cutting data are target values. A typical end mill removes material from the side and along its end face. Finish cuts typically require reduced feed rates. Learn how to choose the right depth of cut for peripheral and slotting milling operations, and how to apply high efficiency milling (hem) strategies for improved productivity and tool life. Feed to be reduced by approximately 50% if loc (length of cut) is over. Hence, there is a depth and a width of cut, and these parameters are generally known as axial depth.

Cutting Parameters for Milling ToolNotes

End Mill Width Of Cut Learn how to choose the right depth of cut for peripheral and slotting milling operations, and how to apply high efficiency milling (hem) strategies for improved productivity and tool life. Find out the definitions, examples, and tips for radial and axial depth of cut, and access a free webinar on hem. All cutting data are target values. The axial cutting depth should be generally reduced to around 70% of the edge length. A typical end mill removes material from the side and along its end face. Finish cuts typically require reduced feed rates. Hence, there is a depth and a width of cut, and these parameters are generally known as axial depth. End mills, htpm, speeds and feeds, slotting and side cutting, metric. Feed to be reduced by approximately 50% if loc (length of cut) is over. Learn how to choose the right depth of cut for peripheral and slotting milling operations, and how to apply high efficiency milling (hem) strategies for improved productivity and tool life. Machine rigidity and chip evacuation should also be. Full slotting with an end mill is a demanding operation.

From www.cutwel.co.uk

Milling Cutters Explained An Expert Guide Cutwel Ltd End Mill Width Of Cut Machine rigidity and chip evacuation should also be. Full slotting with an end mill is a demanding operation. Finish cuts typically require reduced feed rates. Learn how to choose the right depth of cut for peripheral and slotting milling operations, and how to apply high efficiency milling (hem) strategies for improved productivity and tool life. Feed to be reduced by. End Mill Width Of Cut.

From engineeringlearn.com

End Mill Cutter Archives Engineering Learn End Mill Width Of Cut Find out the definitions, examples, and tips for radial and axial depth of cut, and access a free webinar on hem. End mills, htpm, speeds and feeds, slotting and side cutting, metric. Finish cuts typically require reduced feed rates. The axial cutting depth should be generally reduced to around 70% of the edge length. Feed to be reduced by approximately. End Mill Width Of Cut.

From ladynightwish-blackrose.blogspot.com

roughing end mill cutter diagram Say It One More Microblog Portrait End Mill Width Of Cut End mills, htpm, speeds and feeds, slotting and side cutting, metric. Full slotting with an end mill is a demanding operation. A typical end mill removes material from the side and along its end face. Find out the definitions, examples, and tips for radial and axial depth of cut, and access a free webinar on hem. Hence, there is a. End Mill Width Of Cut.

From uk.misumi-ec.com

Milling Tips / Holders Ball End Mills Technical Information Tools End Mill Width Of Cut Feed to be reduced by approximately 50% if loc (length of cut) is over. Hence, there is a depth and a width of cut, and these parameters are generally known as axial depth. Machine rigidity and chip evacuation should also be. Full slotting with an end mill is a demanding operation. All cutting data are target values. Learn how to. End Mill Width Of Cut.

From edwardocooley.blogspot.com

roughing end mill cutter diagram Edwardo Cooley End Mill Width Of Cut Learn how to choose the right depth of cut for peripheral and slotting milling operations, and how to apply high efficiency milling (hem) strategies for improved productivity and tool life. Finish cuts typically require reduced feed rates. Machine rigidity and chip evacuation should also be. Full slotting with an end mill is a demanding operation. All cutting data are target. End Mill Width Of Cut.

From support.bantamtools.com

End Mill Identification Guide Bantam Tools End Mill Width Of Cut Full slotting with an end mill is a demanding operation. All cutting data are target values. A typical end mill removes material from the side and along its end face. Find out the definitions, examples, and tips for radial and axial depth of cut, and access a free webinar on hem. End mills, htpm, speeds and feeds, slotting and side. End Mill Width Of Cut.

From www.researchgate.net

Discretization of the ballend mill cutting edge (a), scheme of cutting End Mill Width Of Cut Learn how to choose the right depth of cut for peripheral and slotting milling operations, and how to apply high efficiency milling (hem) strategies for improved productivity and tool life. Find out the definitions, examples, and tips for radial and axial depth of cut, and access a free webinar on hem. Feed to be reduced by approximately 50% if loc. End Mill Width Of Cut.

From www.alibaba.com

End Mill Cutter Sizes;2flute Flattened End Mills With Straight Shank End Mill Width Of Cut Find out the definitions, examples, and tips for radial and axial depth of cut, and access a free webinar on hem. Finish cuts typically require reduced feed rates. A typical end mill removes material from the side and along its end face. Machine rigidity and chip evacuation should also be. Hence, there is a depth and a width of cut,. End Mill Width Of Cut.

From www.qualitytechtool.com

General Purpose End Mills Metric Quality Tech Tool End Mill Width Of Cut All cutting data are target values. Hence, there is a depth and a width of cut, and these parameters are generally known as axial depth. Machine rigidity and chip evacuation should also be. Learn how to choose the right depth of cut for peripheral and slotting milling operations, and how to apply high efficiency milling (hem) strategies for improved productivity. End Mill Width Of Cut.

From www.endmill.com.au

Choosing the right end mill for the job Adam's Bits End Mill Width Of Cut A typical end mill removes material from the side and along its end face. Full slotting with an end mill is a demanding operation. Learn how to choose the right depth of cut for peripheral and slotting milling operations, and how to apply high efficiency milling (hem) strategies for improved productivity and tool life. All cutting data are target values.. End Mill Width Of Cut.

From www.qualitytechtool.com

General Purpose End Mills Inch Quality Tech Tool End Mill Width Of Cut A typical end mill removes material from the side and along its end face. Find out the definitions, examples, and tips for radial and axial depth of cut, and access a free webinar on hem. Feed to be reduced by approximately 50% if loc (length of cut) is over. Finish cuts typically require reduced feed rates. Hence, there is a. End Mill Width Of Cut.

From www.redlinetools.com

Endmill Selection Guide RedLine Tools Redline Tools End Mill Width Of Cut End mills, htpm, speeds and feeds, slotting and side cutting, metric. Learn how to choose the right depth of cut for peripheral and slotting milling operations, and how to apply high efficiency milling (hem) strategies for improved productivity and tool life. Full slotting with an end mill is a demanding operation. All cutting data are target values. A typical end. End Mill Width Of Cut.

From mavink.com

Standard End Mill Sizes Chart End Mill Width Of Cut All cutting data are target values. Hence, there is a depth and a width of cut, and these parameters are generally known as axial depth. Feed to be reduced by approximately 50% if loc (length of cut) is over. End mills, htpm, speeds and feeds, slotting and side cutting, metric. The axial cutting depth should be generally reduced to around. End Mill Width Of Cut.

From makezine.com

6 Essential End Mills for Your CNC Machine Make End Mill Width Of Cut All cutting data are target values. End mills, htpm, speeds and feeds, slotting and side cutting, metric. A typical end mill removes material from the side and along its end face. The axial cutting depth should be generally reduced to around 70% of the edge length. Machine rigidity and chip evacuation should also be. Learn how to choose the right. End Mill Width Of Cut.

From support.bantamtools.com

End Mill Identification Guide Bantam Tools End Mill Width Of Cut Machine rigidity and chip evacuation should also be. End mills, htpm, speeds and feeds, slotting and side cutting, metric. Finish cuts typically require reduced feed rates. Feed to be reduced by approximately 50% if loc (length of cut) is over. Hence, there is a depth and a width of cut, and these parameters are generally known as axial depth. Find. End Mill Width Of Cut.

From www.speedtigertools.com

End Mill Size Standards Chart & IntroductionSPEED TIGER End Mill Width Of Cut Learn how to choose the right depth of cut for peripheral and slotting milling operations, and how to apply high efficiency milling (hem) strategies for improved productivity and tool life. Find out the definitions, examples, and tips for radial and axial depth of cut, and access a free webinar on hem. Full slotting with an end mill is a demanding. End Mill Width Of Cut.

From enginemechanics.tpub.com

Figure 735.End mill terms. End Mill Width Of Cut Full slotting with an end mill is a demanding operation. Hence, there is a depth and a width of cut, and these parameters are generally known as axial depth. Finish cuts typically require reduced feed rates. End mills, htpm, speeds and feeds, slotting and side cutting, metric. A typical end mill removes material from the side and along its end. End Mill Width Of Cut.

From www.speedtigertools.com

End Mill Cutting & End Milling Technical Guide End Mill Width Of Cut End mills, htpm, speeds and feeds, slotting and side cutting, metric. Full slotting with an end mill is a demanding operation. Finish cuts typically require reduced feed rates. Feed to be reduced by approximately 50% if loc (length of cut) is over. All cutting data are target values. Machine rigidity and chip evacuation should also be. Hence, there is a. End Mill Width Of Cut.

From www.slideserve.com

PPT ME 350 Lecture 5 Chapter 22 & 23 PowerPoint Presentation ID End Mill Width Of Cut Full slotting with an end mill is a demanding operation. The axial cutting depth should be generally reduced to around 70% of the edge length. End mills, htpm, speeds and feeds, slotting and side cutting, metric. Hence, there is a depth and a width of cut, and these parameters are generally known as axial depth. All cutting data are target. End Mill Width Of Cut.

From toolnotes.com

End Mills ToolNotes End Mill Width Of Cut Feed to be reduced by approximately 50% if loc (length of cut) is over. Full slotting with an end mill is a demanding operation. All cutting data are target values. Finish cuts typically require reduced feed rates. Hence, there is a depth and a width of cut, and these parameters are generally known as axial depth. Machine rigidity and chip. End Mill Width Of Cut.

From www.mmc-carbide.com

End Mill Terminology Technical Info / Cutting Formula MITSUBISHI End Mill Width Of Cut Finish cuts typically require reduced feed rates. Hence, there is a depth and a width of cut, and these parameters are generally known as axial depth. Full slotting with an end mill is a demanding operation. Find out the definitions, examples, and tips for radial and axial depth of cut, and access a free webinar on hem. Machine rigidity and. End Mill Width Of Cut.

From toolnotes.com

End Mills ToolNotes End Mill Width Of Cut Finish cuts typically require reduced feed rates. End mills, htpm, speeds and feeds, slotting and side cutting, metric. Find out the definitions, examples, and tips for radial and axial depth of cut, and access a free webinar on hem. Hence, there is a depth and a width of cut, and these parameters are generally known as axial depth. The axial. End Mill Width Of Cut.

From toolnotes.com

Cutting Parameters for Milling ToolNotes End Mill Width Of Cut Machine rigidity and chip evacuation should also be. Finish cuts typically require reduced feed rates. Find out the definitions, examples, and tips for radial and axial depth of cut, and access a free webinar on hem. A typical end mill removes material from the side and along its end face. Full slotting with an end mill is a demanding operation.. End Mill Width Of Cut.

From www.harveyperformance.com

The Anatomy of an End Mill In The Loupe End Mill Width Of Cut Full slotting with an end mill is a demanding operation. Learn how to choose the right depth of cut for peripheral and slotting milling operations, and how to apply high efficiency milling (hem) strategies for improved productivity and tool life. Find out the definitions, examples, and tips for radial and axial depth of cut, and access a free webinar on. End Mill Width Of Cut.

From femjoy-virtuagirl-hd-25.blogspot.com

roughing end mill depth of cut Big History Blogger Photography End Mill Width Of Cut All cutting data are target values. Find out the definitions, examples, and tips for radial and axial depth of cut, and access a free webinar on hem. A typical end mill removes material from the side and along its end face. Machine rigidity and chip evacuation should also be. Learn how to choose the right depth of cut for peripheral. End Mill Width Of Cut.

From www.cnccookbook.com

Ball Nose End Mill [Easy Guide to Ball Cutters] CNCCookbook Be A End Mill Width Of Cut Find out the definitions, examples, and tips for radial and axial depth of cut, and access a free webinar on hem. Feed to be reduced by approximately 50% if loc (length of cut) is over. Full slotting with an end mill is a demanding operation. Hence, there is a depth and a width of cut, and these parameters are generally. End Mill Width Of Cut.

From www.qualitytechtool.com

General Purpose End Mills Inch Quality Tech Tool End Mill Width Of Cut Find out the definitions, examples, and tips for radial and axial depth of cut, and access a free webinar on hem. All cutting data are target values. Hence, there is a depth and a width of cut, and these parameters are generally known as axial depth. A typical end mill removes material from the side and along its end face.. End Mill Width Of Cut.

From huanatools.com

what is an end mill and how to make an end mill Huana Tools End Mill Width Of Cut Feed to be reduced by approximately 50% if loc (length of cut) is over. The axial cutting depth should be generally reduced to around 70% of the edge length. Learn how to choose the right depth of cut for peripheral and slotting milling operations, and how to apply high efficiency milling (hem) strategies for improved productivity and tool life. A. End Mill Width Of Cut.

From thegodalmingpost.blogspot.com

end mill types and uses Best Bit EZine Fonction End Mill Width Of Cut Learn how to choose the right depth of cut for peripheral and slotting milling operations, and how to apply high efficiency milling (hem) strategies for improved productivity and tool life. A typical end mill removes material from the side and along its end face. Machine rigidity and chip evacuation should also be. The axial cutting depth should be generally reduced. End Mill Width Of Cut.

From www.harveyperformance.com

The Anatomy of an End Mill In The Loupe End Mill Width Of Cut Machine rigidity and chip evacuation should also be. Learn how to choose the right depth of cut for peripheral and slotting milling operations, and how to apply high efficiency milling (hem) strategies for improved productivity and tool life. The axial cutting depth should be generally reduced to around 70% of the edge length. End mills, htpm, speeds and feeds, slotting. End Mill Width Of Cut.

From indotech-group.co.id

End Mill Ketahui Jenis Jenis End Mill Indotech Trimitra Abadi End Mill Width Of Cut All cutting data are target values. Learn how to choose the right depth of cut for peripheral and slotting milling operations, and how to apply high efficiency milling (hem) strategies for improved productivity and tool life. Hence, there is a depth and a width of cut, and these parameters are generally known as axial depth. Finish cuts typically require reduced. End Mill Width Of Cut.

From www.penntoolco.com

The Basic Types of End Mills Used in Milling Penn Tool Co., Inc End Mill Width Of Cut Full slotting with an end mill is a demanding operation. The axial cutting depth should be generally reduced to around 70% of the edge length. A typical end mill removes material from the side and along its end face. Learn how to choose the right depth of cut for peripheral and slotting milling operations, and how to apply high efficiency. End Mill Width Of Cut.

From www.practicalmachinist.com

depth and width of cut on a shoulder mill End Mill Width Of Cut A typical end mill removes material from the side and along its end face. Finish cuts typically require reduced feed rates. Find out the definitions, examples, and tips for radial and axial depth of cut, and access a free webinar on hem. Machine rigidity and chip evacuation should also be. Learn how to choose the right depth of cut for. End Mill Width Of Cut.

From www.peaktoolworks.com

Standard Length Endmills (Ball End) Peak Toolworks End Mill Width Of Cut End mills, htpm, speeds and feeds, slotting and side cutting, metric. All cutting data are target values. Learn how to choose the right depth of cut for peripheral and slotting milling operations, and how to apply high efficiency milling (hem) strategies for improved productivity and tool life. Hence, there is a depth and a width of cut, and these parameters. End Mill Width Of Cut.

From huanatools.com

what is an end mill and how to make an end mill Huana Tools End Mill Width Of Cut Machine rigidity and chip evacuation should also be. Hence, there is a depth and a width of cut, and these parameters are generally known as axial depth. A typical end mill removes material from the side and along its end face. The axial cutting depth should be generally reduced to around 70% of the edge length. Learn how to choose. End Mill Width Of Cut.