Eddy Current Testing On Steel . A method of inspection used to check for corrosion under insulation (cui) is referred to as pulsed eddy current testing (pect). Eddy current method based on the reverse magnetostrictive effect (villari effect) can be applied for estimation of applied and residual. Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. It allows for the inspection of materials without the need for direct contact with carbon steel structures, including pipes, vessels, tanks, and spherical tank legs. Pulsed eddy current testing (pect) is an inspection technique used for corrosion under insulation (cui) screening on carbon steel. Cold rolling of austenitic stainless steel results in increase of residual stresses, hardness, and tensile strength and dislocation density.

from sonats-et.com

Eddy current method based on the reverse magnetostrictive effect (villari effect) can be applied for estimation of applied and residual. Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. It allows for the inspection of materials without the need for direct contact with carbon steel structures, including pipes, vessels, tanks, and spherical tank legs. Pulsed eddy current testing (pect) is an inspection technique used for corrosion under insulation (cui) screening on carbon steel. Cold rolling of austenitic stainless steel results in increase of residual stresses, hardness, and tensile strength and dislocation density. A method of inspection used to check for corrosion under insulation (cui) is referred to as pulsed eddy current testing (pect).

Eddy current testing for residual stress measurements (NDT) SONATS

Eddy Current Testing On Steel A method of inspection used to check for corrosion under insulation (cui) is referred to as pulsed eddy current testing (pect). Pulsed eddy current testing (pect) is an inspection technique used for corrosion under insulation (cui) screening on carbon steel. Eddy current method based on the reverse magnetostrictive effect (villari effect) can be applied for estimation of applied and residual. Cold rolling of austenitic stainless steel results in increase of residual stresses, hardness, and tensile strength and dislocation density. Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. It allows for the inspection of materials without the need for direct contact with carbon steel structures, including pipes, vessels, tanks, and spherical tank legs. A method of inspection used to check for corrosion under insulation (cui) is referred to as pulsed eddy current testing (pect).

From www.mechanicalconceptsllc.com

Eddy Current Testing Mechanical Concepts Eddy Current Testing On Steel Cold rolling of austenitic stainless steel results in increase of residual stresses, hardness, and tensile strength and dislocation density. It allows for the inspection of materials without the need for direct contact with carbon steel structures, including pipes, vessels, tanks, and spherical tank legs. Pulsed eddy current testing (pect) is an inspection technique used for corrosion under insulation (cui) screening. Eddy Current Testing On Steel.

From eurotubi.it

Eddy Current Testing of Tubes Eurotubi Eddy Current Testing On Steel Pulsed eddy current testing (pect) is an inspection technique used for corrosion under insulation (cui) screening on carbon steel. Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. Eddy current method based on the reverse magnetostrictive effect (villari effect) can be applied for estimation of applied and residual. A method of inspection. Eddy Current Testing On Steel.

From www.titanmf.com

QCEddyCurrentTesting TITAN Metal Fabricators Eddy Current Testing On Steel It allows for the inspection of materials without the need for direct contact with carbon steel structures, including pipes, vessels, tanks, and spherical tank legs. A method of inspection used to check for corrosion under insulation (cui) is referred to as pulsed eddy current testing (pect). Eddy currents are fields of alternating magnetic current that are created when an alternating. Eddy Current Testing On Steel.

From www.twi-global.com

Eddy Current Testing A Definitive Guide (Includes Eddy Current Array Eddy Current Testing On Steel A method of inspection used to check for corrosion under insulation (cui) is referred to as pulsed eddy current testing (pect). Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. It allows for the inspection of materials without the need for direct contact with carbon steel structures, including pipes, vessels, tanks, and. Eddy Current Testing On Steel.

From www.nickelalloyworld.com

News NDT Method Eddy Current Testing Eddy Current Testing On Steel Eddy current method based on the reverse magnetostrictive effect (villari effect) can be applied for estimation of applied and residual. A method of inspection used to check for corrosion under insulation (cui) is referred to as pulsed eddy current testing (pect). It allows for the inspection of materials without the need for direct contact with carbon steel structures, including pipes,. Eddy Current Testing On Steel.

From dxobsbges.blob.core.windows.net

Eddy Current Weld Inspection Procedure at Joseph Wheeler blog Eddy Current Testing On Steel It allows for the inspection of materials without the need for direct contact with carbon steel structures, including pipes, vessels, tanks, and spherical tank legs. Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. Pulsed eddy current testing (pect) is an inspection technique used for corrosion under insulation (cui) screening on carbon. Eddy Current Testing On Steel.

From www.steelseamlesspipe.com

Stainless Steel U Bend Tube , 100 Eddy Current Test & Hydrostatic Test Eddy Current Testing On Steel A method of inspection used to check for corrosion under insulation (cui) is referred to as pulsed eddy current testing (pect). It allows for the inspection of materials without the need for direct contact with carbon steel structures, including pipes, vessels, tanks, and spherical tank legs. Eddy current method based on the reverse magnetostrictive effect (villari effect) can be applied. Eddy Current Testing On Steel.

From www.theseverngroup.com

Eddy Current Testing 101 The Severn Group Eddy Current Testing On Steel A method of inspection used to check for corrosion under insulation (cui) is referred to as pulsed eddy current testing (pect). Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. It allows for the inspection of materials without the need for direct contact with carbon steel structures, including pipes, vessels, tanks, and. Eddy Current Testing On Steel.

From www.youtube.com

Pulsed Eddy Current on Finned Tube YouTube Eddy Current Testing On Steel Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. A method of inspection used to check for corrosion under insulation (cui) is referred to as pulsed eddy current testing (pect). Eddy current method based on the reverse magnetostrictive effect (villari effect) can be applied for estimation of applied and residual. It allows. Eddy Current Testing On Steel.

From tiat.nl

Eddy Current Testing Tiat Europe B.V. Eddy Current Testing On Steel It allows for the inspection of materials without the need for direct contact with carbon steel structures, including pipes, vessels, tanks, and spherical tank legs. A method of inspection used to check for corrosion under insulation (cui) is referred to as pulsed eddy current testing (pect). Eddy current method based on the reverse magnetostrictive effect (villari effect) can be applied. Eddy Current Testing On Steel.

From www.nde-solutions.com

Eddy Current Testing NDE Solutions Eddy Current Testing On Steel It allows for the inspection of materials without the need for direct contact with carbon steel structures, including pipes, vessels, tanks, and spherical tank legs. Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. A method of inspection used to check for corrosion under insulation (cui) is referred to as pulsed eddy. Eddy Current Testing On Steel.

From www.sumico.com.pk

Eddy Current Testing Service Eddy Current Testing On Steel Pulsed eddy current testing (pect) is an inspection technique used for corrosion under insulation (cui) screening on carbon steel. Eddy current method based on the reverse magnetostrictive effect (villari effect) can be applied for estimation of applied and residual. It allows for the inspection of materials without the need for direct contact with carbon steel structures, including pipes, vessels, tanks,. Eddy Current Testing On Steel.

From joicmatbn.blob.core.windows.net

Thickness Measurement Using Eddy Current at Michael Bjorklund blog Eddy Current Testing On Steel Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. Pulsed eddy current testing (pect) is an inspection technique used for corrosion under insulation (cui) screening on carbon steel. A method of inspection used to check for corrosion under insulation (cui) is referred to as pulsed eddy current testing (pect). It allows for. Eddy Current Testing On Steel.

From www.bharatagritech.com

Variables That Affect The Eddy Current Testing Procedure, 47 OFF Eddy Current Testing On Steel Eddy current method based on the reverse magnetostrictive effect (villari effect) can be applied for estimation of applied and residual. Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. Cold rolling of austenitic stainless steel results in increase of residual stresses, hardness, and tensile strength and dislocation density. It allows for the. Eddy Current Testing On Steel.

From www.valencesurfacetech.com

Eddy Current Testing Methods Valence Surface Technologies Eddy Current Testing On Steel Pulsed eddy current testing (pect) is an inspection technique used for corrosion under insulation (cui) screening on carbon steel. Eddy current method based on the reverse magnetostrictive effect (villari effect) can be applied for estimation of applied and residual. A method of inspection used to check for corrosion under insulation (cui) is referred to as pulsed eddy current testing (pect).. Eddy Current Testing On Steel.

From www.tec-science.com

Eddy current testing (ECT) tecscience Eddy Current Testing On Steel Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. It allows for the inspection of materials without the need for direct contact with carbon steel structures, including pipes, vessels, tanks, and spherical tank legs. Cold rolling of austenitic stainless steel results in increase of residual stresses, hardness, and tensile strength and dislocation. Eddy Current Testing On Steel.

From sonats-et.com

Eddy current testing for residual stress measurements (NDT) SONATS Eddy Current Testing On Steel Cold rolling of austenitic stainless steel results in increase of residual stresses, hardness, and tensile strength and dislocation density. Pulsed eddy current testing (pect) is an inspection technique used for corrosion under insulation (cui) screening on carbon steel. A method of inspection used to check for corrosion under insulation (cui) is referred to as pulsed eddy current testing (pect). Eddy. Eddy Current Testing On Steel.

From www.innerspec.com

Eddy Current Technology Eddy Current Testing On Steel Pulsed eddy current testing (pect) is an inspection technique used for corrosion under insulation (cui) screening on carbon steel. Cold rolling of austenitic stainless steel results in increase of residual stresses, hardness, and tensile strength and dislocation density. Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. Eddy current method based on. Eddy Current Testing On Steel.

From www.qualitymag.com

What Can Eddy Current Testing Do for Me? Quality Magazine Eddy Current Testing On Steel A method of inspection used to check for corrosion under insulation (cui) is referred to as pulsed eddy current testing (pect). Pulsed eddy current testing (pect) is an inspection technique used for corrosion under insulation (cui) screening on carbon steel. Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. Eddy current method. Eddy Current Testing On Steel.

From www.mdpi.com

Sensors Free FullText NonDestructive Testing Using Eddy Current Eddy Current Testing On Steel A method of inspection used to check for corrosion under insulation (cui) is referred to as pulsed eddy current testing (pect). Eddy current method based on the reverse magnetostrictive effect (villari effect) can be applied for estimation of applied and residual. Pulsed eddy current testing (pect) is an inspection technique used for corrosion under insulation (cui) screening on carbon steel.. Eddy Current Testing On Steel.

From www.tcsndt.com.au

Eddy Current Testing TCS NDT Eddy Current Testing On Steel Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. Cold rolling of austenitic stainless steel results in increase of residual stresses, hardness, and tensile strength and dislocation density. A method of inspection used to check for corrosion under insulation (cui) is referred to as pulsed eddy current testing (pect). Pulsed eddy current. Eddy Current Testing On Steel.

From www.researchgate.net

Two types of eddy current signals viz. Impedance plane (XY) and Eddy Current Testing On Steel A method of inspection used to check for corrosion under insulation (cui) is referred to as pulsed eddy current testing (pect). Cold rolling of austenitic stainless steel results in increase of residual stresses, hardness, and tensile strength and dislocation density. It allows for the inspection of materials without the need for direct contact with carbon steel structures, including pipes, vessels,. Eddy Current Testing On Steel.

From blog.foerstergroup.com

Crack testing How does an eddy current test instrument work? Eddy Current Testing On Steel Eddy current method based on the reverse magnetostrictive effect (villari effect) can be applied for estimation of applied and residual. Pulsed eddy current testing (pect) is an inspection technique used for corrosion under insulation (cui) screening on carbon steel. It allows for the inspection of materials without the need for direct contact with carbon steel structures, including pipes, vessels, tanks,. Eddy Current Testing On Steel.

From www.triquestndt.com

Pulsed Eddy Current Inspection (PEC) Eddy Current Testing On Steel A method of inspection used to check for corrosion under insulation (cui) is referred to as pulsed eddy current testing (pect). Eddy current method based on the reverse magnetostrictive effect (villari effect) can be applied for estimation of applied and residual. It allows for the inspection of materials without the need for direct contact with carbon steel structures, including pipes,. Eddy Current Testing On Steel.

From www.researchgate.net

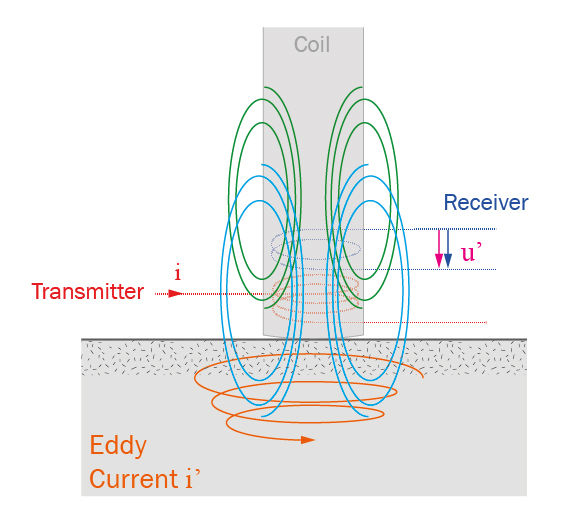

Schematic Eddy currents distribution under a coil on top of a Eddy Current Testing On Steel Cold rolling of austenitic stainless steel results in increase of residual stresses, hardness, and tensile strength and dislocation density. Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. Eddy current method based on the reverse magnetostrictive effect (villari effect) can be applied for estimation of applied and residual. A method of inspection. Eddy Current Testing On Steel.

From ndtblog-us.fujifilm.com

Complete Guide to Eddy Current Testing Fujifilm NDT Eddy Current Testing On Steel Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. Eddy current method based on the reverse magnetostrictive effect (villari effect) can be applied for estimation of applied and residual. It allows for the inspection of materials without the need for direct contact with carbon steel structures, including pipes, vessels, tanks, and spherical. Eddy Current Testing On Steel.

From www.eddyfi.com

Pulsed Eddy Current (PEC) Eddy Current Testing On Steel Cold rolling of austenitic stainless steel results in increase of residual stresses, hardness, and tensile strength and dislocation density. It allows for the inspection of materials without the need for direct contact with carbon steel structures, including pipes, vessels, tanks, and spherical tank legs. Pulsed eddy current testing (pect) is an inspection technique used for corrosion under insulation (cui) screening. Eddy Current Testing On Steel.

From www.onestopndt.com

Applications of Eddy Current Testing OnestopNDT Eddy Current Testing On Steel Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. It allows for the inspection of materials without the need for direct contact with carbon steel structures, including pipes, vessels, tanks, and spherical tank legs. Eddy current method based on the reverse magnetostrictive effect (villari effect) can be applied for estimation of applied. Eddy Current Testing On Steel.

From www.youtube.com

NDT test. IRIS Test. Eddy current test. ECT. RFET. NFT.Shutdown Eddy Current Testing On Steel It allows for the inspection of materials without the need for direct contact with carbon steel structures, including pipes, vessels, tanks, and spherical tank legs. Cold rolling of austenitic stainless steel results in increase of residual stresses, hardness, and tensile strength and dislocation density. Pulsed eddy current testing (pect) is an inspection technique used for corrosion under insulation (cui) screening. Eddy Current Testing On Steel.

From www.ndt.com.ua

Eddy current testing of rails Eddy Current Testing On Steel Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. A method of inspection used to check for corrosion under insulation (cui) is referred to as pulsed eddy current testing (pect). Pulsed eddy current testing (pect) is an inspection technique used for corrosion under insulation (cui) screening on carbon steel. Cold rolling of. Eddy Current Testing On Steel.

From wardvesselandexchanger.com

NonDestructive Testing Methods Eddy Current Testing Ward Vessel and Eddy Current Testing On Steel Eddy current method based on the reverse magnetostrictive effect (villari effect) can be applied for estimation of applied and residual. Pulsed eddy current testing (pect) is an inspection technique used for corrosion under insulation (cui) screening on carbon steel. Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. Cold rolling of austenitic. Eddy Current Testing On Steel.

From www.michlinmetals.com

Eddy Current Testing Metal and Steel Testing NDE Michlin Metals Eddy Current Testing On Steel Pulsed eddy current testing (pect) is an inspection technique used for corrosion under insulation (cui) screening on carbon steel. It allows for the inspection of materials without the need for direct contact with carbon steel structures, including pipes, vessels, tanks, and spherical tank legs. A method of inspection used to check for corrosion under insulation (cui) is referred to as. Eddy Current Testing On Steel.

From www.tec-science.com

Eddy current testing (ECT) tecscience Eddy Current Testing On Steel Cold rolling of austenitic stainless steel results in increase of residual stresses, hardness, and tensile strength and dislocation density. Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. Eddy current method based on the reverse magnetostrictive effect (villari effect) can be applied for estimation of applied and residual. It allows for the. Eddy Current Testing On Steel.

From www.youtube.com

Stainless Steel Tube Eddy Current Inspection YouTube Eddy Current Testing On Steel A method of inspection used to check for corrosion under insulation (cui) is referred to as pulsed eddy current testing (pect). Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. Pulsed eddy current testing (pect) is an inspection technique used for corrosion under insulation (cui) screening on carbon steel. It allows for. Eddy Current Testing On Steel.

From www.foerstergroup.com

Eddy current testing Institut Dr. Foerster GmbH und Co. KG Eddy Current Testing On Steel Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. Pulsed eddy current testing (pect) is an inspection technique used for corrosion under insulation (cui) screening on carbon steel. Cold rolling of austenitic stainless steel results in increase of residual stresses, hardness, and tensile strength and dislocation density. Eddy current method based on. Eddy Current Testing On Steel.