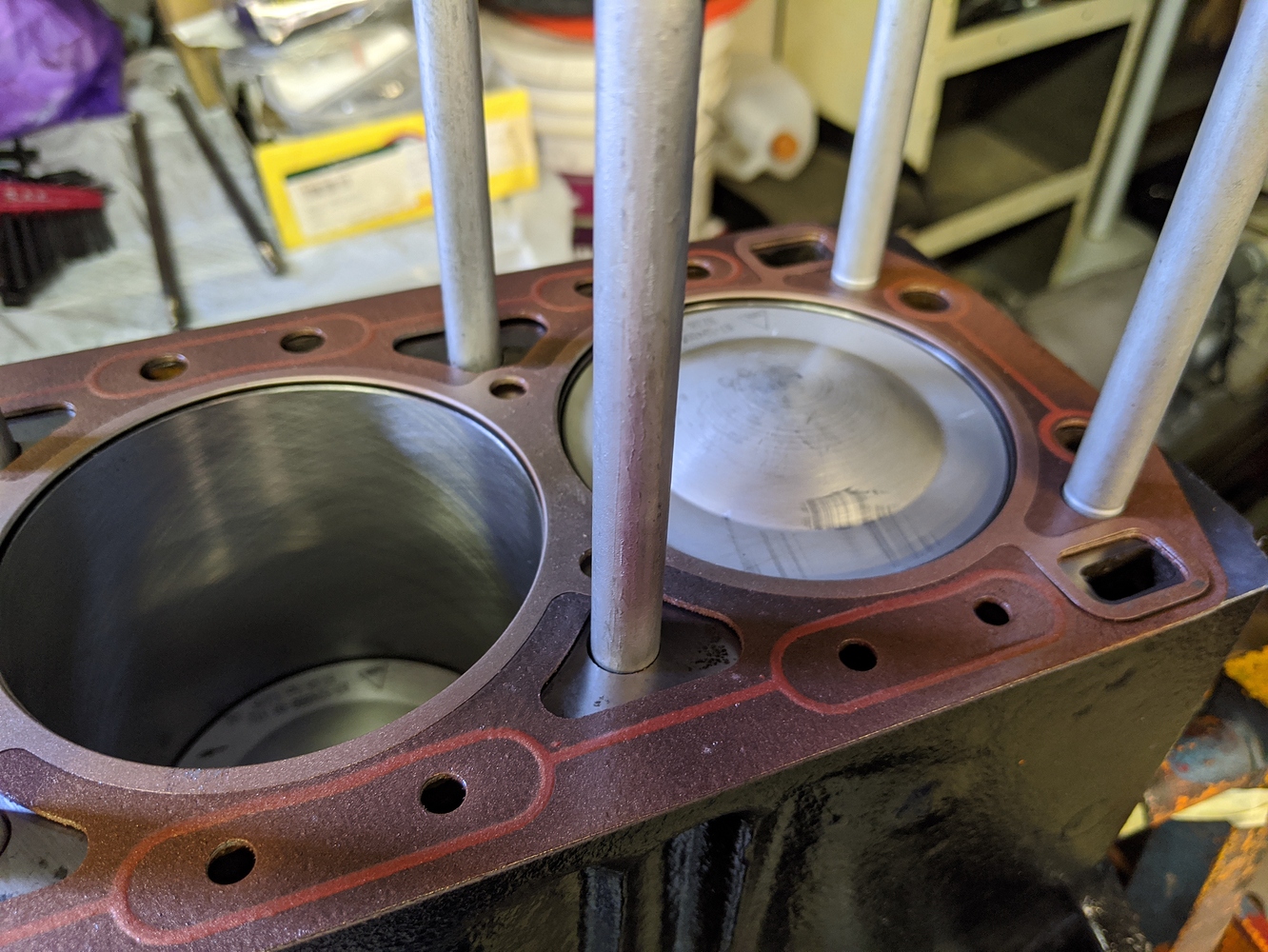

Engine Block Surface Stone . Is there any scenario where a scratch on the engine block surface does not require a (another) milling down? It works only because you can fit the whole block on the sanding surface. Put oil on the surface and stone and just glide. I read that copper spray can be used on the c/head gasket for super tiny. To prep gasket surfaces like this i use a large sharpening stone to make sure i've got a good sealing surface with no bumps or burrs. If the block were 3 x 3 and i had a 1/2 sanding strip, it'd be pointless as i'd never get a uniform finish. Did every engine head come off need resurface head and block before rebolt the head? Fill in the gap between block and pistons with clean grease, then if any bits go on it you can turn the engine over a tad and wipe it off.

from forums.jag-lovers.com

It works only because you can fit the whole block on the sanding surface. To prep gasket surfaces like this i use a large sharpening stone to make sure i've got a good sealing surface with no bumps or burrs. Put oil on the surface and stone and just glide. Did every engine head come off need resurface head and block before rebolt the head? I read that copper spray can be used on the c/head gasket for super tiny. Is there any scenario where a scratch on the engine block surface does not require a (another) milling down? If the block were 3 x 3 and i had a 1/2 sanding strip, it'd be pointless as i'd never get a uniform finish. Fill in the gap between block and pistons with clean grease, then if any bits go on it you can turn the engine over a tad and wipe it off.

Scratched engine block surface after machine work XKEngine Jag

Engine Block Surface Stone Fill in the gap between block and pistons with clean grease, then if any bits go on it you can turn the engine over a tad and wipe it off. Put oil on the surface and stone and just glide. Is there any scenario where a scratch on the engine block surface does not require a (another) milling down? If the block were 3 x 3 and i had a 1/2 sanding strip, it'd be pointless as i'd never get a uniform finish. To prep gasket surfaces like this i use a large sharpening stone to make sure i've got a good sealing surface with no bumps or burrs. Fill in the gap between block and pistons with clean grease, then if any bits go on it you can turn the engine over a tad and wipe it off. I read that copper spray can be used on the c/head gasket for super tiny. Did every engine head come off need resurface head and block before rebolt the head? It works only because you can fit the whole block on the sanding surface.

From www.pinterest.com

How do you grow metal engine blocks from powder, and then CNC machine Engine Block Surface Stone To prep gasket surfaces like this i use a large sharpening stone to make sure i've got a good sealing surface with no bumps or burrs. Is there any scenario where a scratch on the engine block surface does not require a (another) milling down? Put oil on the surface and stone and just glide. Fill in the gap between. Engine Block Surface Stone.

From www.cottandco.com

Granite Surface Block 8” x 12” Engine Block Surface Stone I read that copper spray can be used on the c/head gasket for super tiny. If the block were 3 x 3 and i had a 1/2 sanding strip, it'd be pointless as i'd never get a uniform finish. Did every engine head come off need resurface head and block before rebolt the head? To prep gasket surfaces like this. Engine Block Surface Stone.

From www.youtube.com

SURFACING AN ENGINE BLOCK YouTube Engine Block Surface Stone If the block were 3 x 3 and i had a 1/2 sanding strip, it'd be pointless as i'd never get a uniform finish. I read that copper spray can be used on the c/head gasket for super tiny. Is there any scenario where a scratch on the engine block surface does not require a (another) milling down? It works. Engine Block Surface Stone.

From forums.jag-lovers.com

Scratched engine block surface after machine work XKEngine Jag Engine Block Surface Stone Fill in the gap between block and pistons with clean grease, then if any bits go on it you can turn the engine over a tad and wipe it off. To prep gasket surfaces like this i use a large sharpening stone to make sure i've got a good sealing surface with no bumps or burrs. Put oil on the. Engine Block Surface Stone.

From forums.jag-lovers.com

Scratched engine block surface after machine work XKEngine Jag Engine Block Surface Stone I read that copper spray can be used on the c/head gasket for super tiny. Put oil on the surface and stone and just glide. Did every engine head come off need resurface head and block before rebolt the head? If the block were 3 x 3 and i had a 1/2 sanding strip, it'd be pointless as i'd never. Engine Block Surface Stone.

From www.researchgate.net

The surface of the engine block machined. Download Scientific Diagram Engine Block Surface Stone Did every engine head come off need resurface head and block before rebolt the head? To prep gasket surfaces like this i use a large sharpening stone to make sure i've got a good sealing surface with no bumps or burrs. Fill in the gap between block and pistons with clean grease, then if any bits go on it you. Engine Block Surface Stone.

From eleymet.com

What are Surface Plates A Beginners Guide Eley Metrology Engine Block Surface Stone To prep gasket surfaces like this i use a large sharpening stone to make sure i've got a good sealing surface with no bumps or burrs. Fill in the gap between block and pistons with clean grease, then if any bits go on it you can turn the engine over a tad and wipe it off. It works only because. Engine Block Surface Stone.

From www.youtube.com

R9M & OM626 Checking of Engine block surface Piston protrusion Engine Block Surface Stone I read that copper spray can be used on the c/head gasket for super tiny. It works only because you can fit the whole block on the sanding surface. Put oil on the surface and stone and just glide. Is there any scenario where a scratch on the engine block surface does not require a (another) milling down? If the. Engine Block Surface Stone.

From www.enginelabs.com

Hit The Deck What You Should Know About Engine Block Deck Height Engine Block Surface Stone If the block were 3 x 3 and i had a 1/2 sanding strip, it'd be pointless as i'd never get a uniform finish. I read that copper spray can be used on the c/head gasket for super tiny. Did every engine head come off need resurface head and block before rebolt the head? It works only because you can. Engine Block Surface Stone.

From forums.jag-lovers.com

Scratched engine block surface after machine work XKEngine Jag Engine Block Surface Stone If the block were 3 x 3 and i had a 1/2 sanding strip, it'd be pointless as i'd never get a uniform finish. To prep gasket surfaces like this i use a large sharpening stone to make sure i've got a good sealing surface with no bumps or burrs. Put oil on the surface and stone and just glide.. Engine Block Surface Stone.

From forums.jag-lovers.com

Scratched engine block surface after machine work XKEngine Jag Engine Block Surface Stone It works only because you can fit the whole block on the sanding surface. Put oil on the surface and stone and just glide. Did every engine head come off need resurface head and block before rebolt the head? Is there any scenario where a scratch on the engine block surface does not require a (another) milling down? I read. Engine Block Surface Stone.

From prorace-engineering.co.uk

Block Deck Surface Skimmed/Ground ProRace Engineering Engine Block Surface Stone I read that copper spray can be used on the c/head gasket for super tiny. If the block were 3 x 3 and i had a 1/2 sanding strip, it'd be pointless as i'd never get a uniform finish. To prep gasket surfaces like this i use a large sharpening stone to make sure i've got a good sealing surface. Engine Block Surface Stone.

From www.youtube.com

My Best Method For Cleaning Head Gasket & Other Engine Surfaces YouTube Engine Block Surface Stone If the block were 3 x 3 and i had a 1/2 sanding strip, it'd be pointless as i'd never get a uniform finish. I read that copper spray can be used on the c/head gasket for super tiny. Put oil on the surface and stone and just glide. It works only because you can fit the whole block on. Engine Block Surface Stone.

From forums.jag-lovers.com

Scratched engine block surface after machine work XKEngine Jag Engine Block Surface Stone I read that copper spray can be used on the c/head gasket for super tiny. Put oil on the surface and stone and just glide. Is there any scenario where a scratch on the engine block surface does not require a (another) milling down? To prep gasket surfaces like this i use a large sharpening stone to make sure i've. Engine Block Surface Stone.

From www.youtube.com

Cleaning head gasket surfaces YouTube Engine Block Surface Stone To prep gasket surfaces like this i use a large sharpening stone to make sure i've got a good sealing surface with no bumps or burrs. I read that copper spray can be used on the c/head gasket for super tiny. Did every engine head come off need resurface head and block before rebolt the head? If the block were. Engine Block Surface Stone.

From enginelisttamara.z13.web.core.windows.net

Engine Block Diagnosis And Repair Engine Block Surface Stone It works only because you can fit the whole block on the sanding surface. Fill in the gap between block and pistons with clean grease, then if any bits go on it you can turn the engine over a tad and wipe it off. I read that copper spray can be used on the c/head gasket for super tiny. Is. Engine Block Surface Stone.

From www.youtube.com

Cylinder Head and Block Surface Finish Jay's Tech Tips 18 YouTube Engine Block Surface Stone I read that copper spray can be used on the c/head gasket for super tiny. It works only because you can fit the whole block on the sanding surface. To prep gasket surfaces like this i use a large sharpening stone to make sure i've got a good sealing surface with no bumps or burrs. Did every engine head come. Engine Block Surface Stone.

From www.slideserve.com

PPT CHAPTER 30 ENGINE BLOCKS PowerPoint Presentation ID5736315 Engine Block Surface Stone I read that copper spray can be used on the c/head gasket for super tiny. Did every engine head come off need resurface head and block before rebolt the head? Is there any scenario where a scratch on the engine block surface does not require a (another) milling down? If the block were 3 x 3 and i had a. Engine Block Surface Stone.

From forums.jag-lovers.com

Scratched engine block surface after machine work XKEngine Jag Engine Block Surface Stone Did every engine head come off need resurface head and block before rebolt the head? If the block were 3 x 3 and i had a 1/2 sanding strip, it'd be pointless as i'd never get a uniform finish. It works only because you can fit the whole block on the sanding surface. I read that copper spray can be. Engine Block Surface Stone.

From forums.jag-lovers.com

Scratched engine block surface after machine work XKEngine Jag Engine Block Surface Stone I read that copper spray can be used on the c/head gasket for super tiny. To prep gasket surfaces like this i use a large sharpening stone to make sure i've got a good sealing surface with no bumps or burrs. Put oil on the surface and stone and just glide. Did every engine head come off need resurface head. Engine Block Surface Stone.

From clevershieldcoatings.co.uk

Resimac Maintenance, Repair & Overhaul Solutions Engine Block Surface Stone Did every engine head come off need resurface head and block before rebolt the head? Is there any scenario where a scratch on the engine block surface does not require a (another) milling down? Put oil on the surface and stone and just glide. Fill in the gap between block and pistons with clean grease, then if any bits go. Engine Block Surface Stone.

From forums.fourtitude.com

How to Clean Engine Block Surface For MLS Gaskets? Engine Block Surface Stone If the block were 3 x 3 and i had a 1/2 sanding strip, it'd be pointless as i'd never get a uniform finish. Fill in the gap between block and pistons with clean grease, then if any bits go on it you can turn the engine over a tad and wipe it off. Is there any scenario where a. Engine Block Surface Stone.

From workshopfixoharadowp.z21.web.core.windows.net

Remove Surface Rust From Engine Block Engine Block Surface Stone I read that copper spray can be used on the c/head gasket for super tiny. It works only because you can fit the whole block on the sanding surface. Is there any scenario where a scratch on the engine block surface does not require a (another) milling down? Did every engine head come off need resurface head and block before. Engine Block Surface Stone.

From www.onallcylinders.com

Video How to Check Your Cylinder Head Surface for Flatness or Warping Engine Block Surface Stone Put oil on the surface and stone and just glide. To prep gasket surfaces like this i use a large sharpening stone to make sure i've got a good sealing surface with no bumps or burrs. Fill in the gap between block and pistons with clean grease, then if any bits go on it you can turn the engine over. Engine Block Surface Stone.

From www.wikimotors.org

What is an Engine Block? (with picture) Engine Block Surface Stone If the block were 3 x 3 and i had a 1/2 sanding strip, it'd be pointless as i'd never get a uniform finish. Put oil on the surface and stone and just glide. To prep gasket surfaces like this i use a large sharpening stone to make sure i've got a good sealing surface with no bumps or burrs.. Engine Block Surface Stone.

From www.howacarworks.com

Engine blocks Everything you need to know How a Car Works Engine Block Surface Stone To prep gasket surfaces like this i use a large sharpening stone to make sure i've got a good sealing surface with no bumps or burrs. Fill in the gap between block and pistons with clean grease, then if any bits go on it you can turn the engine over a tad and wipe it off. Put oil on the. Engine Block Surface Stone.

From www.pinterest.com

How do you grow metal engine blocks from powder, and then CNC machine Engine Block Surface Stone Did every engine head come off need resurface head and block before rebolt the head? It works only because you can fit the whole block on the sanding surface. Fill in the gap between block and pistons with clean grease, then if any bits go on it you can turn the engine over a tad and wipe it off. Is. Engine Block Surface Stone.

From forums.jag-lovers.com

Scratched engine block surface after machine work XKEngine Jag Engine Block Surface Stone Did every engine head come off need resurface head and block before rebolt the head? To prep gasket surfaces like this i use a large sharpening stone to make sure i've got a good sealing surface with no bumps or burrs. Is there any scenario where a scratch on the engine block surface does not require a (another) milling down?. Engine Block Surface Stone.

From forums.jag-lovers.com

Scratched engine block surface after machine work XKEngine Jag Engine Block Surface Stone Put oil on the surface and stone and just glide. It works only because you can fit the whole block on the sanding surface. To prep gasket surfaces like this i use a large sharpening stone to make sure i've got a good sealing surface with no bumps or burrs. I read that copper spray can be used on the. Engine Block Surface Stone.

From www.pinterest.com

How do you grow metal engine blocks from powder, and then CNC machine Engine Block Surface Stone If the block were 3 x 3 and i had a 1/2 sanding strip, it'd be pointless as i'd never get a uniform finish. Did every engine head come off need resurface head and block before rebolt the head? It works only because you can fit the whole block on the sanding surface. Is there any scenario where a scratch. Engine Block Surface Stone.

From www.researchgate.net

The top surface of an engine cylinder block. Download Scientific Diagram Engine Block Surface Stone Fill in the gap between block and pistons with clean grease, then if any bits go on it you can turn the engine over a tad and wipe it off. I read that copper spray can be used on the c/head gasket for super tiny. It works only because you can fit the whole block on the sanding surface. Did. Engine Block Surface Stone.

From www.matramotor.com

2&4Stroke Engine Block Surface Machining And Milling Engine Block Surface Stone Fill in the gap between block and pistons with clean grease, then if any bits go on it you can turn the engine over a tad and wipe it off. If the block were 3 x 3 and i had a 1/2 sanding strip, it'd be pointless as i'd never get a uniform finish. Put oil on the surface and. Engine Block Surface Stone.

From techiescience.com

Comprehensive Guide to Engine Block Surface Flatness Measurements Engine Block Surface Stone I read that copper spray can be used on the c/head gasket for super tiny. Put oil on the surface and stone and just glide. It works only because you can fit the whole block on the sanding surface. Fill in the gap between block and pistons with clean grease, then if any bits go on it you can turn. Engine Block Surface Stone.

From mechanics.stackexchange.com

How to Clean Engine Block Surface For MLS Gaskets? Motor Vehicle Engine Block Surface Stone If the block were 3 x 3 and i had a 1/2 sanding strip, it'd be pointless as i'd never get a uniform finish. I read that copper spray can be used on the c/head gasket for super tiny. Did every engine head come off need resurface head and block before rebolt the head? Is there any scenario where a. Engine Block Surface Stone.

From www.onallcylinders.com

Mr. Clean Quick Guide to Prepping a New Engine Block for Assembly Engine Block Surface Stone I read that copper spray can be used on the c/head gasket for super tiny. Put oil on the surface and stone and just glide. Did every engine head come off need resurface head and block before rebolt the head? To prep gasket surfaces like this i use a large sharpening stone to make sure i've got a good sealing. Engine Block Surface Stone.