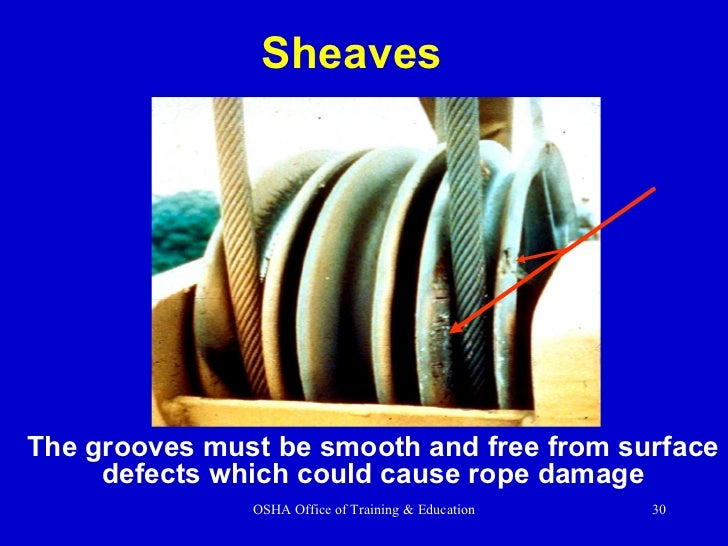

Crane Sheave Failure . Generally results from operational conditions. Mechanical damage caused by the rope contacting the structure of the crane on which it is operating or an external structure—usually of a localized nature. If inspection shows that the reeving is incorrect and excessive side load is being applied to the sheaves, the sheaves should be thoroughly inspected and, if necessary,. There are numerous factors that can cause a failure, and it is essential to complete a best practice forensic investigation to identify the root cause of a ship’s crane failure. Konecranes technicians are trained to identify and correct problems with. Check sheave guards and support / guide sheaves to ensure that the rope has not “jumped out” of the intended reeving system. Improper reeling or unreeling, wrong size or worn sheaves, improper storage, bad splicing are a few. Damaged sheaves can wear ropes prematurely and cause other dangerous hazards, such as binding wire rope. Common failures on sheaves are; Crane owners, crane operators and workers involved in rigging cranes should apply the. The purpose of this safety alert is to highlight the risk of rope sheave failure on mobile cranes. ‣ damage to sheave bearing and the snap rings comes out from sheaves ‣ rubbing of outer surface with the. More can be cited, but these two are the main.

from www.slideshare.net

Mechanical damage caused by the rope contacting the structure of the crane on which it is operating or an external structure—usually of a localized nature. The purpose of this safety alert is to highlight the risk of rope sheave failure on mobile cranes. Common failures on sheaves are; Crane owners, crane operators and workers involved in rigging cranes should apply the. Improper reeling or unreeling, wrong size or worn sheaves, improper storage, bad splicing are a few. Generally results from operational conditions. If inspection shows that the reeving is incorrect and excessive side load is being applied to the sheaves, the sheaves should be thoroughly inspected and, if necessary,. ‣ damage to sheave bearing and the snap rings comes out from sheaves ‣ rubbing of outer surface with the. Damaged sheaves can wear ropes prematurely and cause other dangerous hazards, such as binding wire rope. Konecranes technicians are trained to identify and correct problems with.

Crane safety by abidnadeemkhan

Crane Sheave Failure Konecranes technicians are trained to identify and correct problems with. Konecranes technicians are trained to identify and correct problems with. Damaged sheaves can wear ropes prematurely and cause other dangerous hazards, such as binding wire rope. Generally results from operational conditions. The purpose of this safety alert is to highlight the risk of rope sheave failure on mobile cranes. If inspection shows that the reeving is incorrect and excessive side load is being applied to the sheaves, the sheaves should be thoroughly inspected and, if necessary,. Mechanical damage caused by the rope contacting the structure of the crane on which it is operating or an external structure—usually of a localized nature. Improper reeling or unreeling, wrong size or worn sheaves, improper storage, bad splicing are a few. More can be cited, but these two are the main. Crane owners, crane operators and workers involved in rigging cranes should apply the. Common failures on sheaves are; Check sheave guards and support / guide sheaves to ensure that the rope has not “jumped out” of the intended reeving system. ‣ damage to sheave bearing and the snap rings comes out from sheaves ‣ rubbing of outer surface with the. There are numerous factors that can cause a failure, and it is essential to complete a best practice forensic investigation to identify the root cause of a ship’s crane failure.

From www.eng-tips.com

Liebherr Orion crane failure under 5500t load test Engineering Crane Sheave Failure Improper reeling or unreeling, wrong size or worn sheaves, improper storage, bad splicing are a few. More can be cited, but these two are the main. The purpose of this safety alert is to highlight the risk of rope sheave failure on mobile cranes. ‣ damage to sheave bearing and the snap rings comes out from sheaves ‣ rubbing of. Crane Sheave Failure.

From liftingandrigging.com.my

lifting and rigging Crane wire rope findings and failures Crane Sheave Failure Improper reeling or unreeling, wrong size or worn sheaves, improper storage, bad splicing are a few. Generally results from operational conditions. Damaged sheaves can wear ropes prematurely and cause other dangerous hazards, such as binding wire rope. More can be cited, but these two are the main. If inspection shows that the reeving is incorrect and excessive side load is. Crane Sheave Failure.

From www.reddit.com

Crane failure in high winds. How did this happen? Is the storm prep Crane Sheave Failure More can be cited, but these two are the main. Crane owners, crane operators and workers involved in rigging cranes should apply the. Improper reeling or unreeling, wrong size or worn sheaves, improper storage, bad splicing are a few. Generally results from operational conditions. Common failures on sheaves are; Konecranes technicians are trained to identify and correct problems with. ‣. Crane Sheave Failure.

From www.youtube.com

how to replace crane sheave easy YouTube Crane Sheave Failure Crane owners, crane operators and workers involved in rigging cranes should apply the. Mechanical damage caused by the rope contacting the structure of the crane on which it is operating or an external structure—usually of a localized nature. Generally results from operational conditions. ‣ damage to sheave bearing and the snap rings comes out from sheaves ‣ rubbing of outer. Crane Sheave Failure.

From www.academia.edu

(PDF) Holistic analysis approach and Design Improvement for Crane Crane Sheave Failure Crane owners, crane operators and workers involved in rigging cranes should apply the. Improper reeling or unreeling, wrong size or worn sheaves, improper storage, bad splicing are a few. Mechanical damage caused by the rope contacting the structure of the crane on which it is operating or an external structure—usually of a localized nature. ‣ damage to sheave bearing and. Crane Sheave Failure.

From ar.inspiredpencil.com

Fatigue Failure In Cranes Crane Sheave Failure ‣ damage to sheave bearing and the snap rings comes out from sheaves ‣ rubbing of outer surface with the. Improper reeling or unreeling, wrong size or worn sheaves, improper storage, bad splicing are a few. There are numerous factors that can cause a failure, and it is essential to complete a best practice forensic investigation to identify the root. Crane Sheave Failure.

From www.amsj.com.au

Nearmiss after "catastrophic" crane head sheave failure Australasian Crane Sheave Failure There are numerous factors that can cause a failure, and it is essential to complete a best practice forensic investigation to identify the root cause of a ship’s crane failure. Common failures on sheaves are; Konecranes technicians are trained to identify and correct problems with. If inspection shows that the reeving is incorrect and excessive side load is being applied. Crane Sheave Failure.

From www.drillingformulas.com

Offshore Crane Failure Case Study Drilling Formulas and Drilling Crane Sheave Failure Mechanical damage caused by the rope contacting the structure of the crane on which it is operating or an external structure—usually of a localized nature. The purpose of this safety alert is to highlight the risk of rope sheave failure on mobile cranes. Konecranes technicians are trained to identify and correct problems with. There are numerous factors that can cause. Crane Sheave Failure.

From www.researchgate.net

Buckling failure of the tower crane. Download Scientific Diagram Crane Sheave Failure Check sheave guards and support / guide sheaves to ensure that the rope has not “jumped out” of the intended reeving system. ‣ damage to sheave bearing and the snap rings comes out from sheaves ‣ rubbing of outer surface with the. The purpose of this safety alert is to highlight the risk of rope sheave failure on mobile cranes.. Crane Sheave Failure.

From www.halifaxexaminer.ca

Halifax crane collapsed due to ‘weld failure,’ labour department Crane Sheave Failure ‣ damage to sheave bearing and the snap rings comes out from sheaves ‣ rubbing of outer surface with the. The purpose of this safety alert is to highlight the risk of rope sheave failure on mobile cranes. Damaged sheaves can wear ropes prematurely and cause other dangerous hazards, such as binding wire rope. Improper reeling or unreeling, wrong size. Crane Sheave Failure.

From www.scribd.com

Crane Failure PDF Crane Sheave Failure Improper reeling or unreeling, wrong size or worn sheaves, improper storage, bad splicing are a few. The purpose of this safety alert is to highlight the risk of rope sheave failure on mobile cranes. Mechanical damage caused by the rope contacting the structure of the crane on which it is operating or an external structure—usually of a localized nature. Generally. Crane Sheave Failure.

From www.technomaxme.com

Preventing Overhead Crane Failure Technomax Crane Sheave Failure More can be cited, but these two are the main. There are numerous factors that can cause a failure, and it is essential to complete a best practice forensic investigation to identify the root cause of a ship’s crane failure. ‣ damage to sheave bearing and the snap rings comes out from sheaves ‣ rubbing of outer surface with the.. Crane Sheave Failure.

From maritime-executive.com

Five Common Causes of Crane Failure Crane Sheave Failure Konecranes technicians are trained to identify and correct problems with. Improper reeling or unreeling, wrong size or worn sheaves, improper storage, bad splicing are a few. More can be cited, but these two are the main. There are numerous factors that can cause a failure, and it is essential to complete a best practice forensic investigation to identify the root. Crane Sheave Failure.

From www.ocas.be

Failure analysis on wire rope sheave of crane Ocas Crane Sheave Failure ‣ damage to sheave bearing and the snap rings comes out from sheaves ‣ rubbing of outer surface with the. Improper reeling or unreeling, wrong size or worn sheaves, improper storage, bad splicing are a few. Generally results from operational conditions. Common failures on sheaves are; If inspection shows that the reeving is incorrect and excessive side load is being. Crane Sheave Failure.

From www.imca-int.com

Nearmiss Corrosion caused crane boom failure during heavy lifting IMCA Crane Sheave Failure Check sheave guards and support / guide sheaves to ensure that the rope has not “jumped out” of the intended reeving system. Konecranes technicians are trained to identify and correct problems with. Common failures on sheaves are; Mechanical damage caused by the rope contacting the structure of the crane on which it is operating or an external structure—usually of a. Crane Sheave Failure.

From www.researchgate.net

Buckling failure of the tower crane. Download Scientific Diagram Crane Sheave Failure ‣ damage to sheave bearing and the snap rings comes out from sheaves ‣ rubbing of outer surface with the. The purpose of this safety alert is to highlight the risk of rope sheave failure on mobile cranes. Crane owners, crane operators and workers involved in rigging cranes should apply the. More can be cited, but these two are the. Crane Sheave Failure.

From www.fieldengineers.com.au

Gantry Crane Drive Failure Crane Sheave Failure Konecranes technicians are trained to identify and correct problems with. If inspection shows that the reeving is incorrect and excessive side load is being applied to the sheaves, the sheaves should be thoroughly inspected and, if necessary,. There are numerous factors that can cause a failure, and it is essential to complete a best practice forensic investigation to identify the. Crane Sheave Failure.

From www.youtube.com

Extreme Dangerous Fails Biggest Crane Compilation Heavy Equipment Crane Sheave Failure If inspection shows that the reeving is incorrect and excessive side load is being applied to the sheaves, the sheaves should be thoroughly inspected and, if necessary,. Mechanical damage caused by the rope contacting the structure of the crane on which it is operating or an external structure—usually of a localized nature. Crane owners, crane operators and workers involved in. Crane Sheave Failure.

From www.youtube.com

how to replacement sheaves at the crane YouTube Crane Sheave Failure Common failures on sheaves are; Crane owners, crane operators and workers involved in rigging cranes should apply the. Konecranes technicians are trained to identify and correct problems with. More can be cited, but these two are the main. Improper reeling or unreeling, wrong size or worn sheaves, improper storage, bad splicing are a few. Mechanical damage caused by the rope. Crane Sheave Failure.

From www.worksafe.qld.gov.au

Tower crane hoist rope and brake failures WorkSafe.qld.gov.au Crane Sheave Failure Konecranes technicians are trained to identify and correct problems with. Common failures on sheaves are; More can be cited, but these two are the main. Improper reeling or unreeling, wrong size or worn sheaves, improper storage, bad splicing are a few. If inspection shows that the reeving is incorrect and excessive side load is being applied to the sheaves, the. Crane Sheave Failure.

From www.hseblog.com

Five Common Causes of Crane Failure InDepth Examination Crane Sheave Failure Check sheave guards and support / guide sheaves to ensure that the rope has not “jumped out” of the intended reeving system. Generally results from operational conditions. Damaged sheaves can wear ropes prematurely and cause other dangerous hazards, such as binding wire rope. Improper reeling or unreeling, wrong size or worn sheaves, improper storage, bad splicing are a few. There. Crane Sheave Failure.

From www.slideshare.net

Crane safety by abidnadeemkhan Crane Sheave Failure There are numerous factors that can cause a failure, and it is essential to complete a best practice forensic investigation to identify the root cause of a ship’s crane failure. ‣ damage to sheave bearing and the snap rings comes out from sheaves ‣ rubbing of outer surface with the. Improper reeling or unreeling, wrong size or worn sheaves, improper. Crane Sheave Failure.

From liftingandrigging.com.my

Crane Accident Investigation lifting and rigging Crane Sheave Failure There are numerous factors that can cause a failure, and it is essential to complete a best practice forensic investigation to identify the root cause of a ship’s crane failure. Common failures on sheaves are; Improper reeling or unreeling, wrong size or worn sheaves, improper storage, bad splicing are a few. If inspection shows that the reeving is incorrect and. Crane Sheave Failure.

From www.chegg.com

Solved Consider the failure of a crane sheave as in picture Crane Sheave Failure The purpose of this safety alert is to highlight the risk of rope sheave failure on mobile cranes. Crane owners, crane operators and workers involved in rigging cranes should apply the. Check sheave guards and support / guide sheaves to ensure that the rope has not “jumped out” of the intended reeving system. There are numerous factors that can cause. Crane Sheave Failure.

From www.alatas.com

ROPE SHEAVE ASSEMBLY, FABRICATION, & REPAIRS Alatas Crane Sheave Failure There are numerous factors that can cause a failure, and it is essential to complete a best practice forensic investigation to identify the root cause of a ship’s crane failure. Generally results from operational conditions. Mechanical damage caused by the rope contacting the structure of the crane on which it is operating or an external structure—usually of a localized nature.. Crane Sheave Failure.

From www.imca-int.com

Crane antitwo block securing wire failure IMCA Crane Sheave Failure Common failures on sheaves are; There are numerous factors that can cause a failure, and it is essential to complete a best practice forensic investigation to identify the root cause of a ship’s crane failure. The purpose of this safety alert is to highlight the risk of rope sheave failure on mobile cranes. More can be cited, but these two. Crane Sheave Failure.

From www.researchgate.net

Head sheave failure class table Download Scientific Diagram Crane Sheave Failure Check sheave guards and support / guide sheaves to ensure that the rope has not “jumped out” of the intended reeving system. If inspection shows that the reeving is incorrect and excessive side load is being applied to the sheaves, the sheaves should be thoroughly inspected and, if necessary,. Konecranes technicians are trained to identify and correct problems with. There. Crane Sheave Failure.

From liftingandrigging.com.my

lifting and rigging Crane wire rope findings and failures Crane Sheave Failure Damaged sheaves can wear ropes prematurely and cause other dangerous hazards, such as binding wire rope. ‣ damage to sheave bearing and the snap rings comes out from sheaves ‣ rubbing of outer surface with the. If inspection shows that the reeving is incorrect and excessive side load is being applied to the sheaves, the sheaves should be thoroughly inspected. Crane Sheave Failure.

From www.ocas.be

Failure analysis on wire rope sheave of crane Ocas Crane Sheave Failure Improper reeling or unreeling, wrong size or worn sheaves, improper storage, bad splicing are a few. There are numerous factors that can cause a failure, and it is essential to complete a best practice forensic investigation to identify the root cause of a ship’s crane failure. If inspection shows that the reeving is incorrect and excessive side load is being. Crane Sheave Failure.

From www.scribd.com

Crane Sheave Early Failures PDF Fatigue (Material) Chemical Crane Sheave Failure Improper reeling or unreeling, wrong size or worn sheaves, improper storage, bad splicing are a few. Konecranes technicians are trained to identify and correct problems with. Check sheave guards and support / guide sheaves to ensure that the rope has not “jumped out” of the intended reeving system. Damaged sheaves can wear ropes prematurely and cause other dangerous hazards, such. Crane Sheave Failure.

From ccoschool.us

What to Expect at a Crane & Rigging Inspection Crane Operator School Crane Sheave Failure If inspection shows that the reeving is incorrect and excessive side load is being applied to the sheaves, the sheaves should be thoroughly inspected and, if necessary,. Generally results from operational conditions. Check sheave guards and support / guide sheaves to ensure that the rope has not “jumped out” of the intended reeving system. There are numerous factors that can. Crane Sheave Failure.

From www.mazzellacompanies.com

5 Common Problems with Overhead Cranes and How to Avoid Them Crane Sheave Failure More can be cited, but these two are the main. Generally results from operational conditions. Crane owners, crane operators and workers involved in rigging cranes should apply the. ‣ damage to sheave bearing and the snap rings comes out from sheaves ‣ rubbing of outer surface with the. There are numerous factors that can cause a failure, and it is. Crane Sheave Failure.

From liftingandrigging.com.my

Crane Accident Investigation lifting and rigging Crane Sheave Failure ‣ damage to sheave bearing and the snap rings comes out from sheaves ‣ rubbing of outer surface with the. More can be cited, but these two are the main. Common failures on sheaves are; Damaged sheaves can wear ropes prematurely and cause other dangerous hazards, such as binding wire rope. There are numerous factors that can cause a failure,. Crane Sheave Failure.

From liftingandrigging.com.my

lifting and rigging Crane wire rope findings and failures Crane Sheave Failure Generally results from operational conditions. More can be cited, but these two are the main. The purpose of this safety alert is to highlight the risk of rope sheave failure on mobile cranes. Mechanical damage caused by the rope contacting the structure of the crane on which it is operating or an external structure—usually of a localized nature. There are. Crane Sheave Failure.

From www.chegg.com

Solved Figure A shows the general arrangement of the simple Crane Sheave Failure If inspection shows that the reeving is incorrect and excessive side load is being applied to the sheaves, the sheaves should be thoroughly inspected and, if necessary,. Common failures on sheaves are; Improper reeling or unreeling, wrong size or worn sheaves, improper storage, bad splicing are a few. Check sheave guards and support / guide sheaves to ensure that the. Crane Sheave Failure.