Equipment Layout Requirements . The essential data or documents required for preparation of equipment layout is as 1. Process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. By understanding your workflow and value stream, you can design a layout that maximizes the use of space and resources and ensures your team can work as efficiently as. Plant layout, spacing, and clearances for equipment piping routing encompass the strategic arrangement of industrial facilities, equipment, and. This engineering design guideline describes the guidelines for the layout of plot areas, equipment, pipe racks, piping, platforms, roadways, and. 57 rows it shows location and placement of all equipments in a particular process or utility area along with various types of access and.

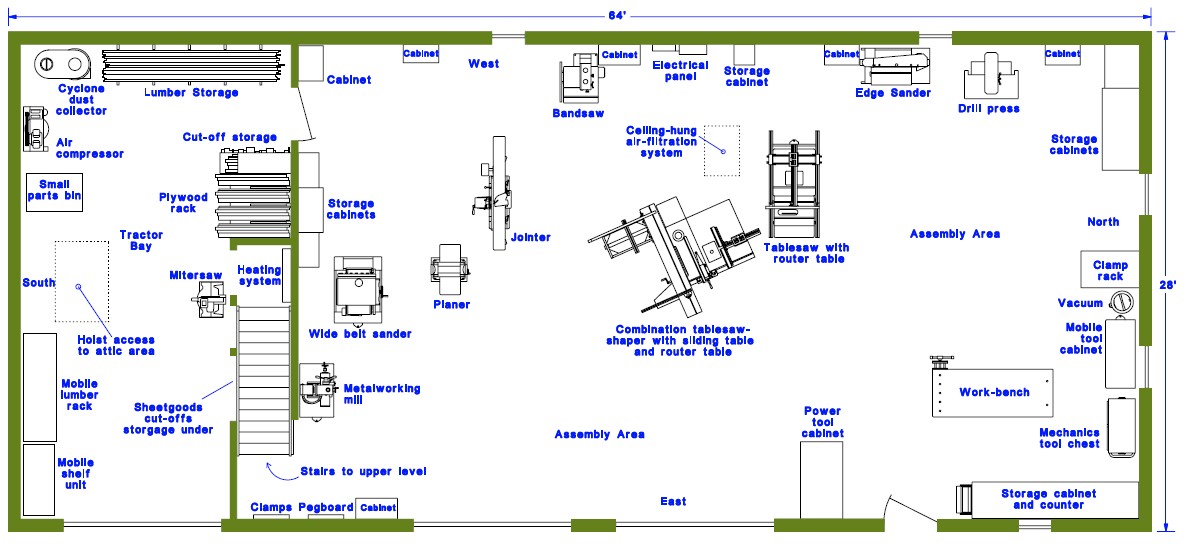

from shywoodworking.blogspot.com

Process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. By understanding your workflow and value stream, you can design a layout that maximizes the use of space and resources and ensures your team can work as efficiently as. Plant layout, spacing, and clearances for equipment piping routing encompass the strategic arrangement of industrial facilities, equipment, and. This engineering design guideline describes the guidelines for the layout of plot areas, equipment, pipe racks, piping, platforms, roadways, and. 57 rows it shows location and placement of all equipments in a particular process or utility area along with various types of access and. The essential data or documents required for preparation of equipment layout is as 1.

Choice layout ideas Share Woodworking Plans

Equipment Layout Requirements The essential data or documents required for preparation of equipment layout is as 1. Process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. By understanding your workflow and value stream, you can design a layout that maximizes the use of space and resources and ensures your team can work as efficiently as. This engineering design guideline describes the guidelines for the layout of plot areas, equipment, pipe racks, piping, platforms, roadways, and. 57 rows it shows location and placement of all equipments in a particular process or utility area along with various types of access and. The essential data or documents required for preparation of equipment layout is as 1. Plant layout, spacing, and clearances for equipment piping routing encompass the strategic arrangement of industrial facilities, equipment, and.

From www.highlandereng.com

Need Facility Layout and Piping Design? Highlander Engineering Equipment Layout Requirements Plant layout, spacing, and clearances for equipment piping routing encompass the strategic arrangement of industrial facilities, equipment, and. By understanding your workflow and value stream, you can design a layout that maximizes the use of space and resources and ensures your team can work as efficiently as. 57 rows it shows location and placement of all equipments in a particular. Equipment Layout Requirements.

From asidental.com

Dental Operatory Design, Layout and Setup Equipment Layout Requirements Process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. Plant layout, spacing, and clearances for equipment piping routing encompass the strategic arrangement of industrial facilities, equipment, and. The essential data or documents required for preparation of equipment layout is as 1. 57 rows it shows location and placement of. Equipment Layout Requirements.

From medicalguidelines.msf.org

Organization and management of a pharmacy MSF Medical Guidelines Equipment Layout Requirements Process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. 57 rows it shows location and placement of all equipments in a particular process or utility area along with various types of access and. This engineering design guideline describes the guidelines for the layout of plot areas, equipment, pipe racks,. Equipment Layout Requirements.

From electrical-engineering-portal.com

LV/MV power substation equipment and wiring requirements EEP Equipment Layout Requirements 57 rows it shows location and placement of all equipments in a particular process or utility area along with various types of access and. The essential data or documents required for preparation of equipment layout is as 1. Plant layout, spacing, and clearances for equipment piping routing encompass the strategic arrangement of industrial facilities, equipment, and. This engineering design guideline. Equipment Layout Requirements.

From bodeniwasues.github.io

Layout Design Tool Layout, Carpentry Equipment Layout Requirements Plant layout, spacing, and clearances for equipment piping routing encompass the strategic arrangement of industrial facilities, equipment, and. Process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. 57 rows it shows location and placement of all equipments in a particular process or utility area along with various types of. Equipment Layout Requirements.

From www.pinterest.com

Layout of Dyeing lab Laboratory equipment, Labs plan, Dark office Equipment Layout Requirements Plant layout, spacing, and clearances for equipment piping routing encompass the strategic arrangement of industrial facilities, equipment, and. By understanding your workflow and value stream, you can design a layout that maximizes the use of space and resources and ensures your team can work as efficiently as. 57 rows it shows location and placement of all equipments in a particular. Equipment Layout Requirements.

From hybridoperatingroom.com

Hybrid OR 3D Designs & Layouts — Hybrid Operating Rooms & Hybrid Cath Equipment Layout Requirements This engineering design guideline describes the guidelines for the layout of plot areas, equipment, pipe racks, piping, platforms, roadways, and. 57 rows it shows location and placement of all equipments in a particular process or utility area along with various types of access and. The essential data or documents required for preparation of equipment layout is as 1. Plant layout,. Equipment Layout Requirements.

From iceperspective15.pythonanywhere.com

Best Kitchen Layout Regulations Grey Blue Island Small Industrial Equipment Layout Requirements 57 rows it shows location and placement of all equipments in a particular process or utility area along with various types of access and. The essential data or documents required for preparation of equipment layout is as 1. Process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. By understanding. Equipment Layout Requirements.

From stlengineering.net

Equipment Layout, Selection, and Specification Archives Stl Engineering Equipment Layout Requirements 57 rows it shows location and placement of all equipments in a particular process or utility area along with various types of access and. The essential data or documents required for preparation of equipment layout is as 1. Plant layout, spacing, and clearances for equipment piping routing encompass the strategic arrangement of industrial facilities, equipment, and. By understanding your workflow. Equipment Layout Requirements.

From thepiping.com

What Is Equipment Layout Equipment Layout Requirements The essential data or documents required for preparation of equipment layout is as 1. This engineering design guideline describes the guidelines for the layout of plot areas, equipment, pipe racks, piping, platforms, roadways, and. By understanding your workflow and value stream, you can design a layout that maximizes the use of space and resources and ensures your team can work. Equipment Layout Requirements.

From superiorrenovations.co.nz

Kitchen Layout Guide To Create a Functional Kitchen Design (2023) Equipment Layout Requirements Plant layout, spacing, and clearances for equipment piping routing encompass the strategic arrangement of industrial facilities, equipment, and. By understanding your workflow and value stream, you can design a layout that maximizes the use of space and resources and ensures your team can work as efficiently as. This engineering design guideline describes the guidelines for the layout of plot areas,. Equipment Layout Requirements.

From bavengineering.com

Equipment layouts BAV Engineering Equipment Layout Requirements Plant layout, spacing, and clearances for equipment piping routing encompass the strategic arrangement of industrial facilities, equipment, and. This engineering design guideline describes the guidelines for the layout of plot areas, equipment, pipe racks, piping, platforms, roadways, and. 57 rows it shows location and placement of all equipments in a particular process or utility area along with various types of. Equipment Layout Requirements.

From www.touchbistro.com

6 Commercial Kitchen Layout Examples & Ideas for Restaurants Equipment Layout Requirements The essential data or documents required for preparation of equipment layout is as 1. By understanding your workflow and value stream, you can design a layout that maximizes the use of space and resources and ensures your team can work as efficiently as. Plant layout, spacing, and clearances for equipment piping routing encompass the strategic arrangement of industrial facilities, equipment,. Equipment Layout Requirements.

From cookprocesssolutions.com

Equipment Layout Cook Process Solutions, LLC Equipment Layout Requirements The essential data or documents required for preparation of equipment layout is as 1. 57 rows it shows location and placement of all equipments in a particular process or utility area along with various types of access and. Process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. Plant layout,. Equipment Layout Requirements.

From houseplanbuilder.blogspot.com

18+ Or Layout Equipment Layout Requirements Process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. The essential data or documents required for preparation of equipment layout is as 1. 57 rows it shows location and placement of all equipments in a particular process or utility area along with various types of access and. This engineering. Equipment Layout Requirements.

From uniqueengineering.com.pk

Equipment List Unique Construction & Engineering Services (Pvt.) Limited Equipment Layout Requirements This engineering design guideline describes the guidelines for the layout of plot areas, equipment, pipe racks, piping, platforms, roadways, and. By understanding your workflow and value stream, you can design a layout that maximizes the use of space and resources and ensures your team can work as efficiently as. The essential data or documents required for preparation of equipment layout. Equipment Layout Requirements.

From www.health.nsw.gov.au

Cleaning and sterilising reusable equipment and instruments Fact sheets Equipment Layout Requirements Process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. 57 rows it shows location and placement of all equipments in a particular process or utility area along with various types of access and. The essential data or documents required for preparation of equipment layout is as 1. This engineering. Equipment Layout Requirements.

From www.meiusa.com

Machine Room Layout MEI Total Elevator Solutions Equipment Layout Requirements Plant layout, spacing, and clearances for equipment piping routing encompass the strategic arrangement of industrial facilities, equipment, and. This engineering design guideline describes the guidelines for the layout of plot areas, equipment, pipe racks, piping, platforms, roadways, and. Process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. The essential. Equipment Layout Requirements.

From www.pinterest.es

Restaurant Design 360 Spiffiest Design, Development, & Commercial Equipment Layout Requirements The essential data or documents required for preparation of equipment layout is as 1. This engineering design guideline describes the guidelines for the layout of plot areas, equipment, pipe racks, piping, platforms, roadways, and. By understanding your workflow and value stream, you can design a layout that maximizes the use of space and resources and ensures your team can work. Equipment Layout Requirements.

From shywoodworking.blogspot.com

Choice layout ideas Share Woodworking Plans Equipment Layout Requirements By understanding your workflow and value stream, you can design a layout that maximizes the use of space and resources and ensures your team can work as efficiently as. This engineering design guideline describes the guidelines for the layout of plot areas, equipment, pipe racks, piping, platforms, roadways, and. Process flow sequence and operating procedures should be thoroughly understood so. Equipment Layout Requirements.

From electrical-engineering-portal.com

Learn how to draft the layout and arrangement drawing of 33/11 kV Equipment Layout Requirements Plant layout, spacing, and clearances for equipment piping routing encompass the strategic arrangement of industrial facilities, equipment, and. Process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. 57 rows it shows location and placement of all equipments in a particular process or utility area along with various types of. Equipment Layout Requirements.

From www.liveabout.com

Commercial Restaurant Kitchen Equipment Checklist Equipment Layout Requirements Plant layout, spacing, and clearances for equipment piping routing encompass the strategic arrangement of industrial facilities, equipment, and. 57 rows it shows location and placement of all equipments in a particular process or utility area along with various types of access and. By understanding your workflow and value stream, you can design a layout that maximizes the use of space. Equipment Layout Requirements.

From cadbull.com

Laboratory Layout Drawing CAD Plan Cadbull Equipment Layout Requirements By understanding your workflow and value stream, you can design a layout that maximizes the use of space and resources and ensures your team can work as efficiently as. Plant layout, spacing, and clearances for equipment piping routing encompass the strategic arrangement of industrial facilities, equipment, and. Process flow sequence and operating procedures should be thoroughly understood so that equipment. Equipment Layout Requirements.

From pos.toasttab.com

How to Design a Bakery Floor Plan Bakery Layouts, Blueprints and Equipment Layout Requirements The essential data or documents required for preparation of equipment layout is as 1. By understanding your workflow and value stream, you can design a layout that maximizes the use of space and resources and ensures your team can work as efficiently as. This engineering design guideline describes the guidelines for the layout of plot areas, equipment, pipe racks, piping,. Equipment Layout Requirements.

From blog.biomall.in

Essentials for setting up a science laboratory Biomall Blog Equipment Layout Requirements The essential data or documents required for preparation of equipment layout is as 1. Plant layout, spacing, and clearances for equipment piping routing encompass the strategic arrangement of industrial facilities, equipment, and. This engineering design guideline describes the guidelines for the layout of plot areas, equipment, pipe racks, piping, platforms, roadways, and. By understanding your workflow and value stream, you. Equipment Layout Requirements.

From www.fitnessgallery.com

How to Design and Layout a Functional Commercial Gym Fitness Gallery Equipment Layout Requirements The essential data or documents required for preparation of equipment layout is as 1. 57 rows it shows location and placement of all equipments in a particular process or utility area along with various types of access and. By understanding your workflow and value stream, you can design a layout that maximizes the use of space and resources and ensures. Equipment Layout Requirements.

From www.pinterest.com

Learn how to optimize your kitchen space with the 4 cooking zones for Equipment Layout Requirements Plant layout, spacing, and clearances for equipment piping routing encompass the strategic arrangement of industrial facilities, equipment, and. 57 rows it shows location and placement of all equipments in a particular process or utility area along with various types of access and. Process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan. Equipment Layout Requirements.

From www.pinterest.com

Restaurant Floor Plans with Dimensions Kitchen Commercial Kitchen Equipment Layout Requirements The essential data or documents required for preparation of equipment layout is as 1. This engineering design guideline describes the guidelines for the layout of plot areas, equipment, pipe racks, piping, platforms, roadways, and. Process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. By understanding your workflow and value. Equipment Layout Requirements.

From www.nachi.org

InterNACHI Inspection Graphics Library Swimming Pools, Whirlpools Equipment Layout Requirements This engineering design guideline describes the guidelines for the layout of plot areas, equipment, pipe racks, piping, platforms, roadways, and. By understanding your workflow and value stream, you can design a layout that maximizes the use of space and resources and ensures your team can work as efficiently as. Plant layout, spacing, and clearances for equipment piping routing encompass the. Equipment Layout Requirements.

From stl.tech

Designing a Data Centre Network What You Should Consider? STL Tech Equipment Layout Requirements 57 rows it shows location and placement of all equipments in a particular process or utility area along with various types of access and. The essential data or documents required for preparation of equipment layout is as 1. Process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. Plant layout,. Equipment Layout Requirements.

From operonstrategist.com

Manufacturing Plant Layout Design for Medical device (Factory Layout Equipment Layout Requirements This engineering design guideline describes the guidelines for the layout of plot areas, equipment, pipe racks, piping, platforms, roadways, and. Process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. By understanding your workflow and value stream, you can design a layout that maximizes the use of space and resources. Equipment Layout Requirements.

From www.researchgate.net

Floor plan of the laboratory room where the measurements took place Equipment Layout Requirements The essential data or documents required for preparation of equipment layout is as 1. This engineering design guideline describes the guidelines for the layout of plot areas, equipment, pipe racks, piping, platforms, roadways, and. Plant layout, spacing, and clearances for equipment piping routing encompass the strategic arrangement of industrial facilities, equipment, and. 57 rows it shows location and placement of. Equipment Layout Requirements.

From www.pooltech.com

CAD Design Pool Tech Your Cedar Rapids, IA Builder Equipment Layout Requirements The essential data or documents required for preparation of equipment layout is as 1. Plant layout, spacing, and clearances for equipment piping routing encompass the strategic arrangement of industrial facilities, equipment, and. Process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. 57 rows it shows location and placement of. Equipment Layout Requirements.

From www.matrixpdm.com

equipment layout Matrix PDM Engineering Equipment Layout Requirements This engineering design guideline describes the guidelines for the layout of plot areas, equipment, pipe racks, piping, platforms, roadways, and. Process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. 57 rows it shows location and placement of all equipments in a particular process or utility area along with various. Equipment Layout Requirements.

From www.pinterest.com

Restaurant Kitchen Layout Approach Part 1 Restaurant kitchen design Equipment Layout Requirements By understanding your workflow and value stream, you can design a layout that maximizes the use of space and resources and ensures your team can work as efficiently as. Plant layout, spacing, and clearances for equipment piping routing encompass the strategic arrangement of industrial facilities, equipment, and. The essential data or documents required for preparation of equipment layout is as. Equipment Layout Requirements.