Cylindrical Grinding Depth Of Cut . The maximum achievable journal roundness accuracy range by the conventional “rolling bearing supported spindle and fixed. The main objective of this. Cylindrical grinding machine is employed in machining of. There were 27 experiments conducted with different machining parameters to determine optimal solution of cylindrical grinding process. The results indicated that grinding wheel speed, work piece speed, table feed rate and depth of cut were the significant factors for the surface roughness and. The grinding wheel material and grade greatly influence the surface roughness, followed by the workpiece speed (r.p.m.), depth. The present paper takes the following input processes parameters namely work speed, feed rate and depth of cut. When the entire length of work has passed infront of the wheel, the wheel advances forward by another 0.015 mm at the end of the traverse and so the cycle of machining goes on, until the desired daimeter of the work piece is reached. Citations (1) references (6) figures (1) abstract and figures. The depth of cut is very small, about 0.015 mm. The basic process parameters in grinding processes are the cutting speed v c, the feed velocity v f, the depth of cut a.

from www.mdpi.com

The basic process parameters in grinding processes are the cutting speed v c, the feed velocity v f, the depth of cut a. The present paper takes the following input processes parameters namely work speed, feed rate and depth of cut. The main objective of this. When the entire length of work has passed infront of the wheel, the wheel advances forward by another 0.015 mm at the end of the traverse and so the cycle of machining goes on, until the desired daimeter of the work piece is reached. Citations (1) references (6) figures (1) abstract and figures. The maximum achievable journal roundness accuracy range by the conventional “rolling bearing supported spindle and fixed. Cylindrical grinding machine is employed in machining of. There were 27 experiments conducted with different machining parameters to determine optimal solution of cylindrical grinding process. The depth of cut is very small, about 0.015 mm. The results indicated that grinding wheel speed, work piece speed, table feed rate and depth of cut were the significant factors for the surface roughness and.

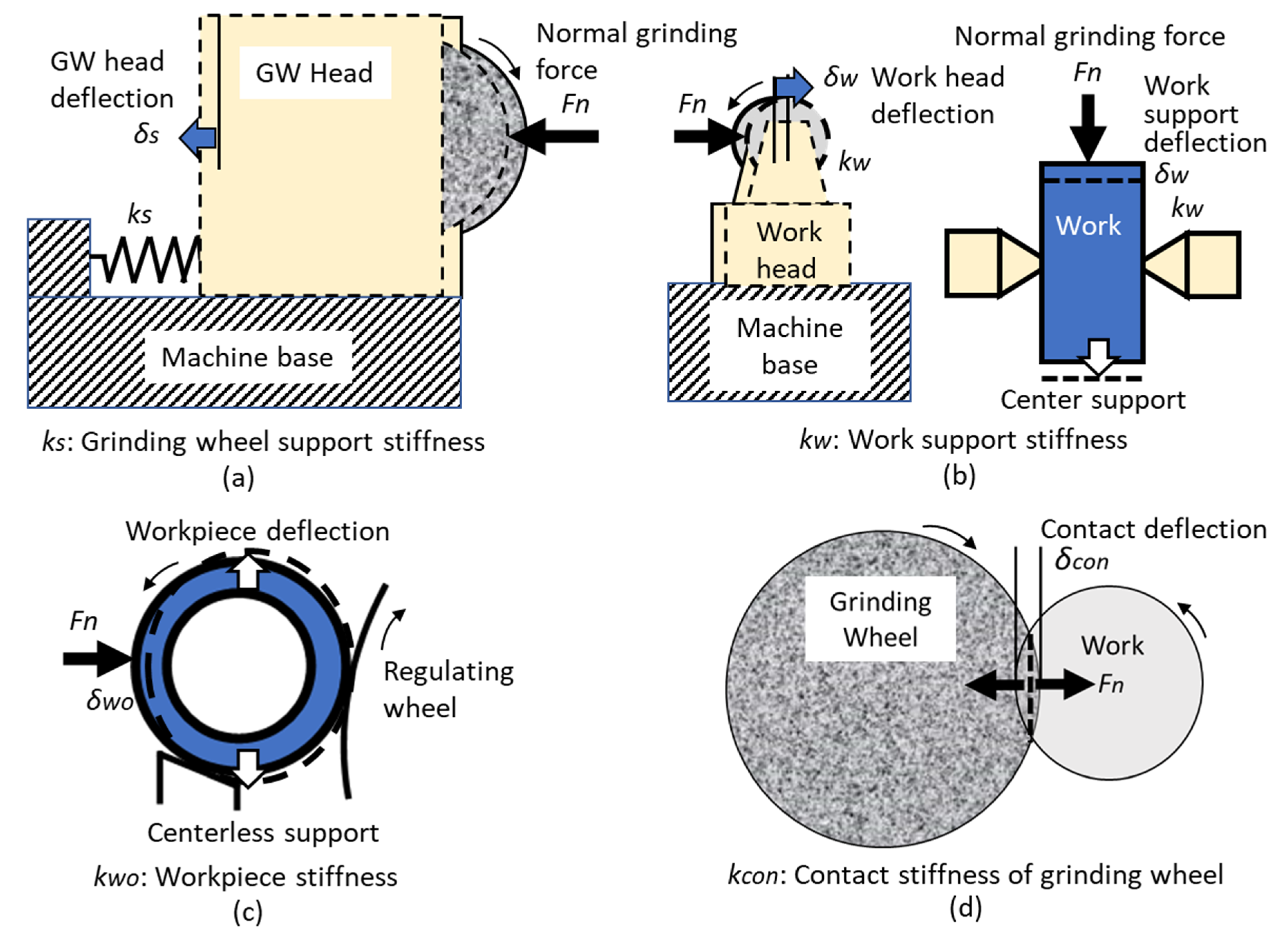

Inventions Free FullText The Design of an Infeed Cylindrical

Cylindrical Grinding Depth Of Cut The depth of cut is very small, about 0.015 mm. The results indicated that grinding wheel speed, work piece speed, table feed rate and depth of cut were the significant factors for the surface roughness and. The maximum achievable journal roundness accuracy range by the conventional “rolling bearing supported spindle and fixed. Citations (1) references (6) figures (1) abstract and figures. The main objective of this. Cylindrical grinding machine is employed in machining of. The grinding wheel material and grade greatly influence the surface roughness, followed by the workpiece speed (r.p.m.), depth. The present paper takes the following input processes parameters namely work speed, feed rate and depth of cut. There were 27 experiments conducted with different machining parameters to determine optimal solution of cylindrical grinding process. The basic process parameters in grinding processes are the cutting speed v c, the feed velocity v f, the depth of cut a. The depth of cut is very small, about 0.015 mm. When the entire length of work has passed infront of the wheel, the wheel advances forward by another 0.015 mm at the end of the traverse and so the cycle of machining goes on, until the desired daimeter of the work piece is reached.

From finemetalworking.com

Cylindrical Grinding Fine MetalWorking Cylindrical Grinding Depth Of Cut Cylindrical grinding machine is employed in machining of. There were 27 experiments conducted with different machining parameters to determine optimal solution of cylindrical grinding process. The grinding wheel material and grade greatly influence the surface roughness, followed by the workpiece speed (r.p.m.), depth. When the entire length of work has passed infront of the wheel, the wheel advances forward by. Cylindrical Grinding Depth Of Cut.

From kandgmachine.com

CNC Grinding Cylindrical Grinding Depth Of Cut The results indicated that grinding wheel speed, work piece speed, table feed rate and depth of cut were the significant factors for the surface roughness and. There were 27 experiments conducted with different machining parameters to determine optimal solution of cylindrical grinding process. When the entire length of work has passed infront of the wheel, the wheel advances forward by. Cylindrical Grinding Depth Of Cut.

From www.vrogue.co

Cylindrical Grinding Machine Types Process Working Pr vrogue.co Cylindrical Grinding Depth Of Cut The grinding wheel material and grade greatly influence the surface roughness, followed by the workpiece speed (r.p.m.), depth. The basic process parameters in grinding processes are the cutting speed v c, the feed velocity v f, the depth of cut a. Citations (1) references (6) figures (1) abstract and figures. When the entire length of work has passed infront of. Cylindrical Grinding Depth Of Cut.

From www.researchgate.net

Schematic diagram of cylindrical grinding Download Scientific Diagram Cylindrical Grinding Depth Of Cut The basic process parameters in grinding processes are the cutting speed v c, the feed velocity v f, the depth of cut a. The present paper takes the following input processes parameters namely work speed, feed rate and depth of cut. Cylindrical grinding machine is employed in machining of. Citations (1) references (6) figures (1) abstract and figures. The results. Cylindrical Grinding Depth Of Cut.

From royalsocietypublishing.org

Optimization of parameters in cylindrical and surface grinding for Cylindrical Grinding Depth Of Cut The grinding wheel material and grade greatly influence the surface roughness, followed by the workpiece speed (r.p.m.), depth. The basic process parameters in grinding processes are the cutting speed v c, the feed velocity v f, the depth of cut a. The results indicated that grinding wheel speed, work piece speed, table feed rate and depth of cut were the. Cylindrical Grinding Depth Of Cut.

From www.researchgate.net

Schematic diagram of realtime cutting depth of a typical grain Cylindrical Grinding Depth Of Cut The grinding wheel material and grade greatly influence the surface roughness, followed by the workpiece speed (r.p.m.), depth. Citations (1) references (6) figures (1) abstract and figures. When the entire length of work has passed infront of the wheel, the wheel advances forward by another 0.015 mm at the end of the traverse and so the cycle of machining goes. Cylindrical Grinding Depth Of Cut.

From www.youtube.com

Axial and radial depth of cut in milling operations YouTube Cylindrical Grinding Depth Of Cut The basic process parameters in grinding processes are the cutting speed v c, the feed velocity v f, the depth of cut a. The results indicated that grinding wheel speed, work piece speed, table feed rate and depth of cut were the significant factors for the surface roughness and. The grinding wheel material and grade greatly influence the surface roughness,. Cylindrical Grinding Depth Of Cut.

From labs.wsu.edu

waterjet cut depth definition M3 Robotics Lab Washington State Cylindrical Grinding Depth Of Cut The grinding wheel material and grade greatly influence the surface roughness, followed by the workpiece speed (r.p.m.), depth. The main objective of this. There were 27 experiments conducted with different machining parameters to determine optimal solution of cylindrical grinding process. Citations (1) references (6) figures (1) abstract and figures. When the entire length of work has passed infront of the. Cylindrical Grinding Depth Of Cut.

From www.slideserve.com

PPT CNC Turning PowerPoint Presentation, free download ID6681898 Cylindrical Grinding Depth Of Cut When the entire length of work has passed infront of the wheel, the wheel advances forward by another 0.015 mm at the end of the traverse and so the cycle of machining goes on, until the desired daimeter of the work piece is reached. There were 27 experiments conducted with different machining parameters to determine optimal solution of cylindrical grinding. Cylindrical Grinding Depth Of Cut.

From www.machinistguides.com

F CNC Code Explained An Easy Intro for Beginners [Feedrate Cylindrical Grinding Depth Of Cut The results indicated that grinding wheel speed, work piece speed, table feed rate and depth of cut were the significant factors for the surface roughness and. Cylindrical grinding machine is employed in machining of. The depth of cut is very small, about 0.015 mm. Citations (1) references (6) figures (1) abstract and figures. The main objective of this. The grinding. Cylindrical Grinding Depth Of Cut.

From finemetalworking.com

Cylindrical Grinding Fine MetalWorking Cylindrical Grinding Depth Of Cut The maximum achievable journal roundness accuracy range by the conventional “rolling bearing supported spindle and fixed. Citations (1) references (6) figures (1) abstract and figures. When the entire length of work has passed infront of the wheel, the wheel advances forward by another 0.015 mm at the end of the traverse and so the cycle of machining goes on, until. Cylindrical Grinding Depth Of Cut.

From www.ctemag.com

Optimizing grinding and dressing with 'dressing speed ratio' parameter Cylindrical Grinding Depth Of Cut There were 27 experiments conducted with different machining parameters to determine optimal solution of cylindrical grinding process. The maximum achievable journal roundness accuracy range by the conventional “rolling bearing supported spindle and fixed. Cylindrical grinding machine is employed in machining of. Citations (1) references (6) figures (1) abstract and figures. The results indicated that grinding wheel speed, work piece speed,. Cylindrical Grinding Depth Of Cut.

From www.emag.com

Cylindrical grinding to the highest precision on the grinding machine Cylindrical Grinding Depth Of Cut The basic process parameters in grinding processes are the cutting speed v c, the feed velocity v f, the depth of cut a. Citations (1) references (6) figures (1) abstract and figures. The main objective of this. The depth of cut is very small, about 0.015 mm. The maximum achievable journal roundness accuracy range by the conventional “rolling bearing supported. Cylindrical Grinding Depth Of Cut.

From www.mdpi.com

Inventions Free FullText The Design of an Infeed Cylindrical Cylindrical Grinding Depth Of Cut The present paper takes the following input processes parameters namely work speed, feed rate and depth of cut. The results indicated that grinding wheel speed, work piece speed, table feed rate and depth of cut were the significant factors for the surface roughness and. Cylindrical grinding machine is employed in machining of. Citations (1) references (6) figures (1) abstract and. Cylindrical Grinding Depth Of Cut.

From www.youtube.com

Does Depth of Cut Make a Difference to Finish YouTube Cylindrical Grinding Depth Of Cut When the entire length of work has passed infront of the wheel, the wheel advances forward by another 0.015 mm at the end of the traverse and so the cycle of machining goes on, until the desired daimeter of the work piece is reached. Cylindrical grinding machine is employed in machining of. The grinding wheel material and grade greatly influence. Cylindrical Grinding Depth Of Cut.

From www.slideserve.com

PPT Tertiary Manufacturing Processes PowerPoint Presentation, free Cylindrical Grinding Depth Of Cut Cylindrical grinding machine is employed in machining of. When the entire length of work has passed infront of the wheel, the wheel advances forward by another 0.015 mm at the end of the traverse and so the cycle of machining goes on, until the desired daimeter of the work piece is reached. The grinding wheel material and grade greatly influence. Cylindrical Grinding Depth Of Cut.

From www.vlr.eng.br

Cylindrical Grinding Diagram vlr.eng.br Cylindrical Grinding Depth Of Cut The present paper takes the following input processes parameters namely work speed, feed rate and depth of cut. The maximum achievable journal roundness accuracy range by the conventional “rolling bearing supported spindle and fixed. Citations (1) references (6) figures (1) abstract and figures. The depth of cut is very small, about 0.015 mm. The grinding wheel material and grade greatly. Cylindrical Grinding Depth Of Cut.

From finemetalworking.com

Cylindrical Grinding Fine MetalWorking Cylindrical Grinding Depth Of Cut The depth of cut is very small, about 0.015 mm. Citations (1) references (6) figures (1) abstract and figures. There were 27 experiments conducted with different machining parameters to determine optimal solution of cylindrical grinding process. The basic process parameters in grinding processes are the cutting speed v c, the feed velocity v f, the depth of cut a. When. Cylindrical Grinding Depth Of Cut.

From www.researchgate.net

Actualgrinding depth of cut measured by surface profilometry Cylindrical Grinding Depth Of Cut Cylindrical grinding machine is employed in machining of. The present paper takes the following input processes parameters namely work speed, feed rate and depth of cut. The maximum achievable journal roundness accuracy range by the conventional “rolling bearing supported spindle and fixed. The main objective of this. The basic process parameters in grinding processes are the cutting speed v c,. Cylindrical Grinding Depth Of Cut.

From www.minaprem.com

What is Depth of Cut (DOC) in Machining? Machining Principles Cylindrical Grinding Depth Of Cut Citations (1) references (6) figures (1) abstract and figures. The depth of cut is very small, about 0.015 mm. The present paper takes the following input processes parameters namely work speed, feed rate and depth of cut. The grinding wheel material and grade greatly influence the surface roughness, followed by the workpiece speed (r.p.m.), depth. There were 27 experiments conducted. Cylindrical Grinding Depth Of Cut.

From www.researchgate.net

Grinding depth of cut versus grain size under vs = 8.37 m/s and Cylindrical Grinding Depth Of Cut The present paper takes the following input processes parameters namely work speed, feed rate and depth of cut. The main objective of this. The maximum achievable journal roundness accuracy range by the conventional “rolling bearing supported spindle and fixed. There were 27 experiments conducted with different machining parameters to determine optimal solution of cylindrical grinding process. The grinding wheel material. Cylindrical Grinding Depth Of Cut.

From www.researchgate.net

Influence of the depth of cut and the grinding process on the specific Cylindrical Grinding Depth Of Cut The present paper takes the following input processes parameters namely work speed, feed rate and depth of cut. Citations (1) references (6) figures (1) abstract and figures. The depth of cut is very small, about 0.015 mm. The grinding wheel material and grade greatly influence the surface roughness, followed by the workpiece speed (r.p.m.), depth. The results indicated that grinding. Cylindrical Grinding Depth Of Cut.

From sctools.online

Axial Depth of Cut (Milling AP) FM Carbide Cylindrical Grinding Depth Of Cut There were 27 experiments conducted with different machining parameters to determine optimal solution of cylindrical grinding process. The basic process parameters in grinding processes are the cutting speed v c, the feed velocity v f, the depth of cut a. When the entire length of work has passed infront of the wheel, the wheel advances forward by another 0.015 mm. Cylindrical Grinding Depth Of Cut.

From toolnotes.com

Cutting Parameters for Turning ToolNotes Cylindrical Grinding Depth Of Cut Cylindrical grinding machine is employed in machining of. The maximum achievable journal roundness accuracy range by the conventional “rolling bearing supported spindle and fixed. The basic process parameters in grinding processes are the cutting speed v c, the feed velocity v f, the depth of cut a. The grinding wheel material and grade greatly influence the surface roughness, followed by. Cylindrical Grinding Depth Of Cut.

From www.researchgate.net

(PDF) Assessment of the actual depth of cutting with cylindrical Cylindrical Grinding Depth Of Cut The main objective of this. Citations (1) references (6) figures (1) abstract and figures. The results indicated that grinding wheel speed, work piece speed, table feed rate and depth of cut were the significant factors for the surface roughness and. Cylindrical grinding machine is employed in machining of. The present paper takes the following input processes parameters namely work speed,. Cylindrical Grinding Depth Of Cut.

From empiremt.com

CNC Cylindrical Grinding Machines Empire Machine Tools Cylindrical Grinding Depth Of Cut There were 27 experiments conducted with different machining parameters to determine optimal solution of cylindrical grinding process. The present paper takes the following input processes parameters namely work speed, feed rate and depth of cut. The maximum achievable journal roundness accuracy range by the conventional “rolling bearing supported spindle and fixed. Citations (1) references (6) figures (1) abstract and figures.. Cylindrical Grinding Depth Of Cut.

From www.minaprem.com

What is Depth of Cut in Machining? Its Unit, Value, Effects and Selection Cylindrical Grinding Depth Of Cut Citations (1) references (6) figures (1) abstract and figures. The grinding wheel material and grade greatly influence the surface roughness, followed by the workpiece speed (r.p.m.), depth. The present paper takes the following input processes parameters namely work speed, feed rate and depth of cut. The main objective of this. The results indicated that grinding wheel speed, work piece speed,. Cylindrical Grinding Depth Of Cut.

From www.mscdirect.com

Sandvik Coromant Cylindrical Connection, 10mm Cutting Width, 28mm Cylindrical Grinding Depth Of Cut Cylindrical grinding machine is employed in machining of. The grinding wheel material and grade greatly influence the surface roughness, followed by the workpiece speed (r.p.m.), depth. The basic process parameters in grinding processes are the cutting speed v c, the feed velocity v f, the depth of cut a. The present paper takes the following input processes parameters namely work. Cylindrical Grinding Depth Of Cut.

From jsmithmoore.com

Cutting speed feed and depth of cut formula Cylindrical Grinding Depth Of Cut The results indicated that grinding wheel speed, work piece speed, table feed rate and depth of cut were the significant factors for the surface roughness and. The basic process parameters in grinding processes are the cutting speed v c, the feed velocity v f, the depth of cut a. The present paper takes the following input processes parameters namely work. Cylindrical Grinding Depth Of Cut.

From www.youtube.com

Cutting Speed Feed Depth of Cut Cutting Time of Grinding Machines Cylindrical Grinding Depth Of Cut There were 27 experiments conducted with different machining parameters to determine optimal solution of cylindrical grinding process. The main objective of this. The maximum achievable journal roundness accuracy range by the conventional “rolling bearing supported spindle and fixed. The present paper takes the following input processes parameters namely work speed, feed rate and depth of cut. The results indicated that. Cylindrical Grinding Depth Of Cut.

From learnmech.com

Types of Cylindrical grinding machine with Diagram Explained Cylindrical Grinding Depth Of Cut The present paper takes the following input processes parameters namely work speed, feed rate and depth of cut. The main objective of this. There were 27 experiments conducted with different machining parameters to determine optimal solution of cylindrical grinding process. The results indicated that grinding wheel speed, work piece speed, table feed rate and depth of cut were the significant. Cylindrical Grinding Depth Of Cut.

From www.youtube.com

Cutting Parameters Cutting Speed, Feed, Depth of cut CNCLearning Cylindrical Grinding Depth Of Cut When the entire length of work has passed infront of the wheel, the wheel advances forward by another 0.015 mm at the end of the traverse and so the cycle of machining goes on, until the desired daimeter of the work piece is reached. The depth of cut is very small, about 0.015 mm. There were 27 experiments conducted with. Cylindrical Grinding Depth Of Cut.

From jsmithmoore.com

Cutting speed feed and depth of cut formula Cylindrical Grinding Depth Of Cut The present paper takes the following input processes parameters namely work speed, feed rate and depth of cut. There were 27 experiments conducted with different machining parameters to determine optimal solution of cylindrical grinding process. The main objective of this. Citations (1) references (6) figures (1) abstract and figures. The depth of cut is very small, about 0.015 mm. The. Cylindrical Grinding Depth Of Cut.

From in.eteachers.edu.vn

Aggregate 125+ cylindrical grinding machine sketch in.eteachers Cylindrical Grinding Depth Of Cut There were 27 experiments conducted with different machining parameters to determine optimal solution of cylindrical grinding process. The grinding wheel material and grade greatly influence the surface roughness, followed by the workpiece speed (r.p.m.), depth. When the entire length of work has passed infront of the wheel, the wheel advances forward by another 0.015 mm at the end of the. Cylindrical Grinding Depth Of Cut.

From www.allied-material.co.jp

Various grinding methods|A.L.M.T. Corp. Cylindrical Grinding Depth Of Cut The basic process parameters in grinding processes are the cutting speed v c, the feed velocity v f, the depth of cut a. The results indicated that grinding wheel speed, work piece speed, table feed rate and depth of cut were the significant factors for the surface roughness and. The grinding wheel material and grade greatly influence the surface roughness,. Cylindrical Grinding Depth Of Cut.