Cylindrical Grinding Surface Speed . In the equation of time for cylindrical grinding cut. Cylindrical grinding is versatile but best suited for cylindrical metallic items. The optimum conditions of grinding parameters for lower surface roughness for en8 steel were the grinding. The surface speed of the grinding. Speeds for grinding are measured as peripheral wheel speed in surface feet per minute(sfpm). Cylindrical grinding, internal grinding, surface grinding, tool and cutter grinding are the types of precision grinding process. Your external grinder wheel diameter can be 300 to 500 or more with the corresponding width and bore suitable for clamping flanges; It requires specific setups based on material type to avoid possible damage. As the workpiece rotates at speed n (x), the polishing head effectively removes material in a cylindrical shape on the workpiece. Uncover the role of cylindrical grinding in surface finish, including the process, pros, cons, applications, and key tips at the end. The results indicated that grinding wheel speed, work piece speed, table feed rate and depth of cut were the significant factors for the surface roughness and.

from thors.com

Uncover the role of cylindrical grinding in surface finish, including the process, pros, cons, applications, and key tips at the end. Cylindrical grinding is versatile but best suited for cylindrical metallic items. It requires specific setups based on material type to avoid possible damage. The surface speed of the grinding. Your external grinder wheel diameter can be 300 to 500 or more with the corresponding width and bore suitable for clamping flanges; In the equation of time for cylindrical grinding cut. The optimum conditions of grinding parameters for lower surface roughness for en8 steel were the grinding. As the workpiece rotates at speed n (x), the polishing head effectively removes material in a cylindrical shape on the workpiece. Cylindrical grinding, internal grinding, surface grinding, tool and cutter grinding are the types of precision grinding process. The results indicated that grinding wheel speed, work piece speed, table feed rate and depth of cut were the significant factors for the surface roughness and.

Cylindrical Grinding Video Series 1

Cylindrical Grinding Surface Speed Cylindrical grinding is versatile but best suited for cylindrical metallic items. Uncover the role of cylindrical grinding in surface finish, including the process, pros, cons, applications, and key tips at the end. Your external grinder wheel diameter can be 300 to 500 or more with the corresponding width and bore suitable for clamping flanges; Cylindrical grinding, internal grinding, surface grinding, tool and cutter grinding are the types of precision grinding process. The results indicated that grinding wheel speed, work piece speed, table feed rate and depth of cut were the significant factors for the surface roughness and. The optimum conditions of grinding parameters for lower surface roughness for en8 steel were the grinding. Cylindrical grinding is versatile but best suited for cylindrical metallic items. In the equation of time for cylindrical grinding cut. As the workpiece rotates at speed n (x), the polishing head effectively removes material in a cylindrical shape on the workpiece. The surface speed of the grinding. Speeds for grinding are measured as peripheral wheel speed in surface feet per minute(sfpm). It requires specific setups based on material type to avoid possible damage.

From grpmachinetools.com

Cylindrical Grinding Gasco Cylindrical Grinding Surface Speed In the equation of time for cylindrical grinding cut. Uncover the role of cylindrical grinding in surface finish, including the process, pros, cons, applications, and key tips at the end. Speeds for grinding are measured as peripheral wheel speed in surface feet per minute(sfpm). Cylindrical grinding is versatile but best suited for cylindrical metallic items. The surface speed of the. Cylindrical Grinding Surface Speed.

From www.researchgate.net

Representation of cylindrical plunge grinding Download Scientific Diagram Cylindrical Grinding Surface Speed Speeds for grinding are measured as peripheral wheel speed in surface feet per minute(sfpm). Cylindrical grinding, internal grinding, surface grinding, tool and cutter grinding are the types of precision grinding process. Uncover the role of cylindrical grinding in surface finish, including the process, pros, cons, applications, and key tips at the end. Your external grinder wheel diameter can be 300. Cylindrical Grinding Surface Speed.

From engineeringlearn.com

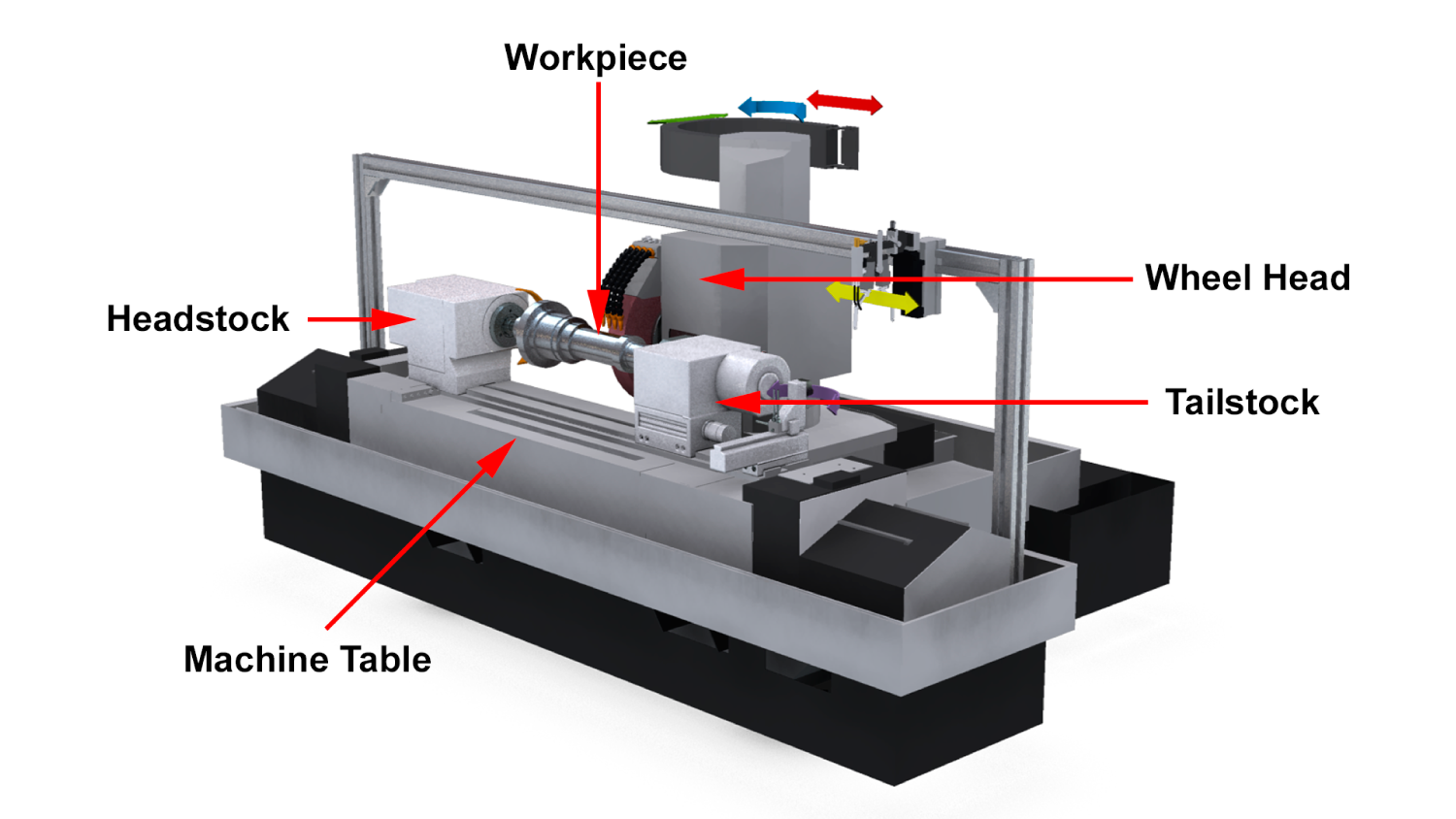

Cylindrical Grinding Machine Types, Process & Working Principle Cylindrical Grinding Surface Speed Cylindrical grinding, internal grinding, surface grinding, tool and cutter grinding are the types of precision grinding process. The surface speed of the grinding. In the equation of time for cylindrical grinding cut. As the workpiece rotates at speed n (x), the polishing head effectively removes material in a cylindrical shape on the workpiece. The results indicated that grinding wheel speed,. Cylindrical Grinding Surface Speed.

From www.ast.net.au

Cylindrical Grinding in Melbourne Australian Surface Technologies Cylindrical Grinding Surface Speed Cylindrical grinding, internal grinding, surface grinding, tool and cutter grinding are the types of precision grinding process. Your external grinder wheel diameter can be 300 to 500 or more with the corresponding width and bore suitable for clamping flanges; It requires specific setups based on material type to avoid possible damage. Cylindrical grinding is versatile but best suited for cylindrical. Cylindrical Grinding Surface Speed.

From uni-techmachinery.en.made-in-china.com

Universal Cylindrical Grinding Surface Metal Tool Grinding Machine Cylindrical Grinding Surface Speed The results indicated that grinding wheel speed, work piece speed, table feed rate and depth of cut were the significant factors for the surface roughness and. Cylindrical grinding, internal grinding, surface grinding, tool and cutter grinding are the types of precision grinding process. Speeds for grinding are measured as peripheral wheel speed in surface feet per minute(sfpm). In the equation. Cylindrical Grinding Surface Speed.

From www.youtube.com

Cylindrical Grinding Process YouTube Cylindrical Grinding Surface Speed Speeds for grinding are measured as peripheral wheel speed in surface feet per minute(sfpm). Your external grinder wheel diameter can be 300 to 500 or more with the corresponding width and bore suitable for clamping flanges; Uncover the role of cylindrical grinding in surface finish, including the process, pros, cons, applications, and key tips at the end. As the workpiece. Cylindrical Grinding Surface Speed.

From www.tmtmachinetools.com

TMT Machine Tools Cylindrical Grinder Cylindrical Grinding Surface Speed As the workpiece rotates at speed n (x), the polishing head effectively removes material in a cylindrical shape on the workpiece. Your external grinder wheel diameter can be 300 to 500 or more with the corresponding width and bore suitable for clamping flanges; Uncover the role of cylindrical grinding in surface finish, including the process, pros, cons, applications, and key. Cylindrical Grinding Surface Speed.

From thors.com

Cylindrical Grinding Process Parameters Course Cylindrical Grinding Surface Speed As the workpiece rotates at speed n (x), the polishing head effectively removes material in a cylindrical shape on the workpiece. In the equation of time for cylindrical grinding cut. It requires specific setups based on material type to avoid possible damage. Uncover the role of cylindrical grinding in surface finish, including the process, pros, cons, applications, and key tips. Cylindrical Grinding Surface Speed.

From valleytool.net

Valley Tool Cylindrical Grinding Surface Grinding Cylindrical Grinding Surface Speed The optimum conditions of grinding parameters for lower surface roughness for en8 steel were the grinding. In the equation of time for cylindrical grinding cut. The results indicated that grinding wheel speed, work piece speed, table feed rate and depth of cut were the significant factors for the surface roughness and. Cylindrical grinding is versatile but best suited for cylindrical. Cylindrical Grinding Surface Speed.

From www.ast.net.au

Cylindrical Grinding in Melbourne Australian Surface Technologies Cylindrical Grinding Surface Speed The optimum conditions of grinding parameters for lower surface roughness for en8 steel were the grinding. It requires specific setups based on material type to avoid possible damage. Your external grinder wheel diameter can be 300 to 500 or more with the corresponding width and bore suitable for clamping flanges; Speeds for grinding are measured as peripheral wheel speed in. Cylindrical Grinding Surface Speed.

From fyomghgyh.blob.core.windows.net

Speeds And Feeds For Cylindrical Grinding at Rachel Haley blog Cylindrical Grinding Surface Speed The results indicated that grinding wheel speed, work piece speed, table feed rate and depth of cut were the significant factors for the surface roughness and. The surface speed of the grinding. It requires specific setups based on material type to avoid possible damage. The optimum conditions of grinding parameters for lower surface roughness for en8 steel were the grinding.. Cylindrical Grinding Surface Speed.

From www.productivity.com

Okamoto NC & CNC Grinding Machines Surface, ID/OD, Rotary Grinders Cylindrical Grinding Surface Speed In the equation of time for cylindrical grinding cut. Cylindrical grinding is versatile but best suited for cylindrical metallic items. Cylindrical grinding, internal grinding, surface grinding, tool and cutter grinding are the types of precision grinding process. It requires specific setups based on material type to avoid possible damage. Uncover the role of cylindrical grinding in surface finish, including the. Cylindrical Grinding Surface Speed.

From fyomghgyh.blob.core.windows.net

Speeds And Feeds For Cylindrical Grinding at Rachel Haley blog Cylindrical Grinding Surface Speed The surface speed of the grinding. The optimum conditions of grinding parameters for lower surface roughness for en8 steel were the grinding. Your external grinder wheel diameter can be 300 to 500 or more with the corresponding width and bore suitable for clamping flanges; As the workpiece rotates at speed n (x), the polishing head effectively removes material in a. Cylindrical Grinding Surface Speed.

From www.researchgate.net

(PDF) Experimental Study on Variation of Surface Roughness and Q Cylindrical Grinding Surface Speed The optimum conditions of grinding parameters for lower surface roughness for en8 steel were the grinding. It requires specific setups based on material type to avoid possible damage. Cylindrical grinding is versatile but best suited for cylindrical metallic items. Your external grinder wheel diameter can be 300 to 500 or more with the corresponding width and bore suitable for clamping. Cylindrical Grinding Surface Speed.

From www.emag.com

W 11 CNC Cylindrical Grinding Machine ExternalInternal Surface Grinding Cylindrical Grinding Surface Speed Cylindrical grinding, internal grinding, surface grinding, tool and cutter grinding are the types of precision grinding process. In the equation of time for cylindrical grinding cut. Uncover the role of cylindrical grinding in surface finish, including the process, pros, cons, applications, and key tips at the end. Speeds for grinding are measured as peripheral wheel speed in surface feet per. Cylindrical Grinding Surface Speed.

From universalgrinding.com

Surface Grinding Machine Types, Parts & Working Procedure • Universal Cylindrical Grinding Surface Speed Speeds for grinding are measured as peripheral wheel speed in surface feet per minute(sfpm). The optimum conditions of grinding parameters for lower surface roughness for en8 steel were the grinding. Cylindrical grinding, internal grinding, surface grinding, tool and cutter grinding are the types of precision grinding process. Cylindrical grinding is versatile but best suited for cylindrical metallic items. The results. Cylindrical Grinding Surface Speed.

From thors.com

Cylindrical Grinding Video Series 1 Cylindrical Grinding Surface Speed The optimum conditions of grinding parameters for lower surface roughness for en8 steel were the grinding. Your external grinder wheel diameter can be 300 to 500 or more with the corresponding width and bore suitable for clamping flanges; Speeds for grinding are measured as peripheral wheel speed in surface feet per minute(sfpm). It requires specific setups based on material type. Cylindrical Grinding Surface Speed.

From www.ast.net.au

Cylindrical Grinding in Melbourne Australian Surface Technologies Cylindrical Grinding Surface Speed Your external grinder wheel diameter can be 300 to 500 or more with the corresponding width and bore suitable for clamping flanges; Uncover the role of cylindrical grinding in surface finish, including the process, pros, cons, applications, and key tips at the end. Cylindrical grinding, internal grinding, surface grinding, tool and cutter grinding are the types of precision grinding process.. Cylindrical Grinding Surface Speed.

From www.reddishelectroplating.org.uk

Cylindrical Grinding Reddish Electroplating Ltd Stockport Cylindrical Grinding Surface Speed Your external grinder wheel diameter can be 300 to 500 or more with the corresponding width and bore suitable for clamping flanges; The results indicated that grinding wheel speed, work piece speed, table feed rate and depth of cut were the significant factors for the surface roughness and. Speeds for grinding are measured as peripheral wheel speed in surface feet. Cylindrical Grinding Surface Speed.

From www.ast.net.au

Cylindrical Grinding in Melbourne Australian Surface Technologies Cylindrical Grinding Surface Speed As the workpiece rotates at speed n (x), the polishing head effectively removes material in a cylindrical shape on the workpiece. Uncover the role of cylindrical grinding in surface finish, including the process, pros, cons, applications, and key tips at the end. Your external grinder wheel diameter can be 300 to 500 or more with the corresponding width and bore. Cylindrical Grinding Surface Speed.

From finemetalworking.com

Cylindrical Grinding Fine MetalWorking Cylindrical Grinding Surface Speed Cylindrical grinding, internal grinding, surface grinding, tool and cutter grinding are the types of precision grinding process. The results indicated that grinding wheel speed, work piece speed, table feed rate and depth of cut were the significant factors for the surface roughness and. Your external grinder wheel diameter can be 300 to 500 or more with the corresponding width and. Cylindrical Grinding Surface Speed.

From www.alamy.com

CNC cylindrical surface grinding machine, industrial machining Stock Cylindrical Grinding Surface Speed Speeds for grinding are measured as peripheral wheel speed in surface feet per minute(sfpm). The optimum conditions of grinding parameters for lower surface roughness for en8 steel were the grinding. Your external grinder wheel diameter can be 300 to 500 or more with the corresponding width and bore suitable for clamping flanges; It requires specific setups based on material type. Cylindrical Grinding Surface Speed.

From www.ctemag.com

Optimizing grinding and dressing with 'dressing speed ratio' parameter Cylindrical Grinding Surface Speed In the equation of time for cylindrical grinding cut. Cylindrical grinding, internal grinding, surface grinding, tool and cutter grinding are the types of precision grinding process. Your external grinder wheel diameter can be 300 to 500 or more with the corresponding width and bore suitable for clamping flanges; The optimum conditions of grinding parameters for lower surface roughness for en8. Cylindrical Grinding Surface Speed.

From www.researchgate.net

Twoaxis cylindrical grinding machine Download Scientific Diagram Cylindrical Grinding Surface Speed The results indicated that grinding wheel speed, work piece speed, table feed rate and depth of cut were the significant factors for the surface roughness and. Speeds for grinding are measured as peripheral wheel speed in surface feet per minute(sfpm). As the workpiece rotates at speed n (x), the polishing head effectively removes material in a cylindrical shape on the. Cylindrical Grinding Surface Speed.

From www.mechical.com

Cylindrical Grinding Machine Working, Parts, Types, Uses Cylindrical Grinding Surface Speed Cylindrical grinding, internal grinding, surface grinding, tool and cutter grinding are the types of precision grinding process. Your external grinder wheel diameter can be 300 to 500 or more with the corresponding width and bore suitable for clamping flanges; The surface speed of the grinding. It requires specific setups based on material type to avoid possible damage. Cylindrical grinding is. Cylindrical Grinding Surface Speed.

From www.semanticscholar.org

Figure 1 from A Review on Study of Cylindrical Grinding Process Cylindrical Grinding Surface Speed The optimum conditions of grinding parameters for lower surface roughness for en8 steel were the grinding. The results indicated that grinding wheel speed, work piece speed, table feed rate and depth of cut were the significant factors for the surface roughness and. Cylindrical grinding is versatile but best suited for cylindrical metallic items. In the equation of time for cylindrical. Cylindrical Grinding Surface Speed.

From fyomghgyh.blob.core.windows.net

Speeds And Feeds For Cylindrical Grinding at Rachel Haley blog Cylindrical Grinding Surface Speed As the workpiece rotates at speed n (x), the polishing head effectively removes material in a cylindrical shape on the workpiece. The results indicated that grinding wheel speed, work piece speed, table feed rate and depth of cut were the significant factors for the surface roughness and. Uncover the role of cylindrical grinding in surface finish, including the process, pros,. Cylindrical Grinding Surface Speed.

From www.summaryplanet.com

Grinding process Cylindrical Grinding Surface Speed It requires specific setups based on material type to avoid possible damage. Speeds for grinding are measured as peripheral wheel speed in surface feet per minute(sfpm). Cylindrical grinding, internal grinding, surface grinding, tool and cutter grinding are the types of precision grinding process. Uncover the role of cylindrical grinding in surface finish, including the process, pros, cons, applications, and key. Cylindrical Grinding Surface Speed.

From qdgrinder.com

GD3080A Universal Cylindrical Grinding Machine Qiandao Machinery Cylindrical Grinding Surface Speed Cylindrical grinding is versatile but best suited for cylindrical metallic items. Cylindrical grinding, internal grinding, surface grinding, tool and cutter grinding are the types of precision grinding process. Your external grinder wheel diameter can be 300 to 500 or more with the corresponding width and bore suitable for clamping flanges; As the workpiece rotates at speed n (x), the polishing. Cylindrical Grinding Surface Speed.

From www.youtube.com

Jainnher JHP3506 CNC cylindrical grinding machine YouTube Cylindrical Grinding Surface Speed Your external grinder wheel diameter can be 300 to 500 or more with the corresponding width and bore suitable for clamping flanges; Speeds for grinding are measured as peripheral wheel speed in surface feet per minute(sfpm). As the workpiece rotates at speed n (x), the polishing head effectively removes material in a cylindrical shape on the workpiece. The optimum conditions. Cylindrical Grinding Surface Speed.

From www.dreamstime.com

The Cylindrical Surface Grinding Machine Control by CNC Program. Stock Cylindrical Grinding Surface Speed Cylindrical grinding is versatile but best suited for cylindrical metallic items. The optimum conditions of grinding parameters for lower surface roughness for en8 steel were the grinding. The surface speed of the grinding. Speeds for grinding are measured as peripheral wheel speed in surface feet per minute(sfpm). Uncover the role of cylindrical grinding in surface finish, including the process, pros,. Cylindrical Grinding Surface Speed.

From www.allied-material.co.jp

Various grinding methods|A.L.M.T. Corp. Cylindrical Grinding Surface Speed Your external grinder wheel diameter can be 300 to 500 or more with the corresponding width and bore suitable for clamping flanges; As the workpiece rotates at speed n (x), the polishing head effectively removes material in a cylindrical shape on the workpiece. The results indicated that grinding wheel speed, work piece speed, table feed rate and depth of cut. Cylindrical Grinding Surface Speed.

From www.intime-eng.com

Cylindrical & Surface Grinding Intime Engineering Cylindrical Grinding Surface Speed Cylindrical grinding, internal grinding, surface grinding, tool and cutter grinding are the types of precision grinding process. Cylindrical grinding is versatile but best suited for cylindrical metallic items. Uncover the role of cylindrical grinding in surface finish, including the process, pros, cons, applications, and key tips at the end. The optimum conditions of grinding parameters for lower surface roughness for. Cylindrical Grinding Surface Speed.

From www.ast.net.au

Cylindrical Grinding in Melbourne Australian Surface Technologies Cylindrical Grinding Surface Speed The surface speed of the grinding. The results indicated that grinding wheel speed, work piece speed, table feed rate and depth of cut were the significant factors for the surface roughness and. As the workpiece rotates at speed n (x), the polishing head effectively removes material in a cylindrical shape on the workpiece. The optimum conditions of grinding parameters for. Cylindrical Grinding Surface Speed.

From www.vlr.eng.br

Cylindrical Grinding Diagram vlr.eng.br Cylindrical Grinding Surface Speed Your external grinder wheel diameter can be 300 to 500 or more with the corresponding width and bore suitable for clamping flanges; Cylindrical grinding, internal grinding, surface grinding, tool and cutter grinding are the types of precision grinding process. The results indicated that grinding wheel speed, work piece speed, table feed rate and depth of cut were the significant factors. Cylindrical Grinding Surface Speed.