Abrasive Wheel Procedure . in addition to looking at essential training needs, the guide also focuses on details such as: the aim of abrasive wheels training is to ensure that operators are working safely with abrasive wheels so. When preparing to install an abrasive wheel, the wheel should be closely inspected for any signs of damage. The installer must confirm compatibility (with material, task and machine) prior to installation. Damaged wheels must not be used. hsg17 is a bank of essential safety measures that form the backbone of best practices in abrasive wheel usage, from guidelines on the appropriate selection of abrasive wheels based on the task to proper storage and handling These bonds are cured at low temperatures. put simply, abrasive wheels are revolving wheels, cylinders, discs or cones made of abrasive particles, which have been bonded together, using inorganic or organic substances. abrasive wheels must be installed by an appropriately trained person. abrasive wheels are wheels, cones or cups that have abrasive particles like grit that are bonded with either inorganic or organic substances like resin. abrasive wheel characteristics 8 an abrasive wheel is usually defined as a wheel consisting of abrasive particles bonded.

from novoabrasive.com

The installer must confirm compatibility (with material, task and machine) prior to installation. hsg17 is a bank of essential safety measures that form the backbone of best practices in abrasive wheel usage, from guidelines on the appropriate selection of abrasive wheels based on the task to proper storage and handling in addition to looking at essential training needs, the guide also focuses on details such as: put simply, abrasive wheels are revolving wheels, cylinders, discs or cones made of abrasive particles, which have been bonded together, using inorganic or organic substances. Damaged wheels must not be used. the aim of abrasive wheels training is to ensure that operators are working safely with abrasive wheels so. These bonds are cured at low temperatures. abrasive wheels must be installed by an appropriately trained person. abrasive wheels are wheels, cones or cups that have abrasive particles like grit that are bonded with either inorganic or organic substances like resin. When preparing to install an abrasive wheel, the wheel should be closely inspected for any signs of damage.

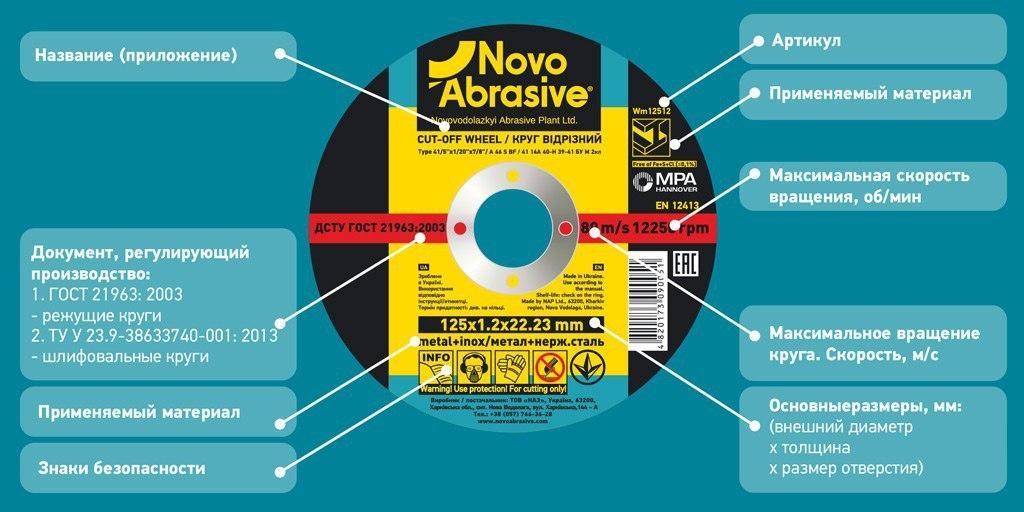

Marking and main parameters of cutting abrasive wheels

Abrasive Wheel Procedure hsg17 is a bank of essential safety measures that form the backbone of best practices in abrasive wheel usage, from guidelines on the appropriate selection of abrasive wheels based on the task to proper storage and handling When preparing to install an abrasive wheel, the wheel should be closely inspected for any signs of damage. hsg17 is a bank of essential safety measures that form the backbone of best practices in abrasive wheel usage, from guidelines on the appropriate selection of abrasive wheels based on the task to proper storage and handling abrasive wheel characteristics 8 an abrasive wheel is usually defined as a wheel consisting of abrasive particles bonded. in addition to looking at essential training needs, the guide also focuses on details such as: The installer must confirm compatibility (with material, task and machine) prior to installation. Damaged wheels must not be used. abrasive wheels are wheels, cones or cups that have abrasive particles like grit that are bonded with either inorganic or organic substances like resin. put simply, abrasive wheels are revolving wheels, cylinders, discs or cones made of abrasive particles, which have been bonded together, using inorganic or organic substances. These bonds are cured at low temperatures. abrasive wheels must be installed by an appropriately trained person. the aim of abrasive wheels training is to ensure that operators are working safely with abrasive wheels so.

From www.trainingandtestingservices.co.uk

Abrasive Wheel Training BAF Accredited Training & Testing Services Abrasive Wheel Procedure Damaged wheels must not be used. the aim of abrasive wheels training is to ensure that operators are working safely with abrasive wheels so. These bonds are cured at low temperatures. The installer must confirm compatibility (with material, task and machine) prior to installation. abrasive wheels are wheels, cones or cups that have abrasive particles like grit that. Abrasive Wheel Procedure.

From www.safetyhub.com

Abrasive Wheel Safety Training Online Safetyhub Abrasive Wheel Procedure The installer must confirm compatibility (with material, task and machine) prior to installation. abrasive wheels are wheels, cones or cups that have abrasive particles like grit that are bonded with either inorganic or organic substances like resin. When preparing to install an abrasive wheel, the wheel should be closely inspected for any signs of damage. the aim of. Abrasive Wheel Procedure.

From www.ihasco.co.uk

Abrasive Wheel Safety Training IIRSM & CPD Accredited iHasco Abrasive Wheel Procedure abrasive wheel characteristics 8 an abrasive wheel is usually defined as a wheel consisting of abrasive particles bonded. in addition to looking at essential training needs, the guide also focuses on details such as: When preparing to install an abrasive wheel, the wheel should be closely inspected for any signs of damage. put simply, abrasive wheels are. Abrasive Wheel Procedure.

From shoal-safetyinnumbers.com

Abrasive Wheels with Practical Cutting/Grinding Training Shoal Abrasive Wheel Procedure the aim of abrasive wheels training is to ensure that operators are working safely with abrasive wheels so. When preparing to install an abrasive wheel, the wheel should be closely inspected for any signs of damage. Damaged wheels must not be used. abrasive wheels must be installed by an appropriately trained person. put simply, abrasive wheels are. Abrasive Wheel Procedure.

From www.ethiretraining.com

The Safe Use Of Abrasive Wheel ET Hire Training Abrasive Wheel Procedure Damaged wheels must not be used. abrasive wheels are wheels, cones or cups that have abrasive particles like grit that are bonded with either inorganic or organic substances like resin. in addition to looking at essential training needs, the guide also focuses on details such as: When preparing to install an abrasive wheel, the wheel should be closely. Abrasive Wheel Procedure.

From www.slideserve.com

PPT Tools Hand and Power PowerPoint Presentation, free download Abrasive Wheel Procedure abrasive wheels must be installed by an appropriately trained person. abrasive wheel characteristics 8 an abrasive wheel is usually defined as a wheel consisting of abrasive particles bonded. These bonds are cured at low temperatures. the aim of abrasive wheels training is to ensure that operators are working safely with abrasive wheels so. Damaged wheels must not. Abrasive Wheel Procedure.

From mjksafety.com

Abrasive Wheel MJK Safety Abrasive Wheel Procedure in addition to looking at essential training needs, the guide also focuses on details such as: When preparing to install an abrasive wheel, the wheel should be closely inspected for any signs of damage. Damaged wheels must not be used. put simply, abrasive wheels are revolving wheels, cylinders, discs or cones made of abrasive particles, which have been. Abrasive Wheel Procedure.

From www.trainingandtestingservices.co.uk

What is abrasive wheel training Training & Testing Services Abrasive Wheel Procedure put simply, abrasive wheels are revolving wheels, cylinders, discs or cones made of abrasive particles, which have been bonded together, using inorganic or organic substances. abrasive wheels must be installed by an appropriately trained person. The installer must confirm compatibility (with material, task and machine) prior to installation. These bonds are cured at low temperatures. abrasive wheel. Abrasive Wheel Procedure.

From pd-training.co.uk

A guide to abrasive wheel training PD Training Abrasive Wheel Procedure abrasive wheels are wheels, cones or cups that have abrasive particles like grit that are bonded with either inorganic or organic substances like resin. These bonds are cured at low temperatures. the aim of abrasive wheels training is to ensure that operators are working safely with abrasive wheels so. Damaged wheels must not be used. in addition. Abrasive Wheel Procedure.

From novoabrasive.com

Marking and main parameters of cutting abrasive wheels Abrasive Wheel Procedure These bonds are cured at low temperatures. the aim of abrasive wheels training is to ensure that operators are working safely with abrasive wheels so. abrasive wheels are wheels, cones or cups that have abrasive particles like grit that are bonded with either inorganic or organic substances like resin. The installer must confirm compatibility (with material, task and. Abrasive Wheel Procedure.

From olivelearning.com.au

Abrasive Wheels Olive Learning Abrasive Wheel Procedure in addition to looking at essential training needs, the guide also focuses on details such as: The installer must confirm compatibility (with material, task and machine) prior to installation. hsg17 is a bank of essential safety measures that form the backbone of best practices in abrasive wheel usage, from guidelines on the appropriate selection of abrasive wheels based. Abrasive Wheel Procedure.

From www.youtube.com

Abrasive Wheel Safety Training Health & Safety Training iHasco Abrasive Wheel Procedure abrasive wheels are wheels, cones or cups that have abrasive particles like grit that are bonded with either inorganic or organic substances like resin. put simply, abrasive wheels are revolving wheels, cylinders, discs or cones made of abrasive particles, which have been bonded together, using inorganic or organic substances. Damaged wheels must not be used. the aim. Abrasive Wheel Procedure.

From ncts.teachable.com

Abrasive Wheels National Construction Training & Safety Abrasive Wheel Procedure When preparing to install an abrasive wheel, the wheel should be closely inspected for any signs of damage. Damaged wheels must not be used. the aim of abrasive wheels training is to ensure that operators are working safely with abrasive wheels so. abrasive wheels are wheels, cones or cups that have abrasive particles like grit that are bonded. Abrasive Wheel Procedure.

From www.ihasco.co.uk

Abrasive Wheel Safety Training IIRSM & CPD Accredited iHasco Abrasive Wheel Procedure When preparing to install an abrasive wheel, the wheel should be closely inspected for any signs of damage. put simply, abrasive wheels are revolving wheels, cylinders, discs or cones made of abrasive particles, which have been bonded together, using inorganic or organic substances. The installer must confirm compatibility (with material, task and machine) prior to installation. in addition. Abrasive Wheel Procedure.

From www.scribd.com

Abrasive Wheels Procedure Abrasive Occupational Safety And Health Abrasive Wheel Procedure the aim of abrasive wheels training is to ensure that operators are working safely with abrasive wheels so. in addition to looking at essential training needs, the guide also focuses on details such as: abrasive wheels are wheels, cones or cups that have abrasive particles like grit that are bonded with either inorganic or organic substances like. Abrasive Wheel Procedure.

From www.youtube.com

Abrasive Wheel Safety Training YouTube Abrasive Wheel Procedure Damaged wheels must not be used. abrasive wheels are wheels, cones or cups that have abrasive particles like grit that are bonded with either inorganic or organic substances like resin. When preparing to install an abrasive wheel, the wheel should be closely inspected for any signs of damage. in addition to looking at essential training needs, the guide. Abrasive Wheel Procedure.

From echo-3.co.uk

Guide to Abrasive Wheels What you need to know to work safely Abrasive Wheel Procedure the aim of abrasive wheels training is to ensure that operators are working safely with abrasive wheels so. abrasive wheels are wheels, cones or cups that have abrasive particles like grit that are bonded with either inorganic or organic substances like resin. abrasive wheels must be installed by an appropriately trained person. Damaged wheels must not be. Abrasive Wheel Procedure.

From www.jjtraininguk.com

Abrasive Wheels Courses, Abrasive Wheels Training JJ Training Abrasive Wheel Procedure When preparing to install an abrasive wheel, the wheel should be closely inspected for any signs of damage. put simply, abrasive wheels are revolving wheels, cylinders, discs or cones made of abrasive particles, which have been bonded together, using inorganic or organic substances. The installer must confirm compatibility (with material, task and machine) prior to installation. abrasive wheel. Abrasive Wheel Procedure.

From www.slideserve.com

PPT Abrasive Grinding Wheels PowerPoint Presentation ID3000348 Abrasive Wheel Procedure abrasive wheels must be installed by an appropriately trained person. in addition to looking at essential training needs, the guide also focuses on details such as: put simply, abrasive wheels are revolving wheels, cylinders, discs or cones made of abrasive particles, which have been bonded together, using inorganic or organic substances. When preparing to install an abrasive. Abrasive Wheel Procedure.

From www.slideserve.com

PPT ABRASIVE WHEEL MACHINERY OSHA 29 CFR 1910.215 PowerPoint Abrasive Wheel Procedure The installer must confirm compatibility (with material, task and machine) prior to installation. in addition to looking at essential training needs, the guide also focuses on details such as: the aim of abrasive wheels training is to ensure that operators are working safely with abrasive wheels so. abrasive wheel characteristics 8 an abrasive wheel is usually defined. Abrasive Wheel Procedure.

From www.3btraining.com

Abrasive Wheels Training Course Half Day Course Abrasive Wheel Procedure Damaged wheels must not be used. abrasive wheels must be installed by an appropriately trained person. The installer must confirm compatibility (with material, task and machine) prior to installation. the aim of abrasive wheels training is to ensure that operators are working safely with abrasive wheels so. put simply, abrasive wheels are revolving wheels, cylinders, discs or. Abrasive Wheel Procedure.

From trimmers-pro.com

Wheel Abrasive Test Abrasive Wheel Procedure These bonds are cured at low temperatures. hsg17 is a bank of essential safety measures that form the backbone of best practices in abrasive wheel usage, from guidelines on the appropriate selection of abrasive wheels based on the task to proper storage and handling abrasive wheel characteristics 8 an abrasive wheel is usually defined as a wheel consisting. Abrasive Wheel Procedure.

From www.dreamstime.com

The Solid End Mill Tool Manual Regrinding Process with Abrasive Wheel Abrasive Wheel Procedure put simply, abrasive wheels are revolving wheels, cylinders, discs or cones made of abrasive particles, which have been bonded together, using inorganic or organic substances. hsg17 is a bank of essential safety measures that form the backbone of best practices in abrasive wheel usage, from guidelines on the appropriate selection of abrasive wheels based on the task to. Abrasive Wheel Procedure.

From www.youtube.com

Safety Series How to mount an abrasive wheel YouTube Abrasive Wheel Procedure When preparing to install an abrasive wheel, the wheel should be closely inspected for any signs of damage. abrasive wheel characteristics 8 an abrasive wheel is usually defined as a wheel consisting of abrasive particles bonded. The installer must confirm compatibility (with material, task and machine) prior to installation. the aim of abrasive wheels training is to ensure. Abrasive Wheel Procedure.

From essentialsiteskills.co.uk

The ESS Guide to Abrasive Wheels Training Essential Site Skills Abrasive Wheel Procedure the aim of abrasive wheels training is to ensure that operators are working safely with abrasive wheels so. hsg17 is a bank of essential safety measures that form the backbone of best practices in abrasive wheel usage, from guidelines on the appropriate selection of abrasive wheels based on the task to proper storage and handling put simply,. Abrasive Wheel Procedure.

From quick-reach.co.uk

Abrasive Wheel Course Quick Reach Abrasive Wheel Procedure hsg17 is a bank of essential safety measures that form the backbone of best practices in abrasive wheel usage, from guidelines on the appropriate selection of abrasive wheels based on the task to proper storage and handling The installer must confirm compatibility (with material, task and machine) prior to installation. abrasive wheel characteristics 8 an abrasive wheel is. Abrasive Wheel Procedure.

From iadc.org

Abrasive WheelEquipped Grinders Checklist Abrasive Wheel Procedure abrasive wheels must be installed by an appropriately trained person. When preparing to install an abrasive wheel, the wheel should be closely inspected for any signs of damage. The installer must confirm compatibility (with material, task and machine) prior to installation. in addition to looking at essential training needs, the guide also focuses on details such as: . Abrasive Wheel Procedure.

From www.ihasco.co.uk

Abrasive Wheel Safety Training IIRSM & CPD Accredited iHasco Abrasive Wheel Procedure abrasive wheels must be installed by an appropriately trained person. in addition to looking at essential training needs, the guide also focuses on details such as: abrasive wheel characteristics 8 an abrasive wheel is usually defined as a wheel consisting of abrasive particles bonded. hsg17 is a bank of essential safety measures that form the backbone. Abrasive Wheel Procedure.

From www.slideshare.net

Safe Working Practices Abrasive Wheel Abrasive Wheel Procedure the aim of abrasive wheels training is to ensure that operators are working safely with abrasive wheels so. These bonds are cured at low temperatures. in addition to looking at essential training needs, the guide also focuses on details such as: Damaged wheels must not be used. put simply, abrasive wheels are revolving wheels, cylinders, discs or. Abrasive Wheel Procedure.

From www.c2safety.co.uk

Abrasive Wheel Training C2 Safety Abrasive Wheel Procedure in addition to looking at essential training needs, the guide also focuses on details such as: the aim of abrasive wheels training is to ensure that operators are working safely with abrasive wheels so. When preparing to install an abrasive wheel, the wheel should be closely inspected for any signs of damage. hsg17 is a bank of. Abrasive Wheel Procedure.

From novoabrasive.com

Interpretation of the Marking of NovoAbrasive abrasive discs according Abrasive Wheel Procedure put simply, abrasive wheels are revolving wheels, cylinders, discs or cones made of abrasive particles, which have been bonded together, using inorganic or organic substances. These bonds are cured at low temperatures. The installer must confirm compatibility (with material, task and machine) prior to installation. When preparing to install an abrasive wheel, the wheel should be closely inspected for. Abrasive Wheel Procedure.

From www.acetrainers.co.uk

Professional Abrasive Wheel Training In Hampshire Abrasive Wheel Procedure abrasive wheels must be installed by an appropriately trained person. put simply, abrasive wheels are revolving wheels, cylinders, discs or cones made of abrasive particles, which have been bonded together, using inorganic or organic substances. in addition to looking at essential training needs, the guide also focuses on details such as: Damaged wheels must not be used.. Abrasive Wheel Procedure.

From www.safework.nsw.gov.au

Safe use of abrasive wheels fact sheet SafeWork NSW Abrasive Wheel Procedure abrasive wheel characteristics 8 an abrasive wheel is usually defined as a wheel consisting of abrasive particles bonded. These bonds are cured at low temperatures. put simply, abrasive wheels are revolving wheels, cylinders, discs or cones made of abrasive particles, which have been bonded together, using inorganic or organic substances. hsg17 is a bank of essential safety. Abrasive Wheel Procedure.

From www.kissafety.co.uk

Abrasive Wheels Understanding the Marking System KIS Health and Abrasive Wheel Procedure abrasive wheels are wheels, cones or cups that have abrasive particles like grit that are bonded with either inorganic or organic substances like resin. abrasive wheel characteristics 8 an abrasive wheel is usually defined as a wheel consisting of abrasive particles bonded. When preparing to install an abrasive wheel, the wheel should be closely inspected for any signs. Abrasive Wheel Procedure.

From www.slideserve.com

PPT ABRASIVE WHEEL MACHINERY OSHA 29 CFR 1910.215 PowerPoint Abrasive Wheel Procedure put simply, abrasive wheels are revolving wheels, cylinders, discs or cones made of abrasive particles, which have been bonded together, using inorganic or organic substances. When preparing to install an abrasive wheel, the wheel should be closely inspected for any signs of damage. hsg17 is a bank of essential safety measures that form the backbone of best practices. Abrasive Wheel Procedure.