Countersinking In Drilling Machine . mapal offers the possibility of manufacturing a countersink step for almost all solid carbide drills as a special solution. countersinking, counterboring, and spotfacing operations can be carried out on drilling machines and usually follow. On the other hand, a counterbore has the sides parallel to each other without any tapering. countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. counterbore and countersink are both machining operations used to create recesses in materials like metal, wood, or plastic, but they serve. countersinks are mainly used for countersinking drill holes, countersinking screws and deburring. In this way two machining. Countersink comes in different angles, including 60°, 82°, and 90°. a countersink is a conical hole that is typically drilled or milled into a material, such as wood, metal, or plastic, to allow the head of a screw or fastener to sit flush with or below the surface of the material. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance.

from www.slideserve.com

It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. In this way two machining. countersinking, counterboring, and spotfacing operations can be carried out on drilling machines and usually follow. countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. Countersink comes in different angles, including 60°, 82°, and 90°. mapal offers the possibility of manufacturing a countersink step for almost all solid carbide drills as a special solution. On the other hand, a counterbore has the sides parallel to each other without any tapering. counterbore and countersink are both machining operations used to create recesses in materials like metal, wood, or plastic, but they serve. countersinks are mainly used for countersinking drill holes, countersinking screws and deburring. a countersink is a conical hole that is typically drilled or milled into a material, such as wood, metal, or plastic, to allow the head of a screw or fastener to sit flush with or below the surface of the material.

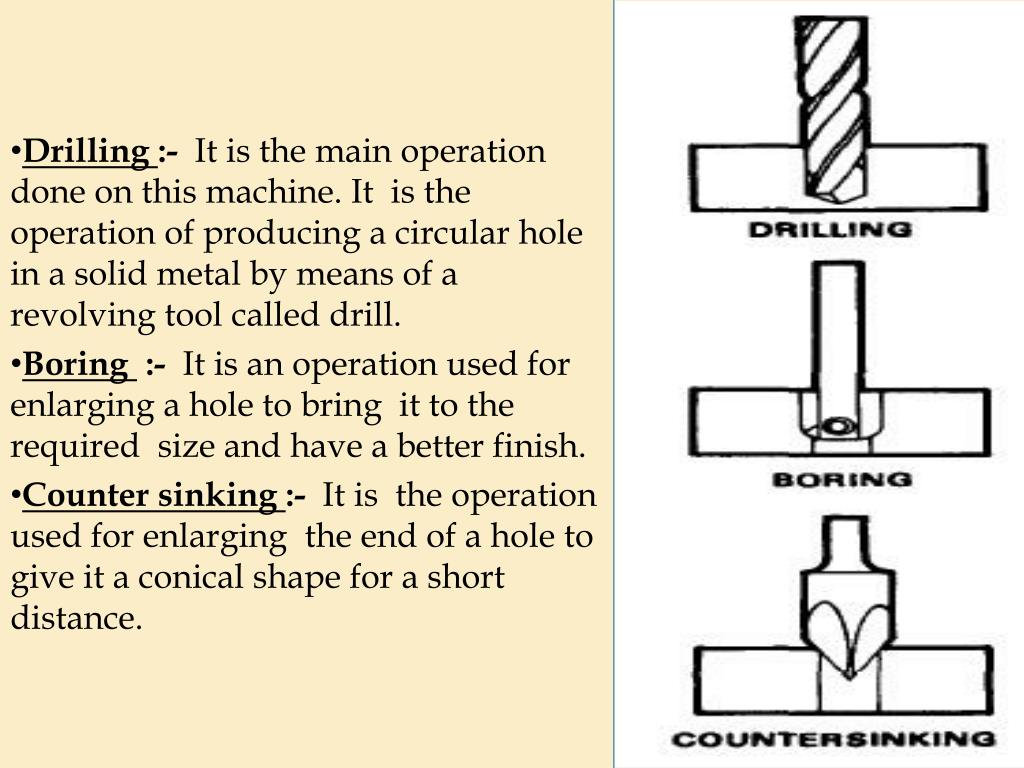

PPT DRILLING MACHINE PowerPoint Presentation, free download ID2015559

Countersinking In Drilling Machine countersinking, counterboring, and spotfacing operations can be carried out on drilling machines and usually follow. countersinks are mainly used for countersinking drill holes, countersinking screws and deburring. mapal offers the possibility of manufacturing a countersink step for almost all solid carbide drills as a special solution. countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. Countersink comes in different angles, including 60°, 82°, and 90°. countersinking, counterboring, and spotfacing operations can be carried out on drilling machines and usually follow. a countersink is a conical hole that is typically drilled or milled into a material, such as wood, metal, or plastic, to allow the head of a screw or fastener to sit flush with or below the surface of the material. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. In this way two machining. counterbore and countersink are both machining operations used to create recesses in materials like metal, wood, or plastic, but they serve. On the other hand, a counterbore has the sides parallel to each other without any tapering.

From www.researchgate.net

Two machine stages of the drillingcountersinking process Download Countersinking In Drilling Machine countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. counterbore and countersink are both machining operations used to create recesses in materials like. Countersinking In Drilling Machine.

From www.rsm-machinery.com

CMG Series CNC Tapping Drilling Milling Chamfering Countersunk Countersinking In Drilling Machine On the other hand, a counterbore has the sides parallel to each other without any tapering. countersinking, counterboring, and spotfacing operations can be carried out on drilling machines and usually follow. mapal offers the possibility of manufacturing a countersink step for almost all solid carbide drills as a special solution. counterbore and countersink are both machining operations. Countersinking In Drilling Machine.

From www.differencebetween.net

Difference Between Counterbore and Countersink Difference Between Countersinking In Drilling Machine On the other hand, a counterbore has the sides parallel to each other without any tapering. Countersink comes in different angles, including 60°, 82°, and 90°. countersinks are mainly used for countersinking drill holes, countersinking screws and deburring. a countersink is a conical hole that is typically drilled or milled into a material, such as wood, metal, or. Countersinking In Drilling Machine.

From unibor.com

E6000 AllRound Drilling, Tapping & Countersinking Machine Unibor Countersinking In Drilling Machine mapal offers the possibility of manufacturing a countersink step for almost all solid carbide drills as a special solution. In this way two machining. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. Countersink comes in different angles, including 60°, 82°, and 90°. On the. Countersinking In Drilling Machine.

From www.penntoolco.com

Euroboor Drilling Machine for Tapping, Threading Countersinking In Drilling Machine In this way two machining. mapal offers the possibility of manufacturing a countersink step for almost all solid carbide drills as a special solution. counterbore and countersink are both machining operations used to create recesses in materials like metal, wood, or plastic, but they serve. It allows the fastener’s head to sit flush with the surface of the. Countersinking In Drilling Machine.

From twprofile.co.za

Drilling TW Profile Services Countersinking In Drilling Machine countersinks are mainly used for countersinking drill holes, countersinking screws and deburring. countersinking, counterboring, and spotfacing operations can be carried out on drilling machines and usually follow. counterbore and countersink are both machining operations used to create recesses in materials like metal, wood, or plastic, but they serve. On the other hand, a counterbore has the sides. Countersinking In Drilling Machine.

From www.penntoolco.com

Euroboor Drilling Machine for Tapping, Threading Countersinking In Drilling Machine In this way two machining. countersinking, counterboring, and spotfacing operations can be carried out on drilling machines and usually follow. counterbore and countersink are both machining operations used to create recesses in materials like metal, wood, or plastic, but they serve. countersinks are mainly used for countersinking drill holes, countersinking screws and deburring. It allows the fastener’s. Countersinking In Drilling Machine.

From www.penntoolco.com

Euroboor Automatic Drilling Machine for Tapping, Threading Countersinking In Drilling Machine countersinks are mainly used for countersinking drill holes, countersinking screws and deburring. counterbore and countersink are both machining operations used to create recesses in materials like metal, wood, or plastic, but they serve. Countersink comes in different angles, including 60°, 82°, and 90°. countersinking is a machining process that creates a conical hole matching the angled shape. Countersinking In Drilling Machine.

From www.youtube.com

Profile drilling machine plate, angle, I beam etc.Tapping Countersinking In Drilling Machine a countersink is a conical hole that is typically drilled or milled into a material, such as wood, metal, or plastic, to allow the head of a screw or fastener to sit flush with or below the surface of the material. In this way two machining. mapal offers the possibility of manufacturing a countersink step for almost all. Countersinking In Drilling Machine.

From www.precisiontoolingchina.com

What is Countersinking? machined turning metal product CNC Countersinking In Drilling Machine It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. a countersink is a conical hole that is typically drilled or milled into a material, such as wood, metal, or plastic, to allow the head of a screw or fastener to sit flush with or below. Countersinking In Drilling Machine.

From www.plantautomation-technology.com

Milling, Drilling And Countersinking Tools Machine Toolsmetal Countersinking In Drilling Machine Countersink comes in different angles, including 60°, 82°, and 90°. countersinking, counterboring, and spotfacing operations can be carried out on drilling machines and usually follow. countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. mapal offers the possibility of manufacturing a countersink step for almost. Countersinking In Drilling Machine.

From www.penntoolco.com

Euroboor Drilling Machine with MT3 Spindle for Tapping Countersinking In Drilling Machine countersinks are mainly used for countersinking drill holes, countersinking screws and deburring. In this way two machining. Countersink comes in different angles, including 60°, 82°, and 90°. countersinking, counterboring, and spotfacing operations can be carried out on drilling machines and usually follow. counterbore and countersink are both machining operations used to create recesses in materials like metal,. Countersinking In Drilling Machine.

From www.pengfamill.com

CNC Horizontal Countersinking Machine Buy CNC Drilling Machine Countersinking In Drilling Machine a countersink is a conical hole that is typically drilled or milled into a material, such as wood, metal, or plastic, to allow the head of a screw or fastener to sit flush with or below the surface of the material. countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk. Countersinking In Drilling Machine.

From www.smlease.com

What are Various Types of Drilling Machine Operations Countersinking In Drilling Machine It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. Countersink comes in different angles, including 60°, 82°, and 90°. countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. countersinks are mainly used. Countersinking In Drilling Machine.

From www.pinterest.com

Operations Related to Drilling Drilling machine, Metal working Countersinking In Drilling Machine countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. countersinking, counterboring, and spotfacing operations can be carried out on drilling machines and usually follow. On the other hand, a counterbore has the sides parallel to each other without any tapering. a countersink is a conical. Countersinking In Drilling Machine.

From unibor.com

E6000 AllRound Drilling, Tapping & Countersinking Machine Unibor Countersinking In Drilling Machine On the other hand, a counterbore has the sides parallel to each other without any tapering. mapal offers the possibility of manufacturing a countersink step for almost all solid carbide drills as a special solution. counterbore and countersink are both machining operations used to create recesses in materials like metal, wood, or plastic, but they serve. Countersink comes. Countersinking In Drilling Machine.

From www.youtube.com

Drilling operations Reaming Counter boring Counter sinking Tapping Countersinking In Drilling Machine countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. countersinking, counterboring, and spotfacing operations can be carried out on drilling machines and usually follow. Countersink comes in different angles, including 60°, 82°, and 90°. a countersink is a conical hole that is typically drilled or. Countersinking In Drilling Machine.

From www.pengfamill.com

CNC Horizontal Countersinking Machine Buy CNC Drilling Machine Countersinking In Drilling Machine In this way two machining. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. Countersink comes in different angles, including 60°, 82°, and 90°. mapal offers the possibility of manufacturing a countersink step for almost all solid carbide drills as a special solution. countersinking,. Countersinking In Drilling Machine.

From www.youtube.com

Coastone Multitapper 1212 Electric tapping counter sinking drilling Countersinking In Drilling Machine mapal offers the possibility of manufacturing a countersink step for almost all solid carbide drills as a special solution. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. countersinking, counterboring, and spotfacing operations can be carried out on drilling machines and usually follow. . Countersinking In Drilling Machine.

From unibor.com

E6000 AllRound Drilling, Tapping & Countersinking Machine Unibor Countersinking In Drilling Machine On the other hand, a counterbore has the sides parallel to each other without any tapering. In this way two machining. countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. a countersink is a conical hole that is typically drilled or milled into a material, such. Countersinking In Drilling Machine.

From exonwmpee.blob.core.windows.net

Countersinking Advantages at Mitchell Pryor blog Countersinking In Drilling Machine a countersink is a conical hole that is typically drilled or milled into a material, such as wood, metal, or plastic, to allow the head of a screw or fastener to sit flush with or below the surface of the material. It allows the fastener’s head to sit flush with the surface of the material or even below it,. Countersinking In Drilling Machine.

From www.deyaphc.com

Flange Drilling Tapping And Countersinking Machine For Concrete Pile Countersinking In Drilling Machine Countersink comes in different angles, including 60°, 82°, and 90°. In this way two machining. countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. a countersink is a conical hole that is typically drilled or milled into a material, such as wood, metal, or plastic, to. Countersinking In Drilling Machine.

From www.youtube.com

Drilling Machine Operations Boring, Reaming, Counter Sinking, Spot Countersinking In Drilling Machine a countersink is a conical hole that is typically drilled or milled into a material, such as wood, metal, or plastic, to allow the head of a screw or fastener to sit flush with or below the surface of the material. countersinks are mainly used for countersinking drill holes, countersinking screws and deburring. In this way two machining.. Countersinking In Drilling Machine.

From www.rsm-machinery.com

CMG Series CNC Tapping Drilling Milling Chamfering Countersunk Countersinking In Drilling Machine countersinking, counterboring, and spotfacing operations can be carried out on drilling machines and usually follow. counterbore and countersink are both machining operations used to create recesses in materials like metal, wood, or plastic, but they serve. In this way two machining. It allows the fastener’s head to sit flush with the surface of the material or even below. Countersinking In Drilling Machine.

From www.researchgate.net

Two machine operations of the drillingcountersinking process Countersinking In Drilling Machine It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. In this way two machining. countersinking, counterboring, and spotfacing operations can be carried out. Countersinking In Drilling Machine.

From www.slideserve.com

PPT DRILLING MACHINE PowerPoint Presentation, free download ID2015559 Countersinking In Drilling Machine countersinking, counterboring, and spotfacing operations can be carried out on drilling machines and usually follow. On the other hand, a counterbore has the sides parallel to each other without any tapering. countersinks are mainly used for countersinking drill holes, countersinking screws and deburring. countersinking is a machining process that creates a conical hole matching the angled shape. Countersinking In Drilling Machine.

From www.youtube.com

Drilling, countersinking and reaming with RTiger Electric Tapping arm Countersinking In Drilling Machine a countersink is a conical hole that is typically drilled or milled into a material, such as wood, metal, or plastic, to allow the head of a screw or fastener to sit flush with or below the surface of the material. In this way two machining. countersinking is a machining process that creates a conical hole matching the. Countersinking In Drilling Machine.

From ecoreprap.com

What is CNC Drilling Definition, Working and Types EcoReprap Countersinking In Drilling Machine countersinking, counterboring, and spotfacing operations can be carried out on drilling machines and usually follow. counterbore and countersink are both machining operations used to create recesses in materials like metal, wood, or plastic, but they serve. countersinks are mainly used for countersinking drill holes, countersinking screws and deburring. mapal offers the possibility of manufacturing a countersink. Countersinking In Drilling Machine.

From www.penntoolco.com

Euroboor Drilling Machine for Tapping & Countersinking ECO Countersinking In Drilling Machine countersinking, counterboring, and spotfacing operations can be carried out on drilling machines and usually follow. countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. In this way two machining. countersinks are mainly used for countersinking drill holes, countersinking screws and deburring. On the other hand,. Countersinking In Drilling Machine.

From www.youtube.com

Drilling & CounterSinking YouTube Countersinking In Drilling Machine mapal offers the possibility of manufacturing a countersink step for almost all solid carbide drills as a special solution. countersinking, counterboring, and spotfacing operations can be carried out on drilling machines and usually follow. a countersink is a conical hole that is typically drilled or milled into a material, such as wood, metal, or plastic, to allow. Countersinking In Drilling Machine.

From www.shutterstock.com

Drilling Countersinking Tapping RoyaltyFree Images, Stock Photos Countersinking In Drilling Machine Countersink comes in different angles, including 60°, 82°, and 90°. mapal offers the possibility of manufacturing a countersink step for almost all solid carbide drills as a special solution. countersinks are mainly used for countersinking drill holes, countersinking screws and deburring. countersinking is a machining process that creates a conical hole matching the angled shape of a. Countersinking In Drilling Machine.

From www.youtube.com

Drilling Machine Operations (हिन्दी), Counter Boring, Counter Sinking Countersinking In Drilling Machine countersinking, counterboring, and spotfacing operations can be carried out on drilling machines and usually follow. a countersink is a conical hole that is typically drilled or milled into a material, such as wood, metal, or plastic, to allow the head of a screw or fastener to sit flush with or below the surface of the material. It allows. Countersinking In Drilling Machine.

From eur.vevor.com

VEVOR Vevor Drilling Machine Mag Drill Kit W/7pc Countersinking In Drilling Machine Countersink comes in different angles, including 60°, 82°, and 90°. mapal offers the possibility of manufacturing a countersink step for almost all solid carbide drills as a special solution. On the other hand, a counterbore has the sides parallel to each other without any tapering. countersinking, counterboring, and spotfacing operations can be carried out on drilling machines and. Countersinking In Drilling Machine.

From www.youtube.com

The MultiSink® Combination Drill & Countersink Tool YouTube Countersinking In Drilling Machine countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. counterbore and countersink are both machining operations used to create recesses in materials like metal, wood, or plastic, but they serve. In this way two machining. Countersink comes in different angles, including 60°, 82°, and 90°. . Countersinking In Drilling Machine.

From www.kempf-tools.com

Countersink Countersinking tool for (drilling) machines MicroLimit Countersinking In Drilling Machine mapal offers the possibility of manufacturing a countersink step for almost all solid carbide drills as a special solution. countersinking, counterboring, and spotfacing operations can be carried out on drilling machines and usually follow. counterbore and countersink are both machining operations used to create recesses in materials like metal, wood, or plastic, but they serve. countersinking. Countersinking In Drilling Machine.