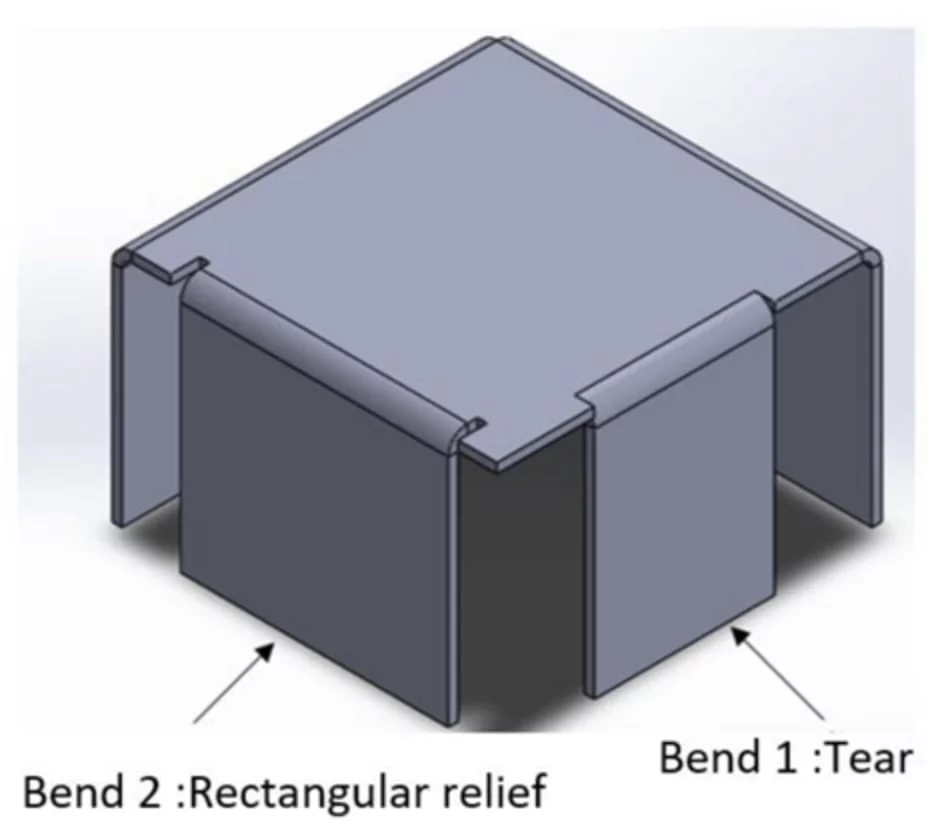

Sheet Metal Bend Relief Guidelines . Rules for designing bend relief. Bend reliefs are two small cuts made in a piece of sheet metal to free up the metal between them. A bend relief prevents tears from occurring where there is a transition between bends or between a bend and a flat surface. Bend relief is provided at the end of the bending edge in sheet metal design to avoid any crack tearing in the corner. Figure a shows a torn part. In this comprehensive guide, we’ll explore the intricate world of sheet metal bend relief guidelines, uncovering advanced. The article discusses making small holes and when to use a punch or laser cutter, inside radius measurements and how they differ depending on whether. Although they are small features, leaving them out can cause. Due to this elastic recovery, it is. They are a great way to ensure a clean. When bending a piece of sheet metal, the residual stresses in the material will cause the sheet to springback slightly after the bending operation.

from neuronicworks.com

Although they are small features, leaving them out can cause. Rules for designing bend relief. They are a great way to ensure a clean. The article discusses making small holes and when to use a punch or laser cutter, inside radius measurements and how they differ depending on whether. When bending a piece of sheet metal, the residual stresses in the material will cause the sheet to springback slightly after the bending operation. Figure a shows a torn part. Due to this elastic recovery, it is. Bend relief is provided at the end of the bending edge in sheet metal design to avoid any crack tearing in the corner. In this comprehensive guide, we’ll explore the intricate world of sheet metal bend relief guidelines, uncovering advanced. Bend reliefs are two small cuts made in a piece of sheet metal to free up the metal between them.

Design for Manufacturing Sheet Metal Deep Dive NeuronicWorks

Sheet Metal Bend Relief Guidelines Bend relief is provided at the end of the bending edge in sheet metal design to avoid any crack tearing in the corner. Although they are small features, leaving them out can cause. The article discusses making small holes and when to use a punch or laser cutter, inside radius measurements and how they differ depending on whether. Bend reliefs are two small cuts made in a piece of sheet metal to free up the metal between them. Figure a shows a torn part. Rules for designing bend relief. In this comprehensive guide, we’ll explore the intricate world of sheet metal bend relief guidelines, uncovering advanced. A bend relief prevents tears from occurring where there is a transition between bends or between a bend and a flat surface. Bend relief is provided at the end of the bending edge in sheet metal design to avoid any crack tearing in the corner. Due to this elastic recovery, it is. When bending a piece of sheet metal, the residual stresses in the material will cause the sheet to springback slightly after the bending operation. They are a great way to ensure a clean.

From sendcutsend.com

How to Design Bend Reliefs & Corner Reliefs for Sheet Metal Parts Sheet Metal Bend Relief Guidelines When bending a piece of sheet metal, the residual stresses in the material will cause the sheet to springback slightly after the bending operation. Bend reliefs are two small cuts made in a piece of sheet metal to free up the metal between them. Due to this elastic recovery, it is. The article discusses making small holes and when to. Sheet Metal Bend Relief Guidelines.

From www.smlease.com

Sheet Metal Design Guidelines How to Design Good Sheet Metal Parts Sheet Metal Bend Relief Guidelines In this comprehensive guide, we’ll explore the intricate world of sheet metal bend relief guidelines, uncovering advanced. Although they are small features, leaving them out can cause. Bend relief is provided at the end of the bending edge in sheet metal design to avoid any crack tearing in the corner. Rules for designing bend relief. The article discusses making small. Sheet Metal Bend Relief Guidelines.

From www.smlease.com

Sheet Metal Design Guidelines How to Design Good Sheet Metal Parts Sheet Metal Bend Relief Guidelines Figure a shows a torn part. Bend relief is provided at the end of the bending edge in sheet metal design to avoid any crack tearing in the corner. Rules for designing bend relief. A bend relief prevents tears from occurring where there is a transition between bends or between a bend and a flat surface. Bend reliefs are two. Sheet Metal Bend Relief Guidelines.

From www.smlease.com

Sheet Metal Design Guidelines How to Design Good Sheet Metal Parts Sheet Metal Bend Relief Guidelines Bend relief is provided at the end of the bending edge in sheet metal design to avoid any crack tearing in the corner. The article discusses making small holes and when to use a punch or laser cutter, inside radius measurements and how they differ depending on whether. Bend reliefs are two small cuts made in a piece of sheet. Sheet Metal Bend Relief Guidelines.

From www.hlhprototypes.com

Mastering the Art of Bending Sheet Metal Design Tips for Success Sheet Metal Bend Relief Guidelines Rules for designing bend relief. Due to this elastic recovery, it is. A bend relief prevents tears from occurring where there is a transition between bends or between a bend and a flat surface. In this comprehensive guide, we’ll explore the intricate world of sheet metal bend relief guidelines, uncovering advanced. They are a great way to ensure a clean.. Sheet Metal Bend Relief Guidelines.

From www.youtube.com

11 Creo Sheet Metal Tutorial Conversion, Corner Relief & Bend Order Sheet Metal Bend Relief Guidelines The article discusses making small holes and when to use a punch or laser cutter, inside radius measurements and how they differ depending on whether. Bend relief is provided at the end of the bending edge in sheet metal design to avoid any crack tearing in the corner. Figure a shows a torn part. Although they are small features, leaving. Sheet Metal Bend Relief Guidelines.

From neuronicworks.com

Design for Manufacturing Sheet Metal Deep Dive NeuronicWorks Sheet Metal Bend Relief Guidelines Bend relief is provided at the end of the bending edge in sheet metal design to avoid any crack tearing in the corner. Figure a shows a torn part. Rules for designing bend relief. Although they are small features, leaving them out can cause. Due to this elastic recovery, it is. Bend reliefs are two small cuts made in a. Sheet Metal Bend Relief Guidelines.

From www.smlease.com

Sheet Metal Design Guidelines How to Design Good Sheet Metal Parts Sheet Metal Bend Relief Guidelines The article discusses making small holes and when to use a punch or laser cutter, inside radius measurements and how they differ depending on whether. Bend relief is provided at the end of the bending edge in sheet metal design to avoid any crack tearing in the corner. Figure a shows a torn part. Bend reliefs are two small cuts. Sheet Metal Bend Relief Guidelines.

From www.thefabricator.com

What to know about sheet metal bend radius and minimum flange Sheet Metal Bend Relief Guidelines Bend relief is provided at the end of the bending edge in sheet metal design to avoid any crack tearing in the corner. The article discusses making small holes and when to use a punch or laser cutter, inside radius measurements and how they differ depending on whether. Due to this elastic recovery, it is. Bend reliefs are two small. Sheet Metal Bend Relief Guidelines.

From hlhrapid.com

Sheet Metal Bending Design Guide Rules, Tips & Considerations Sheet Metal Bend Relief Guidelines They are a great way to ensure a clean. Figure a shows a torn part. In this comprehensive guide, we’ll explore the intricate world of sheet metal bend relief guidelines, uncovering advanced. Bend reliefs are two small cuts made in a piece of sheet metal to free up the metal between them. Rules for designing bend relief. When bending a. Sheet Metal Bend Relief Guidelines.

From www.choonngaiengineering.com

Metal Guidelines Methods of Sheet Metal Bending Sheet Metal Bend Relief Guidelines The article discusses making small holes and when to use a punch or laser cutter, inside radius measurements and how they differ depending on whether. They are a great way to ensure a clean. Rules for designing bend relief. Although they are small features, leaving them out can cause. When bending a piece of sheet metal, the residual stresses in. Sheet Metal Bend Relief Guidelines.

From sendcutsend.com

Guide to Designing Bend Reliefs in Sheet Metal SendCutSend Sheet Metal Bend Relief Guidelines Bend reliefs are two small cuts made in a piece of sheet metal to free up the metal between them. They are a great way to ensure a clean. Rules for designing bend relief. The article discusses making small holes and when to use a punch or laser cutter, inside radius measurements and how they differ depending on whether. Although. Sheet Metal Bend Relief Guidelines.

From www.hlhprototypes.com

Mastering the Art of Bending Sheet Metal Design Tips for Success Sheet Metal Bend Relief Guidelines When bending a piece of sheet metal, the residual stresses in the material will cause the sheet to springback slightly after the bending operation. Rules for designing bend relief. Bend relief is provided at the end of the bending edge in sheet metal design to avoid any crack tearing in the corner. Bend reliefs are two small cuts made in. Sheet Metal Bend Relief Guidelines.

From sendcutsend.com

Guide to Designing Bend Reliefs in Sheet Metal SendCutSend Sheet Metal Bend Relief Guidelines Bend relief is provided at the end of the bending edge in sheet metal design to avoid any crack tearing in the corner. Figure a shows a torn part. Bend reliefs are two small cuts made in a piece of sheet metal to free up the metal between them. When bending a piece of sheet metal, the residual stresses in. Sheet Metal Bend Relief Guidelines.

From www.machinedesign.com

Following DFM Guidelines for Working with Sheet Metal Machine Design Sheet Metal Bend Relief Guidelines Figure a shows a torn part. In this comprehensive guide, we’ll explore the intricate world of sheet metal bend relief guidelines, uncovering advanced. A bend relief prevents tears from occurring where there is a transition between bends or between a bend and a flat surface. Rules for designing bend relief. Although they are small features, leaving them out can cause.. Sheet Metal Bend Relief Guidelines.

From cadinfield.com

Sheet Metal Fabrication Fundamental Cad Infield Sheet Metal Bend Relief Guidelines Figure a shows a torn part. A bend relief prevents tears from occurring where there is a transition between bends or between a bend and a flat surface. They are a great way to ensure a clean. Rules for designing bend relief. The article discusses making small holes and when to use a punch or laser cutter, inside radius measurements. Sheet Metal Bend Relief Guidelines.

From www.protocase.com

Sheet Metal Bending Tolerances Sheet Metal Bend Relief Guidelines In this comprehensive guide, we’ll explore the intricate world of sheet metal bend relief guidelines, uncovering advanced. Bend reliefs are two small cuts made in a piece of sheet metal to free up the metal between them. They are a great way to ensure a clean. Bend relief is provided at the end of the bending edge in sheet metal. Sheet Metal Bend Relief Guidelines.

From www.youtube.com

⚡ Solidworks Sheet Metal Corner Relief YouTube Sheet Metal Bend Relief Guidelines Rules for designing bend relief. Bend relief is provided at the end of the bending edge in sheet metal design to avoid any crack tearing in the corner. Although they are small features, leaving them out can cause. They are a great way to ensure a clean. Due to this elastic recovery, it is. In this comprehensive guide, we’ll explore. Sheet Metal Bend Relief Guidelines.

From www.rapiddirect.com

Sheet Metal Fabrication An Ultimate Guide on Manufacturing Processes Sheet Metal Bend Relief Guidelines A bend relief prevents tears from occurring where there is a transition between bends or between a bend and a flat surface. Due to this elastic recovery, it is. They are a great way to ensure a clean. Although they are small features, leaving them out can cause. In this comprehensive guide, we’ll explore the intricate world of sheet metal. Sheet Metal Bend Relief Guidelines.

From www.youtube.com

Solidworks Sheet Metal Gusset How to Add Strength To Sheet Metal Sheet Metal Bend Relief Guidelines The article discusses making small holes and when to use a punch or laser cutter, inside radius measurements and how they differ depending on whether. Bend reliefs are two small cuts made in a piece of sheet metal to free up the metal between them. In this comprehensive guide, we’ll explore the intricate world of sheet metal bend relief guidelines,. Sheet Metal Bend Relief Guidelines.

From www.hlhprototypes.com

Mastering the Art of Bending Sheet Metal Design Tips for Success Sheet Metal Bend Relief Guidelines When bending a piece of sheet metal, the residual stresses in the material will cause the sheet to springback slightly after the bending operation. Rules for designing bend relief. The article discusses making small holes and when to use a punch or laser cutter, inside radius measurements and how they differ depending on whether. Bend reliefs are two small cuts. Sheet Metal Bend Relief Guidelines.

From sendcutsend.com

Guide to Designing Bend Reliefs SendCutSend Sheet Metal Bend Relief Guidelines In this comprehensive guide, we’ll explore the intricate world of sheet metal bend relief guidelines, uncovering advanced. The article discusses making small holes and when to use a punch or laser cutter, inside radius measurements and how they differ depending on whether. Although they are small features, leaving them out can cause. Due to this elastic recovery, it is. They. Sheet Metal Bend Relief Guidelines.

From www.hsjfabrication.com

Mastering Sheet Metal Bend Relief Guidelines and Techniques A Sheet Metal Bend Relief Guidelines Figure a shows a torn part. Rules for designing bend relief. The article discusses making small holes and when to use a punch or laser cutter, inside radius measurements and how they differ depending on whether. Although they are small features, leaving them out can cause. Due to this elastic recovery, it is. A bend relief prevents tears from occurring. Sheet Metal Bend Relief Guidelines.

From www.hsjfabrication.com

Mastering Sheet Metal Bend Relief Guidelines and Techniques A Sheet Metal Bend Relief Guidelines Although they are small features, leaving them out can cause. A bend relief prevents tears from occurring where there is a transition between bends or between a bend and a flat surface. Rules for designing bend relief. Bend reliefs are two small cuts made in a piece of sheet metal to free up the metal between them. Bend relief is. Sheet Metal Bend Relief Guidelines.

From www.hlhprototypes.com

Mastering the Art of Bending Sheet Metal Design Tips for Success Sheet Metal Bend Relief Guidelines Bend relief is provided at the end of the bending edge in sheet metal design to avoid any crack tearing in the corner. Figure a shows a torn part. When bending a piece of sheet metal, the residual stresses in the material will cause the sheet to springback slightly after the bending operation. Due to this elastic recovery, it is.. Sheet Metal Bend Relief Guidelines.

From smlease.com

Sheetmetal Design Guidelines SMLease Design SMLease Design Sheet Metal Bend Relief Guidelines Rules for designing bend relief. Although they are small features, leaving them out can cause. Figure a shows a torn part. A bend relief prevents tears from occurring where there is a transition between bends or between a bend and a flat surface. In this comprehensive guide, we’ll explore the intricate world of sheet metal bend relief guidelines, uncovering advanced.. Sheet Metal Bend Relief Guidelines.

From subscription.packtpub.com

Sheet Metal properties Mastering SOLIDWORKS Sheet Metal Sheet Metal Bend Relief Guidelines When bending a piece of sheet metal, the residual stresses in the material will cause the sheet to springback slightly after the bending operation. Due to this elastic recovery, it is. Figure a shows a torn part. Bend relief is provided at the end of the bending edge in sheet metal design to avoid any crack tearing in the corner.. Sheet Metal Bend Relief Guidelines.

From geomiq.com

Sheet Metal Design Guide 2021 Update Geomiq Sheet Metal Bend Relief Guidelines The article discusses making small holes and when to use a punch or laser cutter, inside radius measurements and how they differ depending on whether. Bend relief is provided at the end of the bending edge in sheet metal design to avoid any crack tearing in the corner. In this comprehensive guide, we’ll explore the intricate world of sheet metal. Sheet Metal Bend Relief Guidelines.

From sendcutsend.com

Guide to Designing Bend Reliefs in Sheet Metal SendCutSend Sheet Metal Bend Relief Guidelines In this comprehensive guide, we’ll explore the intricate world of sheet metal bend relief guidelines, uncovering advanced. Bend reliefs are two small cuts made in a piece of sheet metal to free up the metal between them. Rules for designing bend relief. Figure a shows a torn part. Bend relief is provided at the end of the bending edge in. Sheet Metal Bend Relief Guidelines.

From www.youtube.com

Design Tips for Sheet Metal Bending YouTube Sheet Metal Bend Relief Guidelines Rules for designing bend relief. Due to this elastic recovery, it is. Although they are small features, leaving them out can cause. Figure a shows a torn part. A bend relief prevents tears from occurring where there is a transition between bends or between a bend and a flat surface. They are a great way to ensure a clean. Bend. Sheet Metal Bend Relief Guidelines.

From www.mech4study.com

Different Sheet Metal Bending Process mech4study Sheet Metal Bend Relief Guidelines Figure a shows a torn part. They are a great way to ensure a clean. The article discusses making small holes and when to use a punch or laser cutter, inside radius measurements and how they differ depending on whether. A bend relief prevents tears from occurring where there is a transition between bends or between a bend and a. Sheet Metal Bend Relief Guidelines.

From robu.in

Sheet Metal Design Basics in 2021 Complete List of Things Sheet Metal Bend Relief Guidelines Figure a shows a torn part. A bend relief prevents tears from occurring where there is a transition between bends or between a bend and a flat surface. Bend relief is provided at the end of the bending edge in sheet metal design to avoid any crack tearing in the corner. Due to this elastic recovery, it is. Although they. Sheet Metal Bend Relief Guidelines.

From www.youtube.com

Bend Reliefs SheetMetal Solutions, Part 4 YouTube Sheet Metal Bend Relief Guidelines Rules for designing bend relief. In this comprehensive guide, we’ll explore the intricate world of sheet metal bend relief guidelines, uncovering advanced. Due to this elastic recovery, it is. They are a great way to ensure a clean. Bend reliefs are two small cuts made in a piece of sheet metal to free up the metal between them. The article. Sheet Metal Bend Relief Guidelines.

From grabcad.com

sheet metal bend relief kerf for holes Sheet Metal Design GrabCAD Sheet Metal Bend Relief Guidelines Bend reliefs are two small cuts made in a piece of sheet metal to free up the metal between them. Due to this elastic recovery, it is. A bend relief prevents tears from occurring where there is a transition between bends or between a bend and a flat surface. When bending a piece of sheet metal, the residual stresses in. Sheet Metal Bend Relief Guidelines.

From www.youtube.com

SolidWorks Sheet Metal Relief Type, Rectangle, Obround and Tear (Rip Sheet Metal Bend Relief Guidelines A bend relief prevents tears from occurring where there is a transition between bends or between a bend and a flat surface. Bend reliefs are two small cuts made in a piece of sheet metal to free up the metal between them. Figure a shows a torn part. Bend relief is provided at the end of the bending edge in. Sheet Metal Bend Relief Guidelines.