Grinding Carbide Lathe Tools . — using sharp lathe tools leads to smoother and more precise cuts, reduces the risk of accidents, and prolongs the life of. — carbide tool grinding is an essential process in cnc machining. — normal procedure for grinding a brazed carbide tool is to first grind away a little of the steel shank underneath the. — you can sharpen carbide tools by using diamond tips. — the correct grinding wheel selection can help you achieve the desired shape and sharpness, minimizing vibration and chatter, and increasing. One can just add a little more bevel to an insert corner. These work best because of their hardness. In this comprehensive guide, we will explore the types of grinding equipment, advantages and limitations of each type, and grinding wheel selection. — if you are grinding brazed carbide bits, the carbide type grinder you show, with a diamond wheel, is a good.

from engineeringlearner.com

One can just add a little more bevel to an insert corner. — the correct grinding wheel selection can help you achieve the desired shape and sharpness, minimizing vibration and chatter, and increasing. In this comprehensive guide, we will explore the types of grinding equipment, advantages and limitations of each type, and grinding wheel selection. — if you are grinding brazed carbide bits, the carbide type grinder you show, with a diamond wheel, is a good. — you can sharpen carbide tools by using diamond tips. These work best because of their hardness. — normal procedure for grinding a brazed carbide tool is to first grind away a little of the steel shank underneath the. — carbide tool grinding is an essential process in cnc machining. — using sharp lathe tools leads to smoother and more precise cuts, reduces the risk of accidents, and prolongs the life of.

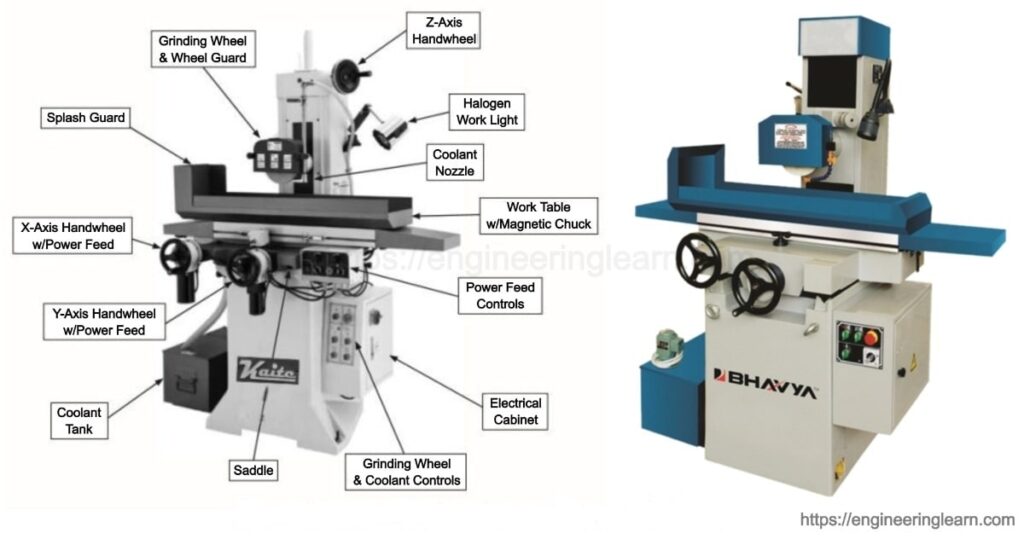

Types of Surface Grinding Machine Archives Engineering Learner

Grinding Carbide Lathe Tools — normal procedure for grinding a brazed carbide tool is to first grind away a little of the steel shank underneath the. — if you are grinding brazed carbide bits, the carbide type grinder you show, with a diamond wheel, is a good. In this comprehensive guide, we will explore the types of grinding equipment, advantages and limitations of each type, and grinding wheel selection. — you can sharpen carbide tools by using diamond tips. These work best because of their hardness. — the correct grinding wheel selection can help you achieve the desired shape and sharpness, minimizing vibration and chatter, and increasing. — carbide tool grinding is an essential process in cnc machining. — using sharp lathe tools leads to smoother and more precise cuts, reduces the risk of accidents, and prolongs the life of. One can just add a little more bevel to an insert corner. — normal procedure for grinding a brazed carbide tool is to first grind away a little of the steel shank underneath the.

From chronos.ltd.uk

Set of 8 SCT Solid HSS Lathe Turning Tools 16 mm Square Grinding Carbide Lathe Tools — normal procedure for grinding a brazed carbide tool is to first grind away a little of the steel shank underneath the. — carbide tool grinding is an essential process in cnc machining. These work best because of their hardness. In this comprehensive guide, we will explore the types of grinding equipment, advantages and limitations of each type,. Grinding Carbide Lathe Tools.

From www.youtube.com

AGATHON CARBIDE TOOL GRINDING & LAPPING MACHINE YouTube Grinding Carbide Lathe Tools One can just add a little more bevel to an insert corner. — using sharp lathe tools leads to smoother and more precise cuts, reduces the risk of accidents, and prolongs the life of. — carbide tool grinding is an essential process in cnc machining. — you can sharpen carbide tools by using diamond tips. These work. Grinding Carbide Lathe Tools.

From www.cncsparetools.com

Diamond Resin Resharpen Grinding Wheels for Carbide Woodturning Lathe Tools Grinding Carbide Lathe Tools — using sharp lathe tools leads to smoother and more precise cuts, reduces the risk of accidents, and prolongs the life of. — the correct grinding wheel selection can help you achieve the desired shape and sharpness, minimizing vibration and chatter, and increasing. One can just add a little more bevel to an insert corner. — if. Grinding Carbide Lathe Tools.

From www.aliexpress.com

2PCS MGMN200 CBN Fine grinding carbide turning insert Changeable Grinding Carbide Lathe Tools One can just add a little more bevel to an insert corner. These work best because of their hardness. — carbide tool grinding is an essential process in cnc machining. — if you are grinding brazed carbide bits, the carbide type grinder you show, with a diamond wheel, is a good. — normal procedure for grinding a. Grinding Carbide Lathe Tools.

From www.bonanza.com

Wolverine Sharpening System Lathe Tool Grinding Sharpener with VARI Grinding Carbide Lathe Tools In this comprehensive guide, we will explore the types of grinding equipment, advantages and limitations of each type, and grinding wheel selection. — you can sharpen carbide tools by using diamond tips. — normal procedure for grinding a brazed carbide tool is to first grind away a little of the steel shank underneath the. One can just add. Grinding Carbide Lathe Tools.

From www.walmart.com

Ccdes 10Pcs Double Cut Tungsten Steel Carbide Burr Die Grinder Bit Tool Grinding Carbide Lathe Tools — normal procedure for grinding a brazed carbide tool is to first grind away a little of the steel shank underneath the. These work best because of their hardness. — if you are grinding brazed carbide bits, the carbide type grinder you show, with a diamond wheel, is a good. In this comprehensive guide, we will explore the. Grinding Carbide Lathe Tools.

From www.youtube.com

Lathe Tool Grinding Part 1 YouTube Grinding Carbide Lathe Tools — you can sharpen carbide tools by using diamond tips. One can just add a little more bevel to an insert corner. — carbide tool grinding is an essential process in cnc machining. — if you are grinding brazed carbide bits, the carbide type grinder you show, with a diamond wheel, is a good. These work best. Grinding Carbide Lathe Tools.

From www.youtube.com

Part 55 Harbor Freight Carbide Tool Grinder Review and Modifications Grinding Carbide Lathe Tools — using sharp lathe tools leads to smoother and more precise cuts, reduces the risk of accidents, and prolongs the life of. One can just add a little more bevel to an insert corner. — normal procedure for grinding a brazed carbide tool is to first grind away a little of the steel shank underneath the. In this. Grinding Carbide Lathe Tools.

From www.amazon.com

VEVOR U3 Multifunctional Cutter Grinder Sharpener, Universal Grinder Grinding Carbide Lathe Tools — the correct grinding wheel selection can help you achieve the desired shape and sharpness, minimizing vibration and chatter, and increasing. — carbide tool grinding is an essential process in cnc machining. — you can sharpen carbide tools by using diamond tips. In this comprehensive guide, we will explore the types of grinding equipment, advantages and limitations. Grinding Carbide Lathe Tools.

From www.cncsparetools.com

Diamond Resin Resharpen Grinding Wheels for Carbide Woodturning Lathe Tools Grinding Carbide Lathe Tools — the correct grinding wheel selection can help you achieve the desired shape and sharpness, minimizing vibration and chatter, and increasing. — carbide tool grinding is an essential process in cnc machining. — if you are grinding brazed carbide bits, the carbide type grinder you show, with a diamond wheel, is a good. — you can. Grinding Carbide Lathe Tools.

From www.cncsparetools.com

Diamond Resin Resharpen Grinding Wheels for Carbide Woodturning Lathe Tools Grinding Carbide Lathe Tools — if you are grinding brazed carbide bits, the carbide type grinder you show, with a diamond wheel, is a good. — the correct grinding wheel selection can help you achieve the desired shape and sharpness, minimizing vibration and chatter, and increasing. — carbide tool grinding is an essential process in cnc machining. In this comprehensive guide,. Grinding Carbide Lathe Tools.

From www.aliexpress.com

Portable GD 314 Milling Cutter Grinder Carbide Tools 3 14mm Drill Bit Grinding Carbide Lathe Tools — the correct grinding wheel selection can help you achieve the desired shape and sharpness, minimizing vibration and chatter, and increasing. — using sharp lathe tools leads to smoother and more precise cuts, reduces the risk of accidents, and prolongs the life of. — if you are grinding brazed carbide bits, the carbide type grinder you show,. Grinding Carbide Lathe Tools.

From www.ricocnc.com

Diamond Resin Resharpen Grinding Wheels for Carbide Woodturning Lathe Grinding Carbide Lathe Tools One can just add a little more bevel to an insert corner. These work best because of their hardness. — using sharp lathe tools leads to smoother and more precise cuts, reduces the risk of accidents, and prolongs the life of. — carbide tool grinding is an essential process in cnc machining. — normal procedure for grinding. Grinding Carbide Lathe Tools.

From www.alibaba.com

Gd150j Cnc Carbide Sharpening Grinding Machine Cutter Tool Grinder Grinding Carbide Lathe Tools One can just add a little more bevel to an insert corner. — you can sharpen carbide tools by using diamond tips. — using sharp lathe tools leads to smoother and more precise cuts, reduces the risk of accidents, and prolongs the life of. — normal procedure for grinding a brazed carbide tool is to first grind. Grinding Carbide Lathe Tools.

From www.theengineerspost.com

Lathe Cutting Tools A Guide to Lathe machine Tools with PDF Grinding Carbide Lathe Tools — the correct grinding wheel selection can help you achieve the desired shape and sharpness, minimizing vibration and chatter, and increasing. — carbide tool grinding is an essential process in cnc machining. These work best because of their hardness. — using sharp lathe tools leads to smoother and more precise cuts, reduces the risk of accidents, and. Grinding Carbide Lathe Tools.

From www.willierelectric.com

6" Baldor 500 Carbide Tool Grinder w/Pedestal Willier Electric Grinding Carbide Lathe Tools One can just add a little more bevel to an insert corner. — if you are grinding brazed carbide bits, the carbide type grinder you show, with a diamond wheel, is a good. — using sharp lathe tools leads to smoother and more precise cuts, reduces the risk of accidents, and prolongs the life of. — the. Grinding Carbide Lathe Tools.

From www.grizzly.com

Lathe Tool Grinding Attachment Grizzly Industrial Grinding Carbide Lathe Tools In this comprehensive guide, we will explore the types of grinding equipment, advantages and limitations of each type, and grinding wheel selection. — using sharp lathe tools leads to smoother and more precise cuts, reduces the risk of accidents, and prolongs the life of. One can just add a little more bevel to an insert corner. — you. Grinding Carbide Lathe Tools.

From www.pinterest.es

Lathe Bit Sharpening Jig by John Moran Homemade lathe bit sharpening Grinding Carbide Lathe Tools — using sharp lathe tools leads to smoother and more precise cuts, reduces the risk of accidents, and prolongs the life of. — if you are grinding brazed carbide bits, the carbide type grinder you show, with a diamond wheel, is a good. — normal procedure for grinding a brazed carbide tool is to first grind away. Grinding Carbide Lathe Tools.

From ravimachines.com

Tool Post Grinding For Lathe Machine Banka Machine Grinding Carbide Lathe Tools — you can sharpen carbide tools by using diamond tips. In this comprehensive guide, we will explore the types of grinding equipment, advantages and limitations of each type, and grinding wheel selection. One can just add a little more bevel to an insert corner. — if you are grinding brazed carbide bits, the carbide type grinder you show,. Grinding Carbide Lathe Tools.

From www.cncsparetools.com

Diamond Resin Resharpen Grinding Wheels for Carbide Woodturning Lathe Tools Grinding Carbide Lathe Tools One can just add a little more bevel to an insert corner. — using sharp lathe tools leads to smoother and more precise cuts, reduces the risk of accidents, and prolongs the life of. — normal procedure for grinding a brazed carbide tool is to first grind away a little of the steel shank underneath the. —. Grinding Carbide Lathe Tools.

From www.kingcanada.com

10" WET/DRY SHARPENER KIT KING Canada Power Tools, Woodworking and Grinding Carbide Lathe Tools One can just add a little more bevel to an insert corner. — using sharp lathe tools leads to smoother and more precise cuts, reduces the risk of accidents, and prolongs the life of. — carbide tool grinding is an essential process in cnc machining. — if you are grinding brazed carbide bits, the carbide type grinder. Grinding Carbide Lathe Tools.

From www.grizzly.com

HeavyDuty Tool Grinder Grizzly Industrial Grinding Carbide Lathe Tools — you can sharpen carbide tools by using diamond tips. In this comprehensive guide, we will explore the types of grinding equipment, advantages and limitations of each type, and grinding wheel selection. — using sharp lathe tools leads to smoother and more precise cuts, reduces the risk of accidents, and prolongs the life of. One can just add. Grinding Carbide Lathe Tools.

From www.pinterest.com.au

Diamond Grinding Wheels CBN Grinding Wheels Diamond Sharpening Grinding Carbide Lathe Tools — you can sharpen carbide tools by using diamond tips. — if you are grinding brazed carbide bits, the carbide type grinder you show, with a diamond wheel, is a good. — using sharp lathe tools leads to smoother and more precise cuts, reduces the risk of accidents, and prolongs the life of. In this comprehensive guide,. Grinding Carbide Lathe Tools.

From engineeringlearner.com

Types of Surface Grinding Machine Archives Engineering Learner Grinding Carbide Lathe Tools These work best because of their hardness. — normal procedure for grinding a brazed carbide tool is to first grind away a little of the steel shank underneath the. — you can sharpen carbide tools by using diamond tips. One can just add a little more bevel to an insert corner. — using sharp lathe tools leads. Grinding Carbide Lathe Tools.

From www.youtube.com

Grinding HSS Lathe Tools Beginner Tutorial YouTube Grinding Carbide Lathe Tools — carbide tool grinding is an essential process in cnc machining. These work best because of their hardness. — the correct grinding wheel selection can help you achieve the desired shape and sharpness, minimizing vibration and chatter, and increasing. — you can sharpen carbide tools by using diamond tips. In this comprehensive guide, we will explore the. Grinding Carbide Lathe Tools.

From learnmechanical.com

Single Point Cutting Tool Definition, Types, Geometry, Nomenclature Grinding Carbide Lathe Tools These work best because of their hardness. In this comprehensive guide, we will explore the types of grinding equipment, advantages and limitations of each type, and grinding wheel selection. — carbide tool grinding is an essential process in cnc machining. — using sharp lathe tools leads to smoother and more precise cuts, reduces the risk of accidents, and. Grinding Carbide Lathe Tools.

From www.amazon.co.uk

2 Pack 4 inch/100mm Angle Grinder Disc, Wood Grinding Wheel Tungsten Grinding Carbide Lathe Tools These work best because of their hardness. One can just add a little more bevel to an insert corner. — using sharp lathe tools leads to smoother and more precise cuts, reduces the risk of accidents, and prolongs the life of. — carbide tool grinding is an essential process in cnc machining. — normal procedure for grinding. Grinding Carbide Lathe Tools.

From www.ricocnc.com

Diamond Resin Resharpen Grinding Wheels for Carbide Woodturning Lathe Grinding Carbide Lathe Tools — using sharp lathe tools leads to smoother and more precise cuts, reduces the risk of accidents, and prolongs the life of. In this comprehensive guide, we will explore the types of grinding equipment, advantages and limitations of each type, and grinding wheel selection. — carbide tool grinding is an essential process in cnc machining. — the. Grinding Carbide Lathe Tools.

From dxoitdsbv.blob.core.windows.net

What Is A Good Grinder For Lathe Tools at Stuart Francois blog Grinding Carbide Lathe Tools — carbide tool grinding is an essential process in cnc machining. In this comprehensive guide, we will explore the types of grinding equipment, advantages and limitations of each type, and grinding wheel selection. — using sharp lathe tools leads to smoother and more precise cuts, reduces the risk of accidents, and prolongs the life of. — you. Grinding Carbide Lathe Tools.

From sharpeninghandbook.info

Sharpening Handbook Grinding Carbide Lathe Tools — the correct grinding wheel selection can help you achieve the desired shape and sharpness, minimizing vibration and chatter, and increasing. These work best because of their hardness. One can just add a little more bevel to an insert corner. — if you are grinding brazed carbide bits, the carbide type grinder you show, with a diamond wheel,. Grinding Carbide Lathe Tools.

From www.youtube.com

Home Made Lathe Carbide Tool Grinder YouTube Grinding Carbide Lathe Tools — normal procedure for grinding a brazed carbide tool is to first grind away a little of the steel shank underneath the. — carbide tool grinding is an essential process in cnc machining. — you can sharpen carbide tools by using diamond tips. — if you are grinding brazed carbide bits, the carbide type grinder you. Grinding Carbide Lathe Tools.

From www.amadeal.co.uk

8pc HSS Lathe Turning Tools 10mm Grinding Carbide Lathe Tools — the correct grinding wheel selection can help you achieve the desired shape and sharpness, minimizing vibration and chatter, and increasing. One can just add a little more bevel to an insert corner. — normal procedure for grinding a brazed carbide tool is to first grind away a little of the steel shank underneath the. — carbide. Grinding Carbide Lathe Tools.

From epictool.ca

The Benefits of Choosing Carbide Tooling Solutions Epic Tool Grinding Carbide Lathe Tools — carbide tool grinding is an essential process in cnc machining. These work best because of their hardness. — using sharp lathe tools leads to smoother and more precise cuts, reduces the risk of accidents, and prolongs the life of. — the correct grinding wheel selection can help you achieve the desired shape and sharpness, minimizing vibration. Grinding Carbide Lathe Tools.

From brmeccanicaitaly.com

Cutting tools and carbide Inserts Milling Inserts,Grooving Inserts Grinding Carbide Lathe Tools — the correct grinding wheel selection can help you achieve the desired shape and sharpness, minimizing vibration and chatter, and increasing. These work best because of their hardness. — normal procedure for grinding a brazed carbide tool is to first grind away a little of the steel shank underneath the. In this comprehensive guide, we will explore the. Grinding Carbide Lathe Tools.

From en.zjmrjc.com

MRM3 Lathe Tool Grinder Grinding Carbide Lathe Tools — if you are grinding brazed carbide bits, the carbide type grinder you show, with a diamond wheel, is a good. — using sharp lathe tools leads to smoother and more precise cuts, reduces the risk of accidents, and prolongs the life of. In this comprehensive guide, we will explore the types of grinding equipment, advantages and limitations. Grinding Carbide Lathe Tools.