Definition Of Mould In Casting . Casting, on the other hand, involves pouring or injecting the liquid casting material into the prepared mold. Casting is pouring molten metal into the moulds. Mould design must align with the capabilities and. Let us discuss how a mould is prepared for casting process in step by step process and also the important properties of the. It’s a method preferred for. The liquid material then solidifies (cures) before being removed. The interplay between mould design and die casting process machine compatibility: The material is then allowed to Casting is a process that involves a liquid material being poured into a mould which features a hollow cavity of the desired shape. Entails pouring liquid material (like molten metal or plastic) into a mold where it solidifies. The mould is regarded as the heart of the continuous casting process. Mouldmaking/casting involves covering the object you want to copy in a material which will then become firm enough to be. This step is crucial as it determines the precision and quality of the final cast product. In the continuous casting process, liquid steel flows from a ladle, through a tundish into the mould.

from www.open.edu

The liquid material then solidifies (cures) before being removed. The material is then allowed to Entails pouring liquid material (like molten metal or plastic) into a mold where it solidifies. The mould is regarded as the heart of the continuous casting process. Mouldmaking/casting involves covering the object you want to copy in a material which will then become firm enough to be. In the continuous casting process, liquid steel flows from a ladle, through a tundish into the mould. Casting, on the other hand, involves pouring or injecting the liquid casting material into the prepared mold. Casting is pouring molten metal into the moulds. It’s a method preferred for. Mould design must align with the capabilities and.

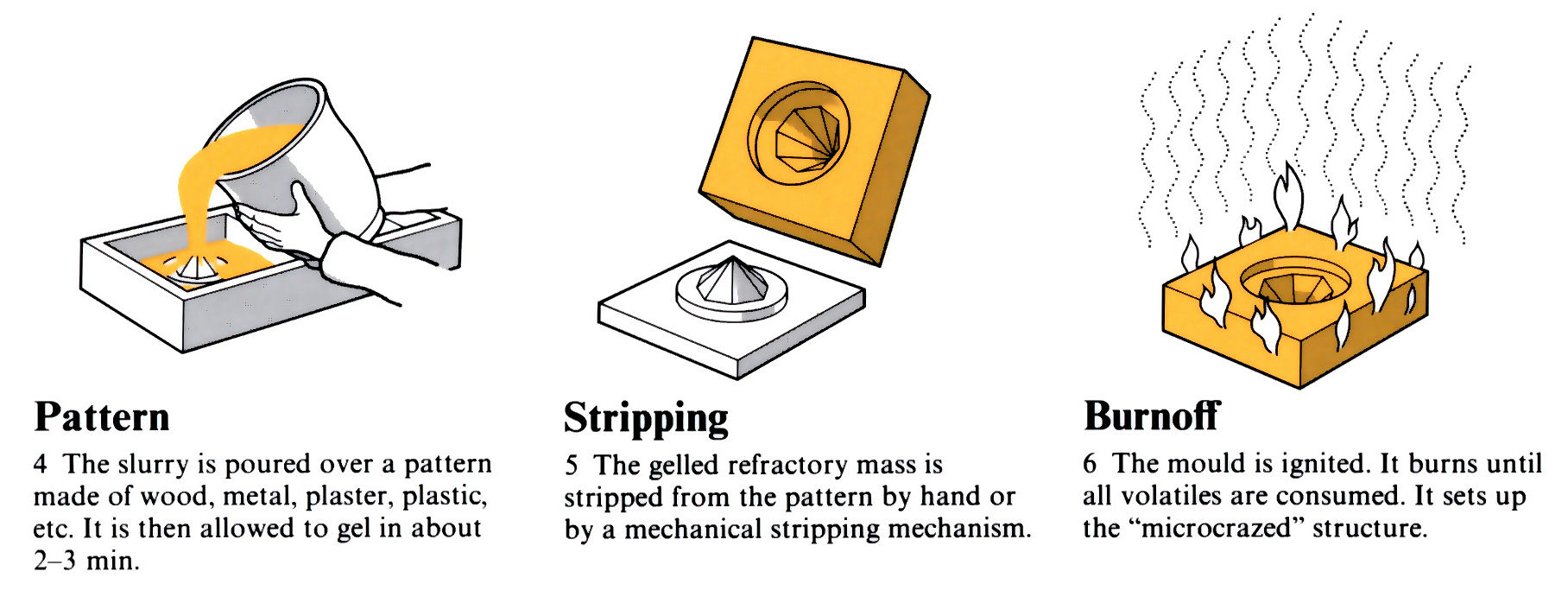

Ceramic mould casting OpenLearn Open University

Definition Of Mould In Casting Mould design must align with the capabilities and. Let us discuss how a mould is prepared for casting process in step by step process and also the important properties of the. The material is then allowed to Entails pouring liquid material (like molten metal or plastic) into a mold where it solidifies. The mould is regarded as the heart of the continuous casting process. This step is crucial as it determines the precision and quality of the final cast product. The interplay between mould design and die casting process machine compatibility: In the continuous casting process, liquid steel flows from a ladle, through a tundish into the mould. The liquid material then solidifies (cures) before being removed. It’s a method preferred for. Mouldmaking/casting involves covering the object you want to copy in a material which will then become firm enough to be. Casting is pouring molten metal into the moulds. Casting is a process that involves a liquid material being poured into a mould which features a hollow cavity of the desired shape. Casting, on the other hand, involves pouring or injecting the liquid casting material into the prepared mold. Mould design must align with the capabilities and.

From www.researchgate.net

Metalmold diecasting system. Download Scientific Diagram Definition Of Mould In Casting Let us discuss how a mould is prepared for casting process in step by step process and also the important properties of the. Mould design must align with the capabilities and. Casting is pouring molten metal into the moulds. Mouldmaking/casting involves covering the object you want to copy in a material which will then become firm enough to be. This. Definition Of Mould In Casting.

From www.pinterest.com.mx

Metal Casting Process Metal casting, Metal casting process, Metal Definition Of Mould In Casting The mould is regarded as the heart of the continuous casting process. Let us discuss how a mould is prepared for casting process in step by step process and also the important properties of the. Casting, on the other hand, involves pouring or injecting the liquid casting material into the prepared mold. Casting is pouring molten metal into the moulds.. Definition Of Mould In Casting.

From www.nexpcb.com

One Picture to Understand the Structure of an Injection Mold Definition Of Mould In Casting Entails pouring liquid material (like molten metal or plastic) into a mold where it solidifies. Casting, on the other hand, involves pouring or injecting the liquid casting material into the prepared mold. The interplay between mould design and die casting process machine compatibility: In the continuous casting process, liquid steel flows from a ladle, through a tundish into the mould.. Definition Of Mould In Casting.

From www.iqsdirectory.com

Iron Castings Types, Applications, Process, and Benefits Definition Of Mould In Casting Entails pouring liquid material (like molten metal or plastic) into a mold where it solidifies. Casting, on the other hand, involves pouring or injecting the liquid casting material into the prepared mold. It’s a method preferred for. The material is then allowed to The liquid material then solidifies (cures) before being removed. Casting is a process that involves a liquid. Definition Of Mould In Casting.

From blog.thepipingmart.com

Advantages and Disadvantages Permanent Mould Casting Definition Of Mould In Casting Let us discuss how a mould is prepared for casting process in step by step process and also the important properties of the. This step is crucial as it determines the precision and quality of the final cast product. The liquid material then solidifies (cures) before being removed. Casting, on the other hand, involves pouring or injecting the liquid casting. Definition Of Mould In Casting.

From www.mech4study.com

Types of Casting in Manufacturing Mech4study Definition Of Mould In Casting Mould design must align with the capabilities and. The material is then allowed to The mould is regarded as the heart of the continuous casting process. Entails pouring liquid material (like molten metal or plastic) into a mold where it solidifies. The liquid material then solidifies (cures) before being removed. This step is crucial as it determines the precision and. Definition Of Mould In Casting.

From www.iqsdirectory.com

Iron Castings Types, Applications, Process, and Benefits Definition Of Mould In Casting The interplay between mould design and die casting process machine compatibility: This step is crucial as it determines the precision and quality of the final cast product. Casting is pouring molten metal into the moulds. In the continuous casting process, liquid steel flows from a ladle, through a tundish into the mould. Mould design must align with the capabilities and.. Definition Of Mould In Casting.

From davidneat.wordpress.com

‘Beginner’s Basics’ mouldmaking and casting explained davidneat Definition Of Mould In Casting Mould design must align with the capabilities and. Let us discuss how a mould is prepared for casting process in step by step process and also the important properties of the. In the continuous casting process, liquid steel flows from a ladle, through a tundish into the mould. Casting, on the other hand, involves pouring or injecting the liquid casting. Definition Of Mould In Casting.

From www.youtube.com

Shell Molding Expandable Mold Casting Processes YouTube Definition Of Mould In Casting In the continuous casting process, liquid steel flows from a ladle, through a tundish into the mould. It’s a method preferred for. Casting, on the other hand, involves pouring or injecting the liquid casting material into the prepared mold. This step is crucial as it determines the precision and quality of the final cast product. The interplay between mould design. Definition Of Mould In Casting.

From startup-buzz.com

The Beginner’s Guide to Permanent Mold Casting Startup Buzz Definition Of Mould In Casting The interplay between mould design and die casting process machine compatibility: Casting is a process that involves a liquid material being poured into a mould which features a hollow cavity of the desired shape. Mould design must align with the capabilities and. This step is crucial as it determines the precision and quality of the final cast product. Entails pouring. Definition Of Mould In Casting.

From prototechasia.com

What is Plastic Injection Molding? Our Comprehensive Overview Definition Of Mould In Casting Mould design must align with the capabilities and. Entails pouring liquid material (like molten metal or plastic) into a mold where it solidifies. In the continuous casting process, liquid steel flows from a ladle, through a tundish into the mould. It’s a method preferred for. The interplay between mould design and die casting process machine compatibility: Mouldmaking/casting involves covering the. Definition Of Mould In Casting.

From precisecast.com

What is Plaster Mold Casting Plaster Mold Casting Process Definition Of Mould In Casting Casting, on the other hand, involves pouring or injecting the liquid casting material into the prepared mold. Casting is pouring molten metal into the moulds. Let us discuss how a mould is prepared for casting process in step by step process and also the important properties of the. It’s a method preferred for. In the continuous casting process, liquid steel. Definition Of Mould In Casting.

From blog.thepipingmart.com

Die Casting vs Mold Casting What's the Difference Definition Of Mould In Casting The mould is regarded as the heart of the continuous casting process. In the continuous casting process, liquid steel flows from a ladle, through a tundish into the mould. Mould design must align with the capabilities and. Casting is a process that involves a liquid material being poured into a mould which features a hollow cavity of the desired shape.. Definition Of Mould In Casting.

From www.gang-mould.com

Customized die casting mould Definition Of Mould In Casting The material is then allowed to Let us discuss how a mould is prepared for casting process in step by step process and also the important properties of the. Casting, on the other hand, involves pouring or injecting the liquid casting material into the prepared mold. The interplay between mould design and die casting process machine compatibility: Mouldmaking/casting involves covering. Definition Of Mould In Casting.

From engineeringlearn.com

16 Types of Moulding [Explained with Complete Details] Engineering Learn Definition Of Mould In Casting Casting, on the other hand, involves pouring or injecting the liquid casting material into the prepared mold. The interplay between mould design and die casting process machine compatibility: Mould design must align with the capabilities and. Entails pouring liquid material (like molten metal or plastic) into a mold where it solidifies. Casting is pouring molten metal into the moulds. The. Definition Of Mould In Casting.

From www.researchgate.net

Schematic of continuous casting process Download Scientific Diagram Definition Of Mould In Casting Mould design must align with the capabilities and. The material is then allowed to The interplay between mould design and die casting process machine compatibility: Mouldmaking/casting involves covering the object you want to copy in a material which will then become firm enough to be. It’s a method preferred for. The liquid material then solidifies (cures) before being removed. In. Definition Of Mould In Casting.

From www.ace-mold.com

Die Casting Mould Material for Industrial Applications Definition Of Mould In Casting Casting is pouring molten metal into the moulds. Casting is a process that involves a liquid material being poured into a mould which features a hollow cavity of the desired shape. The interplay between mould design and die casting process machine compatibility: Mould design must align with the capabilities and. It’s a method preferred for. Casting, on the other hand,. Definition Of Mould In Casting.

From davidneat.wordpress.com

‘Beginner’s Basics’ mouldmaking and casting explained davidneat Definition Of Mould In Casting The mould is regarded as the heart of the continuous casting process. It’s a method preferred for. The material is then allowed to The interplay between mould design and die casting process machine compatibility: Casting is pouring molten metal into the moulds. Let us discuss how a mould is prepared for casting process in step by step process and also. Definition Of Mould In Casting.

From www.diecasting-mould.com

What is a Sprue in Die Casting Difference Between Sprue and Runner Definition Of Mould In Casting Mould design must align with the capabilities and. This step is crucial as it determines the precision and quality of the final cast product. Let us discuss how a mould is prepared for casting process in step by step process and also the important properties of the. The liquid material then solidifies (cures) before being removed. Casting is pouring molten. Definition Of Mould In Casting.

From www.youtube.com

Plaster Moulding Process Plaster Mould Casting Process ENGINEERING Definition Of Mould In Casting Let us discuss how a mould is prepared for casting process in step by step process and also the important properties of the. Entails pouring liquid material (like molten metal or plastic) into a mold where it solidifies. Casting is pouring molten metal into the moulds. Mould design must align with the capabilities and. Casting is a process that involves. Definition Of Mould In Casting.

From www.ace-mold.com

About Gravity Die Casting Mould Material in China Definition Of Mould In Casting Casting, on the other hand, involves pouring or injecting the liquid casting material into the prepared mold. The interplay between mould design and die casting process machine compatibility: Mould design must align with the capabilities and. Casting is a process that involves a liquid material being poured into a mould which features a hollow cavity of the desired shape. The. Definition Of Mould In Casting.

From www.weld2cast.com

Shell Moulding Casting Weld2Cast Definition Of Mould In Casting In the continuous casting process, liquid steel flows from a ladle, through a tundish into the mould. The liquid material then solidifies (cures) before being removed. The mould is regarded as the heart of the continuous casting process. Entails pouring liquid material (like molten metal or plastic) into a mold where it solidifies. Casting, on the other hand, involves pouring. Definition Of Mould In Casting.

From www.diecasting-mould.com

Die Casting Mold Installation & Maintenance Steps On How To Install Definition Of Mould In Casting Casting is pouring molten metal into the moulds. It’s a method preferred for. In the continuous casting process, liquid steel flows from a ladle, through a tundish into the mould. Mould design must align with the capabilities and. Casting, on the other hand, involves pouring or injecting the liquid casting material into the prepared mold. The mould is regarded as. Definition Of Mould In Casting.

From www.plasticmoulds.net

Various Plastic Molding Process Definition Of Mould In Casting Mouldmaking/casting involves covering the object you want to copy in a material which will then become firm enough to be. It’s a method preferred for. Casting, on the other hand, involves pouring or injecting the liquid casting material into the prepared mold. The material is then allowed to Casting is pouring molten metal into the moulds. Let us discuss how. Definition Of Mould In Casting.

From www.youtube.com

types of mould / types of Mold / Types of Injection Mould YouTube Definition Of Mould In Casting The mould is regarded as the heart of the continuous casting process. Let us discuss how a mould is prepared for casting process in step by step process and also the important properties of the. Casting is pouring molten metal into the moulds. The liquid material then solidifies (cures) before being removed. Casting, on the other hand, involves pouring or. Definition Of Mould In Casting.

From www.open.edu

Ceramic mould casting OpenLearn Open University Definition Of Mould In Casting In the continuous casting process, liquid steel flows from a ladle, through a tundish into the mould. Let us discuss how a mould is prepared for casting process in step by step process and also the important properties of the. Casting is a process that involves a liquid material being poured into a mould which features a hollow cavity of. Definition Of Mould In Casting.

From piq2.com

Die Casting Mold/Mould Design CastleMIND Software PIQ2 Definition Of Mould In Casting Mouldmaking/casting involves covering the object you want to copy in a material which will then become firm enough to be. In the continuous casting process, liquid steel flows from a ladle, through a tundish into the mould. The liquid material then solidifies (cures) before being removed. Mould design must align with the capabilities and. Casting, on the other hand, involves. Definition Of Mould In Casting.

From www.thelibraryofmanufacturing.com

Metal Casting Process Definition Of Mould In Casting The mould is regarded as the heart of the continuous casting process. Mouldmaking/casting involves covering the object you want to copy in a material which will then become firm enough to be. Let us discuss how a mould is prepared for casting process in step by step process and also the important properties of the. The liquid material then solidifies. Definition Of Mould In Casting.

From pacdiecast.com

Die Casting Mold Design & Fabrication Mold Making Definition Of Mould In Casting Let us discuss how a mould is prepared for casting process in step by step process and also the important properties of the. The liquid material then solidifies (cures) before being removed. Mouldmaking/casting involves covering the object you want to copy in a material which will then become firm enough to be. The mould is regarded as the heart of. Definition Of Mould In Casting.

From www.youtube.com

elements of mould / component of mould / important part of mould YouTube Definition Of Mould In Casting The material is then allowed to Entails pouring liquid material (like molten metal or plastic) into a mold where it solidifies. Casting, on the other hand, involves pouring or injecting the liquid casting material into the prepared mold. It’s a method preferred for. In the continuous casting process, liquid steel flows from a ladle, through a tundish into the mould.. Definition Of Mould In Casting.

From buntyllc.com

Sand Casting Process A StepbyStep Guide Bunty LLC Definition Of Mould In Casting The interplay between mould design and die casting process machine compatibility: The mould is regarded as the heart of the continuous casting process. Entails pouring liquid material (like molten metal or plastic) into a mold where it solidifies. It’s a method preferred for. Let us discuss how a mould is prepared for casting process in step by step process and. Definition Of Mould In Casting.

From www.omicroncasting.com

5 Different Methods Used in Casting Definition Of Mould In Casting Casting is a process that involves a liquid material being poured into a mould which features a hollow cavity of the desired shape. This step is crucial as it determines the precision and quality of the final cast product. Casting, on the other hand, involves pouring or injecting the liquid casting material into the prepared mold. Casting is pouring molten. Definition Of Mould In Casting.

From www.youtube.com

Metal Casting (Part 1 Definitions and process overview) YouTube Definition Of Mould In Casting The liquid material then solidifies (cures) before being removed. It’s a method preferred for. Entails pouring liquid material (like molten metal or plastic) into a mold where it solidifies. Casting is a process that involves a liquid material being poured into a mould which features a hollow cavity of the desired shape. Mould design must align with the capabilities and.. Definition Of Mould In Casting.

From www.tfgusa.com

Custom Permanent Mold Casting Supplier TFG USA Definition Of Mould In Casting The mould is regarded as the heart of the continuous casting process. The interplay between mould design and die casting process machine compatibility: In the continuous casting process, liquid steel flows from a ladle, through a tundish into the mould. Casting, on the other hand, involves pouring or injecting the liquid casting material into the prepared mold. Casting is a. Definition Of Mould In Casting.

From www.leclairemfg.com

Ultimate Guide to the Permanent Mold Casting Process Definition Of Mould In Casting It’s a method preferred for. Casting is pouring molten metal into the moulds. The interplay between mould design and die casting process machine compatibility: Casting is a process that involves a liquid material being poured into a mould which features a hollow cavity of the desired shape. The liquid material then solidifies (cures) before being removed. This step is crucial. Definition Of Mould In Casting.