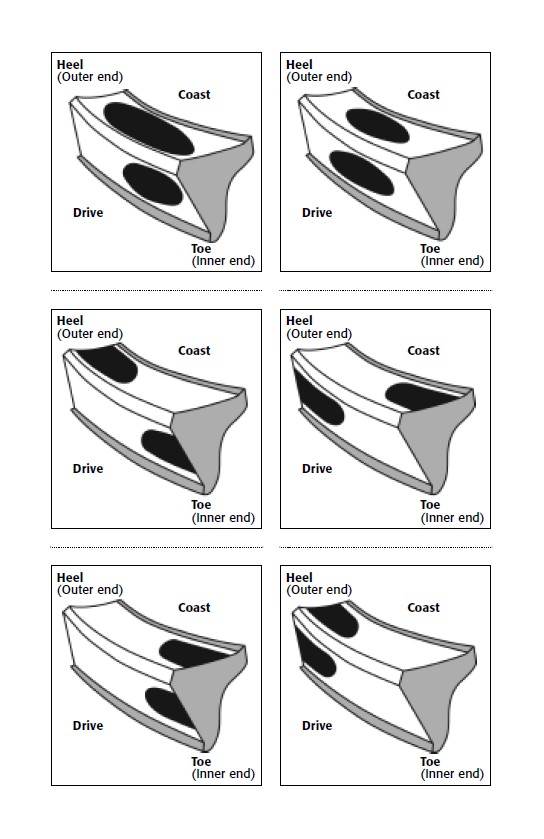

Pinion Gear Depth Patterns . You should see the wear pattern closer to the toe of the tooth with most gear sets. The pattern’s position to the tooth face (ridge/top land) and flank (valley/root) indicates pinion depth. Ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. Drive pattern moves deeper on the tooth (flank contact) and slightly toward the toe. This will move the drive side contact point down towards the. If the gear was manufactured using the face hobbing method, both a and b. After the gears are installed using a pinion depth setting tool, you should always check the wear pattern using a marking compound. Disregard the pattern’s position to the tooth’s heel (ring gear outside diameter) or toe. If your gear tooth pattern is too high, up towards the gear face, you will need to increase your pinion depth by using more or thicker pinion shims. Coast pattern moves deeper on the tooth and toward the heel. The images below illustrate both acceptable and unacceptable ring and pinion gear.

from www.extremeterrain.com

The images below illustrate both acceptable and unacceptable ring and pinion gear. Coast pattern moves deeper on the tooth and toward the heel. You should see the wear pattern closer to the toe of the tooth with most gear sets. After the gears are installed using a pinion depth setting tool, you should always check the wear pattern using a marking compound. Ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. If the gear was manufactured using the face hobbing method, both a and b. If your gear tooth pattern is too high, up towards the gear face, you will need to increase your pinion depth by using more or thicker pinion shims. The pattern’s position to the tooth face (ridge/top land) and flank (valley/root) indicates pinion depth. Disregard the pattern’s position to the tooth’s heel (ring gear outside diameter) or toe. Drive pattern moves deeper on the tooth (flank contact) and slightly toward the toe.

How to Install Yukon Gear Dana 30 Ring Gear and Pinion Kit 4.11 Front

Pinion Gear Depth Patterns After the gears are installed using a pinion depth setting tool, you should always check the wear pattern using a marking compound. The pattern’s position to the tooth face (ridge/top land) and flank (valley/root) indicates pinion depth. If the gear was manufactured using the face hobbing method, both a and b. Ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. Coast pattern moves deeper on the tooth and toward the heel. This will move the drive side contact point down towards the. The images below illustrate both acceptable and unacceptable ring and pinion gear. Disregard the pattern’s position to the tooth’s heel (ring gear outside diameter) or toe. You should see the wear pattern closer to the toe of the tooth with most gear sets. After the gears are installed using a pinion depth setting tool, you should always check the wear pattern using a marking compound. Drive pattern moves deeper on the tooth (flank contact) and slightly toward the toe. If your gear tooth pattern is too high, up towards the gear face, you will need to increase your pinion depth by using more or thicker pinion shims.

From joifptjou.blob.core.windows.net

How To Set Up A Ring And Pinion Gear at Sherron Grant blog Pinion Gear Depth Patterns The pattern’s position to the tooth face (ridge/top land) and flank (valley/root) indicates pinion depth. Ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. After the gears are installed using a pinion depth setting tool, you should always check the wear pattern using a marking compound. The images. Pinion Gear Depth Patterns.

From www.scribd.com

er_Ring_Gear_Contact_Pattern_Interpretation.pdf Gear Tooth Pinion Gear Depth Patterns Ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. This will move the drive side contact point down towards the. If the gear was manufactured using the face hobbing method, both a and b. You should see the wear pattern closer to the toe of the tooth with. Pinion Gear Depth Patterns.

From wiringascensive.z13.web.core.windows.net

Setting Up Ring And Pinion Gears Pinion Gear Depth Patterns This will move the drive side contact point down towards the. After the gears are installed using a pinion depth setting tool, you should always check the wear pattern using a marking compound. The pattern’s position to the tooth face (ridge/top land) and flank (valley/root) indicates pinion depth. Drive pattern moves deeper on the tooth (flank contact) and slightly toward. Pinion Gear Depth Patterns.

From joifptjou.blob.core.windows.net

How To Set Up A Ring And Pinion Gear at Sherron Grant blog Pinion Gear Depth Patterns Coast pattern moves deeper on the tooth and toward the heel. The images below illustrate both acceptable and unacceptable ring and pinion gear. Drive pattern moves deeper on the tooth (flank contact) and slightly toward the toe. If your gear tooth pattern is too high, up towards the gear face, you will need to increase your pinion depth by using. Pinion Gear Depth Patterns.

From classicoldsmobile.com

USA standard gear pinion depth marking? Pinion Gear Depth Patterns If the gear was manufactured using the face hobbing method, both a and b. Ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. This will move the drive side contact point down towards the. Drive pattern moves deeper on the tooth (flank contact) and slightly toward the toe.. Pinion Gear Depth Patterns.

From www.youtube.com

Ring & Pinion Patterns explained, back lash vs pinion depth YouTube Pinion Gear Depth Patterns The pattern’s position to the tooth face (ridge/top land) and flank (valley/root) indicates pinion depth. Disregard the pattern’s position to the tooth’s heel (ring gear outside diameter) or toe. If your gear tooth pattern is too high, up towards the gear face, you will need to increase your pinion depth by using more or thicker pinion shims. Coast pattern moves. Pinion Gear Depth Patterns.

From www.racingjunk.com

Setting Pinion Depth and Backlash RacingJunk News Pinion Gear Depth Patterns The images below illustrate both acceptable and unacceptable ring and pinion gear. If the gear was manufactured using the face hobbing method, both a and b. Coast pattern moves deeper on the tooth and toward the heel. Disregard the pattern’s position to the tooth’s heel (ring gear outside diameter) or toe. Ring and pinion gear pattern is one of the. Pinion Gear Depth Patterns.

From www.racingjunk.com

Setting Pinion Depth and Backlash RacingJunk News Pinion Gear Depth Patterns The images below illustrate both acceptable and unacceptable ring and pinion gear. If your gear tooth pattern is too high, up towards the gear face, you will need to increase your pinion depth by using more or thicker pinion shims. Disregard the pattern’s position to the tooth’s heel (ring gear outside diameter) or toe. After the gears are installed using. Pinion Gear Depth Patterns.

From www.pinterest.com

Acceptable Ring & Pinion Gear Patterns Auto repair, Automotive repair Pinion Gear Depth Patterns Ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. Coast pattern moves deeper on the tooth and toward the heel. Disregard the pattern’s position to the tooth’s heel (ring gear outside diameter) or toe. If the gear was manufactured using the face hobbing method, both a and b.. Pinion Gear Depth Patterns.

From www.reddit.com

Any differential experts care to comment on my ring and pinion pattern Pinion Gear Depth Patterns Drive pattern moves deeper on the tooth (flank contact) and slightly toward the toe. After the gears are installed using a pinion depth setting tool, you should always check the wear pattern using a marking compound. You should see the wear pattern closer to the toe of the tooth with most gear sets. If your gear tooth pattern is too. Pinion Gear Depth Patterns.

From joifptjou.blob.core.windows.net

How To Set Up A Ring And Pinion Gear at Sherron Grant blog Pinion Gear Depth Patterns The pattern’s position to the tooth face (ridge/top land) and flank (valley/root) indicates pinion depth. This will move the drive side contact point down towards the. The images below illustrate both acceptable and unacceptable ring and pinion gear. If your gear tooth pattern is too high, up towards the gear face, you will need to increase your pinion depth by. Pinion Gear Depth Patterns.

From www.youtube.com

How To Measure Differential Pinion Gear Depth With A Self Made Tool Pinion Gear Depth Patterns This will move the drive side contact point down towards the. Disregard the pattern’s position to the tooth’s heel (ring gear outside diameter) or toe. After the gears are installed using a pinion depth setting tool, you should always check the wear pattern using a marking compound. If your gear tooth pattern is too high, up towards the gear face,. Pinion Gear Depth Patterns.

From www.youtube.com

Pinion depth and how to work with measured and specified values YouTube Pinion Gear Depth Patterns The pattern’s position to the tooth face (ridge/top land) and flank (valley/root) indicates pinion depth. If the gear was manufactured using the face hobbing method, both a and b. Ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. This will move the drive side contact point down towards. Pinion Gear Depth Patterns.

From carinmylife.com

Gearing Up How To Install & Set Up a Dana 60 Gearset Car in My Life Pinion Gear Depth Patterns Drive pattern moves deeper on the tooth (flank contact) and slightly toward the toe. If your gear tooth pattern is too high, up towards the gear face, you will need to increase your pinion depth by using more or thicker pinion shims. Disregard the pattern’s position to the tooth’s heel (ring gear outside diameter) or toe. Ring and pinion gear. Pinion Gear Depth Patterns.

From www.youtube.com

The Easiest Way to Read Ring & Pinion Contact Patterns YouTube Pinion Gear Depth Patterns The pattern’s position to the tooth face (ridge/top land) and flank (valley/root) indicates pinion depth. Drive pattern moves deeper on the tooth (flank contact) and slightly toward the toe. This will move the drive side contact point down towards the. Ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set. Pinion Gear Depth Patterns.

From pstoattern.com

Ring Pinion Pattern Patterns Gallery Pinion Gear Depth Patterns The pattern’s position to the tooth face (ridge/top land) and flank (valley/root) indicates pinion depth. You should see the wear pattern closer to the toe of the tooth with most gear sets. Ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. Disregard the pattern’s position to the tooth’s. Pinion Gear Depth Patterns.

From billavista.com

Setup Bible Tech Article by BillaVista Pinion Gear Depth Patterns If the gear was manufactured using the face hobbing method, both a and b. The pattern’s position to the tooth face (ridge/top land) and flank (valley/root) indicates pinion depth. The images below illustrate both acceptable and unacceptable ring and pinion gear. You should see the wear pattern closer to the toe of the tooth with most gear sets. Ring and. Pinion Gear Depth Patterns.

From www.therangerstation.com

Ring & Pinion Installation Instructions The Ranger Station Pinion Gear Depth Patterns If the gear was manufactured using the face hobbing method, both a and b. Drive pattern moves deeper on the tooth (flank contact) and slightly toward the toe. The images below illustrate both acceptable and unacceptable ring and pinion gear. The pattern’s position to the tooth face (ridge/top land) and flank (valley/root) indicates pinion depth. Coast pattern moves deeper on. Pinion Gear Depth Patterns.

From www.americantrucks.com

How to Install Yukon Gear 8.25 in. IFS Front Ring Gear and Pinion Set Pinion Gear Depth Patterns Ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. This will move the drive side contact point down towards the. Drive pattern moves deeper on the tooth (flank contact) and slightly toward the toe. If your gear tooth pattern is too high, up towards the gear face, you. Pinion Gear Depth Patterns.

From www.differentials.com

Two Cut vs. Five Cut Ring & Pinion Gears West Coast Differentials Pinion Gear Depth Patterns The pattern’s position to the tooth face (ridge/top land) and flank (valley/root) indicates pinion depth. Coast pattern moves deeper on the tooth and toward the heel. If the gear was manufactured using the face hobbing method, both a and b. The images below illustrate both acceptable and unacceptable ring and pinion gear. Ring and pinion gear pattern is one of. Pinion Gear Depth Patterns.

From www.racingjunk.com

How to Set up Your Rear Gear Correctly RacingJunk News Pinion Gear Depth Patterns Coast pattern moves deeper on the tooth and toward the heel. The images below illustrate both acceptable and unacceptable ring and pinion gear. If the gear was manufactured using the face hobbing method, both a and b. If your gear tooth pattern is too high, up towards the gear face, you will need to increase your pinion depth by using. Pinion Gear Depth Patterns.

From www.billavista.com

Gear Setup Tech Article by BillaVista Pinion Gear Depth Patterns Ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. The pattern’s position to the tooth face (ridge/top land) and flank (valley/root) indicates pinion depth. This will move the drive side contact point down towards the. If your gear tooth pattern is too high, up towards the gear face,. Pinion Gear Depth Patterns.

From www.yukongear.com

How To Create & Read Ring Gear Patterns Pinion Gear Depth Patterns This will move the drive side contact point down towards the. After the gears are installed using a pinion depth setting tool, you should always check the wear pattern using a marking compound. Drive pattern moves deeper on the tooth (flank contact) and slightly toward the toe. Disregard the pattern’s position to the tooth’s heel (ring gear outside diameter) or. Pinion Gear Depth Patterns.

From loetusjou.blob.core.windows.net

Pinion Gear Pattern at Cynthia Houston blog Pinion Gear Depth Patterns If your gear tooth pattern is too high, up towards the gear face, you will need to increase your pinion depth by using more or thicker pinion shims. Disregard the pattern’s position to the tooth’s heel (ring gear outside diameter) or toe. Coast pattern moves deeper on the tooth and toward the heel. You should see the wear pattern closer. Pinion Gear Depth Patterns.

From www.extremeterrain.com

How to Install Yukon Gear Dana 30 Ring Gear and Pinion Kit 4.11 Front Pinion Gear Depth Patterns If your gear tooth pattern is too high, up towards the gear face, you will need to increase your pinion depth by using more or thicker pinion shims. Drive pattern moves deeper on the tooth (flank contact) and slightly toward the toe. If the gear was manufactured using the face hobbing method, both a and b. Coast pattern moves deeper. Pinion Gear Depth Patterns.

From www.differentials.com

2 Cut Ring & Pinion Gear Setup West Coast Differentials Pinion Gear Depth Patterns If your gear tooth pattern is too high, up towards the gear face, you will need to increase your pinion depth by using more or thicker pinion shims. Coast pattern moves deeper on the tooth and toward the heel. Drive pattern moves deeper on the tooth (flank contact) and slightly toward the toe. Disregard the pattern’s position to the tooth’s. Pinion Gear Depth Patterns.

From www.youtube.com

Ring and Pinion Contact Pattern With Change of Pinion Depth. YouTube Pinion Gear Depth Patterns You should see the wear pattern closer to the toe of the tooth with most gear sets. Disregard the pattern’s position to the tooth’s heel (ring gear outside diameter) or toe. If your gear tooth pattern is too high, up towards the gear face, you will need to increase your pinion depth by using more or thicker pinion shims. The. Pinion Gear Depth Patterns.

From forum.ih8mud.com

Ring paint/ pinion IH8MUD Forum Pinion Gear Depth Patterns Drive pattern moves deeper on the tooth (flank contact) and slightly toward the toe. Disregard the pattern’s position to the tooth’s heel (ring gear outside diameter) or toe. The pattern’s position to the tooth face (ridge/top land) and flank (valley/root) indicates pinion depth. If the gear was manufactured using the face hobbing method, both a and b. If your gear. Pinion Gear Depth Patterns.

From classicoldsmobile.com

USA standard gear pinion depth marking? Pinion Gear Depth Patterns Drive pattern moves deeper on the tooth (flank contact) and slightly toward the toe. Ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. Disregard the pattern’s position to the tooth’s heel (ring gear outside diameter) or toe. The images below illustrate both acceptable and unacceptable ring and pinion. Pinion Gear Depth Patterns.

From www.racingjunk.com

Setting Pinion Depth and Backlash RacingJunk News Pinion Gear Depth Patterns Drive pattern moves deeper on the tooth (flank contact) and slightly toward the toe. You should see the wear pattern closer to the toe of the tooth with most gear sets. Disregard the pattern’s position to the tooth’s heel (ring gear outside diameter) or toe. The images below illustrate both acceptable and unacceptable ring and pinion gear. Coast pattern moves. Pinion Gear Depth Patterns.

From www.racingjunk.com

How to Set up Your Rear Gear Correctly RacingJunk News Pinion Gear Depth Patterns Ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. The pattern’s position to the tooth face (ridge/top land) and flank (valley/root) indicates pinion depth. You should see the wear pattern closer to the toe of the tooth with most gear sets. Coast pattern moves deeper on the tooth. Pinion Gear Depth Patterns.

From www.youtube.com

How to Read and Interpret Gear Patterns (Ring and Pinion) YouTube Pinion Gear Depth Patterns Coast pattern moves deeper on the tooth and toward the heel. Drive pattern moves deeper on the tooth (flank contact) and slightly toward the toe. You should see the wear pattern closer to the toe of the tooth with most gear sets. The pattern’s position to the tooth face (ridge/top land) and flank (valley/root) indicates pinion depth. After the gears. Pinion Gear Depth Patterns.

From www.racingjunk.com

Setting Pinion Depth and Backlash RacingJunk News Pinion Gear Depth Patterns If your gear tooth pattern is too high, up towards the gear face, you will need to increase your pinion depth by using more or thicker pinion shims. Coast pattern moves deeper on the tooth and toward the heel. Disregard the pattern’s position to the tooth’s heel (ring gear outside diameter) or toe. The pattern’s position to the tooth face. Pinion Gear Depth Patterns.

From www.pirate4x4.com

Ring & pinion set up, Jantz Engineering advanced masters course Pinion Gear Depth Patterns This will move the drive side contact point down towards the. If your gear tooth pattern is too high, up towards the gear face, you will need to increase your pinion depth by using more or thicker pinion shims. If the gear was manufactured using the face hobbing method, both a and b. Ring and pinion gear pattern is one. Pinion Gear Depth Patterns.

From www.pirate4x4.com

Figure 6 Pinion Depth Pinion Gear Depth Patterns Ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. You should see the wear pattern closer to the toe of the tooth with most gear sets. The pattern’s position to the tooth face (ridge/top land) and flank (valley/root) indicates pinion depth. If your gear tooth pattern is too. Pinion Gear Depth Patterns.