Best Aluminum For Machining . From grasping the properties of aluminum to mastering cutting speeds, feeds, and cnc programming, this guide aims to provide a concise overview, setting you on the path to confidently navigate the exciting realm of cnc machining for aluminum. Since everyone is cutting it, machining aluminum is a really competitive space. Understanding the best ways to tackle it is important for achieving the desired results. You’ll also learn about the standard aluminum cnc machining techniques and applications. This article discusses aluminum cnc machining, the benefits of using aluminum for cnc machining, and the different grades of aluminum used in cnc machining. They come in a range of options which gives you huge flexibility when embarking on a machining project. Aluminum is a versatile material with a high level of machinability, but it should not be overlooked. Here's an overview of the top aluminum grades commonly used in cnc machining: This guide attempts to provide a quick comparison of five of the most common aluminum alloys for machining. In this article, i’ll share all. Ultimately, the best aluminum for machining is directly related to the purpose or application of the component being machined. Optimizing your tool crib, machine setups, and toolpaths for aluminum is essential to stay ahead of the competition and make your shop more efficient. However, narrowing the best aluminum alloy for the job also becomes harder. This is especially true of production machining. Some of the most commonly used aluminum alloys in machining are mic 6, 2024, 5083, 6061, 7050, and 7075 aluminum alloys.

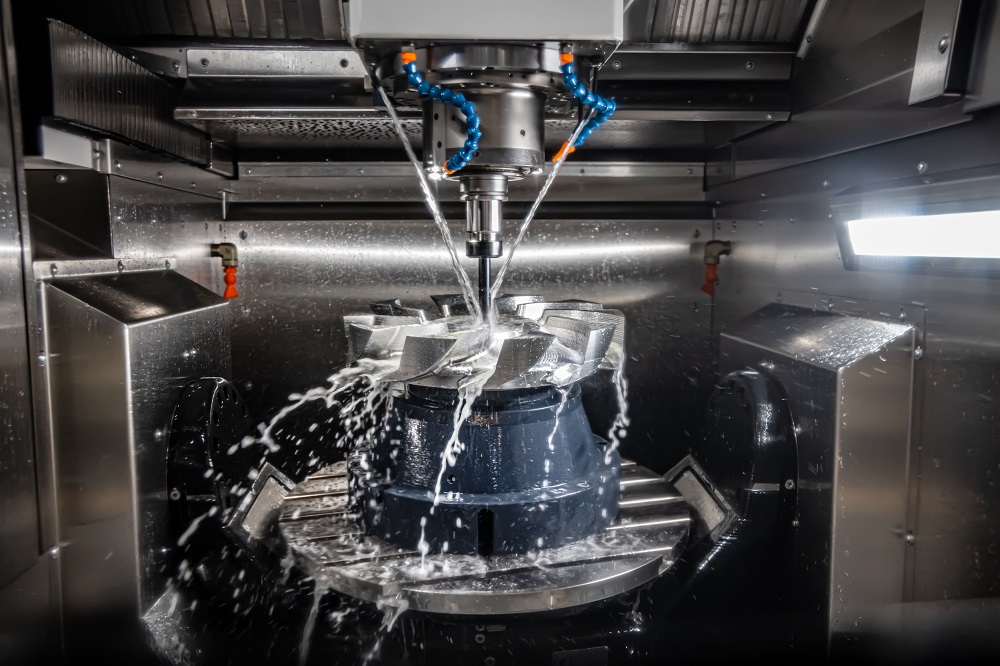

from www.masterfluidsolutions.com

In this article, i’ll share all. From grasping the properties of aluminum to mastering cutting speeds, feeds, and cnc programming, this guide aims to provide a concise overview, setting you on the path to confidently navigate the exciting realm of cnc machining for aluminum. This article discusses aluminum cnc machining, the benefits of using aluminum for cnc machining, and the different grades of aluminum used in cnc machining. They come in a range of options which gives you huge flexibility when embarking on a machining project. You’ll also learn about the standard aluminum cnc machining techniques and applications. Optimizing your tool crib, machine setups, and toolpaths for aluminum is essential to stay ahead of the competition and make your shop more efficient. This guide attempts to provide a quick comparison of five of the most common aluminum alloys for machining. However, narrowing the best aluminum alloy for the job also becomes harder. Here's an overview of the top aluminum grades commonly used in cnc machining: This is especially true of production machining.

The Best Tips for Machining Hard Metals and Alloys Master Fluid Solutions

Best Aluminum For Machining They come in a range of options which gives you huge flexibility when embarking on a machining project. Optimizing your tool crib, machine setups, and toolpaths for aluminum is essential to stay ahead of the competition and make your shop more efficient. Since everyone is cutting it, machining aluminum is a really competitive space. You’ll also learn about the standard aluminum cnc machining techniques and applications. However, narrowing the best aluminum alloy for the job also becomes harder. Some of the most commonly used aluminum alloys in machining are mic 6, 2024, 5083, 6061, 7050, and 7075 aluminum alloys. They come in a range of options which gives you huge flexibility when embarking on a machining project. From grasping the properties of aluminum to mastering cutting speeds, feeds, and cnc programming, this guide aims to provide a concise overview, setting you on the path to confidently navigate the exciting realm of cnc machining for aluminum. Here's an overview of the top aluminum grades commonly used in cnc machining: In this article, i’ll share all. Aluminum is a versatile material with a high level of machinability, but it should not be overlooked. Understanding the best ways to tackle it is important for achieving the desired results. This is especially true of production machining. This article discusses aluminum cnc machining, the benefits of using aluminum for cnc machining, and the different grades of aluminum used in cnc machining. Ultimately, the best aluminum for machining is directly related to the purpose or application of the component being machined. This guide attempts to provide a quick comparison of five of the most common aluminum alloys for machining.

From www.residencestyle.com

Best Advantages of CNC Machining » Residence Style Best Aluminum For Machining This article discusses aluminum cnc machining, the benefits of using aluminum for cnc machining, and the different grades of aluminum used in cnc machining. You’ll also learn about the standard aluminum cnc machining techniques and applications. However, narrowing the best aluminum alloy for the job also becomes harder. This guide attempts to provide a quick comparison of five of the. Best Aluminum For Machining.

From www.youtube.com

Aluminum Machining YouTube Best Aluminum For Machining This guide attempts to provide a quick comparison of five of the most common aluminum alloys for machining. You’ll also learn about the standard aluminum cnc machining techniques and applications. Since everyone is cutting it, machining aluminum is a really competitive space. From grasping the properties of aluminum to mastering cutting speeds, feeds, and cnc programming, this guide aims to. Best Aluminum For Machining.

From winndeavor.com

Best Metals For Machining Winndeavor Best Aluminum For Machining Aluminum is a versatile material with a high level of machinability, but it should not be overlooked. However, narrowing the best aluminum alloy for the job also becomes harder. Here's an overview of the top aluminum grades commonly used in cnc machining: Understanding the best ways to tackle it is important for achieving the desired results. You’ll also learn about. Best Aluminum For Machining.

From www.3erp.com

Aluminum CNC Machining Services Best Aluminum For Machining They come in a range of options which gives you huge flexibility when embarking on a machining project. You’ll also learn about the standard aluminum cnc machining techniques and applications. From grasping the properties of aluminum to mastering cutting speeds, feeds, and cnc programming, this guide aims to provide a concise overview, setting you on the path to confidently navigate. Best Aluminum For Machining.

From cncrapid.com

Aluminum Machining Services, Rapid Prototyping Best Aluminum For Machining From grasping the properties of aluminum to mastering cutting speeds, feeds, and cnc programming, this guide aims to provide a concise overview, setting you on the path to confidently navigate the exciting realm of cnc machining for aluminum. Ultimately, the best aluminum for machining is directly related to the purpose or application of the component being machined. In this article,. Best Aluminum For Machining.

From hdcmfg.com

6060 Aluminum Machining HDC Best Aluminum For Machining This article discusses aluminum cnc machining, the benefits of using aluminum for cnc machining, and the different grades of aluminum used in cnc machining. This guide attempts to provide a quick comparison of five of the most common aluminum alloys for machining. This is especially true of production machining. From grasping the properties of aluminum to mastering cutting speeds, feeds,. Best Aluminum For Machining.

From at-machining.com

Machined Aluminum vs. Cast Aluminum Which Is Right For Your Project? ATMachining Best Aluminum For Machining This is especially true of production machining. Ultimately, the best aluminum for machining is directly related to the purpose or application of the component being machined. You’ll also learn about the standard aluminum cnc machining techniques and applications. Some of the most commonly used aluminum alloys in machining are mic 6, 2024, 5083, 6061, 7050, and 7075 aluminum alloys. Understanding. Best Aluminum For Machining.

From www.rtprototype.com

Your Best Aluminum CNC Machining Supplier in China Best Aluminum For Machining Optimizing your tool crib, machine setups, and toolpaths for aluminum is essential to stay ahead of the competition and make your shop more efficient. You’ll also learn about the standard aluminum cnc machining techniques and applications. From grasping the properties of aluminum to mastering cutting speeds, feeds, and cnc programming, this guide aims to provide a concise overview, setting you. Best Aluminum For Machining.

From www.3erp.com

Aluminum CNC Machining Services Best Aluminum For Machining Ultimately, the best aluminum for machining is directly related to the purpose or application of the component being machined. Understanding the best ways to tackle it is important for achieving the desired results. Since everyone is cutting it, machining aluminum is a really competitive space. From grasping the properties of aluminum to mastering cutting speeds, feeds, and cnc programming, this. Best Aluminum For Machining.

From www.madearia.com

What is Aluminum machining? MadeAria Best Aluminum For Machining This is especially true of production machining. Optimizing your tool crib, machine setups, and toolpaths for aluminum is essential to stay ahead of the competition and make your shop more efficient. Some of the most commonly used aluminum alloys in machining are mic 6, 2024, 5083, 6061, 7050, and 7075 aluminum alloys. This article discusses aluminum cnc machining, the benefits. Best Aluminum For Machining.

From www.3erp.com

Aluminum CNC Machining Services Best Aluminum For Machining In this article, i’ll share all. Aluminum is a versatile material with a high level of machinability, but it should not be overlooked. This is especially true of production machining. Since everyone is cutting it, machining aluminum is a really competitive space. You’ll also learn about the standard aluminum cnc machining techniques and applications. Some of the most commonly used. Best Aluminum For Machining.

From at-machining.com

Aluminum CNC Machining Services from China Custom Parts Best Aluminum For Machining From grasping the properties of aluminum to mastering cutting speeds, feeds, and cnc programming, this guide aims to provide a concise overview, setting you on the path to confidently navigate the exciting realm of cnc machining for aluminum. This article discusses aluminum cnc machining, the benefits of using aluminum for cnc machining, and the different grades of aluminum used in. Best Aluminum For Machining.

From autoprotoway.com

CNC Aluminum Machining For Maximum Benefits AutoProtoWay Best Aluminum For Machining From grasping the properties of aluminum to mastering cutting speeds, feeds, and cnc programming, this guide aims to provide a concise overview, setting you on the path to confidently navigate the exciting realm of cnc machining for aluminum. Understanding the best ways to tackle it is important for achieving the desired results. Aluminum is a versatile material with a high. Best Aluminum For Machining.

From www.youtube.com

Machining A Large Aluminum Part YouTube Best Aluminum For Machining Optimizing your tool crib, machine setups, and toolpaths for aluminum is essential to stay ahead of the competition and make your shop more efficient. Since everyone is cutting it, machining aluminum is a really competitive space. From grasping the properties of aluminum to mastering cutting speeds, feeds, and cnc programming, this guide aims to provide a concise overview, setting you. Best Aluminum For Machining.

From usimn.com

The Basics of Aluminum Machining USI MN Best Aluminum For Machining Ultimately, the best aluminum for machining is directly related to the purpose or application of the component being machined. You’ll also learn about the standard aluminum cnc machining techniques and applications. This guide attempts to provide a quick comparison of five of the most common aluminum alloys for machining. In this article, i’ll share all. This article discusses aluminum cnc. Best Aluminum For Machining.

From www.youtube.com

Manufacturing At Home Machining Large Aluminum Plate with Tormach PCNC 1100 YouTube Best Aluminum For Machining Since everyone is cutting it, machining aluminum is a really competitive space. Optimizing your tool crib, machine setups, and toolpaths for aluminum is essential to stay ahead of the competition and make your shop more efficient. Some of the most commonly used aluminum alloys in machining are mic 6, 2024, 5083, 6061, 7050, and 7075 aluminum alloys. They come in. Best Aluminum For Machining.

From at-machining.com

CNC Machining Aluminum The Basic Guide You Need To Know Best Aluminum For Machining Here's an overview of the top aluminum grades commonly used in cnc machining: Ultimately, the best aluminum for machining is directly related to the purpose or application of the component being machined. Understanding the best ways to tackle it is important for achieving the desired results. You’ll also learn about the standard aluminum cnc machining techniques and applications. Aluminum is. Best Aluminum For Machining.

From www.youtube.com

(1/2) Making a Machinists Hammer Handle and Head from aluminum on the mini lathe YouTube Best Aluminum For Machining Here's an overview of the top aluminum grades commonly used in cnc machining: From grasping the properties of aluminum to mastering cutting speeds, feeds, and cnc programming, this guide aims to provide a concise overview, setting you on the path to confidently navigate the exciting realm of cnc machining for aluminum. This article discusses aluminum cnc machining, the benefits of. Best Aluminum For Machining.

From www.ltc-proto.com

A Brief Guide to Choose the Best Material for CNC Machining Tasks Best Aluminum For Machining Since everyone is cutting it, machining aluminum is a really competitive space. Here's an overview of the top aluminum grades commonly used in cnc machining: Optimizing your tool crib, machine setups, and toolpaths for aluminum is essential to stay ahead of the competition and make your shop more efficient. However, narrowing the best aluminum alloy for the job also becomes. Best Aluminum For Machining.

From www.richardsonmetals.com

Aluminum Machining Services Richardson Metals, Inc. Best Aluminum For Machining However, narrowing the best aluminum alloy for the job also becomes harder. Aluminum is a versatile material with a high level of machinability, but it should not be overlooked. Understanding the best ways to tackle it is important for achieving the desired results. This is especially true of production machining. Since everyone is cutting it, machining aluminum is a really. Best Aluminum For Machining.

From www.fotolog.com

4 Best Tips to Aluminum Machining FotoLog Best Aluminum For Machining Here's an overview of the top aluminum grades commonly used in cnc machining: Aluminum is a versatile material with a high level of machinability, but it should not be overlooked. This guide attempts to provide a quick comparison of five of the most common aluminum alloys for machining. This article discusses aluminum cnc machining, the benefits of using aluminum for. Best Aluminum For Machining.

From hdcmfg.com

Aluminum Machining Services Custom CNC Machining Factory Best Aluminum For Machining However, narrowing the best aluminum alloy for the job also becomes harder. In this article, i’ll share all. This guide attempts to provide a quick comparison of five of the most common aluminum alloys for machining. Some of the most commonly used aluminum alloys in machining are mic 6, 2024, 5083, 6061, 7050, and 7075 aluminum alloys. Ultimately, the best. Best Aluminum For Machining.

From udyamoldisgold.com

CNC Metal Parts Machining The Best Guide Udyamoldisgold Best Aluminum For Machining Optimizing your tool crib, machine setups, and toolpaths for aluminum is essential to stay ahead of the competition and make your shop more efficient. Understanding the best ways to tackle it is important for achieving the desired results. This guide attempts to provide a quick comparison of five of the most common aluminum alloys for machining. This is especially true. Best Aluminum For Machining.

From www.sibaicnc.com

Custom Aluminum Alloys Processing, Precision Machining Supplier Sibai Best Aluminum For Machining Aluminum is a versatile material with a high level of machinability, but it should not be overlooked. From grasping the properties of aluminum to mastering cutting speeds, feeds, and cnc programming, this guide aims to provide a concise overview, setting you on the path to confidently navigate the exciting realm of cnc machining for aluminum. You’ll also learn about the. Best Aluminum For Machining.

From www.essaii.com

Aluminum machining part How does custom cnc machining work? Best Aluminum For Machining This is especially true of production machining. However, narrowing the best aluminum alloy for the job also becomes harder. Aluminum is a versatile material with a high level of machinability, but it should not be overlooked. This guide attempts to provide a quick comparison of five of the most common aluminum alloys for machining. This article discusses aluminum cnc machining,. Best Aluminum For Machining.

From blog.thepipingmart.com

What Is Aluminum Machining? Best Aluminum For Machining Ultimately, the best aluminum for machining is directly related to the purpose or application of the component being machined. Understanding the best ways to tackle it is important for achieving the desired results. However, narrowing the best aluminum alloy for the job also becomes harder. Aluminum is a versatile material with a high level of machinability, but it should not. Best Aluminum For Machining.

From moseys.com

The Best Aluminum for Machining Moseys Production Machinists Best Aluminum For Machining Since everyone is cutting it, machining aluminum is a really competitive space. This guide attempts to provide a quick comparison of five of the most common aluminum alloys for machining. In this article, i’ll share all. You’ll also learn about the standard aluminum cnc machining techniques and applications. Aluminum is a versatile material with a high level of machinability, but. Best Aluminum For Machining.

From www.indiamart.com

Aluminum Machining Tool at best price in Nagpur by Vikas Industrial Suppliers Private Limited Best Aluminum For Machining Understanding the best ways to tackle it is important for achieving the desired results. You’ll also learn about the standard aluminum cnc machining techniques and applications. Here's an overview of the top aluminum grades commonly used in cnc machining: In this article, i’ll share all. Some of the most commonly used aluminum alloys in machining are mic 6, 2024, 5083,. Best Aluminum For Machining.

From powermachinery.com.au

Aluminium Saws Power Machinery Australia Best Aluminum For Machining Some of the most commonly used aluminum alloys in machining are mic 6, 2024, 5083, 6061, 7050, and 7075 aluminum alloys. Optimizing your tool crib, machine setups, and toolpaths for aluminum is essential to stay ahead of the competition and make your shop more efficient. Since everyone is cutting it, machining aluminum is a really competitive space. From grasping the. Best Aluminum For Machining.

From www.theengineerspost.com

Aluminum Machining How to Machine Aluminum Alloys Effectively Best Aluminum For Machining Optimizing your tool crib, machine setups, and toolpaths for aluminum is essential to stay ahead of the competition and make your shop more efficient. They come in a range of options which gives you huge flexibility when embarking on a machining project. Since everyone is cutting it, machining aluminum is a really competitive space. In this article, i’ll share all.. Best Aluminum For Machining.

From www.sunrise-metal.com

Aluminum Machining Parts Aluminum CNC Service Sunrise Metal Best Aluminum For Machining In this article, i’ll share all. This guide attempts to provide a quick comparison of five of the most common aluminum alloys for machining. From grasping the properties of aluminum to mastering cutting speeds, feeds, and cnc programming, this guide aims to provide a concise overview, setting you on the path to confidently navigate the exciting realm of cnc machining. Best Aluminum For Machining.

From hardwareprecision.com

Titanium vs Aluminum Which Metal is Best for CNC Machining? Jinwang Hardware Best Aluminum For Machining Optimizing your tool crib, machine setups, and toolpaths for aluminum is essential to stay ahead of the competition and make your shop more efficient. Here's an overview of the top aluminum grades commonly used in cnc machining: You’ll also learn about the standard aluminum cnc machining techniques and applications. This guide attempts to provide a quick comparison of five of. Best Aluminum For Machining.

From www.masterfluidsolutions.com

The Best Tips for Machining Hard Metals and Alloys Master Fluid Solutions Best Aluminum For Machining This guide attempts to provide a quick comparison of five of the most common aluminum alloys for machining. This article discusses aluminum cnc machining, the benefits of using aluminum for cnc machining, and the different grades of aluminum used in cnc machining. Aluminum is a versatile material with a high level of machinability, but it should not be overlooked. Since. Best Aluminum For Machining.

From hdcmfg.com

Aluminum Machining Services China HDC Best Aluminum For Machining Ultimately, the best aluminum for machining is directly related to the purpose or application of the component being machined. This article discusses aluminum cnc machining, the benefits of using aluminum for cnc machining, and the different grades of aluminum used in cnc machining. Optimizing your tool crib, machine setups, and toolpaths for aluminum is essential to stay ahead of the. Best Aluminum For Machining.

From www.fotolog.com

4 Best Tips to Aluminum Machining FotoLog Best Aluminum For Machining Aluminum is a versatile material with a high level of machinability, but it should not be overlooked. This is especially true of production machining. This guide attempts to provide a quick comparison of five of the most common aluminum alloys for machining. Understanding the best ways to tackle it is important for achieving the desired results. Since everyone is cutting. Best Aluminum For Machining.