Bronze Brass Process . Find out what these different metal extrusion techniques are. The process of applying coloration to bronze sculpture is called “patina.” it is a chemical reaction between the surface of the bronze and a variety of metal salts. It entails having the mold in the shape of the product you want to make. By this process, the mold can be used only once. Brass casting is a process of making brass products from molten brass. Bronze is primarily made of copper and tin, whereas brass combines copper with zinc. This fundamental difference gives each alloy its unique set of properties. Bronze tends to be harder and more durable than brass, making it ideal for applications like sculptures, coins, and bearings. Once molten brass cools, it takes the shape of.

from askanydifference.com

Once molten brass cools, it takes the shape of. It entails having the mold in the shape of the product you want to make. This fundamental difference gives each alloy its unique set of properties. The process of applying coloration to bronze sculpture is called “patina.” it is a chemical reaction between the surface of the bronze and a variety of metal salts. Bronze tends to be harder and more durable than brass, making it ideal for applications like sculptures, coins, and bearings. Brass casting is a process of making brass products from molten brass. By this process, the mold can be used only once. Find out what these different metal extrusion techniques are. Bronze is primarily made of copper and tin, whereas brass combines copper with zinc.

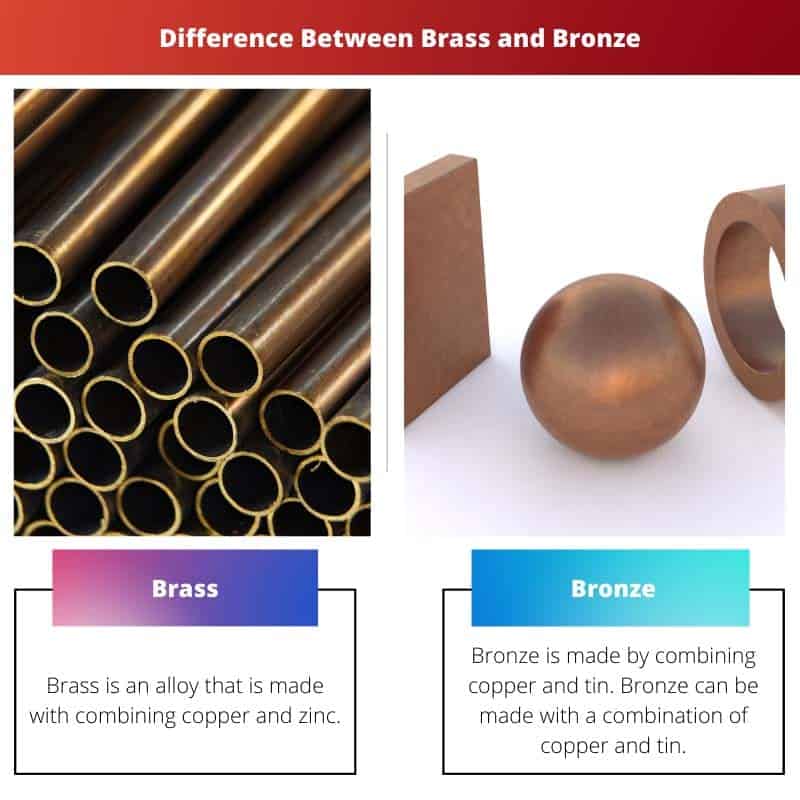

Brass vs Bronze Difference and Comparison

Bronze Brass Process It entails having the mold in the shape of the product you want to make. The process of applying coloration to bronze sculpture is called “patina.” it is a chemical reaction between the surface of the bronze and a variety of metal salts. Bronze is primarily made of copper and tin, whereas brass combines copper with zinc. It entails having the mold in the shape of the product you want to make. Brass casting is a process of making brass products from molten brass. This fundamental difference gives each alloy its unique set of properties. Once molten brass cools, it takes the shape of. By this process, the mold can be used only once. Find out what these different metal extrusion techniques are. Bronze tends to be harder and more durable than brass, making it ideal for applications like sculptures, coins, and bearings.

From blog.thepipingmart.com

DZR Brass vs Bronze What's the Difference Bronze Brass Process Brass casting is a process of making brass products from molten brass. By this process, the mold can be used only once. It entails having the mold in the shape of the product you want to make. This fundamental difference gives each alloy its unique set of properties. Once molten brass cools, it takes the shape of. Bronze is primarily. Bronze Brass Process.

From bollingeratelier.com

Brass Vs Bronze Bollinger Atelier Bronze Brass Process Bronze tends to be harder and more durable than brass, making it ideal for applications like sculptures, coins, and bearings. Bronze is primarily made of copper and tin, whereas brass combines copper with zinc. This fundamental difference gives each alloy its unique set of properties. Once molten brass cools, it takes the shape of. Find out what these different metal. Bronze Brass Process.

From www.elecmat.com

Copper Extrusion Manufacturing Bronze & Brass Extrusions Bronze Brass Process The process of applying coloration to bronze sculpture is called “patina.” it is a chemical reaction between the surface of the bronze and a variety of metal salts. Bronze tends to be harder and more durable than brass, making it ideal for applications like sculptures, coins, and bearings. Find out what these different metal extrusion techniques are. It entails having. Bronze Brass Process.

From henssgenhardware.com

Brass vs Bronze? What's the difference? [Video] Henssgen Hardware Bronze Brass Process Bronze is primarily made of copper and tin, whereas brass combines copper with zinc. This fundamental difference gives each alloy its unique set of properties. The process of applying coloration to bronze sculpture is called “patina.” it is a chemical reaction between the surface of the bronze and a variety of metal salts. Bronze tends to be harder and more. Bronze Brass Process.

From askanydifference.com

Brass vs Bronze Difference and Comparison Bronze Brass Process By this process, the mold can be used only once. Brass casting is a process of making brass products from molten brass. The process of applying coloration to bronze sculpture is called “patina.” it is a chemical reaction between the surface of the bronze and a variety of metal salts. This fundamental difference gives each alloy its unique set of. Bronze Brass Process.

From www.structuresinsider.com

An overview of metals processing methods Material Properties Bronze Brass Process The process of applying coloration to bronze sculpture is called “patina.” it is a chemical reaction between the surface of the bronze and a variety of metal salts. It entails having the mold in the shape of the product you want to make. Bronze tends to be harder and more durable than brass, making it ideal for applications like sculptures,. Bronze Brass Process.

From www.youtube.com

How To Make Metal Sculpture Sculpture Making Process Casting Bronze Brass Statue INDIA'S Bronze Brass Process Find out what these different metal extrusion techniques are. Bronze is primarily made of copper and tin, whereas brass combines copper with zinc. This fundamental difference gives each alloy its unique set of properties. By this process, the mold can be used only once. Bronze tends to be harder and more durable than brass, making it ideal for applications like. Bronze Brass Process.

From www.butserancientfarm.co.uk

Bronze Casting Sword, Axe, Knife, & more — Butser Ancient Farm Bronze Brass Process The process of applying coloration to bronze sculpture is called “patina.” it is a chemical reaction between the surface of the bronze and a variety of metal salts. It entails having the mold in the shape of the product you want to make. This fundamental difference gives each alloy its unique set of properties. Bronze is primarily made of copper. Bronze Brass Process.

From at-machining.com

Bronze vs. Brass vs. Copper Exploring Their Differences ATMachining Bronze Brass Process Bronze tends to be harder and more durable than brass, making it ideal for applications like sculptures, coins, and bearings. Brass casting is a process of making brass products from molten brass. By this process, the mold can be used only once. Bronze is primarily made of copper and tin, whereas brass combines copper with zinc. The process of applying. Bronze Brass Process.

From www.tfgusa.com

Custom Brass Extrusions Manufacturing Company TFG USA Bronze Brass Process By this process, the mold can be used only once. Once molten brass cools, it takes the shape of. This fundamental difference gives each alloy its unique set of properties. The process of applying coloration to bronze sculpture is called “patina.” it is a chemical reaction between the surface of the bronze and a variety of metal salts. Find out. Bronze Brass Process.

From www.thecrucible.org

Bronze Casting 101 Process of Casting Bronze [+How To Learn] Bronze Brass Process Find out what these different metal extrusion techniques are. By this process, the mold can be used only once. This fundamental difference gives each alloy its unique set of properties. The process of applying coloration to bronze sculpture is called “patina.” it is a chemical reaction between the surface of the bronze and a variety of metal salts. Bronze tends. Bronze Brass Process.

From corbinbronze.com

Foundry Corbin Bronze Bronze Brass Process Find out what these different metal extrusion techniques are. This fundamental difference gives each alloy its unique set of properties. By this process, the mold can be used only once. Bronze tends to be harder and more durable than brass, making it ideal for applications like sculptures, coins, and bearings. Bronze is primarily made of copper and tin, whereas brass. Bronze Brass Process.

From www.researchgate.net

Process flow chart for brass defects Download Scientific Diagram Bronze Brass Process Bronze is primarily made of copper and tin, whereas brass combines copper with zinc. By this process, the mold can be used only once. This fundamental difference gives each alloy its unique set of properties. The process of applying coloration to bronze sculpture is called “patina.” it is a chemical reaction between the surface of the bronze and a variety. Bronze Brass Process.

From www.pinterest.ca

Germany Standard Brass Alloys, Brass and Bronze Casting Alloys Process, Standard Brass Alloys Bronze Brass Process Bronze tends to be harder and more durable than brass, making it ideal for applications like sculptures, coins, and bearings. Brass casting is a process of making brass products from molten brass. Bronze is primarily made of copper and tin, whereas brass combines copper with zinc. It entails having the mold in the shape of the product you want to. Bronze Brass Process.

From www.dreamstime.com

Oxidized Copper, Metal Grunge Wall Texture. Vintage Antique Weathered and Worn Rusted Bronze Bronze Brass Process Bronze is primarily made of copper and tin, whereas brass combines copper with zinc. Find out what these different metal extrusion techniques are. By this process, the mold can be used only once. This fundamental difference gives each alloy its unique set of properties. The process of applying coloration to bronze sculpture is called “patina.” it is a chemical reaction. Bronze Brass Process.

From docslib.org

Brass and Bronze Standard Casting Alloys Chart of Specifications DocsLib Bronze Brass Process Bronze tends to be harder and more durable than brass, making it ideal for applications like sculptures, coins, and bearings. Bronze is primarily made of copper and tin, whereas brass combines copper with zinc. Once molten brass cools, it takes the shape of. This fundamental difference gives each alloy its unique set of properties. The process of applying coloration to. Bronze Brass Process.

From bronzework.co.uk

Brass and Bronze BronzeWork Bronze Brass Process It entails having the mold in the shape of the product you want to make. Once molten brass cools, it takes the shape of. Brass casting is a process of making brass products from molten brass. By this process, the mold can be used only once. The process of applying coloration to bronze sculpture is called “patina.” it is a. Bronze Brass Process.

From blog.thepipingmart.com

Brass vs Bronze What's the Difference Bronze Brass Process Bronze tends to be harder and more durable than brass, making it ideal for applications like sculptures, coins, and bearings. It entails having the mold in the shape of the product you want to make. By this process, the mold can be used only once. This fundamental difference gives each alloy its unique set of properties. Find out what these. Bronze Brass Process.

From www.wieland-diversified.com

The Process of Bronze Casting and Its Uses Bronze Brass Process Find out what these different metal extrusion techniques are. Once molten brass cools, it takes the shape of. It entails having the mold in the shape of the product you want to make. Bronze tends to be harder and more durable than brass, making it ideal for applications like sculptures, coins, and bearings. Bronze is primarily made of copper and. Bronze Brass Process.

From techiescientist.com

Brass vs Bronze — Detailed Comparison Techiescientist Bronze Brass Process Once molten brass cools, it takes the shape of. Find out what these different metal extrusion techniques are. By this process, the mold can be used only once. Bronze tends to be harder and more durable than brass, making it ideal for applications like sculptures, coins, and bearings. This fundamental difference gives each alloy its unique set of properties. Brass. Bronze Brass Process.

From vcetec.com

Product ExampleCastings (bronze or brass) VCE Technical Limited Bronze Brass Process It entails having the mold in the shape of the product you want to make. Find out what these different metal extrusion techniques are. This fundamental difference gives each alloy its unique set of properties. Bronze tends to be harder and more durable than brass, making it ideal for applications like sculptures, coins, and bearings. By this process, the mold. Bronze Brass Process.

From www.nationalbronze.com

Back to the Basics Bronze Casting Process National Bronze Manufacturing Bronze Brass Process This fundamental difference gives each alloy its unique set of properties. Once molten brass cools, it takes the shape of. Find out what these different metal extrusion techniques are. Bronze tends to be harder and more durable than brass, making it ideal for applications like sculptures, coins, and bearings. Bronze is primarily made of copper and tin, whereas brass combines. Bronze Brass Process.

From www.thomasnet.com

Bronze Casting A Bronze Age Process for the Modern Era Bronze Brass Process By this process, the mold can be used only once. This fundamental difference gives each alloy its unique set of properties. The process of applying coloration to bronze sculpture is called “patina.” it is a chemical reaction between the surface of the bronze and a variety of metal salts. Bronze tends to be harder and more durable than brass, making. Bronze Brass Process.

From dwdbrass.com

Difference Between Bronze, Brass and Copper Brass Tubes, Copper Pipes Bronze Brass Process Find out what these different metal extrusion techniques are. Bronze is primarily made of copper and tin, whereas brass combines copper with zinc. This fundamental difference gives each alloy its unique set of properties. Once molten brass cools, it takes the shape of. Bronze tends to be harder and more durable than brass, making it ideal for applications like sculptures,. Bronze Brass Process.

From www.kapilsteels.com

Bronze vs Brass What's the Difference Bronze Brass Process Bronze is primarily made of copper and tin, whereas brass combines copper with zinc. Once molten brass cools, it takes the shape of. It entails having the mold in the shape of the product you want to make. Bronze tends to be harder and more durable than brass, making it ideal for applications like sculptures, coins, and bearings. Brass casting. Bronze Brass Process.

From www.objetluxe.com

How We Make Objet Luxe Bronze Brass Process Bronze is primarily made of copper and tin, whereas brass combines copper with zinc. It entails having the mold in the shape of the product you want to make. Find out what these different metal extrusion techniques are. This fundamental difference gives each alloy its unique set of properties. By this process, the mold can be used only once. The. Bronze Brass Process.

From blog.thepipingmart.com

Brass vs. Bronze What's the Difference Bronze Brass Process It entails having the mold in the shape of the product you want to make. This fundamental difference gives each alloy its unique set of properties. Bronze is primarily made of copper and tin, whereas brass combines copper with zinc. Find out what these different metal extrusion techniques are. By this process, the mold can be used only once. Bronze. Bronze Brass Process.

From sciencenotes.org

What Is Brass Made Of? Difference Between Brass and Bronze Bronze Brass Process Bronze tends to be harder and more durable than brass, making it ideal for applications like sculptures, coins, and bearings. Brass casting is a process of making brass products from molten brass. Bronze is primarily made of copper and tin, whereas brass combines copper with zinc. This fundamental difference gives each alloy its unique set of properties. It entails having. Bronze Brass Process.

From www.youtube.com

Large Bronze Casting Process by Coastal Foundry Company of Houston Texas YouTube Bronze Brass Process Find out what these different metal extrusion techniques are. This fundamental difference gives each alloy its unique set of properties. It entails having the mold in the shape of the product you want to make. Once molten brass cools, it takes the shape of. Bronze is primarily made of copper and tin, whereas brass combines copper with zinc. By this. Bronze Brass Process.

From www.differencebetween.com

Difference Between Brass and Bronze Compare the Difference Between Similar Terms Bronze Brass Process It entails having the mold in the shape of the product you want to make. Find out what these different metal extrusion techniques are. By this process, the mold can be used only once. Brass casting is a process of making brass products from molten brass. Bronze is primarily made of copper and tin, whereas brass combines copper with zinc.. Bronze Brass Process.

From www.youtube.com

BRASS VS BRONZE COMPOSITION, DIFFERENCE , ALLOY & USES TECHTALK WITH KAPTAN YouTube Bronze Brass Process Find out what these different metal extrusion techniques are. Once molten brass cools, it takes the shape of. This fundamental difference gives each alloy its unique set of properties. By this process, the mold can be used only once. Bronze is primarily made of copper and tin, whereas brass combines copper with zinc. It entails having the mold in the. Bronze Brass Process.

From www.china-machining.com

Brass vs Bronze Comparison & Differences Gensun Precision Machining Bronze Brass Process By this process, the mold can be used only once. Bronze is primarily made of copper and tin, whereas brass combines copper with zinc. Once molten brass cools, it takes the shape of. The process of applying coloration to bronze sculpture is called “patina.” it is a chemical reaction between the surface of the bronze and a variety of metal. Bronze Brass Process.

From www.pinterest.com

Pin on Brass Components Bronze Brass Process Once molten brass cools, it takes the shape of. By this process, the mold can be used only once. The process of applying coloration to bronze sculpture is called “patina.” it is a chemical reaction between the surface of the bronze and a variety of metal salts. This fundamental difference gives each alloy its unique set of properties. Brass casting. Bronze Brass Process.

From qdaces.en.made-in-china.com

Bronze/Brass/Copper Alloy Sand Casting Process Machining Part for Industry Motor China Die Bronze Brass Process It entails having the mold in the shape of the product you want to make. By this process, the mold can be used only once. Bronze tends to be harder and more durable than brass, making it ideal for applications like sculptures, coins, and bearings. Brass casting is a process of making brass products from molten brass. This fundamental difference. Bronze Brass Process.

From www.sequoia-brass-copper.com

Metal Comparisons Brass vs Bronze Sequoia Brass and Copper Bronze Brass Process Brass casting is a process of making brass products from molten brass. Find out what these different metal extrusion techniques are. It entails having the mold in the shape of the product you want to make. Bronze is primarily made of copper and tin, whereas brass combines copper with zinc. Once molten brass cools, it takes the shape of. Bronze. Bronze Brass Process.