Liquid Level System And Pneumatic System Are Examples Of . The control of liquid levels, for example in a process tank, is an important function. Differentiate between electrical, pneumatic and fluid power systems. Operate through effects of either liquids or gases. Producers typically employ these controllers on production vessels like. A pneumatic level controller works with a control valve to provide liquid level control in oil and gas production. An example would be a hot water tank where water is removed, perhaps for washing down, and the level. Have wide range of applications, e.g., vehicle suspension systems, hydraulic. Liquid level control system is a system specifically designed to control the level of fluid in tanks. At the desired level h in the face. The main aim possessed by these. Water supply, waste treatment, and other chemical processing applications are examples of a general category of fluid systems called. List the basic components of the pneumatic systems.

from www.youtube.com

Operate through effects of either liquids or gases. Water supply, waste treatment, and other chemical processing applications are examples of a general category of fluid systems called. An example would be a hot water tank where water is removed, perhaps for washing down, and the level. A pneumatic level controller works with a control valve to provide liquid level control in oil and gas production. Differentiate between electrical, pneumatic and fluid power systems. Have wide range of applications, e.g., vehicle suspension systems, hydraulic. The main aim possessed by these. At the desired level h in the face. Producers typically employ these controllers on production vessels like. List the basic components of the pneumatic systems.

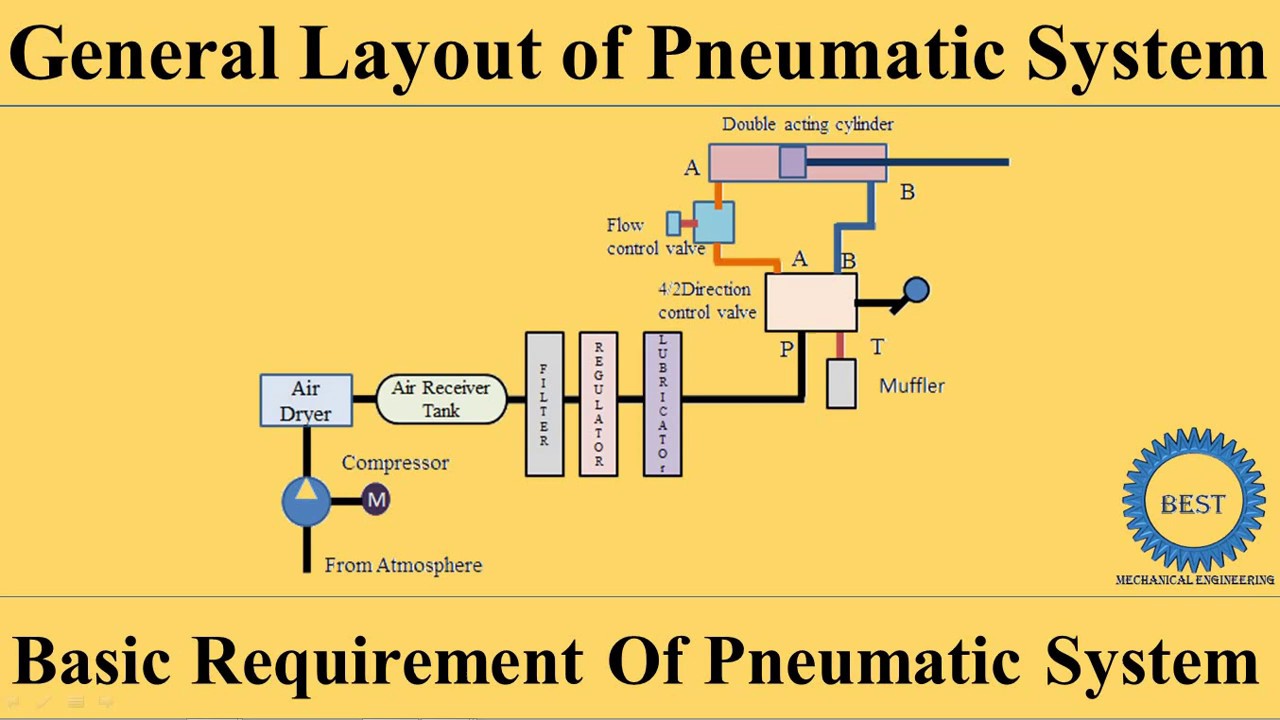

General Layout And Basic Requirement of Pneumatic System YouTube

Liquid Level System And Pneumatic System Are Examples Of A pneumatic level controller works with a control valve to provide liquid level control in oil and gas production. Operate through effects of either liquids or gases. The main aim possessed by these. The control of liquid levels, for example in a process tank, is an important function. Liquid level control system is a system specifically designed to control the level of fluid in tanks. A pneumatic level controller works with a control valve to provide liquid level control in oil and gas production. List the basic components of the pneumatic systems. Differentiate between electrical, pneumatic and fluid power systems. Have wide range of applications, e.g., vehicle suspension systems, hydraulic. Water supply, waste treatment, and other chemical processing applications are examples of a general category of fluid systems called. At the desired level h in the face. Producers typically employ these controllers on production vessels like. An example would be a hot water tank where water is removed, perhaps for washing down, and the level.

From pneumaticmfg.com

What Are Pneumatic Components? Working Principle & Function Liquid Level System And Pneumatic System Are Examples Of A pneumatic level controller works with a control valve to provide liquid level control in oil and gas production. An example would be a hot water tank where water is removed, perhaps for washing down, and the level. Water supply, waste treatment, and other chemical processing applications are examples of a general category of fluid systems called. Have wide range. Liquid Level System And Pneumatic System Are Examples Of.

From www.chiefdelphi.com

FRC Pneumatic System Diagram Control System Chief Delphi Liquid Level System And Pneumatic System Are Examples Of Water supply, waste treatment, and other chemical processing applications are examples of a general category of fluid systems called. An example would be a hot water tank where water is removed, perhaps for washing down, and the level. Differentiate between electrical, pneumatic and fluid power systems. Liquid level control system is a system specifically designed to control the level of. Liquid Level System And Pneumatic System Are Examples Of.

From libloycausatives.z21.web.core.windows.net

Pneumatic Liquid Level Switch Liquid Level System And Pneumatic System Are Examples Of Operate through effects of either liquids or gases. Liquid level control system is a system specifically designed to control the level of fluid in tanks. List the basic components of the pneumatic systems. An example would be a hot water tank where water is removed, perhaps for washing down, and the level. At the desired level h in the face.. Liquid Level System And Pneumatic System Are Examples Of.

From www.chegg.com

A liquidlevel system is shown below. When a Liquid Level System And Pneumatic System Are Examples Of At the desired level h in the face. The control of liquid levels, for example in a process tank, is an important function. An example would be a hot water tank where water is removed, perhaps for washing down, and the level. Liquid level control system is a system specifically designed to control the level of fluid in tanks. The. Liquid Level System And Pneumatic System Are Examples Of.

From www.embedded.com

Designing a liquid level control/delivery system for use in medical Liquid Level System And Pneumatic System Are Examples Of Have wide range of applications, e.g., vehicle suspension systems, hydraulic. Water supply, waste treatment, and other chemical processing applications are examples of a general category of fluid systems called. At the desired level h in the face. Differentiate between electrical, pneumatic and fluid power systems. A pneumatic level controller works with a control valve to provide liquid level control in. Liquid Level System And Pneumatic System Are Examples Of.

From www.championx.com

Series EVS Pneumatic Liquid Level Controller ChampionX Liquid Level System And Pneumatic System Are Examples Of Have wide range of applications, e.g., vehicle suspension systems, hydraulic. An example would be a hot water tank where water is removed, perhaps for washing down, and the level. Operate through effects of either liquids or gases. Producers typically employ these controllers on production vessels like. Differentiate between electrical, pneumatic and fluid power systems. Water supply, waste treatment, and other. Liquid Level System And Pneumatic System Are Examples Of.

From www.chegg.com

Consider the liquid level system shown in Figure 1. Liquid Level System And Pneumatic System Are Examples Of The main aim possessed by these. Water supply, waste treatment, and other chemical processing applications are examples of a general category of fluid systems called. A pneumatic level controller works with a control valve to provide liquid level control in oil and gas production. Differentiate between electrical, pneumatic and fluid power systems. Producers typically employ these controllers on production vessels. Liquid Level System And Pneumatic System Are Examples Of.

From www.chegg.com

Solved For the Liquidlevel System given by Figure 720; Liquid Level System And Pneumatic System Are Examples Of Operate through effects of either liquids or gases. A pneumatic level controller works with a control valve to provide liquid level control in oil and gas production. The control of liquid levels, for example in a process tank, is an important function. At the desired level h in the face. List the basic components of the pneumatic systems. An example. Liquid Level System And Pneumatic System Are Examples Of.

From www.instrumentationtoolbox.com

How a Pneumatic Displacer level sensor is used to Control Liquid Level Liquid Level System And Pneumatic System Are Examples Of An example would be a hot water tank where water is removed, perhaps for washing down, and the level. List the basic components of the pneumatic systems. Producers typically employ these controllers on production vessels like. Differentiate between electrical, pneumatic and fluid power systems. Liquid level control system is a system specifically designed to control the level of fluid in. Liquid Level System And Pneumatic System Are Examples Of.

From www.chegg.com

Solved Pneumatic valve Controller Example 7. Fluid level Liquid Level System And Pneumatic System Are Examples Of List the basic components of the pneumatic systems. Have wide range of applications, e.g., vehicle suspension systems, hydraulic. Operate through effects of either liquids or gases. The main aim possessed by these. The control of liquid levels, for example in a process tank, is an important function. Liquid level control system is a system specifically designed to control the level. Liquid Level System And Pneumatic System Are Examples Of.

From www.chegg.com

Solved Consider the Liquidlevel system and the mechanical Liquid Level System And Pneumatic System Are Examples Of The control of liquid levels, for example in a process tank, is an important function. Operate through effects of either liquids or gases. Have wide range of applications, e.g., vehicle suspension systems, hydraulic. A pneumatic level controller works with a control valve to provide liquid level control in oil and gas production. The main aim possessed by these. Producers typically. Liquid Level System And Pneumatic System Are Examples Of.

From www.youtube.com

Getting started with Pneumatics the Basics YouTube Liquid Level System And Pneumatic System Are Examples Of List the basic components of the pneumatic systems. A pneumatic level controller works with a control valve to provide liquid level control in oil and gas production. An example would be a hot water tank where water is removed, perhaps for washing down, and the level. The main aim possessed by these. Liquid level control system is a system specifically. Liquid Level System And Pneumatic System Are Examples Of.

From www.chegg.com

Solved Consider the liquid level system shown in the figure. Liquid Level System And Pneumatic System Are Examples Of Differentiate between electrical, pneumatic and fluid power systems. An example would be a hot water tank where water is removed, perhaps for washing down, and the level. List the basic components of the pneumatic systems. The control of liquid levels, for example in a process tank, is an important function. Operate through effects of either liquids or gases. The main. Liquid Level System And Pneumatic System Are Examples Of.

From www.aeng.co.uk

Pneumatic Control Systems Liquid Level System And Pneumatic System Are Examples Of At the desired level h in the face. Have wide range of applications, e.g., vehicle suspension systems, hydraulic. Operate through effects of either liquids or gases. List the basic components of the pneumatic systems. Differentiate between electrical, pneumatic and fluid power systems. Liquid level control system is a system specifically designed to control the level of fluid in tanks. Producers. Liquid Level System And Pneumatic System Are Examples Of.

From engineeringlearner.com

Pneumatic Valve Types & Working Principle Engineering Learner Liquid Level System And Pneumatic System Are Examples Of Operate through effects of either liquids or gases. The control of liquid levels, for example in a process tank, is an important function. Have wide range of applications, e.g., vehicle suspension systems, hydraulic. Water supply, waste treatment, and other chemical processing applications are examples of a general category of fluid systems called. Liquid level control system is a system specifically. Liquid Level System And Pneumatic System Are Examples Of.

From www.chegg.com

1 Liquid Level System Figure 1 Diagram of Liquid Liquid Level System And Pneumatic System Are Examples Of A pneumatic level controller works with a control valve to provide liquid level control in oil and gas production. Producers typically employ these controllers on production vessels like. An example would be a hot water tank where water is removed, perhaps for washing down, and the level. List the basic components of the pneumatic systems. Operate through effects of either. Liquid Level System And Pneumatic System Are Examples Of.

From ship-machinery.com

Remote Tank Level Monitoring System Marine Support Equipment Supplier Liquid Level System And Pneumatic System Are Examples Of The control of liquid levels, for example in a process tank, is an important function. The main aim possessed by these. Have wide range of applications, e.g., vehicle suspension systems, hydraulic. Water supply, waste treatment, and other chemical processing applications are examples of a general category of fluid systems called. Differentiate between electrical, pneumatic and fluid power systems. A pneumatic. Liquid Level System And Pneumatic System Are Examples Of.

From www.chegg.com

Solved Problem 2 A singletank liquidlevel system is shown, Liquid Level System And Pneumatic System Are Examples Of An example would be a hot water tank where water is removed, perhaps for washing down, and the level. A pneumatic level controller works with a control valve to provide liquid level control in oil and gas production. Have wide range of applications, e.g., vehicle suspension systems, hydraulic. List the basic components of the pneumatic systems. Operate through effects of. Liquid Level System And Pneumatic System Are Examples Of.

From control.com

Basics of Pneumatic Instruments Overview Textbook Liquid Level System And Pneumatic System Are Examples Of Producers typically employ these controllers on production vessels like. Differentiate between electrical, pneumatic and fluid power systems. List the basic components of the pneumatic systems. The control of liquid levels, for example in a process tank, is an important function. Have wide range of applications, e.g., vehicle suspension systems, hydraulic. Water supply, waste treatment, and other chemical processing applications are. Liquid Level System And Pneumatic System Are Examples Of.

From instrumentationtools.com

Integrating Processes Liquid Level Control Inst Tools Liquid Level System And Pneumatic System Are Examples Of The main aim possessed by these. Differentiate between electrical, pneumatic and fluid power systems. An example would be a hot water tank where water is removed, perhaps for washing down, and the level. A pneumatic level controller works with a control valve to provide liquid level control in oil and gas production. Producers typically employ these controllers on production vessels. Liquid Level System And Pneumatic System Are Examples Of.

From www.studypool.com

SOLUTION Liquid level systems examples with answers of Liquid Level System And Pneumatic System Are Examples Of Liquid level control system is a system specifically designed to control the level of fluid in tanks. An example would be a hot water tank where water is removed, perhaps for washing down, and the level. Operate through effects of either liquids or gases. Producers typically employ these controllers on production vessels like. Differentiate between electrical, pneumatic and fluid power. Liquid Level System And Pneumatic System Are Examples Of.

From mrpranav.com

Pneumatic Systems & Components An Industrial Guide Liquid Level System And Pneumatic System Are Examples Of List the basic components of the pneumatic systems. Operate through effects of either liquids or gases. An example would be a hot water tank where water is removed, perhaps for washing down, and the level. Liquid level control system is a system specifically designed to control the level of fluid in tanks. Water supply, waste treatment, and other chemical processing. Liquid Level System And Pneumatic System Are Examples Of.

From www.caretxdigital.com

Schematic Diagram Of Pneumatic System Wiring Diagram and Schematics Liquid Level System And Pneumatic System Are Examples Of List the basic components of the pneumatic systems. At the desired level h in the face. The control of liquid levels, for example in a process tank, is an important function. A pneumatic level controller works with a control valve to provide liquid level control in oil and gas production. The main aim possessed by these. Water supply, waste treatment,. Liquid Level System And Pneumatic System Are Examples Of.

From www.ecplaza.net

Pneumatic Liquid Level Indicating Transmitter/Controller Guangdong Liquid Level System And Pneumatic System Are Examples Of Differentiate between electrical, pneumatic and fluid power systems. Producers typically employ these controllers on production vessels like. Operate through effects of either liquids or gases. The control of liquid levels, for example in a process tank, is an important function. The main aim possessed by these. Have wide range of applications, e.g., vehicle suspension systems, hydraulic. List the basic components. Liquid Level System And Pneumatic System Are Examples Of.

From engineeringlearner.com

Pneumatic Control System Engineering Learner Liquid Level System And Pneumatic System Are Examples Of Operate through effects of either liquids or gases. An example would be a hot water tank where water is removed, perhaps for washing down, and the level. The control of liquid levels, for example in a process tank, is an important function. List the basic components of the pneumatic systems. At the desired level h in the face. Producers typically. Liquid Level System And Pneumatic System Are Examples Of.

From www.youtube.com

General Layout And Basic Requirement of Pneumatic System YouTube Liquid Level System And Pneumatic System Are Examples Of At the desired level h in the face. The control of liquid levels, for example in a process tank, is an important function. A pneumatic level controller works with a control valve to provide liquid level control in oil and gas production. Producers typically employ these controllers on production vessels like. List the basic components of the pneumatic systems. An. Liquid Level System And Pneumatic System Are Examples Of.

From www.chegg.com

Solved 1. For the liquid level system shown in Figure 1 Liquid Level System And Pneumatic System Are Examples Of Liquid level control system is a system specifically designed to control the level of fluid in tanks. Water supply, waste treatment, and other chemical processing applications are examples of a general category of fluid systems called. List the basic components of the pneumatic systems. Have wide range of applications, e.g., vehicle suspension systems, hydraulic. The control of liquid levels, for. Liquid Level System And Pneumatic System Are Examples Of.

From www.researchgate.net

Block diagram of liquid level control system in a buffer tank Liquid Level System And Pneumatic System Are Examples Of Water supply, waste treatment, and other chemical processing applications are examples of a general category of fluid systems called. Producers typically employ these controllers on production vessels like. At the desired level h in the face. Have wide range of applications, e.g., vehicle suspension systems, hydraulic. An example would be a hot water tank where water is removed, perhaps for. Liquid Level System And Pneumatic System Are Examples Of.

From www.chegg.com

Solved Consider the liquid level system shown in Fig. 1. It Liquid Level System And Pneumatic System Are Examples Of The main aim possessed by these. Operate through effects of either liquids or gases. Water supply, waste treatment, and other chemical processing applications are examples of a general category of fluid systems called. Differentiate between electrical, pneumatic and fluid power systems. Have wide range of applications, e.g., vehicle suspension systems, hydraulic. An example would be a hot water tank where. Liquid Level System And Pneumatic System Are Examples Of.

From www.diagramelectric.co

Pneumatic Schematic Examples Wiring Diagram Liquid Level System And Pneumatic System Are Examples Of A pneumatic level controller works with a control valve to provide liquid level control in oil and gas production. Producers typically employ these controllers on production vessels like. The control of liquid levels, for example in a process tank, is an important function. List the basic components of the pneumatic systems. The main aim possessed by these. Differentiate between electrical,. Liquid Level System And Pneumatic System Are Examples Of.

From www.instrumentationtoolbox.com

How a Pneumatic Displacer level sensor is used to Control Liquid Level Liquid Level System And Pneumatic System Are Examples Of The control of liquid levels, for example in a process tank, is an important function. List the basic components of the pneumatic systems. At the desired level h in the face. The main aim possessed by these. Differentiate between electrical, pneumatic and fluid power systems. Producers typically employ these controllers on production vessels like. Water supply, waste treatment, and other. Liquid Level System And Pneumatic System Are Examples Of.

From fyotqxgoy.blob.core.windows.net

Pneumatic Valve Symbols at Tobias Richter blog Liquid Level System And Pneumatic System Are Examples Of Differentiate between electrical, pneumatic and fluid power systems. A pneumatic level controller works with a control valve to provide liquid level control in oil and gas production. Operate through effects of either liquids or gases. List the basic components of the pneumatic systems. The control of liquid levels, for example in a process tank, is an important function. Water supply,. Liquid Level System And Pneumatic System Are Examples Of.

From www.researchgate.net

Pneumatic circuit schematic diagram of multicylinder single Liquid Level System And Pneumatic System Are Examples Of Differentiate between electrical, pneumatic and fluid power systems. At the desired level h in the face. Water supply, waste treatment, and other chemical processing applications are examples of a general category of fluid systems called. The control of liquid levels, for example in a process tank, is an important function. Producers typically employ these controllers on production vessels like. A. Liquid Level System And Pneumatic System Are Examples Of.

From www.eeweb.com

RD LiquidLevel Control and Delivery System EE Liquid Level System And Pneumatic System Are Examples Of The control of liquid levels, for example in a process tank, is an important function. List the basic components of the pneumatic systems. The main aim possessed by these. Differentiate between electrical, pneumatic and fluid power systems. A pneumatic level controller works with a control valve to provide liquid level control in oil and gas production. Have wide range of. Liquid Level System And Pneumatic System Are Examples Of.

From instrumentationtools.com

Pneumatic Handbook Practical Guide Free Download Liquid Level System And Pneumatic System Are Examples Of Have wide range of applications, e.g., vehicle suspension systems, hydraulic. Water supply, waste treatment, and other chemical processing applications are examples of a general category of fluid systems called. An example would be a hot water tank where water is removed, perhaps for washing down, and the level. At the desired level h in the face. The control of liquid. Liquid Level System And Pneumatic System Are Examples Of.