What End Mill To Use . Navigating the vast array of end mills available in the market can be a daunting task, especially when precision is paramount. And which is the best end mill for aluminium, and which are the best end mill for. Choosing the right end mill for your machining operations is decisive, dramatically affecting the efficiency and quality of the. Discover the key to efficient machining with our comprehensive guide on selecting the right endmills for different. See the different categories of end. Surface feet per minute, inches per minute, revolutions per minute, chipload per tooth, feed per revolution, metal removal rate. For instance, which are the best end mills? Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear chips often, lubricate the end mill, and test the cut before milling the entire. End mills come in a. End mills are used to remove material from a workpiece by advancing the tool into the material along its rotation axis.

from toolnotes.com

Choosing the right end mill for your machining operations is decisive, dramatically affecting the efficiency and quality of the. For instance, which are the best end mills? End mills come in a. And which is the best end mill for aluminium, and which are the best end mill for. End mills are used to remove material from a workpiece by advancing the tool into the material along its rotation axis. Discover the key to efficient machining with our comprehensive guide on selecting the right endmills for different. Navigating the vast array of end mills available in the market can be a daunting task, especially when precision is paramount. Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear chips often, lubricate the end mill, and test the cut before milling the entire. See the different categories of end. Surface feet per minute, inches per minute, revolutions per minute, chipload per tooth, feed per revolution, metal removal rate.

End Mills ToolNotes

What End Mill To Use Navigating the vast array of end mills available in the market can be a daunting task, especially when precision is paramount. Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear chips often, lubricate the end mill, and test the cut before milling the entire. See the different categories of end. Choosing the right end mill for your machining operations is decisive, dramatically affecting the efficiency and quality of the. End mills come in a. And which is the best end mill for aluminium, and which are the best end mill for. Discover the key to efficient machining with our comprehensive guide on selecting the right endmills for different. Surface feet per minute, inches per minute, revolutions per minute, chipload per tooth, feed per revolution, metal removal rate. For instance, which are the best end mills? Navigating the vast array of end mills available in the market can be a daunting task, especially when precision is paramount. End mills are used to remove material from a workpiece by advancing the tool into the material along its rotation axis.

From simmonslosonfere.blogspot.com

Ball Nose End Mill Speeds and Feeds Simmons Losonfere What End Mill To Use Choosing the right end mill for your machining operations is decisive, dramatically affecting the efficiency and quality of the. Navigating the vast array of end mills available in the market can be a daunting task, especially when precision is paramount. For instance, which are the best end mills? See the different categories of end. Secure the workpiece, choose the right. What End Mill To Use.

From www.canadianmetalworking.com

End mill geometry boosts trochoidal milling Canadian Metalworking What End Mill To Use Discover the key to efficient machining with our comprehensive guide on selecting the right endmills for different. Choosing the right end mill for your machining operations is decisive, dramatically affecting the efficiency and quality of the. End mills come in a. End mills are used to remove material from a workpiece by advancing the tool into the material along its. What End Mill To Use.

From www.penntoolco.com

The Basic Types of End Mills Used in Milling Penn Tool Co., Inc What End Mill To Use See the different categories of end. For instance, which are the best end mills? Choosing the right end mill for your machining operations is decisive, dramatically affecting the efficiency and quality of the. Surface feet per minute, inches per minute, revolutions per minute, chipload per tooth, feed per revolution, metal removal rate. Navigating the vast array of end mills available. What End Mill To Use.

From makezine.com

6 Essential End Mills for Your CNC Machine Make What End Mill To Use Choosing the right end mill for your machining operations is decisive, dramatically affecting the efficiency and quality of the. End mills come in a. Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear chips often, lubricate the end mill, and test the cut before milling the entire. End mills are used to remove. What End Mill To Use.

From www.penntoolco.com

The Basic Types of End Mills Used in Milling Penn Tool Co., Inc What End Mill To Use Surface feet per minute, inches per minute, revolutions per minute, chipload per tooth, feed per revolution, metal removal rate. Choosing the right end mill for your machining operations is decisive, dramatically affecting the efficiency and quality of the. End mills come in a. Discover the key to efficient machining with our comprehensive guide on selecting the right endmills for different.. What End Mill To Use.

From huanatools.com

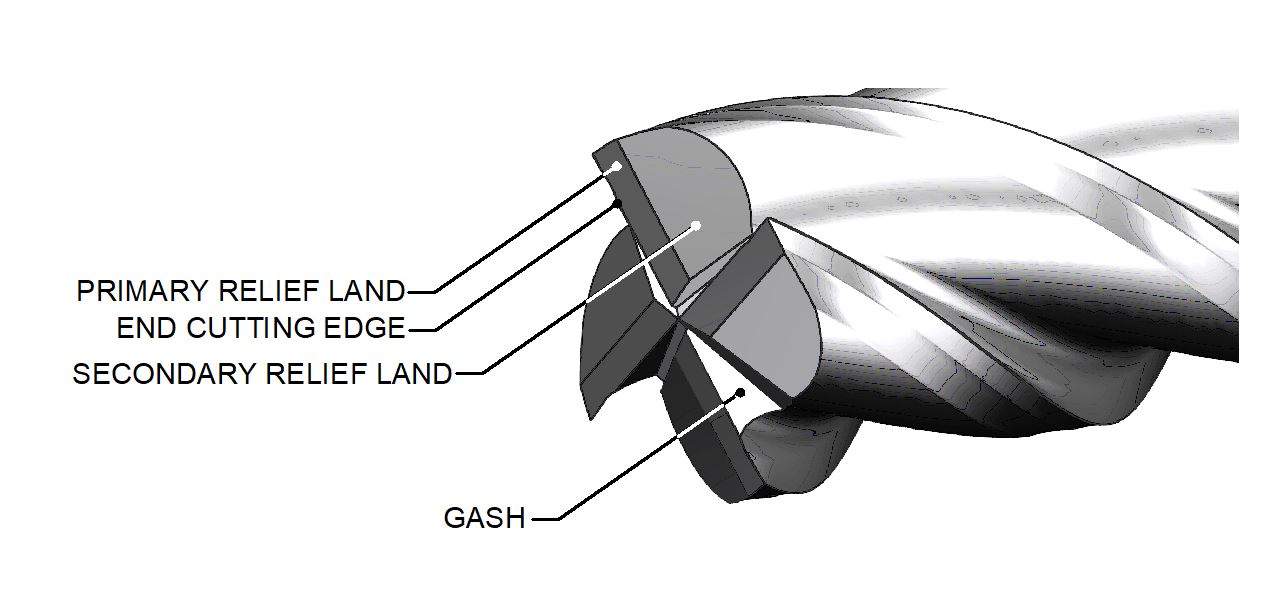

ANATOMY OF AN END MILL AND ITS COMPONENTS Huana Tools What End Mill To Use End mills come in a. And which is the best end mill for aluminium, and which are the best end mill for. Surface feet per minute, inches per minute, revolutions per minute, chipload per tooth, feed per revolution, metal removal rate. End mills are used to remove material from a workpiece by advancing the tool into the material along its. What End Mill To Use.

From tac-tools.com.my

3 Flutes endmill, precision super finishing end mill, from diameter 0.3mm onward Tac Tools What End Mill To Use End mills are used to remove material from a workpiece by advancing the tool into the material along its rotation axis. Discover the key to efficient machining with our comprehensive guide on selecting the right endmills for different. Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear chips often, lubricate the end mill,. What End Mill To Use.

From www.austgen.com.au

Best Drilling End Mills 2018 Guide Melbourne Metal Fabrication What End Mill To Use Surface feet per minute, inches per minute, revolutions per minute, chipload per tooth, feed per revolution, metal removal rate. End mills are used to remove material from a workpiece by advancing the tool into the material along its rotation axis. End mills come in a. Choosing the right end mill for your machining operations is decisive, dramatically affecting the efficiency. What End Mill To Use.

From drillbitguru.com

6 Best End Mills For Aluminum (2023 Reviews) What End Mill To Use End mills come in a. Discover the key to efficient machining with our comprehensive guide on selecting the right endmills for different. Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear chips often, lubricate the end mill, and test the cut before milling the entire. Choosing the right end mill for your machining. What End Mill To Use.

From huanatools.com

what is an end mill and how to make an end mill Huana Tools What End Mill To Use See the different categories of end. End mills come in a. Surface feet per minute, inches per minute, revolutions per minute, chipload per tooth, feed per revolution, metal removal rate. And which is the best end mill for aluminium, and which are the best end mill for. Navigating the vast array of end mills available in the market can be. What End Mill To Use.

From engineeringlearn.com

End Mill Cutter Archives Engineering Learn What End Mill To Use Navigating the vast array of end mills available in the market can be a daunting task, especially when precision is paramount. For instance, which are the best end mills? Discover the key to efficient machining with our comprehensive guide on selecting the right endmills for different. End mills are used to remove material from a workpiece by advancing the tool. What End Mill To Use.

From www.mscdirect.com

Kennametal end mill selection chart by use What End Mill To Use Discover the key to efficient machining with our comprehensive guide on selecting the right endmills for different. Navigating the vast array of end mills available in the market can be a daunting task, especially when precision is paramount. Surface feet per minute, inches per minute, revolutions per minute, chipload per tooth, feed per revolution, metal removal rate. End mills come. What End Mill To Use.

From www.meridiansupplycompany.com

End Mill Meridian Supply Company What End Mill To Use End mills come in a. For instance, which are the best end mills? Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear chips often, lubricate the end mill, and test the cut before milling the entire. Discover the key to efficient machining with our comprehensive guide on selecting the right endmills for different.. What End Mill To Use.

From www.cutwel.co.uk

Milling Cutters Explained An Expert Guide Cutwel Ltd What End Mill To Use For instance, which are the best end mills? Discover the key to efficient machining with our comprehensive guide on selecting the right endmills for different. Surface feet per minute, inches per minute, revolutions per minute, chipload per tooth, feed per revolution, metal removal rate. See the different categories of end. End mills come in a. Choosing the right end mill. What End Mill To Use.

From www.redlinetools.com

Endmill Selection Guide RedLine Tools Redline Tools What End Mill To Use Navigating the vast array of end mills available in the market can be a daunting task, especially when precision is paramount. End mills come in a. See the different categories of end. For instance, which are the best end mills? End mills are used to remove material from a workpiece by advancing the tool into the material along its rotation. What End Mill To Use.

From toolnotes.com

End Mills ToolNotes What End Mill To Use Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear chips often, lubricate the end mill, and test the cut before milling the entire. Navigating the vast array of end mills available in the market can be a daunting task, especially when precision is paramount. For instance, which are the best end mills? End. What End Mill To Use.

From huanatools.com

what is an end mill and how to make an end mill Huana Tools What End Mill To Use End mills come in a. Surface feet per minute, inches per minute, revolutions per minute, chipload per tooth, feed per revolution, metal removal rate. Choosing the right end mill for your machining operations is decisive, dramatically affecting the efficiency and quality of the. See the different categories of end. Navigating the vast array of end mills available in the market. What End Mill To Use.

From www.speedtigertools.com

End Mill Cutting & End Milling Technical Guide What End Mill To Use See the different categories of end. Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear chips often, lubricate the end mill, and test the cut before milling the entire. End mills are used to remove material from a workpiece by advancing the tool into the material along its rotation axis. And which is. What End Mill To Use.

From medium.com

End mill Selection Guide — How to Choose from all types of end mills by CreterJason Medium What End Mill To Use See the different categories of end. And which is the best end mill for aluminium, and which are the best end mill for. Discover the key to efficient machining with our comprehensive guide on selecting the right endmills for different. Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear chips often, lubricate the. What End Mill To Use.

From endmill.com.au

Choosing the right end mill for the job Adam's Bits What End Mill To Use For instance, which are the best end mills? Surface feet per minute, inches per minute, revolutions per minute, chipload per tooth, feed per revolution, metal removal rate. Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear chips often, lubricate the end mill, and test the cut before milling the entire. Navigating the vast. What End Mill To Use.

From www.shop-apt.co.uk

Carbide End Mill for General Use 16mm Diameter 4 Flute 150mm Long AlTiN Coated 45HRC Associated What End Mill To Use End mills come in a. Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear chips often, lubricate the end mill, and test the cut before milling the entire. For instance, which are the best end mills? Discover the key to efficient machining with our comprehensive guide on selecting the right endmills for different.. What End Mill To Use.

From thegodalmingpost.blogspot.com

end mill types and uses Best Bit EZine Fonction What End Mill To Use For instance, which are the best end mills? End mills are used to remove material from a workpiece by advancing the tool into the material along its rotation axis. Navigating the vast array of end mills available in the market can be a daunting task, especially when precision is paramount. See the different categories of end. Choosing the right end. What End Mill To Use.

From gloriambroyleso.blob.core.windows.net

Using An End Mill at gloriambroyleso blog What End Mill To Use Choosing the right end mill for your machining operations is decisive, dramatically affecting the efficiency and quality of the. End mills are used to remove material from a workpiece by advancing the tool into the material along its rotation axis. And which is the best end mill for aluminium, and which are the best end mill for. For instance, which. What End Mill To Use.

From www.ukocarbide.com

What is the difference between the coating of end mill? What End Mill To Use End mills are used to remove material from a workpiece by advancing the tool into the material along its rotation axis. See the different categories of end. And which is the best end mill for aluminium, and which are the best end mill for. Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear. What End Mill To Use.

From www.mmc-carbide.com

End Mill Terminology Technical Info / Cutting Formula MITSUBISHI MATERIALS CORPORATION What End Mill To Use Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear chips often, lubricate the end mill, and test the cut before milling the entire. For instance, which are the best end mills? Choosing the right end mill for your machining operations is decisive, dramatically affecting the efficiency and quality of the. Navigating the vast. What End Mill To Use.

From www.championcuttingtool.com

End Mills XLVC What End Mill To Use Surface feet per minute, inches per minute, revolutions per minute, chipload per tooth, feed per revolution, metal removal rate. Discover the key to efficient machining with our comprehensive guide on selecting the right endmills for different. And which is the best end mill for aluminium, and which are the best end mill for. Secure the workpiece, choose the right speed. What End Mill To Use.

From epictool.ca

End Milling Solutions Epic Tool What End Mill To Use For instance, which are the best end mills? Surface feet per minute, inches per minute, revolutions per minute, chipload per tooth, feed per revolution, metal removal rate. End mills come in a. Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear chips often, lubricate the end mill, and test the cut before milling. What End Mill To Use.

From huanatools.com

Roughing vs. Finishing End Mill How Do They Differ? Huana Tools What End Mill To Use End mills are used to remove material from a workpiece by advancing the tool into the material along its rotation axis. Choosing the right end mill for your machining operations is decisive, dramatically affecting the efficiency and quality of the. Discover the key to efficient machining with our comprehensive guide on selecting the right endmills for different. Surface feet per. What End Mill To Use.

From www.speedtigertools.com

The Beginners Guide of CNC End Mill (2023 Edition)SPEED TIGER What End Mill To Use See the different categories of end. End mills are used to remove material from a workpiece by advancing the tool into the material along its rotation axis. Discover the key to efficient machining with our comprehensive guide on selecting the right endmills for different. Surface feet per minute, inches per minute, revolutions per minute, chipload per tooth, feed per revolution,. What End Mill To Use.

From www.harveyperformance.com

The Anatomy of an End Mill In The Loupe What End Mill To Use And which is the best end mill for aluminium, and which are the best end mill for. Choosing the right end mill for your machining operations is decisive, dramatically affecting the efficiency and quality of the. End mills come in a. See the different categories of end. Surface feet per minute, inches per minute, revolutions per minute, chipload per tooth,. What End Mill To Use.

From indotech-group.co.id

End Mill Ketahui Jenis Jenis End Mill Indotech Trimitra Abadi What End Mill To Use End mills are used to remove material from a workpiece by advancing the tool into the material along its rotation axis. Choosing the right end mill for your machining operations is decisive, dramatically affecting the efficiency and quality of the. For instance, which are the best end mills? End mills come in a. Navigating the vast array of end mills. What End Mill To Use.

From toolnotes.com

End Mills ToolNotes What End Mill To Use Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear chips often, lubricate the end mill, and test the cut before milling the entire. See the different categories of end. Surface feet per minute, inches per minute, revolutions per minute, chipload per tooth, feed per revolution, metal removal rate. End mills are used to. What End Mill To Use.

From support.bantamtools.com

End Mill Identification Guide Bantam Tools What End Mill To Use For instance, which are the best end mills? Navigating the vast array of end mills available in the market can be a daunting task, especially when precision is paramount. Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear chips often, lubricate the end mill, and test the cut before milling the entire. See. What End Mill To Use.

From tooltalk.blog

Choosing the Right End Mill Coating for Each Application Tool Talk What End Mill To Use And which is the best end mill for aluminium, and which are the best end mill for. Choosing the right end mill for your machining operations is decisive, dramatically affecting the efficiency and quality of the. Discover the key to efficient machining with our comprehensive guide on selecting the right endmills for different. End mills come in a. Secure the. What End Mill To Use.

From aronson-campbell.com

Tapered End Mill AronsonCampbell Custom Versatility for Any Job What End Mill To Use And which is the best end mill for aluminium, and which are the best end mill for. See the different categories of end. Choosing the right end mill for your machining operations is decisive, dramatically affecting the efficiency and quality of the. End mills are used to remove material from a workpiece by advancing the tool into the material along. What End Mill To Use.