Wire Edm Not Cutting . In a fanuc, you just say s1; Because most or all wire edm machines use some sort of servo control to maintain the desired spark gap, variables such as flushing, part shape and internal stress relief can dramatically effect cutting speed of both rough cut and subsequent skim cuts. Flushing pressure is to low, not enough volume of dielectric, foreign. Wire breakage after cutting more than 3/16” can have the following causes; The wire edm process generates no cutting forces or vibration, allowing intricate features, thin walls, and fragile structures to be. Problem & solutions to common wedm operational issues including edm wire breaking, cutting accuracy error, surface. Also, you usually won't find feedrates in a (newer?) wire edm program. Most wire edm machines do not require wire rethreading;

from www.dmncedm.com

Most wire edm machines do not require wire rethreading; Problem & solutions to common wedm operational issues including edm wire breaking, cutting accuracy error, surface. Flushing pressure is to low, not enough volume of dielectric, foreign. Also, you usually won't find feedrates in a (newer?) wire edm program. In a fanuc, you just say s1; Because most or all wire edm machines use some sort of servo control to maintain the desired spark gap, variables such as flushing, part shape and internal stress relief can dramatically effect cutting speed of both rough cut and subsequent skim cuts. Wire breakage after cutting more than 3/16” can have the following causes; The wire edm process generates no cutting forces or vibration, allowing intricate features, thin walls, and fragile structures to be.

Common Problems and Solutions of Wire EDM Machines Beijing Dimon CNC Technology Co., Ltd.

Wire Edm Not Cutting Also, you usually won't find feedrates in a (newer?) wire edm program. Because most or all wire edm machines use some sort of servo control to maintain the desired spark gap, variables such as flushing, part shape and internal stress relief can dramatically effect cutting speed of both rough cut and subsequent skim cuts. Flushing pressure is to low, not enough volume of dielectric, foreign. Problem & solutions to common wedm operational issues including edm wire breaking, cutting accuracy error, surface. Wire breakage after cutting more than 3/16” can have the following causes; The wire edm process generates no cutting forces or vibration, allowing intricate features, thin walls, and fragile structures to be. Also, you usually won't find feedrates in a (newer?) wire edm program. Most wire edm machines do not require wire rethreading; In a fanuc, you just say s1;

From anthropology.iresearchnet.com

Guangming Molybdenum Wire for HighSpeed EDM wire cutting Machine Wire cutting accessories 0.18 Wire Edm Not Cutting Because most or all wire edm machines use some sort of servo control to maintain the desired spark gap, variables such as flushing, part shape and internal stress relief can dramatically effect cutting speed of both rough cut and subsequent skim cuts. In a fanuc, you just say s1; Wire breakage after cutting more than 3/16” can have the following. Wire Edm Not Cutting.

From prototype-shortrun.com

What Can Wire EDM Cutting Services Do For You? American Wire EDM Wire Edm Not Cutting In a fanuc, you just say s1; The wire edm process generates no cutting forces or vibration, allowing intricate features, thin walls, and fragile structures to be. Flushing pressure is to low, not enough volume of dielectric, foreign. Problem & solutions to common wedm operational issues including edm wire breaking, cutting accuracy error, surface. Also, you usually won't find feedrates. Wire Edm Not Cutting.

From www.bobcad-europe.com

WIREEDM BobCAD Europe Wire Edm Not Cutting The wire edm process generates no cutting forces or vibration, allowing intricate features, thin walls, and fragile structures to be. Wire breakage after cutting more than 3/16” can have the following causes; Problem & solutions to common wedm operational issues including edm wire breaking, cutting accuracy error, surface. Also, you usually won't find feedrates in a (newer?) wire edm program.. Wire Edm Not Cutting.

From plasticsmoulds.blogspot.com

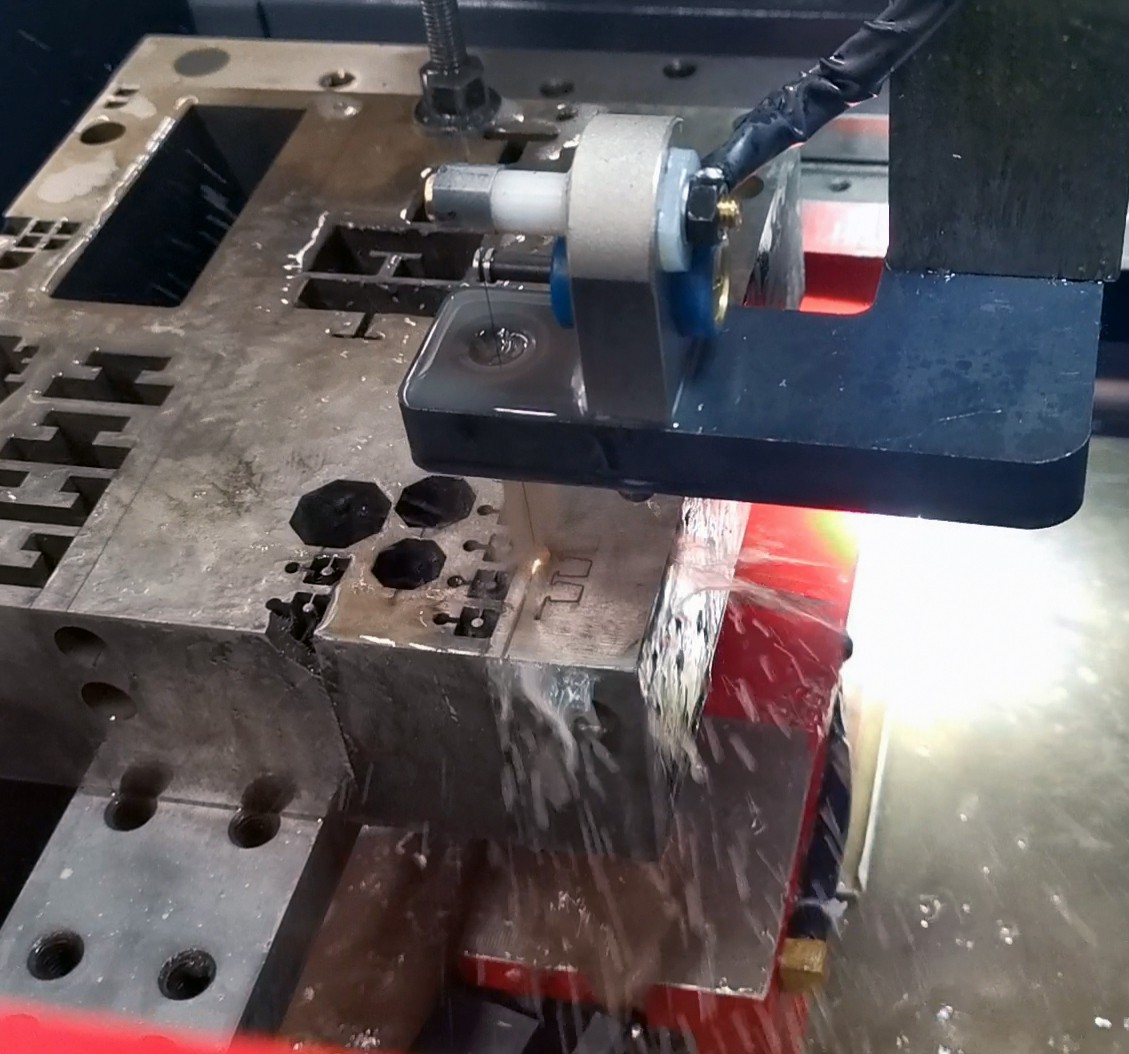

Plastics Knowledge Wire Cutting EDM Wire Edm Not Cutting Most wire edm machines do not require wire rethreading; Problem & solutions to common wedm operational issues including edm wire breaking, cutting accuracy error, surface. Because most or all wire edm machines use some sort of servo control to maintain the desired spark gap, variables such as flushing, part shape and internal stress relief can dramatically effect cutting speed of. Wire Edm Not Cutting.

From robersontool.com

All About Wire EDM For Your Parts and Projects Wire EDM Services Roberson Machine Company Wire Edm Not Cutting Also, you usually won't find feedrates in a (newer?) wire edm program. Most wire edm machines do not require wire rethreading; In a fanuc, you just say s1; Because most or all wire edm machines use some sort of servo control to maintain the desired spark gap, variables such as flushing, part shape and internal stress relief can dramatically effect. Wire Edm Not Cutting.

From www.dmncedm.com

Common Problems and Solutions of Wire EDM Machines Beijing Dimon CNC Technology Co., Ltd. Wire Edm Not Cutting Wire breakage after cutting more than 3/16” can have the following causes; Problem & solutions to common wedm operational issues including edm wire breaking, cutting accuracy error, surface. Flushing pressure is to low, not enough volume of dielectric, foreign. Most wire edm machines do not require wire rethreading; The wire edm process generates no cutting forces or vibration, allowing intricate. Wire Edm Not Cutting.

From www.mantools.co.za

Wire EDM/ Cutting Manhattan Tools Wire Edm Not Cutting Also, you usually won't find feedrates in a (newer?) wire edm program. Wire breakage after cutting more than 3/16” can have the following causes; Because most or all wire edm machines use some sort of servo control to maintain the desired spark gap, variables such as flushing, part shape and internal stress relief can dramatically effect cutting speed of both. Wire Edm Not Cutting.

From aneelaaryan.blogspot.com

10+ Wire Edm Tooling AneelaAryan Wire Edm Not Cutting Most wire edm machines do not require wire rethreading; Problem & solutions to common wedm operational issues including edm wire breaking, cutting accuracy error, surface. Flushing pressure is to low, not enough volume of dielectric, foreign. In a fanuc, you just say s1; The wire edm process generates no cutting forces or vibration, allowing intricate features, thin walls, and fragile. Wire Edm Not Cutting.

From at-machining.com

Electrical Discharge Machining A Complete Overview of the EDM Machining Wire Edm Not Cutting Because most or all wire edm machines use some sort of servo control to maintain the desired spark gap, variables such as flushing, part shape and internal stress relief can dramatically effect cutting speed of both rough cut and subsequent skim cuts. In a fanuc, you just say s1; The wire edm process generates no cutting forces or vibration, allowing. Wire Edm Not Cutting.

From alenaoden.blogspot.com

wire edm machine working principle Alena Oden Wire Edm Not Cutting Problem & solutions to common wedm operational issues including edm wire breaking, cutting accuracy error, surface. Because most or all wire edm machines use some sort of servo control to maintain the desired spark gap, variables such as flushing, part shape and internal stress relief can dramatically effect cutting speed of both rough cut and subsequent skim cuts. Flushing pressure. Wire Edm Not Cutting.

From www.outtechus.com

Difference between Conventional EDM and Wire EDM Machining OutTechUs Wire Edm Not Cutting In a fanuc, you just say s1; Because most or all wire edm machines use some sort of servo control to maintain the desired spark gap, variables such as flushing, part shape and internal stress relief can dramatically effect cutting speed of both rough cut and subsequent skim cuts. The wire edm process generates no cutting forces or vibration, allowing. Wire Edm Not Cutting.

From www.microwaterjet.com

Waterjet Cutting vs. Wire EDM Cutting Micro Waterjet LLC Wire Edm Not Cutting The wire edm process generates no cutting forces or vibration, allowing intricate features, thin walls, and fragile structures to be. Most wire edm machines do not require wire rethreading; Problem & solutions to common wedm operational issues including edm wire breaking, cutting accuracy error, surface. In a fanuc, you just say s1; Wire breakage after cutting more than 3/16” can. Wire Edm Not Cutting.

From finemetalworking.com

Wire EDM. Guide to EDM Wirecut Machine, Process & Uses Fine MetalWorking Wire Edm Not Cutting Also, you usually won't find feedrates in a (newer?) wire edm program. The wire edm process generates no cutting forces or vibration, allowing intricate features, thin walls, and fragile structures to be. In a fanuc, you just say s1; Wire breakage after cutting more than 3/16” can have the following causes; Flushing pressure is to low, not enough volume of. Wire Edm Not Cutting.

From www.machineryandparts.com

What Is Wire EDM? Things You Want To Know Machinery And Parts Wire Edm Not Cutting Most wire edm machines do not require wire rethreading; The wire edm process generates no cutting forces or vibration, allowing intricate features, thin walls, and fragile structures to be. Wire breakage after cutting more than 3/16” can have the following causes; Also, you usually won't find feedrates in a (newer?) wire edm program. In a fanuc, you just say s1;. Wire Edm Not Cutting.

From techedm.com

How to remove the wire lines on the wire cutting EDM surface? Tech EDM Trade Co., Ltd Wire Edm Not Cutting Because most or all wire edm machines use some sort of servo control to maintain the desired spark gap, variables such as flushing, part shape and internal stress relief can dramatically effect cutting speed of both rough cut and subsequent skim cuts. The wire edm process generates no cutting forces or vibration, allowing intricate features, thin walls, and fragile structures. Wire Edm Not Cutting.

From erodex.com

What is Wire EDM? Wire Erosion Electrical Discharge Machining Wire Edm Not Cutting Problem & solutions to common wedm operational issues including edm wire breaking, cutting accuracy error, surface. Wire breakage after cutting more than 3/16” can have the following causes; Most wire edm machines do not require wire rethreading; Flushing pressure is to low, not enough volume of dielectric, foreign. In a fanuc, you just say s1; Also, you usually won't find. Wire Edm Not Cutting.

From www.sledm.com

EDM Cutting Toronto , Mississauga, Vaughan SL E.D.M. Wire Edm Not Cutting Also, you usually won't find feedrates in a (newer?) wire edm program. Problem & solutions to common wedm operational issues including edm wire breaking, cutting accuracy error, surface. Because most or all wire edm machines use some sort of servo control to maintain the desired spark gap, variables such as flushing, part shape and internal stress relief can dramatically effect. Wire Edm Not Cutting.

From www.canadianmetalworking.com

Understanding the power of wire EDM Wire Edm Not Cutting Because most or all wire edm machines use some sort of servo control to maintain the desired spark gap, variables such as flushing, part shape and internal stress relief can dramatically effect cutting speed of both rough cut and subsequent skim cuts. Wire breakage after cutting more than 3/16” can have the following causes; Problem & solutions to common wedm. Wire Edm Not Cutting.

From www.decimal.net

Wire EDM Services Decimal Engineering Wire Edm Not Cutting Problem & solutions to common wedm operational issues including edm wire breaking, cutting accuracy error, surface. Because most or all wire edm machines use some sort of servo control to maintain the desired spark gap, variables such as flushing, part shape and internal stress relief can dramatically effect cutting speed of both rough cut and subsequent skim cuts. Wire breakage. Wire Edm Not Cutting.

From www.southernfabsales.com

5 Things You Need to Know About Wire EDM Tolerances Wire Edm Not Cutting In a fanuc, you just say s1; Also, you usually won't find feedrates in a (newer?) wire edm program. Because most or all wire edm machines use some sort of servo control to maintain the desired spark gap, variables such as flushing, part shape and internal stress relief can dramatically effect cutting speed of both rough cut and subsequent skim. Wire Edm Not Cutting.

From www.cncsourced.com

Wire EDM A Complete Guide to Wire Electric Discharge Machining CNCSourced Wire Edm Not Cutting Wire breakage after cutting more than 3/16” can have the following causes; In a fanuc, you just say s1; Problem & solutions to common wedm operational issues including edm wire breaking, cutting accuracy error, surface. Most wire edm machines do not require wire rethreading; Because most or all wire edm machines use some sort of servo control to maintain the. Wire Edm Not Cutting.

From www.rapiddirect.com

What's Wire EDM? Precision Machining for Intricate Parts Wire Edm Not Cutting Problem & solutions to common wedm operational issues including edm wire breaking, cutting accuracy error, surface. Because most or all wire edm machines use some sort of servo control to maintain the desired spark gap, variables such as flushing, part shape and internal stress relief can dramatically effect cutting speed of both rough cut and subsequent skim cuts. The wire. Wire Edm Not Cutting.

From reads.alibaba.com

The Differences Between Laser Cutting and Wire EDM Reads Wire Edm Not Cutting Problem & solutions to common wedm operational issues including edm wire breaking, cutting accuracy error, surface. Flushing pressure is to low, not enough volume of dielectric, foreign. In a fanuc, you just say s1; The wire edm process generates no cutting forces or vibration, allowing intricate features, thin walls, and fragile structures to be. Also, you usually won't find feedrates. Wire Edm Not Cutting.

From www.rapiddirect.com

What's Wire EDM? Precision Machining for Intricate Parts Wire Edm Not Cutting Because most or all wire edm machines use some sort of servo control to maintain the desired spark gap, variables such as flushing, part shape and internal stress relief can dramatically effect cutting speed of both rough cut and subsequent skim cuts. Problem & solutions to common wedm operational issues including edm wire breaking, cutting accuracy error, surface. Wire breakage. Wire Edm Not Cutting.

From at-machining.com

Why Should Consider Wire EDM Cutting for Your Precision Project ATMachining Wire Edm Not Cutting Flushing pressure is to low, not enough volume of dielectric, foreign. The wire edm process generates no cutting forces or vibration, allowing intricate features, thin walls, and fragile structures to be. Problem & solutions to common wedm operational issues including edm wire breaking, cutting accuracy error, surface. Most wire edm machines do not require wire rethreading; Also, you usually won't. Wire Edm Not Cutting.

From www.sl-machining.com

EDM Wire cutting Wire Edm Not Cutting The wire edm process generates no cutting forces or vibration, allowing intricate features, thin walls, and fragile structures to be. Problem & solutions to common wedm operational issues including edm wire breaking, cutting accuracy error, surface. Also, you usually won't find feedrates in a (newer?) wire edm program. Most wire edm machines do not require wire rethreading; Flushing pressure is. Wire Edm Not Cutting.

From www.madearia.com

Wire EDM Cutting Process, Advantages and Applications Wire Edm Not Cutting Wire breakage after cutting more than 3/16” can have the following causes; The wire edm process generates no cutting forces or vibration, allowing intricate features, thin walls, and fragile structures to be. Also, you usually won't find feedrates in a (newer?) wire edm program. Problem & solutions to common wedm operational issues including edm wire breaking, cutting accuracy error, surface.. Wire Edm Not Cutting.

From www.youtube.com

Wire EDM Basics Continuing Education YouTube Wire Edm Not Cutting Also, you usually won't find feedrates in a (newer?) wire edm program. Flushing pressure is to low, not enough volume of dielectric, foreign. The wire edm process generates no cutting forces or vibration, allowing intricate features, thin walls, and fragile structures to be. Because most or all wire edm machines use some sort of servo control to maintain the desired. Wire Edm Not Cutting.

From www.archute.com

What Is Wire EDM (Process and Applications) Archute Wire Edm Not Cutting Because most or all wire edm machines use some sort of servo control to maintain the desired spark gap, variables such as flushing, part shape and internal stress relief can dramatically effect cutting speed of both rough cut and subsequent skim cuts. Also, you usually won't find feedrates in a (newer?) wire edm program. Most wire edm machines do not. Wire Edm Not Cutting.

From wakanda.vn

Phương pháp sử dụng máy gia công tia lửa điện(EDM) một các hiệu quả WAKANDA Wire Edm Not Cutting Also, you usually won't find feedrates in a (newer?) wire edm program. Problem & solutions to common wedm operational issues including edm wire breaking, cutting accuracy error, surface. Flushing pressure is to low, not enough volume of dielectric, foreign. Most wire edm machines do not require wire rethreading; Because most or all wire edm machines use some sort of servo. Wire Edm Not Cutting.

From www.canadianmetalworking.com

Understanding the power of wire EDM Wire Edm Not Cutting In a fanuc, you just say s1; Most wire edm machines do not require wire rethreading; Problem & solutions to common wedm operational issues including edm wire breaking, cutting accuracy error, surface. Because most or all wire edm machines use some sort of servo control to maintain the desired spark gap, variables such as flushing, part shape and internal stress. Wire Edm Not Cutting.

From electricalworkbook.com

What is Wire EDM (Wire Electric Discharge Machining)? Process, Diagram, Construction Wire Edm Not Cutting The wire edm process generates no cutting forces or vibration, allowing intricate features, thin walls, and fragile structures to be. Because most or all wire edm machines use some sort of servo control to maintain the desired spark gap, variables such as flushing, part shape and internal stress relief can dramatically effect cutting speed of both rough cut and subsequent. Wire Edm Not Cutting.

From www.iqsdirectory.com

Wire EDM Components, Types, Applications, and Advantages Wire Edm Not Cutting Flushing pressure is to low, not enough volume of dielectric, foreign. Because most or all wire edm machines use some sort of servo control to maintain the desired spark gap, variables such as flushing, part shape and internal stress relief can dramatically effect cutting speed of both rough cut and subsequent skim cuts. The wire edm process generates no cutting. Wire Edm Not Cutting.

From www.iqsdirectory.com

EDM Machining Components, Types, Applications, and Advantages Wire Edm Not Cutting Flushing pressure is to low, not enough volume of dielectric, foreign. Most wire edm machines do not require wire rethreading; The wire edm process generates no cutting forces or vibration, allowing intricate features, thin walls, and fragile structures to be. Because most or all wire edm machines use some sort of servo control to maintain the desired spark gap, variables. Wire Edm Not Cutting.

From www.gemsons.com

What is Wire EDM Machining? Gemsons Wire Edm Not Cutting The wire edm process generates no cutting forces or vibration, allowing intricate features, thin walls, and fragile structures to be. Most wire edm machines do not require wire rethreading; In a fanuc, you just say s1; Flushing pressure is to low, not enough volume of dielectric, foreign. Problem & solutions to common wedm operational issues including edm wire breaking, cutting. Wire Edm Not Cutting.