Reverse Return Chilled Water Piping System . If the flow resistance of each piping path from a common source point to a common return point is the same, the flow will divide equally. Because the reverse return system requires an additional length of pipe at least the length of the return header, there is additional head loss that must be overcome by the head. Branch chilled water return temperature of 48.2°f. The physics necessary for this are simple: The temperature of the chilled water returning to the central plant will be 51.4°f after the water. Just reverse the chilled water return pipe such that the first air handling unit (ahu) that receives the chilled water supply is the last ahu that provides the chilled water. Piping insulation reduces heat gain into the. Reverse return piping was developed to help achieve this goal. Reverse return piping, that the pressure drop would be the same for all devices, this is not certain. In many hydronic systems, there’s a need to divide the overall system flow into equal streams that pass through several identical components. Solve at load, mitigate at plant. Do not run more chillers than needed (water. In many hydronic systems, there’s a need to divide the overall system flow into equal streams that pass through several identical components.

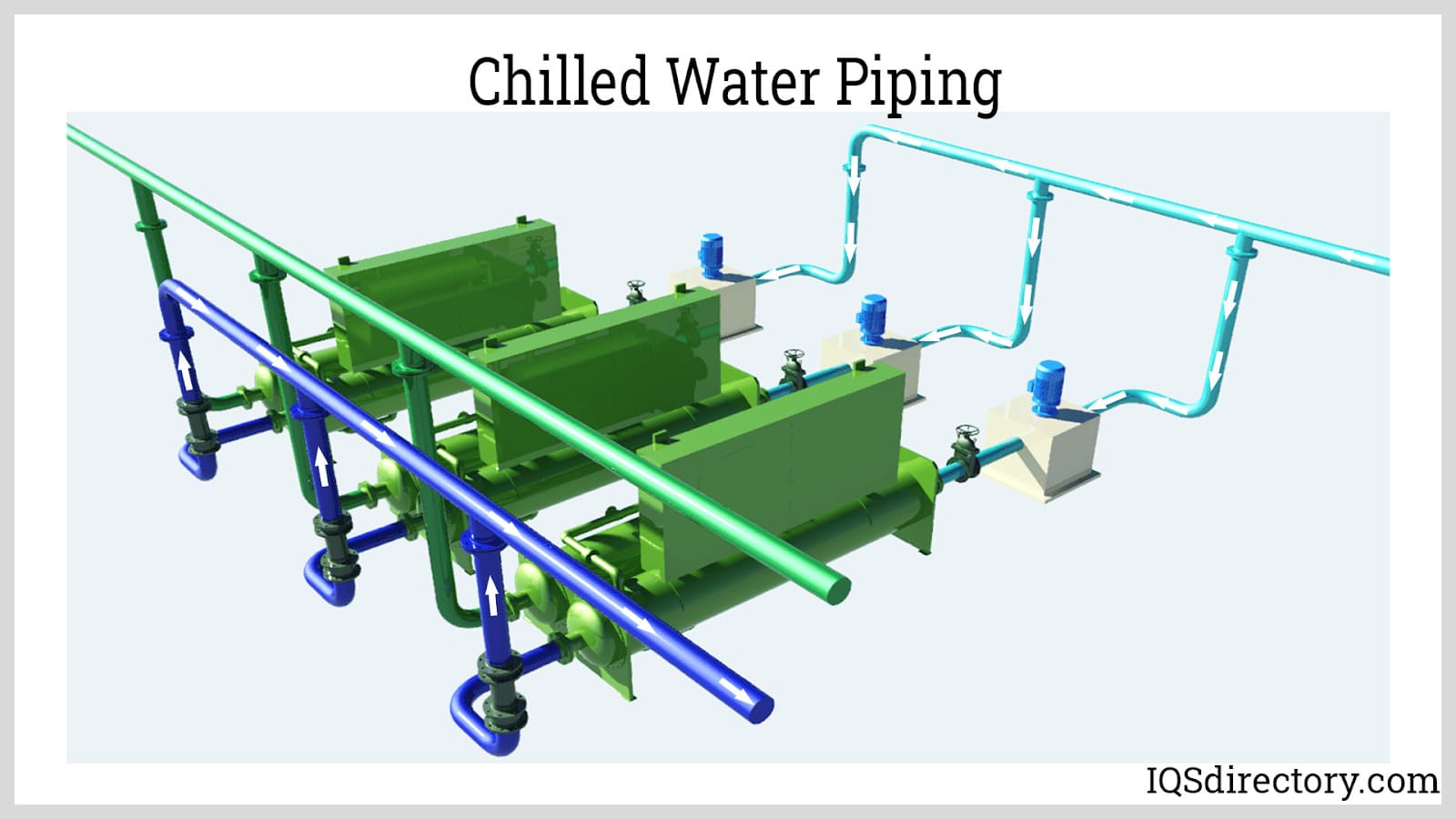

from www.iqsdirectory.com

Piping insulation reduces heat gain into the. Reverse return piping, that the pressure drop would be the same for all devices, this is not certain. Just reverse the chilled water return pipe such that the first air handling unit (ahu) that receives the chilled water supply is the last ahu that provides the chilled water. The temperature of the chilled water returning to the central plant will be 51.4°f after the water. The physics necessary for this are simple: If the flow resistance of each piping path from a common source point to a common return point is the same, the flow will divide equally. Because the reverse return system requires an additional length of pipe at least the length of the return header, there is additional head loss that must be overcome by the head. Do not run more chillers than needed (water. Branch chilled water return temperature of 48.2°f. In many hydronic systems, there’s a need to divide the overall system flow into equal streams that pass through several identical components.

Water Chiller What Is It? How Does It Work? Types, Uses

Reverse Return Chilled Water Piping System Because the reverse return system requires an additional length of pipe at least the length of the return header, there is additional head loss that must be overcome by the head. The physics necessary for this are simple: The temperature of the chilled water returning to the central plant will be 51.4°f after the water. Just reverse the chilled water return pipe such that the first air handling unit (ahu) that receives the chilled water supply is the last ahu that provides the chilled water. In many hydronic systems, there’s a need to divide the overall system flow into equal streams that pass through several identical components. Branch chilled water return temperature of 48.2°f. In many hydronic systems, there’s a need to divide the overall system flow into equal streams that pass through several identical components. Solve at load, mitigate at plant. Piping insulation reduces heat gain into the. Reverse return piping, that the pressure drop would be the same for all devices, this is not certain. Do not run more chillers than needed (water. Reverse return piping was developed to help achieve this goal. If the flow resistance of each piping path from a common source point to a common return point is the same, the flow will divide equally. Because the reverse return system requires an additional length of pipe at least the length of the return header, there is additional head loss that must be overcome by the head.

From jmpblog.squarespace.com

Variable Primary Chilled Water Systems Part 3 The Basics of Variable Reverse Return Chilled Water Piping System Reverse return piping, that the pressure drop would be the same for all devices, this is not certain. If the flow resistance of each piping path from a common source point to a common return point is the same, the flow will divide equally. The physics necessary for this are simple: Because the reverse return system requires an additional length. Reverse Return Chilled Water Piping System.

From usermanualadjuvant.z1.web.core.windows.net

Boiler Piping Schematic Diagram Reverse Return Chilled Water Piping System Reverse return piping, that the pressure drop would be the same for all devices, this is not certain. Just reverse the chilled water return pipe such that the first air handling unit (ahu) that receives the chilled water supply is the last ahu that provides the chilled water. The physics necessary for this are simple: If the flow resistance of. Reverse Return Chilled Water Piping System.

From manualliblatten.z19.web.core.windows.net

Reverse Return Piping Diagram Water Heaters Reverse Return Chilled Water Piping System Piping insulation reduces heat gain into the. Branch chilled water return temperature of 48.2°f. In many hydronic systems, there’s a need to divide the overall system flow into equal streams that pass through several identical components. The physics necessary for this are simple: Because the reverse return system requires an additional length of pipe at least the length of the. Reverse Return Chilled Water Piping System.

From www.wiringtrust.com

Chiller System Schematic Diagram Wiring Diagram Reverse Return Chilled Water Piping System The temperature of the chilled water returning to the central plant will be 51.4°f after the water. Piping insulation reduces heat gain into the. Because the reverse return system requires an additional length of pipe at least the length of the return header, there is additional head loss that must be overcome by the head. Just reverse the chilled water. Reverse Return Chilled Water Piping System.

From support.veregy.com

Hydronic Heating Veregy Reverse Return Chilled Water Piping System If the flow resistance of each piping path from a common source point to a common return point is the same, the flow will divide equally. Solve at load, mitigate at plant. Piping insulation reduces heat gain into the. Reverse return piping, that the pressure drop would be the same for all devices, this is not certain. Reverse return piping. Reverse Return Chilled Water Piping System.

From jmpcoblog.com

How To Size A Waterside Economizer Part 4 Chilled Water Piping Reverse Return Chilled Water Piping System Reverse return piping was developed to help achieve this goal. Piping insulation reduces heat gain into the. The physics necessary for this are simple: Branch chilled water return temperature of 48.2°f. Because the reverse return system requires an additional length of pipe at least the length of the return header, there is additional head loss that must be overcome by. Reverse Return Chilled Water Piping System.

From www.youtube.com

Chilled Water Piping connection for Chillers with various sensors YouTube Reverse Return Chilled Water Piping System Do not run more chillers than needed (water. Branch chilled water return temperature of 48.2°f. Because the reverse return system requires an additional length of pipe at least the length of the return header, there is additional head loss that must be overcome by the head. If the flow resistance of each piping path from a common source point to. Reverse Return Chilled Water Piping System.

From www.tradeindia.com

Chilled Water Piping System at 60000.00 INR in Pune Star Airconditioning Reverse Return Chilled Water Piping System Piping insulation reduces heat gain into the. Just reverse the chilled water return pipe such that the first air handling unit (ahu) that receives the chilled water supply is the last ahu that provides the chilled water. The temperature of the chilled water returning to the central plant will be 51.4°f after the water. Solve at load, mitigate at plant.. Reverse Return Chilled Water Piping System.

From enginelibthanehoods.z21.web.core.windows.net

Chilled Water Piping Schematic Reverse Return Chilled Water Piping System Just reverse the chilled water return pipe such that the first air handling unit (ahu) that receives the chilled water supply is the last ahu that provides the chilled water. The temperature of the chilled water returning to the central plant will be 51.4°f after the water. In many hydronic systems, there’s a need to divide the overall system flow. Reverse Return Chilled Water Piping System.

From www.pmmag.com

When and how to use reverse return piping 20161116 Plumbing and Reverse Return Chilled Water Piping System Branch chilled water return temperature of 48.2°f. Reverse return piping, that the pressure drop would be the same for all devices, this is not certain. Do not run more chillers than needed (water. In many hydronic systems, there’s a need to divide the overall system flow into equal streams that pass through several identical components. In many hydronic systems, there’s. Reverse Return Chilled Water Piping System.

From www.pmmag.com

When and how to use reverse return piping 20161116 Plumbing and Reverse Return Chilled Water Piping System The physics necessary for this are simple: In many hydronic systems, there’s a need to divide the overall system flow into equal streams that pass through several identical components. If the flow resistance of each piping path from a common source point to a common return point is the same, the flow will divide equally. Do not run more chillers. Reverse Return Chilled Water Piping System.

From www.endocool.com

Guide to Chilled Water Systems and Improving Efficiency EndoCool Reverse Return Chilled Water Piping System The physics necessary for this are simple: Branch chilled water return temperature of 48.2°f. Just reverse the chilled water return pipe such that the first air handling unit (ahu) that receives the chilled water supply is the last ahu that provides the chilled water. Solve at load, mitigate at plant. Because the reverse return system requires an additional length of. Reverse Return Chilled Water Piping System.

From oupo44qbfixmachine.z13.web.core.windows.net

Chilled Water Piping Schematic Reverse Return Chilled Water Piping System The physics necessary for this are simple: In many hydronic systems, there’s a need to divide the overall system flow into equal streams that pass through several identical components. Reverse return piping was developed to help achieve this goal. Piping insulation reduces heat gain into the. Because the reverse return system requires an additional length of pipe at least the. Reverse Return Chilled Water Piping System.

From www.pmmag.com

When and how to use reverse return piping 20161116 Plumbing and Reverse Return Chilled Water Piping System In many hydronic systems, there’s a need to divide the overall system flow into equal streams that pass through several identical components. Because the reverse return system requires an additional length of pipe at least the length of the return header, there is additional head loss that must be overcome by the head. Branch chilled water return temperature of 48.2°f.. Reverse Return Chilled Water Piping System.

From cimonetti41schematic.z4.web.core.windows.net

Chilled Water Piping Schematic Pdf Reverse Return Chilled Water Piping System Because the reverse return system requires an additional length of pipe at least the length of the return header, there is additional head loss that must be overcome by the head. Just reverse the chilled water return pipe such that the first air handling unit (ahu) that receives the chilled water supply is the last ahu that provides the chilled. Reverse Return Chilled Water Piping System.

From www.engproguides.com

Expansion Tank Design Guide, How to Size and Select an Expansion Tank Reverse Return Chilled Water Piping System Because the reverse return system requires an additional length of pipe at least the length of the return header, there is additional head loss that must be overcome by the head. Solve at load, mitigate at plant. Just reverse the chilled water return pipe such that the first air handling unit (ahu) that receives the chilled water supply is the. Reverse Return Chilled Water Piping System.

From www.flowbalance.com.au

Pipe System Flushing Flow Balance Reverse Return Chilled Water Piping System Solve at load, mitigate at plant. The temperature of the chilled water returning to the central plant will be 51.4°f after the water. Branch chilled water return temperature of 48.2°f. In many hydronic systems, there’s a need to divide the overall system flow into equal streams that pass through several identical components. If the flow resistance of each piping path. Reverse Return Chilled Water Piping System.

From www.foamglas.com

The impact of moisture in chilled water insulation systems Reverse Return Chilled Water Piping System Because the reverse return system requires an additional length of pipe at least the length of the return header, there is additional head loss that must be overcome by the head. Branch chilled water return temperature of 48.2°f. Reverse return piping was developed to help achieve this goal. In many hydronic systems, there’s a need to divide the overall system. Reverse Return Chilled Water Piping System.

From loerfjaze.blob.core.windows.net

Hot And Cold Water Not Mixing In Shower at Amy Todd blog Reverse Return Chilled Water Piping System Reverse return piping was developed to help achieve this goal. Piping insulation reduces heat gain into the. Because the reverse return system requires an additional length of pipe at least the length of the return header, there is additional head loss that must be overcome by the head. If the flow resistance of each piping path from a common source. Reverse Return Chilled Water Piping System.

From exyvudqcj.blob.core.windows.net

How Does A Chilled Water Hvac System Work at Lillian Wall blog Reverse Return Chilled Water Piping System Because the reverse return system requires an additional length of pipe at least the length of the return header, there is additional head loss that must be overcome by the head. In many hydronic systems, there’s a need to divide the overall system flow into equal streams that pass through several identical components. Piping insulation reduces heat gain into the.. Reverse Return Chilled Water Piping System.

From publish-p45436-e208674.adobeaemcloud.com

Proper Insulation of Chilled Water Pipe Systems Johns Manville Reverse Return Chilled Water Piping System The physics necessary for this are simple: Piping insulation reduces heat gain into the. If the flow resistance of each piping path from a common source point to a common return point is the same, the flow will divide equally. Reverse return piping was developed to help achieve this goal. Solve at load, mitigate at plant. Just reverse the chilled. Reverse Return Chilled Water Piping System.

From e6lemen3vschematic.z19.web.core.windows.net

Reverse Return Piping Diagram Water Heaters Reverse Return Chilled Water Piping System In many hydronic systems, there’s a need to divide the overall system flow into equal streams that pass through several identical components. Branch chilled water return temperature of 48.2°f. Reverse return piping was developed to help achieve this goal. If the flow resistance of each piping path from a common source point to a common return point is the same,. Reverse Return Chilled Water Piping System.

From www.dreamstime.com

Chilled Water Supply and Return Pipe System. Stock Photo Image of Reverse Return Chilled Water Piping System Just reverse the chilled water return pipe such that the first air handling unit (ahu) that receives the chilled water supply is the last ahu that provides the chilled water. In many hydronic systems, there’s a need to divide the overall system flow into equal streams that pass through several identical components. Branch chilled water return temperature of 48.2°f. In. Reverse Return Chilled Water Piping System.

From mungfali.com

Chilled Water Piping Schematic Reverse Return Chilled Water Piping System The temperature of the chilled water returning to the central plant will be 51.4°f after the water. Do not run more chillers than needed (water. If the flow resistance of each piping path from a common source point to a common return point is the same, the flow will divide equally. Reverse return piping, that the pressure drop would be. Reverse Return Chilled Water Piping System.

From mungfali.com

Chilled Water Piping Diagram Reverse Return Chilled Water Piping System Reverse return piping was developed to help achieve this goal. Just reverse the chilled water return pipe such that the first air handling unit (ahu) that receives the chilled water supply is the last ahu that provides the chilled water. Because the reverse return system requires an additional length of pipe at least the length of the return header, there. Reverse Return Chilled Water Piping System.

From www.pmmag.com

When and how to use reverse return piping 20161116 Plumbing and Reverse Return Chilled Water Piping System Reverse return piping was developed to help achieve this goal. Just reverse the chilled water return pipe such that the first air handling unit (ahu) that receives the chilled water supply is the last ahu that provides the chilled water. Reverse return piping, that the pressure drop would be the same for all devices, this is not certain. The temperature. Reverse Return Chilled Water Piping System.

From www.pmmag.com

When and how to use reverse return piping 20161116 Plumbing and Reverse Return Chilled Water Piping System Because the reverse return system requires an additional length of pipe at least the length of the return header, there is additional head loss that must be overcome by the head. If the flow resistance of each piping path from a common source point to a common return point is the same, the flow will divide equally. Just reverse the. Reverse Return Chilled Water Piping System.

From www.dreamstime.com

Typical Balancing Valve Installation for Chilled Water Pipe Apply for Reverse Return Chilled Water Piping System Piping insulation reduces heat gain into the. In many hydronic systems, there’s a need to divide the overall system flow into equal streams that pass through several identical components. Just reverse the chilled water return pipe such that the first air handling unit (ahu) that receives the chilled water supply is the last ahu that provides the chilled water. Reverse. Reverse Return Chilled Water Piping System.

From www.iqsdirectory.com

Water Chiller What Is It? How Does It Work? Types, Uses Reverse Return Chilled Water Piping System The physics necessary for this are simple: Solve at load, mitigate at plant. In many hydronic systems, there’s a need to divide the overall system flow into equal streams that pass through several identical components. Just reverse the chilled water return pipe such that the first air handling unit (ahu) that receives the chilled water supply is the last ahu. Reverse Return Chilled Water Piping System.

From www.pmmag.com

When and how to use reverse return piping 20161116 Plumbing and Reverse Return Chilled Water Piping System If the flow resistance of each piping path from a common source point to a common return point is the same, the flow will divide equally. Just reverse the chilled water return pipe such that the first air handling unit (ahu) that receives the chilled water supply is the last ahu that provides the chilled water. Branch chilled water return. Reverse Return Chilled Water Piping System.

From methodstatementhq.com

Cleaning and flushing of the Chilled Water Piping System Method Reverse Return Chilled Water Piping System Do not run more chillers than needed (water. If the flow resistance of each piping path from a common source point to a common return point is the same, the flow will divide equally. Piping insulation reduces heat gain into the. Because the reverse return system requires an additional length of pipe at least the length of the return header,. Reverse Return Chilled Water Piping System.

From www.pmmag.com

When and how to use reverse return piping 20161116 Plumbing and Reverse Return Chilled Water Piping System The temperature of the chilled water returning to the central plant will be 51.4°f after the water. Because the reverse return system requires an additional length of pipe at least the length of the return header, there is additional head loss that must be overcome by the head. Reverse return piping was developed to help achieve this goal. Piping insulation. Reverse Return Chilled Water Piping System.