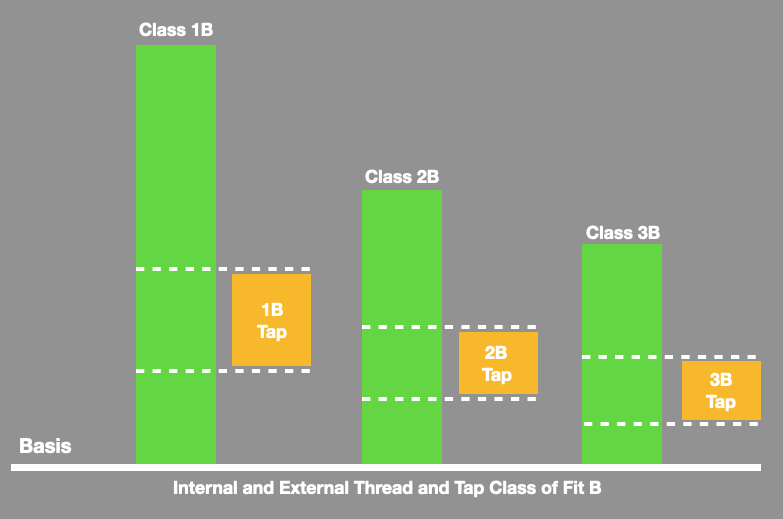

Thread Tap Limits . The thread tap limits are designated by the letter d (ground, high) above basic pitch diameter, or u (ground, low) below basic pitch diameter. Lower tolerance (iso 1) generates a. There are two methods for. Our detailed chart ensures precise thread fit and optimal performance for your needs. H limits are used to properly size a tap for the threaded hole to be produced. As an example, in sizes m25 and. When tapping conditions are not normal, the 40% may need to be adjusted. A for screws and b for nuts (or. H (high) represents a pitch diameter that is larger than the basic pitch diameter, and l (low) represents a pitch diameter that is smaller. H and l limits are used for inch size ground thread taps. When encountering an internal threaded hole requiring it to be plated, it normally needs to be produced oversize to accommodate the plating. Tolerance on internal thread (nut) normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. They are selected based upon the tolerance required for the part. There are (3) established classes of thread, designated in the unified series by adding:

from www.nextgentooling.com

As an example, in sizes m25 and. They are selected based upon the tolerance required for the part. Tolerance on internal thread (nut) normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. Lower tolerance (iso 1) generates a. Our detailed chart ensures precise thread fit and optimal performance for your needs. There are (3) established classes of thread, designated in the unified series by adding: There are two methods for. When encountering an internal threaded hole requiring it to be plated, it normally needs to be produced oversize to accommodate the plating. When tapping conditions are not normal, the 40% may need to be adjusted. H limits are used to properly size a tap for the threaded hole to be produced.

Understanding Class of Fit Tap Tolerance for UNC/UNCF NEXT GENERATION

Thread Tap Limits When tapping conditions are not normal, the 40% may need to be adjusted. When tapping conditions are not normal, the 40% may need to be adjusted. H (high) represents a pitch diameter that is larger than the basic pitch diameter, and l (low) represents a pitch diameter that is smaller. H limits are used to properly size a tap for the threaded hole to be produced. The thread tap limits are designated by the letter d (ground, high) above basic pitch diameter, or u (ground, low) below basic pitch diameter. H and l limits are used for inch size ground thread taps. Lower tolerance (iso 1) generates a. There are two methods for. As an example, in sizes m25 and. Tolerance on internal thread (nut) normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. Our detailed chart ensures precise thread fit and optimal performance for your needs. There are (3) established classes of thread, designated in the unified series by adding: They are selected based upon the tolerance required for the part. A for screws and b for nuts (or. When encountering an internal threaded hole requiring it to be plated, it normally needs to be produced oversize to accommodate the plating.

From www.amazon.com

Kodiak Cutting Tools KCT202717 USA Made 1/420 Hand Threading Tap Set Thread Tap Limits Our detailed chart ensures precise thread fit and optimal performance for your needs. Lower tolerance (iso 1) generates a. They are selected based upon the tolerance required for the part. When tapping conditions are not normal, the 40% may need to be adjusted. The thread tap limits are designated by the letter d (ground, high) above basic pitch diameter, or. Thread Tap Limits.

From www.pinterest.ph

metric fine tap drill chart Metric Thread Chart, Metric Measurement Thread Tap Limits They are selected based upon the tolerance required for the part. Our detailed chart ensures precise thread fit and optimal performance for your needs. H and l limits are used for inch size ground thread taps. As an example, in sizes m25 and. Tolerance on internal thread (nut) normal tap tolerance is iso 2 (6h), which generates an average quality. Thread Tap Limits.

From schematicpaliza06.z22.web.core.windows.net

Standard Tap Thread Size Thread Tap Limits They are selected based upon the tolerance required for the part. Our detailed chart ensures precise thread fit and optimal performance for your needs. When tapping conditions are not normal, the 40% may need to be adjusted. Lower tolerance (iso 1) generates a. A for screws and b for nuts (or. H and l limits are used for inch size. Thread Tap Limits.

From scienceagogo.com

Starrett Inch/Metric Tap Drill Sizes Decimal Equivalents Chart Thread Tap Limits Tolerance on internal thread (nut) normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. H limits are used to properly size a tap for the threaded hole to be produced. They are selected based upon the tolerance required for the part. H (high) represents a pitch diameter that is larger than the. Thread Tap Limits.

From tqslogistic.com

Luctool 632 UNC Hand Tap Taper GH3 Limit 4 Flute HSS Taper Chamfer Thread Tap Limits There are two methods for. H and l limits are used for inch size ground thread taps. Our detailed chart ensures precise thread fit and optimal performance for your needs. They are selected based upon the tolerance required for the part. When encountering an internal threaded hole requiring it to be plated, it normally needs to be produced oversize to. Thread Tap Limits.

From cezqrdnd.blob.core.windows.net

How To Tap A Thread In Stainless Steel at Maria Seifert blog Thread Tap Limits They are selected based upon the tolerance required for the part. Our detailed chart ensures precise thread fit and optimal performance for your needs. As an example, in sizes m25 and. There are (3) established classes of thread, designated in the unified series by adding: There are two methods for. When tapping conditions are not normal, the 40% may need. Thread Tap Limits.

From www.nextgentooling.com

Understanding Class of Fit Tap Tolerance for UNC/UNCF NEXT GENERATION Thread Tap Limits Lower tolerance (iso 1) generates a. H and l limits are used for inch size ground thread taps. There are (3) established classes of thread, designated in the unified series by adding: There are two methods for. When tapping conditions are not normal, the 40% may need to be adjusted. A for screws and b for nuts (or. As an. Thread Tap Limits.

From joianecuv.blob.core.windows.net

What Is The Standard Tap Hole Size at Ophelia Kobayashi blog Thread Tap Limits A for screws and b for nuts (or. They are selected based upon the tolerance required for the part. H and l limits are used for inch size ground thread taps. The thread tap limits are designated by the letter d (ground, high) above basic pitch diameter, or u (ground, low) below basic pitch diameter. When tapping conditions are not. Thread Tap Limits.

From www.sampletemplates.com

Tap Drill Chart 14+ Download Free Documents in PDF, Excel Thread Tap Limits H limits are used to properly size a tap for the threaded hole to be produced. They are selected based upon the tolerance required for the part. H (high) represents a pitch diameter that is larger than the basic pitch diameter, and l (low) represents a pitch diameter that is smaller. H and l limits are used for inch size. Thread Tap Limits.

From www.lazada.com.my

TRYANY DIY Metric Taper Countersink Threaded Bit Compound Tap Tap Drill Thread Tap Limits When encountering an internal threaded hole requiring it to be plated, it normally needs to be produced oversize to accommodate the plating. H (high) represents a pitch diameter that is larger than the basic pitch diameter, and l (low) represents a pitch diameter that is smaller. When tapping conditions are not normal, the 40% may need to be adjusted. Our. Thread Tap Limits.

From ar.inspiredpencil.com

Metric Thread Tolerance Chart Thread Tap Limits There are (3) established classes of thread, designated in the unified series by adding: As an example, in sizes m25 and. The thread tap limits are designated by the letter d (ground, high) above basic pitch diameter, or u (ground, low) below basic pitch diameter. A for screws and b for nuts (or. Lower tolerance (iso 1) generates a. There. Thread Tap Limits.

From www.recoiltools.com.au

Threading Tap Intermediate Metric Recoil Thread Tap Limits The thread tap limits are designated by the letter d (ground, high) above basic pitch diameter, or u (ground, low) below basic pitch diameter. H and l limits are used for inch size ground thread taps. A for screws and b for nuts (or. When encountering an internal threaded hole requiring it to be plated, it normally needs to be. Thread Tap Limits.

From www.onallcylinders.com

Tap & Die 101 How to Use a Tap & Die Set to Cut Internal & External Thread Tap Limits Tolerance on internal thread (nut) normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. When tapping conditions are not normal, the 40% may need to be adjusted. As an example, in sizes m25 and. When encountering an internal threaded hole requiring it to be plated, it normally needs to be produced oversize. Thread Tap Limits.

From www.gwstoolgroup.com

Tapping Tip How HLimits Relate to Class of Fit (Part 2) GWS Tool Group Thread Tap Limits H limits are used to properly size a tap for the threaded hole to be produced. There are (3) established classes of thread, designated in the unified series by adding: A for screws and b for nuts (or. When encountering an internal threaded hole requiring it to be plated, it normally needs to be produced oversize to accommodate the plating.. Thread Tap Limits.

From bdteletalk.com

Find the Best LeftHand Thread Tap for Your Needs Thread Tap Limits When tapping conditions are not normal, the 40% may need to be adjusted. The thread tap limits are designated by the letter d (ground, high) above basic pitch diameter, or u (ground, low) below basic pitch diameter. Lower tolerance (iso 1) generates a. When encountering an internal threaded hole requiring it to be plated, it normally needs to be produced. Thread Tap Limits.

From www.universalnetworkcable.com

Thread Forming Tap Chart Universal Network Thread Tap Limits H and l limits are used for inch size ground thread taps. There are (3) established classes of thread, designated in the unified series by adding: Our detailed chart ensures precise thread fit and optimal performance for your needs. There are two methods for. When encountering an internal threaded hole requiring it to be plated, it normally needs to be. Thread Tap Limits.

From www.classiccarrestorationclub.com

Cutting Threads An Introduction to Using a Tap to Thread Bolt Holes Thread Tap Limits There are two methods for. The thread tap limits are designated by the letter d (ground, high) above basic pitch diameter, or u (ground, low) below basic pitch diameter. When encountering an internal threaded hole requiring it to be plated, it normally needs to be produced oversize to accommodate the plating. As an example, in sizes m25 and. When tapping. Thread Tap Limits.

From atelier-yuwa.ciao.jp

Tap Drill Charts atelieryuwa.ciao.jp Thread Tap Limits The thread tap limits are designated by the letter d (ground, high) above basic pitch diameter, or u (ground, low) below basic pitch diameter. They are selected based upon the tolerance required for the part. A for screws and b for nuts (or. There are two methods for. H (high) represents a pitch diameter that is larger than the basic. Thread Tap Limits.

From tooling.tw

Reference information on threading nuts with nut taps. Thread Tap Limits The thread tap limits are designated by the letter d (ground, high) above basic pitch diameter, or u (ground, low) below basic pitch diameter. As an example, in sizes m25 and. Tolerance on internal thread (nut) normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. Lower tolerance (iso 1) generates a. There. Thread Tap Limits.

From joiplngew.blob.core.windows.net

Thread Insert Tap Sizes at Anton Ma blog Thread Tap Limits When encountering an internal threaded hole requiring it to be plated, it normally needs to be produced oversize to accommodate the plating. There are two methods for. They are selected based upon the tolerance required for the part. Tolerance on internal thread (nut) normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut.. Thread Tap Limits.

From www.scribd.com

Tap Chart Metric Threads Thread Tap Limits When tapping conditions are not normal, the 40% may need to be adjusted. As an example, in sizes m25 and. There are (3) established classes of thread, designated in the unified series by adding: There are two methods for. They are selected based upon the tolerance required for the part. When encountering an internal threaded hole requiring it to be. Thread Tap Limits.

From www.formsbirds.com

Metric Tap Drill Chart Free Download Thread Tap Limits When tapping conditions are not normal, the 40% may need to be adjusted. Tolerance on internal thread (nut) normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. There are (3) established classes of thread, designated in the unified series by adding: H limits are used to properly size a tap for the. Thread Tap Limits.

From mavink.com

Tap Drill Chart For Threads Thread Tap Limits As an example, in sizes m25 and. When encountering an internal threaded hole requiring it to be plated, it normally needs to be produced oversize to accommodate the plating. Lower tolerance (iso 1) generates a. Our detailed chart ensures precise thread fit and optimal performance for your needs. When tapping conditions are not normal, the 40% may need to be. Thread Tap Limits.

From www.sumipol.com

THREAD LIMIT PLUG GAUGE (ISO TYPE JIS / GPNP) Sumipol Thread Tap Limits Our detailed chart ensures precise thread fit and optimal performance for your needs. As an example, in sizes m25 and. H (high) represents a pitch diameter that is larger than the basic pitch diameter, and l (low) represents a pitch diameter that is smaller. A for screws and b for nuts (or. When encountering an internal threaded hole requiring it. Thread Tap Limits.

From www.pinterest.co.uk

SAE UNC UNF Threads Tap & Drill Chart Toolbox eBay Drill bit Thread Tap Limits A for screws and b for nuts (or. There are (3) established classes of thread, designated in the unified series by adding: When encountering an internal threaded hole requiring it to be plated, it normally needs to be produced oversize to accommodate the plating. When tapping conditions are not normal, the 40% may need to be adjusted. The thread tap. Thread Tap Limits.

From www.ozon.ru

Screw thread production to close limits, manufacturing methods of Thread Tap Limits A for screws and b for nuts (or. Tolerance on internal thread (nut) normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. The thread tap limits are designated by the letter d (ground, high) above basic pitch diameter, or u (ground, low) below basic pitch diameter. H (high) represents a pitch diameter. Thread Tap Limits.

From www.tannerbolt.com

1/2"13 321 Spiral Point Tap 3211/213 Tanner Thread Tap Limits When tapping conditions are not normal, the 40% may need to be adjusted. H limits are used to properly size a tap for the threaded hole to be produced. Our detailed chart ensures precise thread fit and optimal performance for your needs. H (high) represents a pitch diameter that is larger than the basic pitch diameter, and l (low) represents. Thread Tap Limits.

From www.newmantools.com

Everything you wanted to know about taps but were afraid to ask, styles Thread Tap Limits When tapping conditions are not normal, the 40% may need to be adjusted. When encountering an internal threaded hole requiring it to be plated, it normally needs to be produced oversize to accommodate the plating. Tolerance on internal thread (nut) normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. A for screws. Thread Tap Limits.

From www.scribd.com

Tap Chart UNC_UNF Threads Thread Tap Limits Our detailed chart ensures precise thread fit and optimal performance for your needs. Tolerance on internal thread (nut) normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. H and l limits are used for inch size ground thread taps. H limits are used to properly size a tap for the threaded hole. Thread Tap Limits.

From www.jarviscuttingtools.com

HLimits Jarvis Cutting Tools Thread Tap Limits H and l limits are used for inch size ground thread taps. Our detailed chart ensures precise thread fit and optimal performance for your needs. There are (3) established classes of thread, designated in the unified series by adding: As an example, in sizes m25 and. H limits are used to properly size a tap for the threaded hole to. Thread Tap Limits.

From www.bossard.com.cn

Limits for metric (standard) coarse threads Bossard China Thread Tap Limits A for screws and b for nuts (or. When tapping conditions are not normal, the 40% may need to be adjusted. As an example, in sizes m25 and. H (high) represents a pitch diameter that is larger than the basic pitch diameter, and l (low) represents a pitch diameter that is smaller. There are two methods for. Our detailed chart. Thread Tap Limits.

From www.gaugestools.com

UNIFIED SCREW THREADS Thread Tap Limits The thread tap limits are designated by the letter d (ground, high) above basic pitch diameter, or u (ground, low) below basic pitch diameter. H and l limits are used for inch size ground thread taps. Our detailed chart ensures precise thread fit and optimal performance for your needs. There are (3) established classes of thread, designated in the unified. Thread Tap Limits.

From mavink.com

Npt Thread Dimensions Chart Thread Tap Limits When tapping conditions are not normal, the 40% may need to be adjusted. H and l limits are used for inch size ground thread taps. There are two methods for. Our detailed chart ensures precise thread fit and optimal performance for your needs. A for screws and b for nuts (or. H (high) represents a pitch diameter that is larger. Thread Tap Limits.

From www.bladeforums.com

reverse tapping head question Thread Tap Limits Tolerance on internal thread (nut) normal tap tolerance is iso 2 (6h), which generates an average quality fit between screw and nut. They are selected based upon the tolerance required for the part. Our detailed chart ensures precise thread fit and optimal performance for your needs. H and l limits are used for inch size ground thread taps. The thread. Thread Tap Limits.

From www.amazon.com

ATOPLEE Metric Thread Tap, M10 HSS 6542 Right Hand Thread Thread Tap Limits There are two methods for. Our detailed chart ensures precise thread fit and optimal performance for your needs. The thread tap limits are designated by the letter d (ground, high) above basic pitch diameter, or u (ground, low) below basic pitch diameter. As an example, in sizes m25 and. A for screws and b for nuts (or. H (high) represents. Thread Tap Limits.