Cutter Diameter To Depth Ratio . Mikehalloran (mechanical) 7 feb 15 03:37. The depth of cut is derived from. Designers measure the depth of cut values in millimeters or inches, which ranges from 0.1 to 1mm. The feed rate is calculated based on the feed per tooth, spindle speed, and the number of cutter teeth. Every machining operation entails a radial and axial depth of cut strategy. The cutter diameter (d c) is measured over the point (pk), where the main cutting edge meets the parallel land. The most important diameter to. A good rule of thumb is to add space equal to at least four times the depth of the undercut between the machined wall and any other internal wall. Depth of cut (doc) in machining. Three or four diameters of extension from the collet face makes pocketing easy; Radial depth of cut (rdoc), the distance a tool is stepping over into a workpiece; Depth of cut and stepover (width of cut) are crucial variables when milling pockets, profiling, facing, and any other machining operation where you’ll be cutting with the flutes on.

from www.mscdirect.com

Three or four diameters of extension from the collet face makes pocketing easy; The feed rate is calculated based on the feed per tooth, spindle speed, and the number of cutter teeth. Depth of cut and stepover (width of cut) are crucial variables when milling pockets, profiling, facing, and any other machining operation where you’ll be cutting with the flutes on. Depth of cut (doc) in machining. Designers measure the depth of cut values in millimeters or inches, which ranges from 0.1 to 1mm. The most important diameter to. The depth of cut is derived from. The cutter diameter (d c) is measured over the point (pk), where the main cutting edge meets the parallel land. A good rule of thumb is to add space equal to at least four times the depth of the undercut between the machined wall and any other internal wall. Every machining operation entails a radial and axial depth of cut strategy.

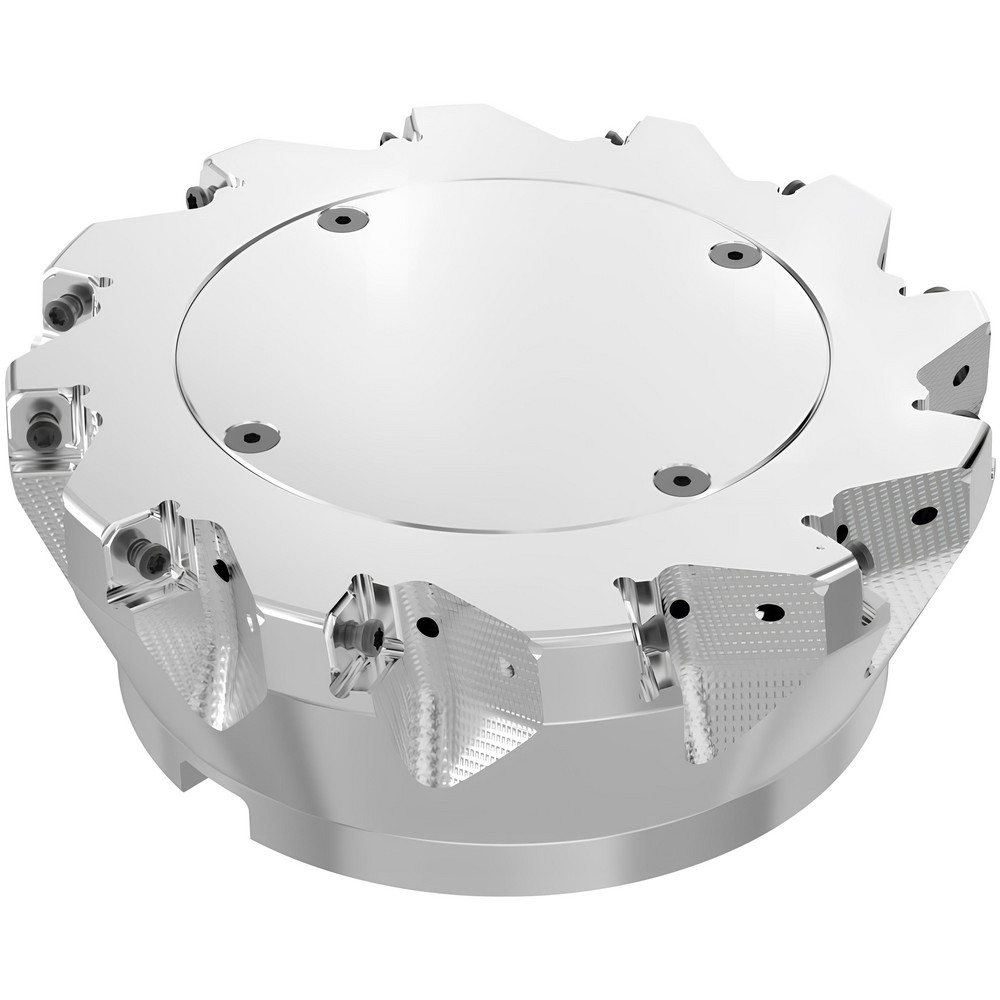

Seco Indexable Chamfer & Angle Face Mills; Minimum Cutting Diameter

Cutter Diameter To Depth Ratio The most important diameter to. Radial depth of cut (rdoc), the distance a tool is stepping over into a workpiece; Mikehalloran (mechanical) 7 feb 15 03:37. Every machining operation entails a radial and axial depth of cut strategy. Designers measure the depth of cut values in millimeters or inches, which ranges from 0.1 to 1mm. A good rule of thumb is to add space equal to at least four times the depth of the undercut between the machined wall and any other internal wall. Three or four diameters of extension from the collet face makes pocketing easy; The feed rate is calculated based on the feed per tooth, spindle speed, and the number of cutter teeth. Depth of cut (doc) in machining. Depth of cut and stepover (width of cut) are crucial variables when milling pockets, profiling, facing, and any other machining operation where you’ll be cutting with the flutes on. The most important diameter to. The depth of cut is derived from. The cutter diameter (d c) is measured over the point (pk), where the main cutting edge meets the parallel land.

From www.researchgate.net

Evolution of maximum depth of cut at various damping ratios for the 45 Cutter Diameter To Depth Ratio Mikehalloran (mechanical) 7 feb 15 03:37. Three or four diameters of extension from the collet face makes pocketing easy; Designers measure the depth of cut values in millimeters or inches, which ranges from 0.1 to 1mm. The depth of cut is derived from. The most important diameter to. The cutter diameter (d c) is measured over the point (pk), where. Cutter Diameter To Depth Ratio.

From www.mscdirect.com

Seco Indexable Chamfer & Angle Face Mills; Minimum Cutting Diameter Cutter Diameter To Depth Ratio Depth of cut (doc) in machining. Designers measure the depth of cut values in millimeters or inches, which ranges from 0.1 to 1mm. The most important diameter to. Three or four diameters of extension from the collet face makes pocketing easy; Mikehalloran (mechanical) 7 feb 15 03:37. The feed rate is calculated based on the feed per tooth, spindle speed,. Cutter Diameter To Depth Ratio.

From www.peaktoolworks.com

METRIC THREADMILLS Peak Toolworks Cutter Diameter To Depth Ratio Depth of cut and stepover (width of cut) are crucial variables when milling pockets, profiling, facing, and any other machining operation where you’ll be cutting with the flutes on. Every machining operation entails a radial and axial depth of cut strategy. Radial depth of cut (rdoc), the distance a tool is stepping over into a workpiece; Mikehalloran (mechanical) 7 feb. Cutter Diameter To Depth Ratio.

From www.youtube.com

THREAD CUTTING GEAR CALCULATION FORMULA ON LATHE M/C IN हिंदी YouTube Cutter Diameter To Depth Ratio The feed rate is calculated based on the feed per tooth, spindle speed, and the number of cutter teeth. The most important diameter to. Depth of cut (doc) in machining. Radial depth of cut (rdoc), the distance a tool is stepping over into a workpiece; The depth of cut is derived from. Every machining operation entails a radial and axial. Cutter Diameter To Depth Ratio.

From tillescenter.org

18mm Diameter x 50mm Depth of Cut HSS Steelmax SMAC18M2 Annular Cutter Diameter To Depth Ratio Designers measure the depth of cut values in millimeters or inches, which ranges from 0.1 to 1mm. Radial depth of cut (rdoc), the distance a tool is stepping over into a workpiece; The most important diameter to. The feed rate is calculated based on the feed per tooth, spindle speed, and the number of cutter teeth. Depth of cut (doc). Cutter Diameter To Depth Ratio.

From www.mscdirect.com

Widia Indexable Chamfer & Angle Face Mills; Minimum Cutting Diameter Cutter Diameter To Depth Ratio The cutter diameter (d c) is measured over the point (pk), where the main cutting edge meets the parallel land. The feed rate is calculated based on the feed per tooth, spindle speed, and the number of cutter teeth. The depth of cut is derived from. Three or four diameters of extension from the collet face makes pocketing easy; A. Cutter Diameter To Depth Ratio.

From engineeringlearn.com

Types of Milling Cutter Tools and Their Uses [with Pictures Cutter Diameter To Depth Ratio Designers measure the depth of cut values in millimeters or inches, which ranges from 0.1 to 1mm. The feed rate is calculated based on the feed per tooth, spindle speed, and the number of cutter teeth. Mikehalloran (mechanical) 7 feb 15 03:37. The most important diameter to. Three or four diameters of extension from the collet face makes pocketing easy;. Cutter Diameter To Depth Ratio.

From solidcam.help

Drilling Operation Levels page Cutter Diameter To Depth Ratio Radial depth of cut (rdoc), the distance a tool is stepping over into a workpiece; Designers measure the depth of cut values in millimeters or inches, which ranges from 0.1 to 1mm. A good rule of thumb is to add space equal to at least four times the depth of the undercut between the machined wall and any other internal. Cutter Diameter To Depth Ratio.

From www.youtube.com

02_04_P3 Calculating Cutting Speed, Feed, and Machining Time for Cutter Diameter To Depth Ratio Every machining operation entails a radial and axial depth of cut strategy. Depth of cut and stepover (width of cut) are crucial variables when milling pockets, profiling, facing, and any other machining operation where you’ll be cutting with the flutes on. A good rule of thumb is to add space equal to at least four times the depth of the. Cutter Diameter To Depth Ratio.

From www.mscdirect.com

Seco Indexable Chamfer & Angle Face Mills; Minimum Cutting Diameter Cutter Diameter To Depth Ratio Radial depth of cut (rdoc), the distance a tool is stepping over into a workpiece; The depth of cut is derived from. Depth of cut (doc) in machining. Designers measure the depth of cut values in millimeters or inches, which ranges from 0.1 to 1mm. The feed rate is calculated based on the feed per tooth, spindle speed, and the. Cutter Diameter To Depth Ratio.

From simmonslosonfere.blogspot.com

Ball Nose End Mill Speeds and Feeds Simmons Losonfere Cutter Diameter To Depth Ratio Designers measure the depth of cut values in millimeters or inches, which ranges from 0.1 to 1mm. Depth of cut and stepover (width of cut) are crucial variables when milling pockets, profiling, facing, and any other machining operation where you’ll be cutting with the flutes on. The cutter diameter (d c) is measured over the point (pk), where the main. Cutter Diameter To Depth Ratio.

From www.mscdirect.com

Seco Indexable Chamfer & Angle Face Mills; Minimum Cutting Diameter Cutter Diameter To Depth Ratio Depth of cut (doc) in machining. Every machining operation entails a radial and axial depth of cut strategy. The feed rate is calculated based on the feed per tooth, spindle speed, and the number of cutter teeth. Three or four diameters of extension from the collet face makes pocketing easy; The cutter diameter (d c) is measured over the point. Cutter Diameter To Depth Ratio.

From www.routerforums.com

cutter diameter vs cut depth Router Forums Cutter Diameter To Depth Ratio The most important diameter to. The depth of cut is derived from. A good rule of thumb is to add space equal to at least four times the depth of the undercut between the machined wall and any other internal wall. Designers measure the depth of cut values in millimeters or inches, which ranges from 0.1 to 1mm. Radial depth. Cutter Diameter To Depth Ratio.

From www.chegg.com

Solved Assume that a facemilling operation shown in Fig Cutter Diameter To Depth Ratio Depth of cut and stepover (width of cut) are crucial variables when milling pockets, profiling, facing, and any other machining operation where you’ll be cutting with the flutes on. The depth of cut is derived from. A good rule of thumb is to add space equal to at least four times the depth of the undercut between the machined wall. Cutter Diameter To Depth Ratio.

From www.mscdirect.com

Seco Indexable Chamfer & Angle Face Mills; Minimum Cutting Diameter Cutter Diameter To Depth Ratio The feed rate is calculated based on the feed per tooth, spindle speed, and the number of cutter teeth. A good rule of thumb is to add space equal to at least four times the depth of the undercut between the machined wall and any other internal wall. The cutter diameter (d c) is measured over the point (pk), where. Cutter Diameter To Depth Ratio.

From slideplayer.com

Cutting diameter tolerances 1/32" through 31/64" ", ppt download Cutter Diameter To Depth Ratio Every machining operation entails a radial and axial depth of cut strategy. Depth of cut and stepover (width of cut) are crucial variables when milling pockets, profiling, facing, and any other machining operation where you’ll be cutting with the flutes on. Three or four diameters of extension from the collet face makes pocketing easy; The cutter diameter (d c) is. Cutter Diameter To Depth Ratio.

From www.mscdirect.com

Seco Indexable Chamfer & Angle Face Mills; Minimum Cutting Diameter Cutter Diameter To Depth Ratio The most important diameter to. A good rule of thumb is to add space equal to at least four times the depth of the undercut between the machined wall and any other internal wall. Every machining operation entails a radial and axial depth of cut strategy. Depth of cut and stepover (width of cut) are crucial variables when milling pockets,. Cutter Diameter To Depth Ratio.

From www.speedtigertools.com

End Mill Size Standards Chart & IntroductionSPEED TIGER Cutter Diameter To Depth Ratio Radial depth of cut (rdoc), the distance a tool is stepping over into a workpiece; Designers measure the depth of cut values in millimeters or inches, which ranges from 0.1 to 1mm. Depth of cut (doc) in machining. Depth of cut and stepover (width of cut) are crucial variables when milling pockets, profiling, facing, and any other machining operation where. Cutter Diameter To Depth Ratio.

From www.carbideanddiamondtooling.com

Annular Cutter 4 Inch Depth of Cut 3/4 to 4 Inch Diameter HSS 94SE Cutter Diameter To Depth Ratio A good rule of thumb is to add space equal to at least four times the depth of the undercut between the machined wall and any other internal wall. The cutter diameter (d c) is measured over the point (pk), where the main cutting edge meets the parallel land. Radial depth of cut (rdoc), the distance a tool is stepping. Cutter Diameter To Depth Ratio.

From www.mscdirect.com

Seco Indexable Chamfer & Angle Face Mills; Minimum Cutting Diameter Cutter Diameter To Depth Ratio The depth of cut is derived from. Mikehalloran (mechanical) 7 feb 15 03:37. Every machining operation entails a radial and axial depth of cut strategy. A good rule of thumb is to add space equal to at least four times the depth of the undercut between the machined wall and any other internal wall. Radial depth of cut (rdoc), the. Cutter Diameter To Depth Ratio.

From au.rs-online.com

H1810460 Sutton Tools HSS 46mm Cutting Diameter Drilling Cutter Diameter To Depth Ratio A good rule of thumb is to add space equal to at least four times the depth of the undercut between the machined wall and any other internal wall. Mikehalloran (mechanical) 7 feb 15 03:37. Every machining operation entails a radial and axial depth of cut strategy. Depth of cut and stepover (width of cut) are crucial variables when milling. Cutter Diameter To Depth Ratio.

From easyjoint.en.made-in-china.com

8PCS HSS Annular Cutter Set, 7/16" to 3/4" Cutting Diameter X 1 Cutter Diameter To Depth Ratio A good rule of thumb is to add space equal to at least four times the depth of the undercut between the machined wall and any other internal wall. Every machining operation entails a radial and axial depth of cut strategy. Radial depth of cut (rdoc), the distance a tool is stepping over into a workpiece; The feed rate is. Cutter Diameter To Depth Ratio.

From www.mscdirect.com

Ceratizit Indexable SquareShoulder End Mills; Minimum Cutting Cutter Diameter To Depth Ratio Radial depth of cut (rdoc), the distance a tool is stepping over into a workpiece; Depth of cut (doc) in machining. The depth of cut is derived from. The feed rate is calculated based on the feed per tooth, spindle speed, and the number of cutter teeth. Depth of cut and stepover (width of cut) are crucial variables when milling. Cutter Diameter To Depth Ratio.

From www.jlwranglerforums.com

Ok to mix and match Ring and Pinion Brands? Jeep Wrangler Forums (JL Cutter Diameter To Depth Ratio The cutter diameter (d c) is measured over the point (pk), where the main cutting edge meets the parallel land. The most important diameter to. Every machining operation entails a radial and axial depth of cut strategy. Depth of cut (doc) in machining. Three or four diameters of extension from the collet face makes pocketing easy; The depth of cut. Cutter Diameter To Depth Ratio.

From www.alibaba.com

35mm And 50mm Cutting Depth Weldon And Universal Shank Tct Annular Cutter Diameter To Depth Ratio Every machining operation entails a radial and axial depth of cut strategy. Depth of cut and stepover (width of cut) are crucial variables when milling pockets, profiling, facing, and any other machining operation where you’ll be cutting with the flutes on. The feed rate is calculated based on the feed per tooth, spindle speed, and the number of cutter teeth.. Cutter Diameter To Depth Ratio.

From www.vevor.ca

VEVOR Annular Cutter Set, 6 pcs 3/4" Weldon Shank, 2" Cutting Depth and Cutter Diameter To Depth Ratio The cutter diameter (d c) is measured over the point (pk), where the main cutting edge meets the parallel land. Radial depth of cut (rdoc), the distance a tool is stepping over into a workpiece; Mikehalloran (mechanical) 7 feb 15 03:37. Depth of cut and stepover (width of cut) are crucial variables when milling pockets, profiling, facing, and any other. Cutter Diameter To Depth Ratio.

From www.yandles.co.uk

1/2' corner bead cutter, diameter 31.9mm, depth of cutter 22.5mm Cutter Diameter To Depth Ratio Depth of cut (doc) in machining. Radial depth of cut (rdoc), the distance a tool is stepping over into a workpiece; Mikehalloran (mechanical) 7 feb 15 03:37. The feed rate is calculated based on the feed per tooth, spindle speed, and the number of cutter teeth. Every machining operation entails a radial and axial depth of cut strategy. Three or. Cutter Diameter To Depth Ratio.

From www.mscdirect.com

Tungaloy Indexable SquareShoulder End Mills; Minimum Cutting Cutter Diameter To Depth Ratio Depth of cut (doc) in machining. A good rule of thumb is to add space equal to at least four times the depth of the undercut between the machined wall and any other internal wall. The cutter diameter (d c) is measured over the point (pk), where the main cutting edge meets the parallel land. Three or four diameters of. Cutter Diameter To Depth Ratio.

From www.redlinetools.com

Endmill Selection Guide RedLine Tools Redline Tools Cutter Diameter To Depth Ratio Three or four diameters of extension from the collet face makes pocketing easy; Designers measure the depth of cut values in millimeters or inches, which ranges from 0.1 to 1mm. Depth of cut and stepover (width of cut) are crucial variables when milling pockets, profiling, facing, and any other machining operation where you’ll be cutting with the flutes on. The. Cutter Diameter To Depth Ratio.

From www.chegg.com

Solved '1. A face milling cutter of diameter D is used to Cutter Diameter To Depth Ratio Three or four diameters of extension from the collet face makes pocketing easy; The feed rate is calculated based on the feed per tooth, spindle speed, and the number of cutter teeth. Depth of cut (doc) in machining. The depth of cut is derived from. A good rule of thumb is to add space equal to at least four times. Cutter Diameter To Depth Ratio.

From www.mscdirect.com

Seco Indexable Chamfer & Angle Face Mills; Minimum Cutting Diameter Cutter Diameter To Depth Ratio The most important diameter to. Depth of cut (doc) in machining. Designers measure the depth of cut values in millimeters or inches, which ranges from 0.1 to 1mm. The depth of cut is derived from. Three or four diameters of extension from the collet face makes pocketing easy; Depth of cut and stepover (width of cut) are crucial variables when. Cutter Diameter To Depth Ratio.

From www.mscdirect.com

Kyocera Indexable Chamfer & Angle End Mills; Cutting Diameter Cutter Diameter To Depth Ratio Designers measure the depth of cut values in millimeters or inches, which ranges from 0.1 to 1mm. A good rule of thumb is to add space equal to at least four times the depth of the undercut between the machined wall and any other internal wall. Depth of cut (doc) in machining. The cutter diameter (d c) is measured over. Cutter Diameter To Depth Ratio.

From my.misumi-ec.com

Milling Tips / Holders Ball End Mills Technical Information Tools Cutter Diameter To Depth Ratio Designers measure the depth of cut values in millimeters or inches, which ranges from 0.1 to 1mm. Radial depth of cut (rdoc), the distance a tool is stepping over into a workpiece; Mikehalloran (mechanical) 7 feb 15 03:37. Depth of cut (doc) in machining. The feed rate is calculated based on the feed per tooth, spindle speed, and the number. Cutter Diameter To Depth Ratio.

From www.routerforums.com

cutter diameter vs cut depth Router Forums Cutter Diameter To Depth Ratio Three or four diameters of extension from the collet face makes pocketing easy; The depth of cut is derived from. Depth of cut (doc) in machining. Radial depth of cut (rdoc), the distance a tool is stepping over into a workpiece; The feed rate is calculated based on the feed per tooth, spindle speed, and the number of cutter teeth.. Cutter Diameter To Depth Ratio.

From www.mscdirect.com

Komet Indexable Countersinks; Included Angle 90.00; Maximum Cutting Cutter Diameter To Depth Ratio The cutter diameter (d c) is measured over the point (pk), where the main cutting edge meets the parallel land. Radial depth of cut (rdoc), the distance a tool is stepping over into a workpiece; Depth of cut (doc) in machining. Every machining operation entails a radial and axial depth of cut strategy. The depth of cut is derived from.. Cutter Diameter To Depth Ratio.