Solder Wire To Pcb Pad . A solution that i share is to pretin both the pad and the wire with the solder, using a flux. Soldering wire to pcb pad. You heat the wire and pcb pad, melting the solder wire and. The pcb pad and wire go through heating, while the solder. You attach wires to printed circuit boards (pcb) in a process called soldering. Using hot bar reflow soldering to join a tin coated copper. Dip the wire in the flux. I'd probably use small 30 gauge wire wrap wire. With the updated picture, i. By using solder with flux (however you achieve that), it should be easy to solder small wires to the pads. Is there a standard that gives the hole and pad size for soldering a wire to a pcb? If your component pins are not long enough, you can use a thin wire of good solder through the pad holes and solder to the component pins, and the other end to the pad connector and fix it with hot melt adhesive to prevent the The lead tin alloy is the solder wire type suitable for this process. Attaching wires to the circuit board is through a process called soldering. To pretin the wire, i suggest melting some of the solder in a crucible or solder pot.

from www.theengineeringknowledge.com

The pcb pad and wire go through heating, while the solder. You heat the wire and pcb pad, melting the solder wire and. Soldering wire to pcb pad. You attach wires to printed circuit boards (pcb) in a process called soldering. A solution that i share is to pretin both the pad and the wire with the solder, using a flux. Using hot bar reflow soldering to join a tin coated copper. To pretin the wire, i suggest melting some of the solder in a crucible or solder pot. By using solder with flux (however you achieve that), it should be easy to solder small wires to the pads. With the updated picture, i. Dip the wire in the flux.

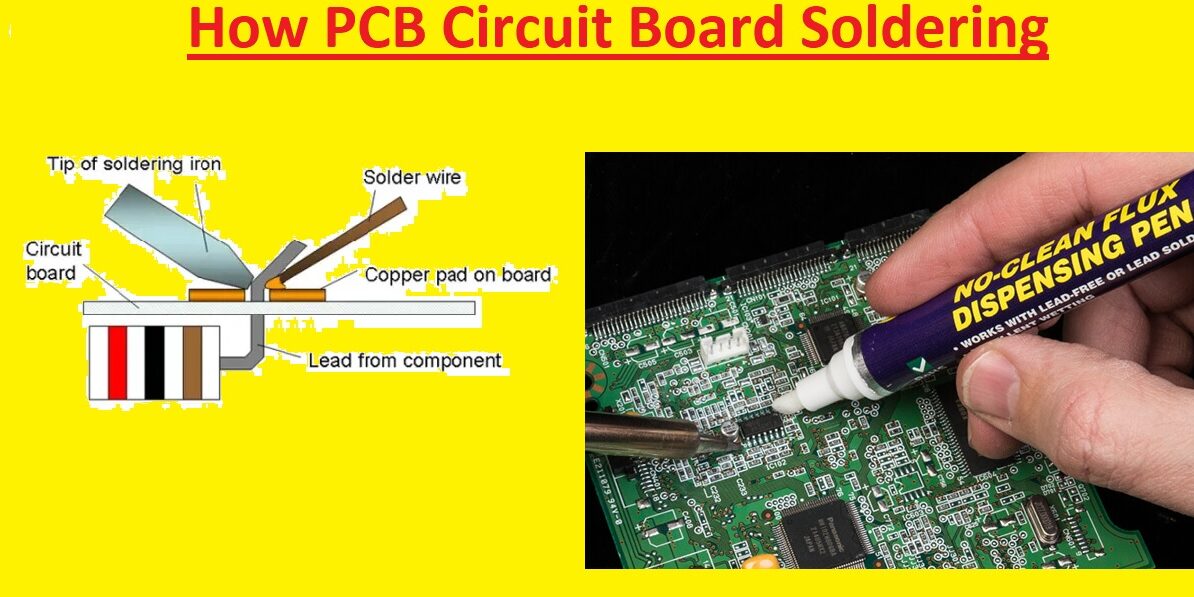

Learn How PCB Circuit Board Soldering Guide for Beginners

Solder Wire To Pcb Pad Dip the wire in the flux. To pretin the wire, i suggest melting some of the solder in a crucible or solder pot. I'd probably use small 30 gauge wire wrap wire. The pcb pad and wire go through heating, while the solder. Soldering wire to pcb pad. If your component pins are not long enough, you can use a thin wire of good solder through the pad holes and solder to the component pins, and the other end to the pad connector and fix it with hot melt adhesive to prevent the With the updated picture, i. Attaching wires to the circuit board is through a process called soldering. Dip the wire in the flux. Using hot bar reflow soldering to join a tin coated copper. Is there a standard that gives the hole and pad size for soldering a wire to a pcb? A solution that i share is to pretin both the pad and the wire with the solder, using a flux. By using solder with flux (however you achieve that), it should be easy to solder small wires to the pads. The lead tin alloy is the solder wire type suitable for this process. You attach wires to printed circuit boards (pcb) in a process called soldering. You heat the wire and pcb pad, melting the solder wire and.

From www.hartmann.gs

Soldering of single stranded wires on a PCB Hartmann.gs Mobile Solder Wire To Pcb Pad The pcb pad and wire go through heating, while the solder. With the updated picture, i. Dip the wire in the flux. To pretin the wire, i suggest melting some of the solder in a crucible or solder pot. By using solder with flux (however you achieve that), it should be easy to solder small wires to the pads. Is. Solder Wire To Pcb Pad.

From www.youtube.com

How to Solder a Wire to a Circuit Board YouTube Solder Wire To Pcb Pad You heat the wire and pcb pad, melting the solder wire and. The lead tin alloy is the solder wire type suitable for this process. I'd probably use small 30 gauge wire wrap wire. With the updated picture, i. Soldering wire to pcb pad. If your component pins are not long enough, you can use a thin wire of good. Solder Wire To Pcb Pad.

From learn.sparkfun.com

Working with Wire SparkFun Learn Solder Wire To Pcb Pad With the updated picture, i. By using solder with flux (however you achieve that), it should be easy to solder small wires to the pads. Using hot bar reflow soldering to join a tin coated copper. If your component pins are not long enough, you can use a thin wire of good solder through the pad holes and solder to. Solder Wire To Pcb Pad.

From www.pcbway.com

How to Solder PCB Engineering Technical PCBway Solder Wire To Pcb Pad Is there a standard that gives the hole and pad size for soldering a wire to a pcb? A solution that i share is to pretin both the pad and the wire with the solder, using a flux. Attaching wires to the circuit board is through a process called soldering. By using solder with flux (however you achieve that), it. Solder Wire To Pcb Pad.

From electronics.stackexchange.com

connector What is the best way to solder these wires to circuit board Solder Wire To Pcb Pad With the updated picture, i. Using hot bar reflow soldering to join a tin coated copper. Dip the wire in the flux. Soldering wire to pcb pad. The lead tin alloy is the solder wire type suitable for this process. The pcb pad and wire go through heating, while the solder. To pretin the wire, i suggest melting some of. Solder Wire To Pcb Pad.

From electronics.stackexchange.com

soldering White solder pads on throughhole PCB Electrical Solder Wire To Pcb Pad Soldering wire to pcb pad. You attach wires to printed circuit boards (pcb) in a process called soldering. Attaching wires to the circuit board is through a process called soldering. By using solder with flux (however you achieve that), it should be easy to solder small wires to the pads. You heat the wire and pcb pad, melting the solder. Solder Wire To Pcb Pad.

From www.youtube.com

East Bay RC Soldering Guide, Part 7 Wires and Solder Pads YouTube Solder Wire To Pcb Pad Using hot bar reflow soldering to join a tin coated copper. To pretin the wire, i suggest melting some of the solder in a crucible or solder pot. The lead tin alloy is the solder wire type suitable for this process. With the updated picture, i. You heat the wire and pcb pad, melting the solder wire and. A solution. Solder Wire To Pcb Pad.

From www.pcbaaa.com

The complete guide to PCB pad :types, size, spacing, repair and Solder Wire To Pcb Pad Dip the wire in the flux. By using solder with flux (however you achieve that), it should be easy to solder small wires to the pads. The pcb pad and wire go through heating, while the solder. Soldering wire to pcb pad. Attaching wires to the circuit board is through a process called soldering. You attach wires to printed circuit. Solder Wire To Pcb Pad.

From www.hartmann.gs

Soldering of single stranded wires on a PCB Hartmann.gs Mobile Solder Wire To Pcb Pad Soldering wire to pcb pad. You attach wires to printed circuit boards (pcb) in a process called soldering. You heat the wire and pcb pad, melting the solder wire and. Is there a standard that gives the hole and pad size for soldering a wire to a pcb? The pcb pad and wire go through heating, while the solder. Using. Solder Wire To Pcb Pad.

From electronics.stackexchange.com

soldering How to solder stainless steel electrode to PCB pad Solder Wire To Pcb Pad Dip the wire in the flux. A solution that i share is to pretin both the pad and the wire with the solder, using a flux. You attach wires to printed circuit boards (pcb) in a process called soldering. Using hot bar reflow soldering to join a tin coated copper. The pcb pad and wire go through heating, while the. Solder Wire To Pcb Pad.

From hillmancurtis.com

How to Solder Wire to PCB Solder Wire To Pcb Pad The lead tin alloy is the solder wire type suitable for this process. You heat the wire and pcb pad, melting the solder wire and. Dip the wire in the flux. To pretin the wire, i suggest melting some of the solder in a crucible or solder pot. A solution that i share is to pretin both the pad and. Solder Wire To Pcb Pad.

From itecnotes.com

Electronic How To Repair Ripped Off Solder Pad On PCB Valuable Tech Solder Wire To Pcb Pad Soldering wire to pcb pad. By using solder with flux (however you achieve that), it should be easy to solder small wires to the pads. Using hot bar reflow soldering to join a tin coated copper. Dip the wire in the flux. Attaching wires to the circuit board is through a process called soldering. I'd probably use small 30 gauge. Solder Wire To Pcb Pad.

From oscarliang.com

Soldering Guide for RC Quadcopter Beginners Oscar Liang Solder Wire To Pcb Pad By using solder with flux (however you achieve that), it should be easy to solder small wires to the pads. The lead tin alloy is the solder wire type suitable for this process. A solution that i share is to pretin both the pad and the wire with the solder, using a flux. The pcb pad and wire go through. Solder Wire To Pcb Pad.

From www.youtube.com

Welding Wire to PCB Pad YouTube Solder Wire To Pcb Pad The pcb pad and wire go through heating, while the solder. The lead tin alloy is the solder wire type suitable for this process. You heat the wire and pcb pad, melting the solder wire and. I'd probably use small 30 gauge wire wrap wire. Is there a standard that gives the hole and pad size for soldering a wire. Solder Wire To Pcb Pad.

From www.youtube.com

How to Solder on PCB properly Soldering Techniques for Beginners Solder Wire To Pcb Pad I'd probably use small 30 gauge wire wrap wire. Using hot bar reflow soldering to join a tin coated copper. To pretin the wire, i suggest melting some of the solder in a crucible or solder pot. A solution that i share is to pretin both the pad and the wire with the solder, using a flux. Is there a. Solder Wire To Pcb Pad.

From itecnotes.com

Electronic How To Repair Ripped Off Solder Pad On PCB Valuable Tech Solder Wire To Pcb Pad With the updated picture, i. Soldering wire to pcb pad. If your component pins are not long enough, you can use a thin wire of good solder through the pad holes and solder to the component pins, and the other end to the pad connector and fix it with hot melt adhesive to prevent the You attach wires to printed. Solder Wire To Pcb Pad.

From www.youtube.com

IoT32 RPTCQ Soldering Flat Flex to PCB LCD Initial Power Up and Solder Wire To Pcb Pad You attach wires to printed circuit boards (pcb) in a process called soldering. Is there a standard that gives the hole and pad size for soldering a wire to a pcb? You heat the wire and pcb pad, melting the solder wire and. Attaching wires to the circuit board is through a process called soldering. If your component pins are. Solder Wire To Pcb Pad.

From qtech-us.com

The complete guide to PCB pad :types, size, spacing, repair and Solder Wire To Pcb Pad Is there a standard that gives the hole and pad size for soldering a wire to a pcb? You heat the wire and pcb pad, melting the solder wire and. Using hot bar reflow soldering to join a tin coated copper. By using solder with flux (however you achieve that), it should be easy to solder small wires to the. Solder Wire To Pcb Pad.

From www.pcba-manufacturers.com

The ultimate approach to PCB wiring PCBA Manufacturers Solder Wire To Pcb Pad To pretin the wire, i suggest melting some of the solder in a crucible or solder pot. You heat the wire and pcb pad, melting the solder wire and. I'd probably use small 30 gauge wire wrap wire. You attach wires to printed circuit boards (pcb) in a process called soldering. By using solder with flux (however you achieve that),. Solder Wire To Pcb Pad.

From www.circuits-diy.com

PCB Soldering Techniques & Best Practices For Absolute Beginners Solder Wire To Pcb Pad Dip the wire in the flux. Using hot bar reflow soldering to join a tin coated copper. Soldering wire to pcb pad. I'd probably use small 30 gauge wire wrap wire. Is there a standard that gives the hole and pad size for soldering a wire to a pcb? If your component pins are not long enough, you can use. Solder Wire To Pcb Pad.

From reversepcb.com

Solder Pad Basics Knowledge and Extra Tips Reversepcb Solder Wire To Pcb Pad Is there a standard that gives the hole and pad size for soldering a wire to a pcb? The lead tin alloy is the solder wire type suitable for this process. A solution that i share is to pretin both the pad and the wire with the solder, using a flux. I'd probably use small 30 gauge wire wrap wire.. Solder Wire To Pcb Pad.

From www.hartmann.gs

Soldering of single stranded wires on a PCB Hartmann.gs Mobile Solder Wire To Pcb Pad Dip the wire in the flux. Using hot bar reflow soldering to join a tin coated copper. You attach wires to printed circuit boards (pcb) in a process called soldering. To pretin the wire, i suggest melting some of the solder in a crucible or solder pot. Attaching wires to the circuit board is through a process called soldering. If. Solder Wire To Pcb Pad.

From hillmancurtis.com

How to Solder Wire to PCB Solder Wire To Pcb Pad You heat the wire and pcb pad, melting the solder wire and. By using solder with flux (however you achieve that), it should be easy to solder small wires to the pads. A solution that i share is to pretin both the pad and the wire with the solder, using a flux. Attaching wires to the circuit board is through. Solder Wire To Pcb Pad.

From www.header-connector.com

PCB Wire To Board Solder Connector 10 Pin 2.54mm Pitch Gold Contact Plating Solder Wire To Pcb Pad The lead tin alloy is the solder wire type suitable for this process. I'd probably use small 30 gauge wire wrap wire. Attaching wires to the circuit board is through a process called soldering. By using solder with flux (however you achieve that), it should be easy to solder small wires to the pads. The pcb pad and wire go. Solder Wire To Pcb Pad.

From pcbdesign.netlify.app

Pcb Solder Pad Solder Wire To Pcb Pad With the updated picture, i. You heat the wire and pcb pad, melting the solder wire and. The lead tin alloy is the solder wire type suitable for this process. Attaching wires to the circuit board is through a process called soldering. Soldering wire to pcb pad. Using hot bar reflow soldering to join a tin coated copper. By using. Solder Wire To Pcb Pad.

From www.naa.edu

Essential Avionics Tools for a New Technician National Aviation Academy Solder Wire To Pcb Pad If your component pins are not long enough, you can use a thin wire of good solder through the pad holes and solder to the component pins, and the other end to the pad connector and fix it with hot melt adhesive to prevent the To pretin the wire, i suggest melting some of the solder in a crucible or. Solder Wire To Pcb Pad.

From www.pcbway.com

How to Solder PCB Engineering Technical PCBway Solder Wire To Pcb Pad The pcb pad and wire go through heating, while the solder. Attaching wires to the circuit board is through a process called soldering. To pretin the wire, i suggest melting some of the solder in a crucible or solder pot. Is there a standard that gives the hole and pad size for soldering a wire to a pcb? The lead. Solder Wire To Pcb Pad.

From www.youtube.com

Electronics for beginners How to solder wires to a circuit board Solder Wire To Pcb Pad The pcb pad and wire go through heating, while the solder. Using hot bar reflow soldering to join a tin coated copper. To pretin the wire, i suggest melting some of the solder in a crucible or solder pot. I'd probably use small 30 gauge wire wrap wire. Attaching wires to the circuit board is through a process called soldering.. Solder Wire To Pcb Pad.

From www.youtube.com

Soldering a 12 AWG wire to a gold plated pad YouTube Solder Wire To Pcb Pad Using hot bar reflow soldering to join a tin coated copper. I'd probably use small 30 gauge wire wrap wire. The pcb pad and wire go through heating, while the solder. If your component pins are not long enough, you can use a thin wire of good solder through the pad holes and solder to the component pins, and the. Solder Wire To Pcb Pad.

From www.youtube.com

How to Solder Wires Properly on PCB YouTube Solder Wire To Pcb Pad Using hot bar reflow soldering to join a tin coated copper. Soldering wire to pcb pad. A solution that i share is to pretin both the pad and the wire with the solder, using a flux. Attaching wires to the circuit board is through a process called soldering. If your component pins are not long enough, you can use a. Solder Wire To Pcb Pad.

From pcbdesign.netlify.app

Pcb Solder Pad Solder Wire To Pcb Pad If your component pins are not long enough, you can use a thin wire of good solder through the pad holes and solder to the component pins, and the other end to the pad connector and fix it with hot melt adhesive to prevent the By using solder with flux (however you achieve that), it should be easy to solder. Solder Wire To Pcb Pad.

From www.theengineeringknowledge.com

Learn How PCB Circuit Board Soldering Guide for Beginners Solder Wire To Pcb Pad By using solder with flux (however you achieve that), it should be easy to solder small wires to the pads. Dip the wire in the flux. You heat the wire and pcb pad, melting the solder wire and. If your component pins are not long enough, you can use a thin wire of good solder through the pad holes and. Solder Wire To Pcb Pad.

From www.pcbway.com

How to Solder PCB Engineering Technical PCBway Solder Wire To Pcb Pad To pretin the wire, i suggest melting some of the solder in a crucible or solder pot. A solution that i share is to pretin both the pad and the wire with the solder, using a flux. Is there a standard that gives the hole and pad size for soldering a wire to a pcb? You heat the wire and. Solder Wire To Pcb Pad.

From learn.sparkfun.com

How to Work with Jumper Pads and PCB Traces SparkFun Learn Solder Wire To Pcb Pad You heat the wire and pcb pad, melting the solder wire and. The pcb pad and wire go through heating, while the solder. To pretin the wire, i suggest melting some of the solder in a crucible or solder pot. By using solder with flux (however you achieve that), it should be easy to solder small wires to the pads.. Solder Wire To Pcb Pad.

From toolsweek.com

How to Solder Wires to a Circuit Board (5 Steps) Solder Wire To Pcb Pad Soldering wire to pcb pad. A solution that i share is to pretin both the pad and the wire with the solder, using a flux. To pretin the wire, i suggest melting some of the solder in a crucible or solder pot. Dip the wire in the flux. By using solder with flux (however you achieve that), it should be. Solder Wire To Pcb Pad.