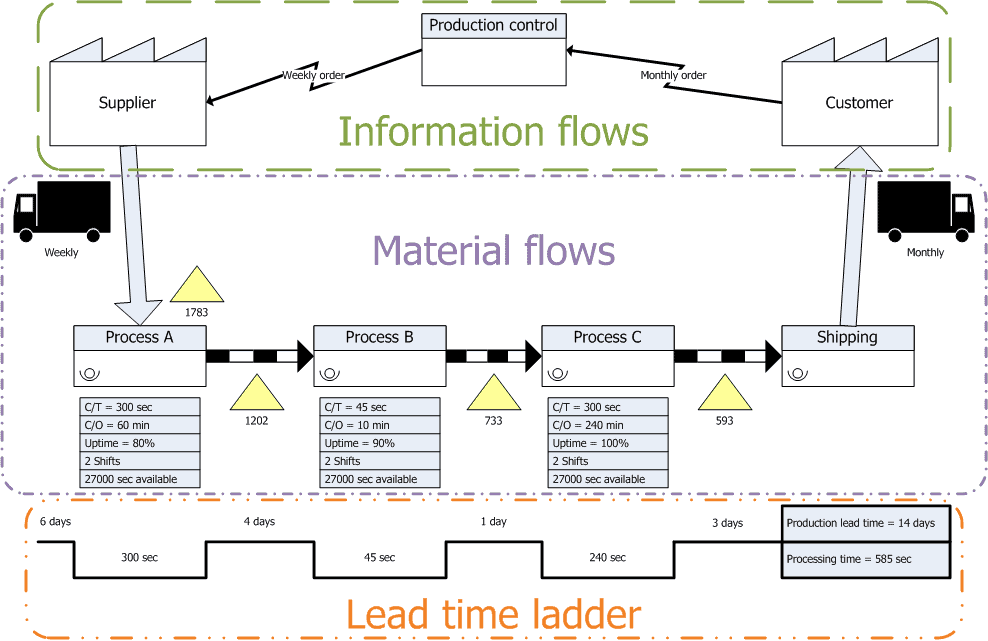

Vsm Symbols And Meaning . This guide provides a quick introduction to the basic standardized symbols for value stream mapping. In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history, benefits for product managers and examples of successful implementations. Originally introduced by the lean enterprise institute in. The pursuit towards a lean process starts. Value stream maps utilize a standard set of. Value stream mapping (vsm) is a valuable tool for process managers and teams alike. Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. Value stream mapping (vsm) is a lean manufacturing technique used to analyze, design, and manage the flow of materials and information required to bring a product to a customer.

from www.cnccookbook.com

The pursuit towards a lean process starts. Value stream mapping (vsm) is a lean manufacturing technique used to analyze, design, and manage the flow of materials and information required to bring a product to a customer. Value stream mapping (vsm) is a valuable tool for process managers and teams alike. Originally introduced by the lean enterprise institute in. This guide provides a quick introduction to the basic standardized symbols for value stream mapping. Value stream maps utilize a standard set of. Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history, benefits for product managers and examples of successful implementations.

Standard Work and Takt Time Lean Manufacturing Principles Part 5

Vsm Symbols And Meaning This guide provides a quick introduction to the basic standardized symbols for value stream mapping. Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. Value stream maps utilize a standard set of. Value stream mapping (vsm) is a valuable tool for process managers and teams alike. The pursuit towards a lean process starts. Originally introduced by the lean enterprise institute in. Value stream mapping (vsm) is a lean manufacturing technique used to analyze, design, and manage the flow of materials and information required to bring a product to a customer. This guide provides a quick introduction to the basic standardized symbols for value stream mapping. In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history, benefits for product managers and examples of successful implementations.

From www.youtube.com

VSM Symbols and Icons General, Process Flow, Information Flow Vsm Symbols And Meaning Value stream mapping (vsm) is a valuable tool for process managers and teams alike. This guide provides a quick introduction to the basic standardized symbols for value stream mapping. The pursuit towards a lean process starts. Originally introduced by the lean enterprise institute in. Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase. Vsm Symbols And Meaning.

From www.chegg.com

Solved 1.2 Symbols A VSM utilizes symbols to depict as well Vsm Symbols And Meaning Value stream mapping (vsm) is a valuable tool for process managers and teams alike. Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. The pursuit towards a lean process starts. In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history, benefits for product. Vsm Symbols And Meaning.

From www.pinterest.com

VSM Icons Pinterest Program evaluation Vsm Symbols And Meaning The pursuit towards a lean process starts. Value stream mapping (vsm) is a lean manufacturing technique used to analyze, design, and manage the flow of materials and information required to bring a product to a customer. Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. Originally introduced by the. Vsm Symbols And Meaning.

From www.atlassian.com

Value Stream Mapping Atlassian Vsm Symbols And Meaning Value stream mapping (vsm) is a valuable tool for process managers and teams alike. In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history, benefits for product managers and examples of successful implementations. Originally introduced by the lean enterprise institute in. This guide provides a quick introduction to the basic standardized symbols for value. Vsm Symbols And Meaning.

From www.goodyearrubber.com

VSM Symbols Goodyear Rubber Vsm Symbols And Meaning Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. Value stream mapping (vsm) is a lean manufacturing technique used to analyze, design, and manage the flow of materials and information required to bring a product to a customer. This guide provides a quick introduction to the basic standardized symbols. Vsm Symbols And Meaning.

From logowiki.net

VSM Visual Management Systems Logo, image, download logo Vsm Symbols And Meaning Value stream maps utilize a standard set of. Value stream mapping (vsm) is a lean manufacturing technique used to analyze, design, and manage the flow of materials and information required to bring a product to a customer. The pursuit towards a lean process starts. Originally introduced by the lean enterprise institute in. Value stream mapping (vsm) is a valuable tool. Vsm Symbols And Meaning.

From www.congress-intercultural.eu

Value Stream Mapping Ultimate Guide On VSM Creately Value, 42 OFF Vsm Symbols And Meaning Value stream mapping (vsm) is a lean manufacturing technique used to analyze, design, and manage the flow of materials and information required to bring a product to a customer. This guide provides a quick introduction to the basic standardized symbols for value stream mapping. Value stream maps utilize a standard set of. Value stream mapping (vsm) is a powerful tool. Vsm Symbols And Meaning.

From mavink.com

Vsm Symbols Ppt Vsm Symbols And Meaning Originally introduced by the lean enterprise institute in. Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history, benefits for product managers and examples of successful implementations. Value stream maps utilize a standard set. Vsm Symbols And Meaning.

From sixsigmadsi.com

10 Easy Steps to Complete a Value Stream Map (VSM) Vsm Symbols And Meaning This guide provides a quick introduction to the basic standardized symbols for value stream mapping. The pursuit towards a lean process starts. Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. Value stream mapping (vsm) is a valuable tool for process managers and teams alike. In this comprehensive guide,. Vsm Symbols And Meaning.

From www.youtube.com

VSM 2 How to build a VSM? Symbols and Steps YouTube Vsm Symbols And Meaning Originally introduced by the lean enterprise institute in. Value stream mapping (vsm) is a lean manufacturing technique used to analyze, design, and manage the flow of materials and information required to bring a product to a customer. The pursuit towards a lean process starts. Value stream maps utilize a standard set of. Value stream mapping (vsm) is a valuable tool. Vsm Symbols And Meaning.

From leanmanufacturing.online

Steps to create Value Stream Mapping Enhancing Your Business Performance Vsm Symbols And Meaning Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. Value stream maps utilize a standard set of. The pursuit towards a lean process starts. Value stream mapping (vsm) is a valuable tool for process managers and teams alike. In this comprehensive guide, we’ll dive into the ins and outs. Vsm Symbols And Meaning.

From sixsigmadsi.com

Lean Six Sigma Value Stream Map Online Training Vsm Symbols And Meaning Value stream maps utilize a standard set of. This guide provides a quick introduction to the basic standardized symbols for value stream mapping. Originally introduced by the lean enterprise institute in. Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. The pursuit towards a lean process starts. Value stream. Vsm Symbols And Meaning.

From www.youtube.com

VSM Symbols YouTube Vsm Symbols And Meaning Originally introduced by the lean enterprise institute in. Value stream mapping (vsm) is a valuable tool for process managers and teams alike. In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history, benefits for product managers and examples of successful implementations. The pursuit towards a lean process starts. Value stream mapping (vsm) is a. Vsm Symbols And Meaning.

From www.conceptdraw.com

VSM Template Value Stream Mapping Software Vsm Symbols And Meaning Originally introduced by the lean enterprise institute in. The pursuit towards a lean process starts. In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history, benefits for product managers and examples of successful implementations. This guide provides a quick introduction to the basic standardized symbols for value stream mapping. Value stream mapping (vsm) is. Vsm Symbols And Meaning.

From geekflare.com

7 Value Stream Mapping (VSM) Tools to Increase Efficiency and Sales Vsm Symbols And Meaning Value stream mapping (vsm) is a lean manufacturing technique used to analyze, design, and manage the flow of materials and information required to bring a product to a customer. This guide provides a quick introduction to the basic standardized symbols for value stream mapping. Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase. Vsm Symbols And Meaning.

From manager-jobs-management.blogspot.com

Value Stream Map advertising and marketing tools Vsm Symbols And Meaning Value stream maps utilize a standard set of. Value stream mapping (vsm) is a lean manufacturing technique used to analyze, design, and manage the flow of materials and information required to bring a product to a customer. This guide provides a quick introduction to the basic standardized symbols for value stream mapping. The pursuit towards a lean process starts. Value. Vsm Symbols And Meaning.

From www.pinterest.com

10 Easy Steps to Complete a Value Stream Map Value stream mapping Vsm Symbols And Meaning Originally introduced by the lean enterprise institute in. In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history, benefits for product managers and examples of successful implementations. Value stream maps utilize a standard set of. Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various. Vsm Symbols And Meaning.

From www.pinterest.co.uk

value stream mapping symbols and icons in QI Macros for Excel Value Vsm Symbols And Meaning Value stream mapping (vsm) is a valuable tool for process managers and teams alike. This guide provides a quick introduction to the basic standardized symbols for value stream mapping. Value stream mapping (vsm) is a lean manufacturing technique used to analyze, design, and manage the flow of materials and information required to bring a product to a customer. Value stream. Vsm Symbols And Meaning.

From userwiringarthromere.z13.web.core.windows.net

Vsm Symbols In Excel Vsm Symbols And Meaning In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history, benefits for product managers and examples of successful implementations. This guide provides a quick introduction to the basic standardized symbols for value stream mapping. The pursuit towards a lean process starts. Value stream mapping (vsm) is a powerful tool that is used to optimize. Vsm Symbols And Meaning.

From www.youtube.com

What is Value Stream Mapping ? How to create Simplified Value Stream Vsm Symbols And Meaning Value stream maps utilize a standard set of. Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. Value stream mapping (vsm) is a valuable tool for process managers and teams alike. This guide provides a quick introduction to the basic standardized symbols for value stream mapping. In this comprehensive. Vsm Symbols And Meaning.

From www.linkedin.com

Value Stream Mapping (VSM) A Simple Tool That Provides Remarkable Value Vsm Symbols And Meaning This guide provides a quick introduction to the basic standardized symbols for value stream mapping. Originally introduced by the lean enterprise institute in. Value stream mapping (vsm) is a valuable tool for process managers and teams alike. The pursuit towards a lean process starts. Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase. Vsm Symbols And Meaning.

From 19january2017snapshot.epa.gov

Lean & Environment Toolkit Appendix A Lean Practices EPA US EPA Vsm Symbols And Meaning Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. The pursuit towards a lean process starts. Value stream mapping (vsm) is a lean manufacturing technique used to analyze, design, and manage the flow of materials and information required to bring a product to a customer. In this comprehensive guide,. Vsm Symbols And Meaning.

From mungfali.com

VSM Symbols PPT Vsm Symbols And Meaning Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. Value stream maps utilize a standard set of. In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history, benefits for product managers and examples of successful implementations. The pursuit towards a lean process starts.. Vsm Symbols And Meaning.

From hubpages.com

How to Create a Value Stream Map Mapping your value stream VSM Vsm Symbols And Meaning Originally introduced by the lean enterprise institute in. Value stream maps utilize a standard set of. The pursuit towards a lean process starts. In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history, benefits for product managers and examples of successful implementations. This guide provides a quick introduction to the basic standardized symbols for. Vsm Symbols And Meaning.

From www.aiophotoz.com

Value Stream Mapping Symbols And Icons Value Stream Mapping Map Icons Vsm Symbols And Meaning The pursuit towards a lean process starts. Value stream mapping (vsm) is a lean manufacturing technique used to analyze, design, and manage the flow of materials and information required to bring a product to a customer. This guide provides a quick introduction to the basic standardized symbols for value stream mapping. Value stream maps utilize a standard set of. In. Vsm Symbols And Meaning.

From strategicmanagementinsight.com

Value Stream Mapping (VSM) All You Need to Know SM Insight Vsm Symbols And Meaning Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. Value stream mapping (vsm) is a lean manufacturing technique used to analyze, design, and manage the flow of materials and information required to bring a product to a customer. This guide provides a quick introduction to the basic standardized symbols. Vsm Symbols And Meaning.

From www.cnccookbook.com

Standard Work and Takt Time Lean Manufacturing Principles Part 5 Vsm Symbols And Meaning Originally introduced by the lean enterprise institute in. Value stream maps utilize a standard set of. The pursuit towards a lean process starts. In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history, benefits for product managers and examples of successful implementations. Value stream mapping (vsm) is a lean manufacturing technique used to analyze,. Vsm Symbols And Meaning.

From slidemodel.com

PPT Value Stream Mapping Symbols 1 SlideModel Vsm Symbols And Meaning This guide provides a quick introduction to the basic standardized symbols for value stream mapping. Value stream mapping (vsm) is a valuable tool for process managers and teams alike. In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history, benefits for product managers and examples of successful implementations. Value stream mapping (vsm) is a. Vsm Symbols And Meaning.

From www.leonardo-group.com

Value Stream Analysis and Design Leonardo Group GmbH Vsm Symbols And Meaning In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history, benefits for product managers and examples of successful implementations. Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. This guide provides a quick introduction to the basic standardized symbols for value stream mapping.. Vsm Symbols And Meaning.

From www.systems2win.com

Value Stream Mapping Symbols Vsm Symbols And Meaning This guide provides a quick introduction to the basic standardized symbols for value stream mapping. Value stream mapping (vsm) is a lean manufacturing technique used to analyze, design, and manage the flow of materials and information required to bring a product to a customer. The pursuit towards a lean process starts. Value stream mapping (vsm) is a powerful tool that. Vsm Symbols And Meaning.

From www.vrogue.co

Value Stream Mapping Symbols Basic Flowchart Symbols vrogue.co Vsm Symbols And Meaning Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. Value stream maps utilize a standard set of. The pursuit towards a lean process starts. Value stream mapping (vsm) is a valuable tool for process managers and teams alike. Value stream mapping (vsm) is a lean manufacturing technique used to. Vsm Symbols And Meaning.

From bid.meetbirmingham.com

Value Stream Mapping Significado EDULEARN Vsm Symbols And Meaning Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. Value stream maps utilize a standard set of. Value stream mapping (vsm) is a lean manufacturing technique used to analyze, design, and manage the flow of materials and information required to bring a product to a customer. Originally introduced by. Vsm Symbols And Meaning.

From www.edrawsoft.com

Une liste complète des symboles de cartographie de la chaîne de valeur Vsm Symbols And Meaning Value stream mapping (vsm) is a lean manufacturing technique used to analyze, design, and manage the flow of materials and information required to bring a product to a customer. Value stream mapping (vsm) is a valuable tool for process managers and teams alike. In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history, benefits. Vsm Symbols And Meaning.

From www.conceptdraw.com

VSM symbols Vsm Symbols And Meaning Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. The pursuit towards a lean process starts. Originally introduced by the lean enterprise institute in. This guide provides a quick introduction to the basic standardized symbols for value stream mapping. Value stream mapping (vsm) is a valuable tool for process. Vsm Symbols And Meaning.

From www.qualitybook.org

Value stream mapping (VSM) Vsm Symbols And Meaning Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. Value stream mapping (vsm) is a valuable tool for process managers and teams alike. The pursuit towards a lean process starts. Originally introduced by the lean enterprise institute in. This guide provides a quick introduction to the basic standardized symbols. Vsm Symbols And Meaning.