Abrasive Wheels Designs . Designing a custom grinding wheel for a new application is a highly collaborative and detailed process. By selecting the ideal abrasive type, grit size, bond material, and wheel geometry, you can optimize the wheel's performance to achieve superior results with every grind. Because of the depressed design, an elevated hub can also be employed to secure the wheel firmly in place. Browse the vast selection of norton grinding and cutting wheels. The resulting bonded wheels are thin enough to make a clean cut, and rigid and durable enough to cut through multiple parts on a production line.

from www.slideshare.net

Designing a custom grinding wheel for a new application is a highly collaborative and detailed process. The resulting bonded wheels are thin enough to make a clean cut, and rigid and durable enough to cut through multiple parts on a production line. By selecting the ideal abrasive type, grit size, bond material, and wheel geometry, you can optimize the wheel's performance to achieve superior results with every grind. Because of the depressed design, an elevated hub can also be employed to secure the wheel firmly in place. Browse the vast selection of norton grinding and cutting wheels.

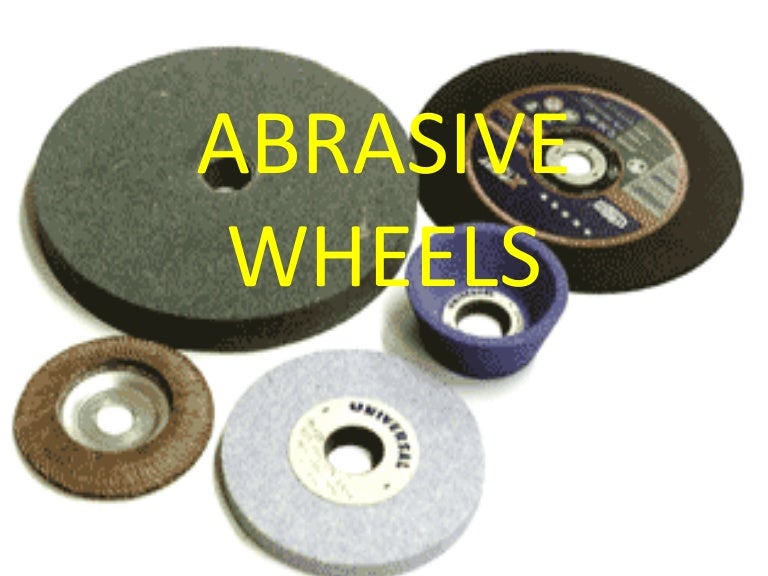

Abrasive wheels

Abrasive Wheels Designs The resulting bonded wheels are thin enough to make a clean cut, and rigid and durable enough to cut through multiple parts on a production line. By selecting the ideal abrasive type, grit size, bond material, and wheel geometry, you can optimize the wheel's performance to achieve superior results with every grind. The resulting bonded wheels are thin enough to make a clean cut, and rigid and durable enough to cut through multiple parts on a production line. Browse the vast selection of norton grinding and cutting wheels. Because of the depressed design, an elevated hub can also be employed to secure the wheel firmly in place. Designing a custom grinding wheel for a new application is a highly collaborative and detailed process.

From strongjohn.com

Abrasive Wheels Strong John Abrasive Wheels Designs Browse the vast selection of norton grinding and cutting wheels. By selecting the ideal abrasive type, grit size, bond material, and wheel geometry, you can optimize the wheel's performance to achieve superior results with every grind. Because of the depressed design, an elevated hub can also be employed to secure the wheel firmly in place. Designing a custom grinding wheel. Abrasive Wheels Designs.

From www.consulting-trading.com

Coated Abrasives ICT Abrasive Wheels Designs By selecting the ideal abrasive type, grit size, bond material, and wheel geometry, you can optimize the wheel's performance to achieve superior results with every grind. The resulting bonded wheels are thin enough to make a clean cut, and rigid and durable enough to cut through multiple parts on a production line. Designing a custom grinding wheel for a new. Abrasive Wheels Designs.

From theleedenstore.com.my

Abrasive Wheel Archives The Leeden Store Abrasive Wheels Designs The resulting bonded wheels are thin enough to make a clean cut, and rigid and durable enough to cut through multiple parts on a production line. By selecting the ideal abrasive type, grit size, bond material, and wheel geometry, you can optimize the wheel's performance to achieve superior results with every grind. Designing a custom grinding wheel for a new. Abrasive Wheels Designs.

From news.thomasnet.com

Abrasive Wheel Flexible Mesh Design Runs Cool Abrasive Wheels Designs Designing a custom grinding wheel for a new application is a highly collaborative and detailed process. The resulting bonded wheels are thin enough to make a clean cut, and rigid and durable enough to cut through multiple parts on a production line. By selecting the ideal abrasive type, grit size, bond material, and wheel geometry, you can optimize the wheel's. Abrasive Wheels Designs.

From www.3m.com

Standard Abrasives™ Type 27 Unitized Wheel 700 Series 3M United States Abrasive Wheels Designs Because of the depressed design, an elevated hub can also be employed to secure the wheel firmly in place. Browse the vast selection of norton grinding and cutting wheels. By selecting the ideal abrasive type, grit size, bond material, and wheel geometry, you can optimize the wheel's performance to achieve superior results with every grind. The resulting bonded wheels are. Abrasive Wheels Designs.

From olivelearning.com.au

Abrasive Wheels Olive Learning Abrasive Wheels Designs Because of the depressed design, an elevated hub can also be employed to secure the wheel firmly in place. Designing a custom grinding wheel for a new application is a highly collaborative and detailed process. The resulting bonded wheels are thin enough to make a clean cut, and rigid and durable enough to cut through multiple parts on a production. Abrasive Wheels Designs.

From moleroda.com

Abrasive Wheels Moleroda Finishing Systems Abrasive Wheels Designs By selecting the ideal abrasive type, grit size, bond material, and wheel geometry, you can optimize the wheel's performance to achieve superior results with every grind. Browse the vast selection of norton grinding and cutting wheels. Designing a custom grinding wheel for a new application is a highly collaborative and detailed process. The resulting bonded wheels are thin enough to. Abrasive Wheels Designs.

From www.grainger.com

UNITED ABRASIVESSAIT, 3 in Abrasive Wheel Dia, Ceramic, Abrasive Cut Abrasive Wheels Designs The resulting bonded wheels are thin enough to make a clean cut, and rigid and durable enough to cut through multiple parts on a production line. Designing a custom grinding wheel for a new application is a highly collaborative and detailed process. Because of the depressed design, an elevated hub can also be employed to secure the wheel firmly in. Abrasive Wheels Designs.

From www.slideshare.net

Abrasive wheels Abrasive Wheels Designs Because of the depressed design, an elevated hub can also be employed to secure the wheel firmly in place. By selecting the ideal abrasive type, grit size, bond material, and wheel geometry, you can optimize the wheel's performance to achieve superior results with every grind. Browse the vast selection of norton grinding and cutting wheels. The resulting bonded wheels are. Abrasive Wheels Designs.

From www.jjtraininguk.com

Abrasive Wheels Courses, Abrasive Wheels Training JJ Training Abrasive Wheels Designs The resulting bonded wheels are thin enough to make a clean cut, and rigid and durable enough to cut through multiple parts on a production line. Because of the depressed design, an elevated hub can also be employed to secure the wheel firmly in place. By selecting the ideal abrasive type, grit size, bond material, and wheel geometry, you can. Abrasive Wheels Designs.

From safetymatters.ie

Abrasive Wheels Training Safety Matters Abrasive Wheels Designs Designing a custom grinding wheel for a new application is a highly collaborative and detailed process. The resulting bonded wheels are thin enough to make a clean cut, and rigid and durable enough to cut through multiple parts on a production line. Browse the vast selection of norton grinding and cutting wheels. By selecting the ideal abrasive type, grit size,. Abrasive Wheels Designs.

From www.indiamart.com

Emery Paper, Polishing Abrasive Coated Abrasive Flap Wheel at Rs 160 Abrasive Wheels Designs The resulting bonded wheels are thin enough to make a clean cut, and rigid and durable enough to cut through multiple parts on a production line. Browse the vast selection of norton grinding and cutting wheels. By selecting the ideal abrasive type, grit size, bond material, and wheel geometry, you can optimize the wheel's performance to achieve superior results with. Abrasive Wheels Designs.

From www.healthsafetyonline.co.uk

AbrasiveWheels Abrasive Wheels Designs By selecting the ideal abrasive type, grit size, bond material, and wheel geometry, you can optimize the wheel's performance to achieve superior results with every grind. Because of the depressed design, an elevated hub can also be employed to secure the wheel firmly in place. The resulting bonded wheels are thin enough to make a clean cut, and rigid and. Abrasive Wheels Designs.

From www.dexpan.com

Abrasive cutoff wheels for metal cutting 14" x 1/8" x 1" (Box of 25) Abrasive Wheels Designs Designing a custom grinding wheel for a new application is a highly collaborative and detailed process. The resulting bonded wheels are thin enough to make a clean cut, and rigid and durable enough to cut through multiple parts on a production line. Because of the depressed design, an elevated hub can also be employed to secure the wheel firmly in. Abrasive Wheels Designs.

From www.faithfulltools.com

Abrasive Flap Wheels Abrasive Wheels Designs By selecting the ideal abrasive type, grit size, bond material, and wheel geometry, you can optimize the wheel's performance to achieve superior results with every grind. Because of the depressed design, an elevated hub can also be employed to secure the wheel firmly in place. Designing a custom grinding wheel for a new application is a highly collaborative and detailed. Abrasive Wheels Designs.

From www.alibaba.com

Metal Finishing Convolute Abrasive Wheel Mf 5a Med 12x2x5 For Coarser Abrasive Wheels Designs By selecting the ideal abrasive type, grit size, bond material, and wheel geometry, you can optimize the wheel's performance to achieve superior results with every grind. Browse the vast selection of norton grinding and cutting wheels. Designing a custom grinding wheel for a new application is a highly collaborative and detailed process. The resulting bonded wheels are thin enough to. Abrasive Wheels Designs.

From www.ethiretraining.com

The Safe Use Of Abrasive Wheel ET Hire Training Abrasive Wheels Designs Because of the depressed design, an elevated hub can also be employed to secure the wheel firmly in place. Designing a custom grinding wheel for a new application is a highly collaborative and detailed process. By selecting the ideal abrasive type, grit size, bond material, and wheel geometry, you can optimize the wheel's performance to achieve superior results with every. Abrasive Wheels Designs.

From www.cgwabrasives.com

7 Circular Saw Wheels Cutting Wheels CGW Abrasives Abrasive Wheels Designs Designing a custom grinding wheel for a new application is a highly collaborative and detailed process. The resulting bonded wheels are thin enough to make a clean cut, and rigid and durable enough to cut through multiple parts on a production line. Browse the vast selection of norton grinding and cutting wheels. Because of the depressed design, an elevated hub. Abrasive Wheels Designs.

From www.lowes.com

Norton Bluefire Bonded Abrasive 14in Cutoff Wheel in the Abrasive Abrasive Wheels Designs By selecting the ideal abrasive type, grit size, bond material, and wheel geometry, you can optimize the wheel's performance to achieve superior results with every grind. Because of the depressed design, an elevated hub can also be employed to secure the wheel firmly in place. The resulting bonded wheels are thin enough to make a clean cut, and rigid and. Abrasive Wheels Designs.

From www.youtube.com

Safety Series How to mount an abrasive wheel YouTube Abrasive Wheels Designs Because of the depressed design, an elevated hub can also be employed to secure the wheel firmly in place. Designing a custom grinding wheel for a new application is a highly collaborative and detailed process. Browse the vast selection of norton grinding and cutting wheels. The resulting bonded wheels are thin enough to make a clean cut, and rigid and. Abrasive Wheels Designs.

From www.indiamart.com

Brown Polished Radiant Non Woven Matt Abrasives Wheel, For Polishing Abrasive Wheels Designs Because of the depressed design, an elevated hub can also be employed to secure the wheel firmly in place. Browse the vast selection of norton grinding and cutting wheels. Designing a custom grinding wheel for a new application is a highly collaborative and detailed process. By selecting the ideal abrasive type, grit size, bond material, and wheel geometry, you can. Abrasive Wheels Designs.

From www.cgwabrasives.com

Reinforced Cut Off Wheels Type 1 Cutting Wheels CGW Abrasives Abrasive Wheels Designs Designing a custom grinding wheel for a new application is a highly collaborative and detailed process. The resulting bonded wheels are thin enough to make a clean cut, and rigid and durable enough to cut through multiple parts on a production line. By selecting the ideal abrasive type, grit size, bond material, and wheel geometry, you can optimize the wheel's. Abrasive Wheels Designs.

From www.cgwabrasives.com

Surface Grinding Vitrified Wheels Vitrified Wheels CGW Abrasives Abrasive Wheels Designs By selecting the ideal abrasive type, grit size, bond material, and wheel geometry, you can optimize the wheel's performance to achieve superior results with every grind. The resulting bonded wheels are thin enough to make a clean cut, and rigid and durable enough to cut through multiple parts on a production line. Designing a custom grinding wheel for a new. Abrasive Wheels Designs.

From www.dreamstime.com

Abrasives wheel stock photo. Image of machine, rough 74669918 Abrasive Wheels Designs The resulting bonded wheels are thin enough to make a clean cut, and rigid and durable enough to cut through multiple parts on a production line. Because of the depressed design, an elevated hub can also be employed to secure the wheel firmly in place. Browse the vast selection of norton grinding and cutting wheels. By selecting the ideal abrasive. Abrasive Wheels Designs.

From www.eastwoodmachinery.co.uk

Abrasive wheels EMS Eastwood Machinery Services Woodworking Abrasive Wheels Designs Because of the depressed design, an elevated hub can also be employed to secure the wheel firmly in place. Browse the vast selection of norton grinding and cutting wheels. Designing a custom grinding wheel for a new application is a highly collaborative and detailed process. By selecting the ideal abrasive type, grit size, bond material, and wheel geometry, you can. Abrasive Wheels Designs.

From arcabrasives.com

8" x 2" x 1" Unmounted Flap Wheel, 80 Grit ARC Abrasives, Inc. Abrasive Wheels Designs The resulting bonded wheels are thin enough to make a clean cut, and rigid and durable enough to cut through multiple parts on a production line. By selecting the ideal abrasive type, grit size, bond material, and wheel geometry, you can optimize the wheel's performance to achieve superior results with every grind. Browse the vast selection of norton grinding and. Abrasive Wheels Designs.

From owneaster.com

Best 3M Abrasive Wheel The Best Choice Abrasive Wheels Designs By selecting the ideal abrasive type, grit size, bond material, and wheel geometry, you can optimize the wheel's performance to achieve superior results with every grind. The resulting bonded wheels are thin enough to make a clean cut, and rigid and durable enough to cut through multiple parts on a production line. Browse the vast selection of norton grinding and. Abrasive Wheels Designs.

From www.camarossaudio.com

abrasive grinding wheel manufacturers exclusive designs Abrasive Wheels Designs The resulting bonded wheels are thin enough to make a clean cut, and rigid and durable enough to cut through multiple parts on a production line. Designing a custom grinding wheel for a new application is a highly collaborative and detailed process. By selecting the ideal abrasive type, grit size, bond material, and wheel geometry, you can optimize the wheel's. Abrasive Wheels Designs.

From www.lowes.com

DEWALT Zirconia 4.5in 60Grit Grinding Wheel in the Abrasive Wheels Abrasive Wheels Designs Designing a custom grinding wheel for a new application is a highly collaborative and detailed process. Because of the depressed design, an elevated hub can also be employed to secure the wheel firmly in place. By selecting the ideal abrasive type, grit size, bond material, and wheel geometry, you can optimize the wheel's performance to achieve superior results with every. Abrasive Wheels Designs.

From echo-3.co.uk

Guide to Abrasive Wheels What you need to know to work safely Abrasive Wheels Designs Because of the depressed design, an elevated hub can also be employed to secure the wheel firmly in place. Browse the vast selection of norton grinding and cutting wheels. The resulting bonded wheels are thin enough to make a clean cut, and rigid and durable enough to cut through multiple parts on a production line. By selecting the ideal abrasive. Abrasive Wheels Designs.

From www.hswalsh.com

Abrasive Wheels Abrasive Wheels Designs The resulting bonded wheels are thin enough to make a clean cut, and rigid and durable enough to cut through multiple parts on a production line. By selecting the ideal abrasive type, grit size, bond material, and wheel geometry, you can optimize the wheel's performance to achieve superior results with every grind. Because of the depressed design, an elevated hub. Abrasive Wheels Designs.

From www.e-aircraftsupply.com

50051115332246 Standard Abrasives™ Metal Finishing Wheel 858882, 12 Abrasive Wheels Designs By selecting the ideal abrasive type, grit size, bond material, and wheel geometry, you can optimize the wheel's performance to achieve superior results with every grind. Browse the vast selection of norton grinding and cutting wheels. Because of the depressed design, an elevated hub can also be employed to secure the wheel firmly in place. The resulting bonded wheels are. Abrasive Wheels Designs.

From www.dreamstime.com

Abrasives wheel stock photo. Image of disc, wheel, construction 74669942 Abrasive Wheels Designs Browse the vast selection of norton grinding and cutting wheels. The resulting bonded wheels are thin enough to make a clean cut, and rigid and durable enough to cut through multiple parts on a production line. By selecting the ideal abrasive type, grit size, bond material, and wheel geometry, you can optimize the wheel's performance to achieve superior results with. Abrasive Wheels Designs.

From www.lowes.com

Shopsmith Stripping Wheel Ceramic 4.5in 60Grit Paint Stripping Disc Abrasive Wheels Designs By selecting the ideal abrasive type, grit size, bond material, and wheel geometry, you can optimize the wheel's performance to achieve superior results with every grind. Browse the vast selection of norton grinding and cutting wheels. Designing a custom grinding wheel for a new application is a highly collaborative and detailed process. The resulting bonded wheels are thin enough to. Abrasive Wheels Designs.

From catalogo.mab.tools

Coated abrasives MABTOOLS Abrasives Catalog Abrasive Wheels Designs Designing a custom grinding wheel for a new application is a highly collaborative and detailed process. The resulting bonded wheels are thin enough to make a clean cut, and rigid and durable enough to cut through multiple parts on a production line. Browse the vast selection of norton grinding and cutting wheels. Because of the depressed design, an elevated hub. Abrasive Wheels Designs.