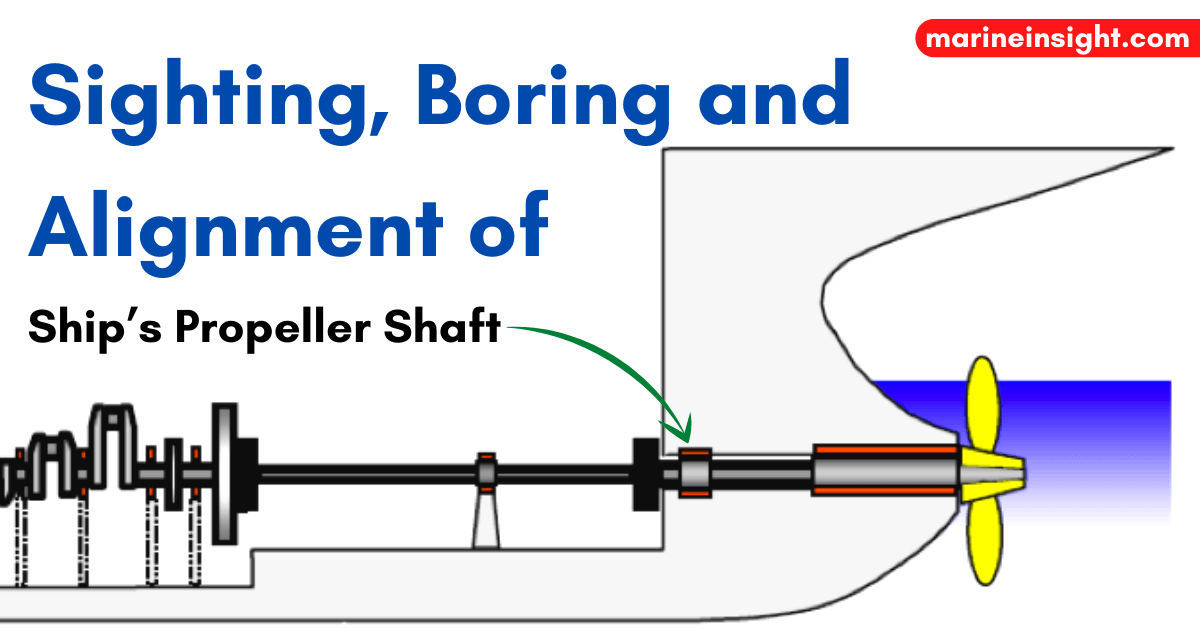

Shafting System Of A Ship . Shafting alignment is performed in several stages, starting with the shaft line design, and includes calculating the elastic line and bearing loads, installation of shafting parts. Sighting and boring of a ship’s stern tube is done to establish practically the centreline of shafting, as accurately as per the design. A method is suggested for selecting the optimal shafting arrangement by which to secure the shaft flexibility of a ship to which a. The design of a marine system, divided into three steps, is examined. The basic operational requirement for a marine propulsion shafting system is to transmit the torque over the required range of speeds. Steady, alternating forces and moments, generated by. One bearing at its forward end (called the forward bush bearing) and the other at its aft end (called the aft bush bearing). The stern tube consists of two bearings. In order to understand the answers let us look at the various common propulsion systems deployed in marine crafts.

from www.pinnaxis.com

A method is suggested for selecting the optimal shafting arrangement by which to secure the shaft flexibility of a ship to which a. Shafting alignment is performed in several stages, starting with the shaft line design, and includes calculating the elastic line and bearing loads, installation of shafting parts. Sighting and boring of a ship’s stern tube is done to establish practically the centreline of shafting, as accurately as per the design. The stern tube consists of two bearings. The basic operational requirement for a marine propulsion shafting system is to transmit the torque over the required range of speeds. In order to understand the answers let us look at the various common propulsion systems deployed in marine crafts. One bearing at its forward end (called the forward bush bearing) and the other at its aft end (called the aft bush bearing). The design of a marine system, divided into three steps, is examined. Steady, alternating forces and moments, generated by.

Propeller Shaft An Overview ScienceDirect Topics, 53 OFF

Shafting System Of A Ship The design of a marine system, divided into three steps, is examined. Steady, alternating forces and moments, generated by. Sighting and boring of a ship’s stern tube is done to establish practically the centreline of shafting, as accurately as per the design. The stern tube consists of two bearings. One bearing at its forward end (called the forward bush bearing) and the other at its aft end (called the aft bush bearing). Shafting alignment is performed in several stages, starting with the shaft line design, and includes calculating the elastic line and bearing loads, installation of shafting parts. The design of a marine system, divided into three steps, is examined. The basic operational requirement for a marine propulsion shafting system is to transmit the torque over the required range of speeds. A method is suggested for selecting the optimal shafting arrangement by which to secure the shaft flexibility of a ship to which a. In order to understand the answers let us look at the various common propulsion systems deployed in marine crafts.

From www.scotforge.com

Marine Propulsion Shafts Scot Shafting System Of A Ship A method is suggested for selecting the optimal shafting arrangement by which to secure the shaft flexibility of a ship to which a. Steady, alternating forces and moments, generated by. The stern tube consists of two bearings. The design of a marine system, divided into three steps, is examined. One bearing at its forward end (called the forward bush bearing). Shafting System Of A Ship.

From www.maritimepropulsion.com

Tropical Opts For Seawater Lubricated Shaft Package Shafting System Of A Ship Shafting alignment is performed in several stages, starting with the shaft line design, and includes calculating the elastic line and bearing loads, installation of shafting parts. Steady, alternating forces and moments, generated by. The design of a marine system, divided into three steps, is examined. The stern tube consists of two bearings. The basic operational requirement for a marine propulsion. Shafting System Of A Ship.

From www.wartsila.com

Wärtsilä Shaft Generator economical electrical power generation Shafting System Of A Ship The stern tube consists of two bearings. The design of a marine system, divided into three steps, is examined. One bearing at its forward end (called the forward bush bearing) and the other at its aft end (called the aft bush bearing). Sighting and boring of a ship’s stern tube is done to establish practically the centreline of shafting, as. Shafting System Of A Ship.

From ar.inspiredpencil.com

Ship Propeller Shaft Shafting System Of A Ship One bearing at its forward end (called the forward bush bearing) and the other at its aft end (called the aft bush bearing). The design of a marine system, divided into three steps, is examined. In order to understand the answers let us look at the various common propulsion systems deployed in marine crafts. The stern tube consists of two. Shafting System Of A Ship.

From thenavalarch.com

Marine Propeller Shafting and Shafting Alignment Part 1 TheNavalArch Shafting System Of A Ship Steady, alternating forces and moments, generated by. One bearing at its forward end (called the forward bush bearing) and the other at its aft end (called the aft bush bearing). The basic operational requirement for a marine propulsion shafting system is to transmit the torque over the required range of speeds. In order to understand the answers let us look. Shafting System Of A Ship.

From www.youtube.com

Michell Bearings hydrodynamic propeller shaft bearing and thrust block Shafting System Of A Ship Steady, alternating forces and moments, generated by. In order to understand the answers let us look at the various common propulsion systems deployed in marine crafts. Sighting and boring of a ship’s stern tube is done to establish practically the centreline of shafting, as accurately as per the design. The stern tube consists of two bearings. One bearing at its. Shafting System Of A Ship.

From www.vesselfinder.com

Thordon Bearings Water Lubricated Propeller Shaft Bearings Found to Shafting System Of A Ship A method is suggested for selecting the optimal shafting arrangement by which to secure the shaft flexibility of a ship to which a. The basic operational requirement for a marine propulsion shafting system is to transmit the torque over the required range of speeds. In order to understand the answers let us look at the various common propulsion systems deployed. Shafting System Of A Ship.

From www.marineinsight.com

Understanding Stern Tube Arrangement on Ships Shafting System Of A Ship Shafting alignment is performed in several stages, starting with the shaft line design, and includes calculating the elastic line and bearing loads, installation of shafting parts. Steady, alternating forces and moments, generated by. One bearing at its forward end (called the forward bush bearing) and the other at its aft end (called the aft bush bearing). Sighting and boring of. Shafting System Of A Ship.

From journals.sagepub.com

Coupled vibration characteristics of a submarine propellershafthull Shafting System Of A Ship One bearing at its forward end (called the forward bush bearing) and the other at its aft end (called the aft bush bearing). The stern tube consists of two bearings. A method is suggested for selecting the optimal shafting arrangement by which to secure the shaft flexibility of a ship to which a. Steady, alternating forces and moments, generated by.. Shafting System Of A Ship.

From www.mdpi.com

Applied Sciences Free FullText Changes in Propeller Shaft Behavior Shafting System Of A Ship Shafting alignment is performed in several stages, starting with the shaft line design, and includes calculating the elastic line and bearing loads, installation of shafting parts. Sighting and boring of a ship’s stern tube is done to establish practically the centreline of shafting, as accurately as per the design. The design of a marine system, divided into three steps, is. Shafting System Of A Ship.

From www.youtube.com

Propeller Shafting System and Thrust Block Detailed videoSimple Shafting System Of A Ship Shafting alignment is performed in several stages, starting with the shaft line design, and includes calculating the elastic line and bearing loads, installation of shafting parts. The stern tube consists of two bearings. Steady, alternating forces and moments, generated by. Sighting and boring of a ship’s stern tube is done to establish practically the centreline of shafting, as accurately as. Shafting System Of A Ship.

From www.researchgate.net

Schematic diagram of marine propulsion system. Download Scientific Shafting System Of A Ship Sighting and boring of a ship’s stern tube is done to establish practically the centreline of shafting, as accurately as per the design. Steady, alternating forces and moments, generated by. A method is suggested for selecting the optimal shafting arrangement by which to secure the shaft flexibility of a ship to which a. The design of a marine system, divided. Shafting System Of A Ship.

From www.marineengineersknowledge.com

Explained Thrust bearing working principle and where it is located Shafting System Of A Ship The design of a marine system, divided into three steps, is examined. The stern tube consists of two bearings. The basic operational requirement for a marine propulsion shafting system is to transmit the torque over the required range of speeds. One bearing at its forward end (called the forward bush bearing) and the other at its aft end (called the. Shafting System Of A Ship.

From maritime-executive.com

The End of OilLubricated Propeller Shafts Shafting System Of A Ship Steady, alternating forces and moments, generated by. Shafting alignment is performed in several stages, starting with the shaft line design, and includes calculating the elastic line and bearing loads, installation of shafting parts. The basic operational requirement for a marine propulsion shafting system is to transmit the torque over the required range of speeds. The stern tube consists of two. Shafting System Of A Ship.

From thenavalarch.com

Marine Propeller Shafting and Shafting Alignment Part 1 TheNavalArch Shafting System Of A Ship The stern tube consists of two bearings. In order to understand the answers let us look at the various common propulsion systems deployed in marine crafts. The design of a marine system, divided into three steps, is examined. One bearing at its forward end (called the forward bush bearing) and the other at its aft end (called the aft bush. Shafting System Of A Ship.

From lshipdesign.blogspot.com

Learn Ship Design SCREW PROPELLER PART 1 Shafting System Of A Ship Steady, alternating forces and moments, generated by. The basic operational requirement for a marine propulsion shafting system is to transmit the torque over the required range of speeds. One bearing at its forward end (called the forward bush bearing) and the other at its aft end (called the aft bush bearing). In order to understand the answers let us look. Shafting System Of A Ship.

From dir.indiamart.com

Ship Shaft at Best Price in India Shafting System Of A Ship The stern tube consists of two bearings. The design of a marine system, divided into three steps, is examined. One bearing at its forward end (called the forward bush bearing) and the other at its aft end (called the aft bush bearing). In order to understand the answers let us look at the various common propulsion systems deployed in marine. Shafting System Of A Ship.

From shaftdesigner.software

ShaftDesigner shaft alignment and vibrations software Shafting System Of A Ship Steady, alternating forces and moments, generated by. A method is suggested for selecting the optimal shafting arrangement by which to secure the shaft flexibility of a ship to which a. One bearing at its forward end (called the forward bush bearing) and the other at its aft end (called the aft bush bearing). Shafting alignment is performed in several stages,. Shafting System Of A Ship.

From www.somersforge.com

Propeller Shaft Marine Shafting Somers Shafting System Of A Ship The stern tube consists of two bearings. In order to understand the answers let us look at the various common propulsion systems deployed in marine crafts. Sighting and boring of a ship’s stern tube is done to establish practically the centreline of shafting, as accurately as per the design. The design of a marine system, divided into three steps, is. Shafting System Of A Ship.

From peacecommission.kdsg.gov.ng

SHIP PROPELLER AND SHAFTING SYSTEM Shafting System Of A Ship One bearing at its forward end (called the forward bush bearing) and the other at its aft end (called the aft bush bearing). In order to understand the answers let us look at the various common propulsion systems deployed in marine crafts. The design of a marine system, divided into three steps, is examined. The stern tube consists of two. Shafting System Of A Ship.

From www.pinnaxis.com

Propeller Shaft An Overview ScienceDirect Topics, 53 OFF Shafting System Of A Ship In order to understand the answers let us look at the various common propulsion systems deployed in marine crafts. Sighting and boring of a ship’s stern tube is done to establish practically the centreline of shafting, as accurately as per the design. One bearing at its forward end (called the forward bush bearing) and the other at its aft end. Shafting System Of A Ship.

From www.wzsolid.com

Ship Shaft Main Shaft Stern Shaft Propeller Shaft Shaft System For Shafting System Of A Ship Steady, alternating forces and moments, generated by. Shafting alignment is performed in several stages, starting with the shaft line design, and includes calculating the elastic line and bearing loads, installation of shafting parts. The stern tube consists of two bearings. One bearing at its forward end (called the forward bush bearing) and the other at its aft end (called the. Shafting System Of A Ship.

From shaftsoftware.com

Highend software for propulsion shaft calculation The Shaft Shafting System Of A Ship A method is suggested for selecting the optimal shafting arrangement by which to secure the shaft flexibility of a ship to which a. In order to understand the answers let us look at the various common propulsion systems deployed in marine crafts. One bearing at its forward end (called the forward bush bearing) and the other at its aft end. Shafting System Of A Ship.

From www.rivieramm.com

Riviera Opinion Alignment technology keeps research vessel straight Shafting System Of A Ship Sighting and boring of a ship’s stern tube is done to establish practically the centreline of shafting, as accurately as per the design. One bearing at its forward end (called the forward bush bearing) and the other at its aft end (called the aft bush bearing). The stern tube consists of two bearings. The design of a marine system, divided. Shafting System Of A Ship.

From www.researchgate.net

Propeller Shaft arrangement [6]. Download Scientific Diagram Shafting System Of A Ship In order to understand the answers let us look at the various common propulsion systems deployed in marine crafts. Shafting alignment is performed in several stages, starting with the shaft line design, and includes calculating the elastic line and bearing loads, installation of shafting parts. Steady, alternating forces and moments, generated by. The design of a marine system, divided into. Shafting System Of A Ship.

From www.semanticscholar.org

[PDF] Common failures of ship propulsion shafts Semantic Scholar Shafting System Of A Ship Sighting and boring of a ship’s stern tube is done to establish practically the centreline of shafting, as accurately as per the design. Steady, alternating forces and moments, generated by. The stern tube consists of two bearings. One bearing at its forward end (called the forward bush bearing) and the other at its aft end (called the aft bush bearing).. Shafting System Of A Ship.

From www.researchgate.net

Schematic diagram of submarine propulsion shafting system. Download Shafting System Of A Ship Sighting and boring of a ship’s stern tube is done to establish practically the centreline of shafting, as accurately as per the design. The basic operational requirement for a marine propulsion shafting system is to transmit the torque over the required range of speeds. The stern tube consists of two bearings. A method is suggested for selecting the optimal shafting. Shafting System Of A Ship.

From www.supersoarmarine.com

Marine Propeller, Marine Shafting System, Marine Rudder System Shafting System Of A Ship Sighting and boring of a ship’s stern tube is done to establish practically the centreline of shafting, as accurately as per the design. The basic operational requirement for a marine propulsion shafting system is to transmit the torque over the required range of speeds. One bearing at its forward end (called the forward bush bearing) and the other at its. Shafting System Of A Ship.

From honestcable.com

Ship Cable / Marine Ship Wiring Cables Manufacturer Shafting System Of A Ship The design of a marine system, divided into three steps, is examined. In order to understand the answers let us look at the various common propulsion systems deployed in marine crafts. Steady, alternating forces and moments, generated by. The stern tube consists of two bearings. Sighting and boring of a ship’s stern tube is done to establish practically the centreline. Shafting System Of A Ship.

From www.nauticexpo.com

Ship propulsion system DIRECT DRIVEN Brunvoll controllablepitch Shafting System Of A Ship A method is suggested for selecting the optimal shafting arrangement by which to secure the shaft flexibility of a ship to which a. Steady, alternating forces and moments, generated by. The basic operational requirement for a marine propulsion shafting system is to transmit the torque over the required range of speeds. One bearing at its forward end (called the forward. Shafting System Of A Ship.

From thordonbearings.com

Propeller Shaft Bearing Systems Shafting System Of A Ship The stern tube consists of two bearings. The basic operational requirement for a marine propulsion shafting system is to transmit the torque over the required range of speeds. In order to understand the answers let us look at the various common propulsion systems deployed in marine crafts. A method is suggested for selecting the optimal shafting arrangement by which to. Shafting System Of A Ship.

From www.ynfpublishers.com

Main Propulsion Systems for New Chemical Tankers Yellow & Finch Shafting System Of A Ship The design of a marine system, divided into three steps, is examined. Steady, alternating forces and moments, generated by. A method is suggested for selecting the optimal shafting arrangement by which to secure the shaft flexibility of a ship to which a. Shafting alignment is performed in several stages, starting with the shaft line design, and includes calculating the elastic. Shafting System Of A Ship.

From en.weichaihm.com

The introduction of ship propulsion system WEICHAI HEAVY MACHINERY CO Shafting System Of A Ship A method is suggested for selecting the optimal shafting arrangement by which to secure the shaft flexibility of a ship to which a. One bearing at its forward end (called the forward bush bearing) and the other at its aft end (called the aft bush bearing). Steady, alternating forces and moments, generated by. Sighting and boring of a ship’s stern. Shafting System Of A Ship.

From www.researchgate.net

Basic parameters of the marine propulsion shafting system. Download Table Shafting System Of A Ship The design of a marine system, divided into three steps, is examined. Shafting alignment is performed in several stages, starting with the shaft line design, and includes calculating the elastic line and bearing loads, installation of shafting parts. One bearing at its forward end (called the forward bush bearing) and the other at its aft end (called the aft bush. Shafting System Of A Ship.

From www.researchgate.net

(PDF) Research on MDO of Ship Propulsion Shafting Dynamics Considering Shafting System Of A Ship Steady, alternating forces and moments, generated by. The basic operational requirement for a marine propulsion shafting system is to transmit the torque over the required range of speeds. One bearing at its forward end (called the forward bush bearing) and the other at its aft end (called the aft bush bearing). The design of a marine system, divided into three. Shafting System Of A Ship.