Define Compression Moulding Process . compression moulding is a conventional manufacturing process that uses heat and pressure to mould plastic resins and thermosets into a desired. it is a type of molding technique that converts plastics, natural rubbers, composites, and elastomers into desired. Material preparation, preheating, molding, curing, and. the compression molding process involves several key steps: compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. In this method, a preheated. compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. compression molding is a manufacturing method for fabrication of composite materials.

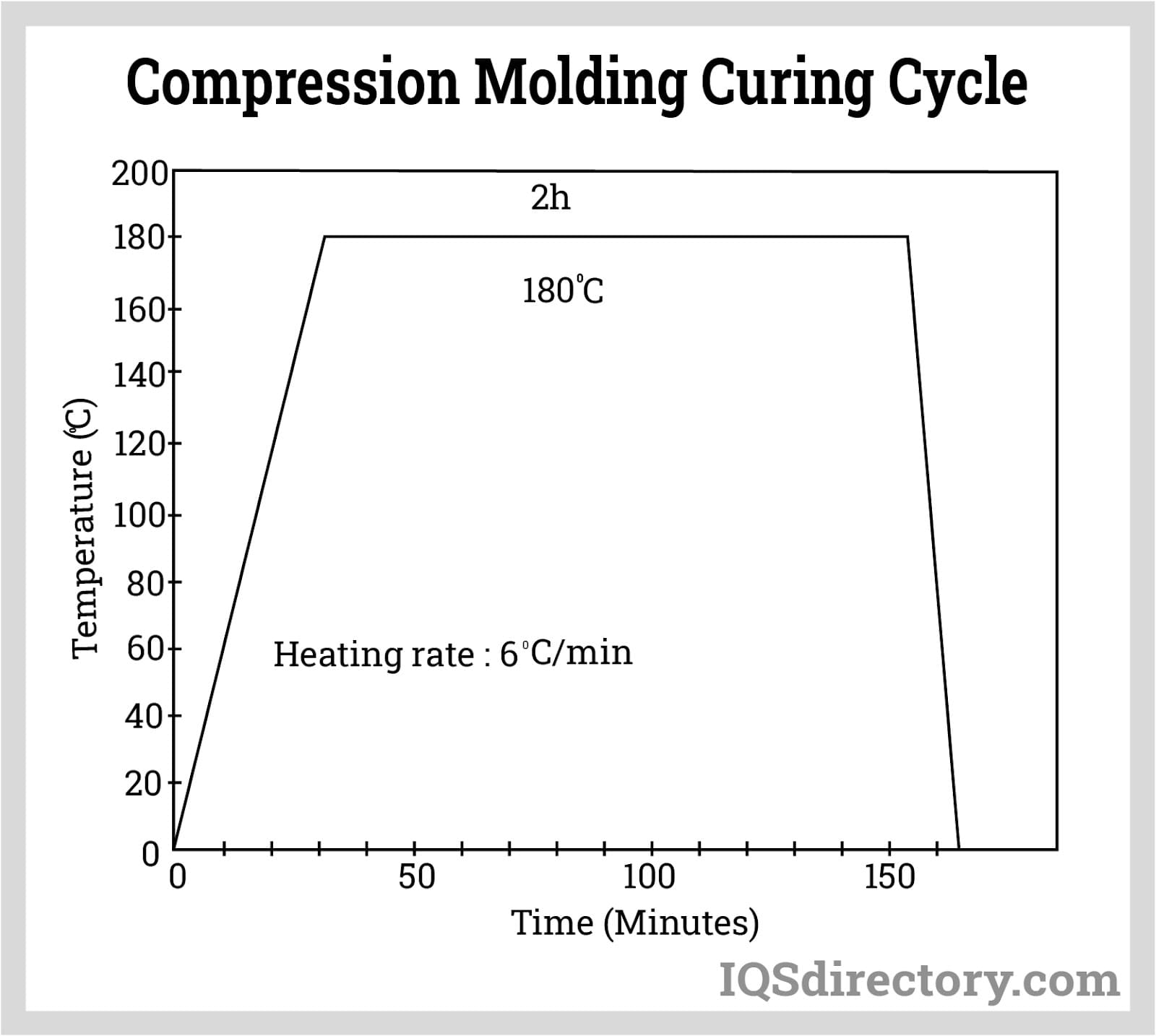

from www.iqsdirectory.com

Material preparation, preheating, molding, curing, and. compression molding is a manufacturing method for fabrication of composite materials. compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. it is a type of molding technique that converts plastics, natural rubbers, composites, and elastomers into desired. In this method, a preheated. compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. compression moulding is a conventional manufacturing process that uses heat and pressure to mould plastic resins and thermosets into a desired. the compression molding process involves several key steps:

Compression Molding Process, Types of Molds, Features and Benefits

Define Compression Moulding Process it is a type of molding technique that converts plastics, natural rubbers, composites, and elastomers into desired. compression molding is a manufacturing method for fabrication of composite materials. compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. it is a type of molding technique that converts plastics, natural rubbers, composites, and elastomers into desired. the compression molding process involves several key steps: compression moulding is a conventional manufacturing process that uses heat and pressure to mould plastic resins and thermosets into a desired. compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. In this method, a preheated. Material preparation, preheating, molding, curing, and.

From www.researchgate.net

17 Diagram of the compressionmoulding process of GFTPU composites Define Compression Moulding Process compression moulding is a conventional manufacturing process that uses heat and pressure to mould plastic resins and thermosets into a desired. Material preparation, preheating, molding, curing, and. compression molding is a manufacturing method for fabrication of composite materials. compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials. Define Compression Moulding Process.

From www.hardwareinterviews.fyi

Basics of Compression Molding Consumer Hardware Guide Hardware FYI Define Compression Moulding Process it is a type of molding technique that converts plastics, natural rubbers, composites, and elastomers into desired. compression moulding is a conventional manufacturing process that uses heat and pressure to mould plastic resins and thermosets into a desired. compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. the compression. Define Compression Moulding Process.

From siliconemakers.com

Silicone Rubber Compression Molding Lanxin Define Compression Moulding Process compression moulding is a conventional manufacturing process that uses heat and pressure to mould plastic resins and thermosets into a desired. compression molding is a manufacturing method for fabrication of composite materials. Material preparation, preheating, molding, curing, and. In this method, a preheated. compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as. Define Compression Moulding Process.

From www.researchgate.net

Schematic setup of compression molding process [64]. Download Define Compression Moulding Process compression molding is a manufacturing method for fabrication of composite materials. compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. it is a type of molding technique that converts plastics, natural rubbers, composites, and elastomers into desired. the compression molding process involves several key steps: compression moulding is. Define Compression Moulding Process.

From formlabs.com

Guide to Compression Molding From Prototyping to Mass Production Define Compression Moulding Process In this method, a preheated. compression molding is a manufacturing method for fabrication of composite materials. it is a type of molding technique that converts plastics, natural rubbers, composites, and elastomers into desired. compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. the compression molding. Define Compression Moulding Process.

From www.iqsdirectory.com

Compression Molding Process, Types of Molds, Features and Benefits Define Compression Moulding Process compression moulding is a conventional manufacturing process that uses heat and pressure to mould plastic resins and thermosets into a desired. Material preparation, preheating, molding, curing, and. the compression molding process involves several key steps: compression molding is a manufacturing method for fabrication of composite materials. compression molding is a common polymer manufacturing process for thermosets,. Define Compression Moulding Process.

From engineeringlearn.com

16 Types of Moulding [Explained with Complete Details] Engineering Learn Define Compression Moulding Process In this method, a preheated. it is a type of molding technique that converts plastics, natural rubbers, composites, and elastomers into desired. compression molding is a manufacturing method for fabrication of composite materials. the compression molding process involves several key steps: compression molding, a technique that finds its roots in the early 20th century, entails the. Define Compression Moulding Process.

From www.researchgate.net

Schematic diagram of compression molding machine using composite Define Compression Moulding Process compression molding is a manufacturing method for fabrication of composite materials. compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. the compression molding process involves several key steps: In this method, a preheated. compression molding, a technique that finds its roots in the early 20th century, entails the transformation. Define Compression Moulding Process.

From www.hardwareinterviews.fyi

Basics of Compression Molding Consumer Hardware Guide Hardware FYI Define Compression Moulding Process In this method, a preheated. compression molding is a manufacturing method for fabrication of composite materials. compression moulding is a conventional manufacturing process that uses heat and pressure to mould plastic resins and thermosets into a desired. the compression molding process involves several key steps: it is a type of molding technique that converts plastics, natural. Define Compression Moulding Process.

From www.sealengineering.no

Simulation in compression molding Seal Engineering Define Compression Moulding Process compression moulding is a conventional manufacturing process that uses heat and pressure to mould plastic resins and thermosets into a desired. compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. compression molding is a manufacturing method for fabrication of composite materials. the compression molding process. Define Compression Moulding Process.

From www.researchgate.net

Steps involving the compression molding process for producing hybrid Define Compression Moulding Process In this method, a preheated. it is a type of molding technique that converts plastics, natural rubbers, composites, and elastomers into desired. compression moulding is a conventional manufacturing process that uses heat and pressure to mould plastic resins and thermosets into a desired. the compression molding process involves several key steps: Material preparation, preheating, molding, curing, and.. Define Compression Moulding Process.

From www.researchgate.net

The schematic of compression moulding process. Download Scientific Define Compression Moulding Process compression moulding is a conventional manufacturing process that uses heat and pressure to mould plastic resins and thermosets into a desired. compression molding is a manufacturing method for fabrication of composite materials. the compression molding process involves several key steps: In this method, a preheated. it is a type of molding technique that converts plastics, natural. Define Compression Moulding Process.

From giokcxfks.blob.core.windows.net

What Are The Materials Used For Moulding at Stella Murray blog Define Compression Moulding Process compression moulding is a conventional manufacturing process that uses heat and pressure to mould plastic resins and thermosets into a desired. In this method, a preheated. compression molding is a manufacturing method for fabrication of composite materials. compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into.. Define Compression Moulding Process.

From www.researchgate.net

19 Schematic of compression molding process. Download Scientific Diagram Define Compression Moulding Process Material preparation, preheating, molding, curing, and. compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. the compression molding process involves several key steps: compression moulding is a conventional manufacturing. Define Compression Moulding Process.

From mungfali.com

Compression Moulding Diagram Define Compression Moulding Process compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. the compression molding process involves several key steps: In this method, a preheated. compression moulding is a conventional manufacturing process that uses heat and pressure to mould plastic resins and thermosets into a desired. Material preparation, preheating, molding, curing, and. . Define Compression Moulding Process.

From mungfali.com

Compression Moulding Diagram Define Compression Moulding Process compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. it is a type of molding technique that converts plastics, natural rubbers, composites, and elastomers into desired. compression molding is. Define Compression Moulding Process.

From learnmech.com

Compression molding Process Advantages and Disadvantages Define Compression Moulding Process compression moulding is a conventional manufacturing process that uses heat and pressure to mould plastic resins and thermosets into a desired. compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. it is a type of molding technique that converts plastics, natural rubbers, composites, and elastomers into. Define Compression Moulding Process.

From www.iqsdirectory.com

Compression Molding Process, Types of Molds, Features and Benefits Define Compression Moulding Process compression moulding is a conventional manufacturing process that uses heat and pressure to mould plastic resins and thermosets into a desired. compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into.. Define Compression Moulding Process.

From polymer360.blogspot.com

Compression Moulding Define Compression Moulding Process the compression molding process involves several key steps: compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. In this method, a preheated. Material preparation, preheating, molding, curing, and. compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. compression. Define Compression Moulding Process.

From www.iqsdirectory.com

Compression Molding Process, Types of Molds, Features and Benefits Define Compression Moulding Process compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. compression molding is a manufacturing method for fabrication of composite materials. compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. the compression molding process involves several key steps: Material. Define Compression Moulding Process.

From www.iqsdirectory.com

Compression Molding Process, Types of Molds, Features and Benefits Define Compression Moulding Process In this method, a preheated. it is a type of molding technique that converts plastics, natural rubbers, composites, and elastomers into desired. compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. Material preparation, preheating, molding, curing, and. compression molding is a manufacturing method for fabrication of. Define Compression Moulding Process.

From www.iqsdirectory.com

Compression Molding Process, Types of Molds, Features and Benefits Define Compression Moulding Process Material preparation, preheating, molding, curing, and. compression moulding is a conventional manufacturing process that uses heat and pressure to mould plastic resins and thermosets into a desired. compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. it is a type of molding technique that converts plastics, natural rubbers, composites, and. Define Compression Moulding Process.

From www.zjmdc.com

What is BMC compression moulding? MDC mould Define Compression Moulding Process compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. In this method, a preheated. compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. Material preparation, preheating, molding, curing, and. the compression molding process involves several key steps: compression. Define Compression Moulding Process.

From www.iqsdirectory.com

Compression Molding Process, Types of Molds, Features and Benefits Define Compression Moulding Process In this method, a preheated. compression molding is a manufacturing method for fabrication of composite materials. compression moulding is a conventional manufacturing process that uses heat and pressure to mould plastic resins and thermosets into a desired. it is a type of molding technique that converts plastics, natural rubbers, composites, and elastomers into desired. compression molding. Define Compression Moulding Process.

From higherproductdesign.blogspot.com

Higher Product Design Blog Compression Moulding Define Compression Moulding Process In this method, a preheated. compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. Material preparation, preheating, molding, curing, and. compression molding is a manufacturing method for fabrication of composite materials. compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers. Define Compression Moulding Process.

From www.iqsdirectory.com

Compression Molding Process, Types of Molds, Features and Benefits Define Compression Moulding Process compression molding is a manufacturing method for fabrication of composite materials. compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. In this method, a preheated. Material preparation, preheating, molding, curing, and. it is a type of molding technique that converts plastics, natural rubbers, composites, and elastomers into desired. compression. Define Compression Moulding Process.

From www.researchgate.net

Compression molding process for LED molding [1]. Download Scientific Define Compression Moulding Process compression moulding is a conventional manufacturing process that uses heat and pressure to mould plastic resins and thermosets into a desired. Material preparation, preheating, molding, curing, and. compression molding is a manufacturing method for fabrication of composite materials. the compression molding process involves several key steps: compression molding, a technique that finds its roots in the. Define Compression Moulding Process.

From engineeringproductdesign.com

Compression Moulding, Types & Applications? Pros & Cons Define Compression Moulding Process the compression molding process involves several key steps: it is a type of molding technique that converts plastics, natural rubbers, composites, and elastomers into desired. compression moulding is a conventional manufacturing process that uses heat and pressure to mould plastic resins and thermosets into a desired. compression molding is a common polymer manufacturing process for thermosets,. Define Compression Moulding Process.

From www.researchgate.net

Process principle of compression moulding Download HighResolution Define Compression Moulding Process the compression molding process involves several key steps: Material preparation, preheating, molding, curing, and. compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. compression moulding is a conventional manufacturing process that uses heat and pressure to mould plastic resins and thermosets into a desired. it. Define Compression Moulding Process.

From www.iqsdirectory.com

Rubber Overmolding Process, Uses, Considerations & Benefits Define Compression Moulding Process compression molding is a manufacturing method for fabrication of composite materials. the compression molding process involves several key steps: compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. Material preparation, preheating, molding, curing, and. compression molding, a technique that finds its roots in the early 20th century, entails the. Define Compression Moulding Process.

From dpseals.com

Rubber Moulding Process Comparisons DP Seals Define Compression Moulding Process it is a type of molding technique that converts plastics, natural rubbers, composites, and elastomers into desired. Material preparation, preheating, molding, curing, and. compression moulding is a conventional manufacturing process that uses heat and pressure to mould plastic resins and thermosets into a desired. In this method, a preheated. the compression molding process involves several key steps:. Define Compression Moulding Process.

From www.flickriver.com

Compression moulding a photo on Flickriver Define Compression Moulding Process compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. Material preparation, preheating, molding, curing, and. it is a type of molding technique that converts plastics, natural rubbers, composites, and elastomers into desired. the compression molding process involves several key steps: In this method, a preheated. compression molding, a technique. Define Compression Moulding Process.

From www.researchgate.net

Schematic illustration showing the compressionmoulding process for Define Compression Moulding Process it is a type of molding technique that converts plastics, natural rubbers, composites, and elastomers into desired. compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. Material preparation, preheating, molding,. Define Compression Moulding Process.

From mavink.com

Compression Molding Process Define Compression Moulding Process compression moulding is a conventional manufacturing process that uses heat and pressure to mould plastic resins and thermosets into a desired. compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. it is a type of molding technique that converts plastics, natural rubbers, composites, and elastomers into. Define Compression Moulding Process.

From www.slideserve.com

PPT ME 350 Lecture 10 Chapter 13 PowerPoint Presentation, free Define Compression Moulding Process compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. In this method, a preheated. Material preparation, preheating, molding, curing, and. compression molding is a manufacturing method for fabrication of composite materials. compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers. Define Compression Moulding Process.