Plastic Injection Molding Machine Definition . That transforms raw plastic pellets into a myriad of products. using a specialized hydraulic or electric machine, the process melts, injects and sets plastic into the shape of a. injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. an injection molding machine is the most important equipment for injection molding; simply put, an injection molding machine is an intricate piece of equipment that produces plastic parts by. Finally, the moulded part, known typically as moulding, is extracted from the mould. plastics injection molding accounts for nearly 50% of all plastic processing methods. This marvel of modern engineering melds heat and pressure to morph plastics into shapes and sizes ranging from simple bottle caps to complex automotive components.

from www.igus.com

using a specialized hydraulic or electric machine, the process melts, injects and sets plastic into the shape of a. simply put, an injection molding machine is an intricate piece of equipment that produces plastic parts by. That transforms raw plastic pellets into a myriad of products. This marvel of modern engineering melds heat and pressure to morph plastics into shapes and sizes ranging from simple bottle caps to complex automotive components. plastics injection molding accounts for nearly 50% of all plastic processing methods. an injection molding machine is the most important equipment for injection molding; injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. Finally, the moulded part, known typically as moulding, is extracted from the mould.

for plastic injection molding machines

Plastic Injection Molding Machine Definition Finally, the moulded part, known typically as moulding, is extracted from the mould. injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. That transforms raw plastic pellets into a myriad of products. plastics injection molding accounts for nearly 50% of all plastic processing methods. using a specialized hydraulic or electric machine, the process melts, injects and sets plastic into the shape of a. This marvel of modern engineering melds heat and pressure to morph plastics into shapes and sizes ranging from simple bottle caps to complex automotive components. Finally, the moulded part, known typically as moulding, is extracted from the mould. simply put, an injection molding machine is an intricate piece of equipment that produces plastic parts by. an injection molding machine is the most important equipment for injection molding;

From www.twi-global.com

What is Injection Moulding? Definition, Types and Materials TWI Plastic Injection Molding Machine Definition simply put, an injection molding machine is an intricate piece of equipment that produces plastic parts by. That transforms raw plastic pellets into a myriad of products. an injection molding machine is the most important equipment for injection molding; plastics injection molding accounts for nearly 50% of all plastic processing methods. using a specialized hydraulic or. Plastic Injection Molding Machine Definition.

From www.iqsdirectory.com

Plastic Injection Molding What Is It? How Does It Work? Plastic Injection Molding Machine Definition using a specialized hydraulic or electric machine, the process melts, injects and sets plastic into the shape of a. Finally, the moulded part, known typically as moulding, is extracted from the mould. an injection molding machine is the most important equipment for injection molding; simply put, an injection molding machine is an intricate piece of equipment that. Plastic Injection Molding Machine Definition.

From www.made-in-china.com

Plastic Injection Molding Machine (120 TON HDT120) Plastic Machine Plastic Injection Molding Machine Definition using a specialized hydraulic or electric machine, the process melts, injects and sets plastic into the shape of a. Finally, the moulded part, known typically as moulding, is extracted from the mould. simply put, an injection molding machine is an intricate piece of equipment that produces plastic parts by. This marvel of modern engineering melds heat and pressure. Plastic Injection Molding Machine Definition.

From www.arptech.com.au

Injection Moulding Process Explained ArpTechBlog Plastic Injection Molding Machine Definition This marvel of modern engineering melds heat and pressure to morph plastics into shapes and sizes ranging from simple bottle caps to complex automotive components. using a specialized hydraulic or electric machine, the process melts, injects and sets plastic into the shape of a. injection moulding (im) is a manufacturing process in which a polymer is heated to. Plastic Injection Molding Machine Definition.

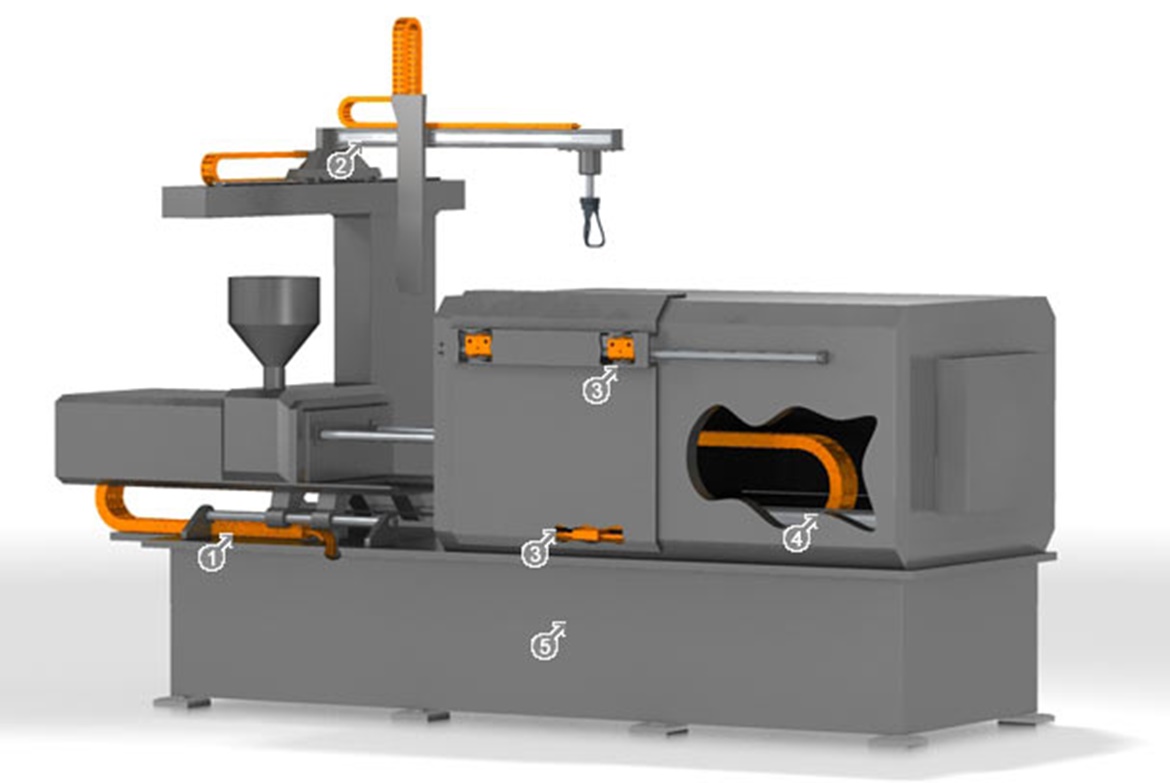

From www.lk.world

PLASTIC INJECTION MOLDING MACHINES LK Machinery Plastic Injection Molding Machine Definition plastics injection molding accounts for nearly 50% of all plastic processing methods. using a specialized hydraulic or electric machine, the process melts, injects and sets plastic into the shape of a. That transforms raw plastic pellets into a myriad of products. This marvel of modern engineering melds heat and pressure to morph plastics into shapes and sizes ranging. Plastic Injection Molding Machine Definition.

From prototechasia.com

What is Plastic Injection Molding? Our Comprehensive Overview Plastic Injection Molding Machine Definition plastics injection molding accounts for nearly 50% of all plastic processing methods. an injection molding machine is the most important equipment for injection molding; using a specialized hydraulic or electric machine, the process melts, injects and sets plastic into the shape of a. This marvel of modern engineering melds heat and pressure to morph plastics into shapes. Plastic Injection Molding Machine Definition.

From www.accupacking.com

170 Ton Automatic Plastic Injection Moulding Machine Horizontal Style Plastic Injection Molding Machine Definition plastics injection molding accounts for nearly 50% of all plastic processing methods. injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. Finally, the moulded part, known typically as moulding, is extracted from the mould. simply put, an injection. Plastic Injection Molding Machine Definition.

From www.simcobox.com

Plastic Injection Molding an Introduction by SimcoBox Plastic Injection Molding Machine Definition That transforms raw plastic pellets into a myriad of products. Finally, the moulded part, known typically as moulding, is extracted from the mould. injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. an injection molding machine is the most. Plastic Injection Molding Machine Definition.

From roboticsandautomationnews.com

Plastic Injection Molding Machines Types and Benefits Robotics Plastic Injection Molding Machine Definition Finally, the moulded part, known typically as moulding, is extracted from the mould. plastics injection molding accounts for nearly 50% of all plastic processing methods. using a specialized hydraulic or electric machine, the process melts, injects and sets plastic into the shape of a. simply put, an injection molding machine is an intricate piece of equipment that. Plastic Injection Molding Machine Definition.

From www.cdn-inc.com

Plastic Injection Molding Process Guide 2019 Full Process Explained Plastic Injection Molding Machine Definition injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. Finally, the moulded part, known typically as moulding, is extracted from the mould. simply put, an injection molding machine is an intricate piece of equipment that produces plastic parts by.. Plastic Injection Molding Machine Definition.

From themechanicalengineering.com

Injection Molding Definition, Construction, Working Process Plastic Injection Molding Machine Definition Finally, the moulded part, known typically as moulding, is extracted from the mould. That transforms raw plastic pellets into a myriad of products. This marvel of modern engineering melds heat and pressure to morph plastics into shapes and sizes ranging from simple bottle caps to complex automotive components. an injection molding machine is the most important equipment for injection. Plastic Injection Molding Machine Definition.

From www.3erp.com

What is Injection Molding and How Does it Work Definition & Working Plastic Injection Molding Machine Definition an injection molding machine is the most important equipment for injection molding; injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. Finally, the moulded part, known typically as moulding, is extracted from the mould. plastics injection molding accounts. Plastic Injection Molding Machine Definition.

From nbsurui.en.made-in-china.com

Fully Automatic Plastic Injection Molding/Moulding Machine for Plastic Plastic Injection Molding Machine Definition This marvel of modern engineering melds heat and pressure to morph plastics into shapes and sizes ranging from simple bottle caps to complex automotive components. injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. That transforms raw plastic pellets into. Plastic Injection Molding Machine Definition.

From www.rnaautomation.com

Robotics in Injection Moulding RNA Automation Plastic Injection Molding Machine Definition That transforms raw plastic pellets into a myriad of products. an injection molding machine is the most important equipment for injection molding; injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. simply put, an injection molding machine is. Plastic Injection Molding Machine Definition.

From www.log-imm.com

LOG Injection Molding Machine S8300T Servo Injection Molding Machine Plastic Injection Molding Machine Definition Finally, the moulded part, known typically as moulding, is extracted from the mould. That transforms raw plastic pellets into a myriad of products. injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. an injection molding machine is the most. Plastic Injection Molding Machine Definition.

From www.plastic-injectionmoldingmachine.com

10kW 120 Ton Injection Molding Machine , Small Plastic Injection Plastic Injection Molding Machine Definition That transforms raw plastic pellets into a myriad of products. injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. plastics injection molding accounts for nearly 50% of all plastic processing methods. an injection molding machine is the most. Plastic Injection Molding Machine Definition.

From www.hollyplasticparts.com

Plastic Injection Molding Glossary, download Terminology Document Plastic Injection Molding Machine Definition Finally, the moulded part, known typically as moulding, is extracted from the mould. That transforms raw plastic pellets into a myriad of products. an injection molding machine is the most important equipment for injection molding; simply put, an injection molding machine is an intricate piece of equipment that produces plastic parts by. This marvel of modern engineering melds. Plastic Injection Molding Machine Definition.

From www.ace-mold.com

Tools and Construction Methods of Plastic Injection Mold Making ACE Group Plastic Injection Molding Machine Definition injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. using a specialized hydraulic or electric machine, the process melts, injects and sets plastic into the shape of a. Finally, the moulded part, known typically as moulding, is extracted from. Plastic Injection Molding Machine Definition.

From www.magneticplaten.com

Injection Molding Basics What Is It and How Does It Work HVR MAG Plastic Injection Molding Machine Definition an injection molding machine is the most important equipment for injection molding; simply put, an injection molding machine is an intricate piece of equipment that produces plastic parts by. plastics injection molding accounts for nearly 50% of all plastic processing methods. This marvel of modern engineering melds heat and pressure to morph plastics into shapes and sizes. Plastic Injection Molding Machine Definition.

From sealectplastics.com

A Newbies Guide to Plastic Injection Molding SEALECT Plastics Plastic Injection Molding Machine Definition injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. simply put, an injection molding machine is an intricate piece of equipment that produces plastic parts by. using a specialized hydraulic or electric machine, the process melts, injects and. Plastic Injection Molding Machine Definition.

From predictabledesigns.com

Introduction to Injection Molding Plastic Injection Molding Machine Definition injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. That transforms raw plastic pellets into a myriad of products. plastics injection molding accounts for nearly 50% of all plastic processing methods. an injection molding machine is the most. Plastic Injection Molding Machine Definition.

From www.sourceint.com

Plastic Injection Molding The Manufacturing & Design Guide Source Plastic Injection Molding Machine Definition This marvel of modern engineering melds heat and pressure to morph plastics into shapes and sizes ranging from simple bottle caps to complex automotive components. an injection molding machine is the most important equipment for injection molding; using a specialized hydraulic or electric machine, the process melts, injects and sets plastic into the shape of a. plastics. Plastic Injection Molding Machine Definition.

From www.igus.com

for plastic injection molding machines Plastic Injection Molding Machine Definition That transforms raw plastic pellets into a myriad of products. injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. plastics injection molding accounts for nearly 50% of all plastic processing methods. Finally, the moulded part, known typically as moulding,. Plastic Injection Molding Machine Definition.

From www.youtube.com

Injection Molding Machine For Plastic Crate YouTube Plastic Injection Molding Machine Definition injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. This marvel of modern engineering melds heat and pressure to morph plastics into shapes and sizes ranging from simple bottle caps to complex automotive components. plastics injection molding accounts for. Plastic Injection Molding Machine Definition.

From bnt-machinery.com

How does injection moulding machine work? What is its structure? BNT Plastic Injection Molding Machine Definition Finally, the moulded part, known typically as moulding, is extracted from the mould. simply put, an injection molding machine is an intricate piece of equipment that produces plastic parts by. plastics injection molding accounts for nearly 50% of all plastic processing methods. That transforms raw plastic pellets into a myriad of products. using a specialized hydraulic or. Plastic Injection Molding Machine Definition.

From techsavvy.co.in

Sole Guide about PLASTIC INJECTION MOLDS TechSavvy Engineers Plastic Injection Molding Machine Definition This marvel of modern engineering melds heat and pressure to morph plastics into shapes and sizes ranging from simple bottle caps to complex automotive components. That transforms raw plastic pellets into a myriad of products. using a specialized hydraulic or electric machine, the process melts, injects and sets plastic into the shape of a. plastics injection molding accounts. Plastic Injection Molding Machine Definition.

From www.ace-mold.com

A 2020 Guide to Electric Plastic Injection Molding Machine ACE Group Plastic Injection Molding Machine Definition Finally, the moulded part, known typically as moulding, is extracted from the mould. plastics injection molding accounts for nearly 50% of all plastic processing methods. using a specialized hydraulic or electric machine, the process melts, injects and sets plastic into the shape of a. This marvel of modern engineering melds heat and pressure to morph plastics into shapes. Plastic Injection Molding Machine Definition.

From mavink.com

Injection Molding Machine Diagram Plastic Injection Molding Machine Definition an injection molding machine is the most important equipment for injection molding; That transforms raw plastic pellets into a myriad of products. plastics injection molding accounts for nearly 50% of all plastic processing methods. using a specialized hydraulic or electric machine, the process melts, injects and sets plastic into the shape of a. Finally, the moulded part,. Plastic Injection Molding Machine Definition.

From yingtu.en.made-in-china.com

Sm22000 2200 Tons of High Quality Automatic Plastic Injection Molding Plastic Injection Molding Machine Definition Finally, the moulded part, known typically as moulding, is extracted from the mould. This marvel of modern engineering melds heat and pressure to morph plastics into shapes and sizes ranging from simple bottle caps to complex automotive components. simply put, an injection molding machine is an intricate piece of equipment that produces plastic parts by. an injection molding. Plastic Injection Molding Machine Definition.

From www.xcentricmold.com

Injection Molding Process Xcentric Mold & Engineering Plastic Injection Molding Machine Definition That transforms raw plastic pellets into a myriad of products. simply put, an injection molding machine is an intricate piece of equipment that produces plastic parts by. This marvel of modern engineering melds heat and pressure to morph plastics into shapes and sizes ranging from simple bottle caps to complex automotive components. injection moulding (im) is a manufacturing. Plastic Injection Molding Machine Definition.

From www.nexpcb.com

One Picture to Understand the Structure of an Injection Mold Plastic Injection Molding Machine Definition using a specialized hydraulic or electric machine, the process melts, injects and sets plastic into the shape of a. plastics injection molding accounts for nearly 50% of all plastic processing methods. This marvel of modern engineering melds heat and pressure to morph plastics into shapes and sizes ranging from simple bottle caps to complex automotive components. injection. Plastic Injection Molding Machine Definition.

From www.rutlandplastics.co.uk

How does injection moulding work Rutland Plastics Plastic Injection Molding Machine Definition injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. plastics injection molding accounts for nearly 50% of all plastic processing methods. That transforms raw plastic pellets into a myriad of products. an injection molding machine is the most. Plastic Injection Molding Machine Definition.

From www.kaysun.com

Injection Molding Step by Step How Are Plastic Parts Made? Plastic Injection Molding Machine Definition simply put, an injection molding machine is an intricate piece of equipment that produces plastic parts by. an injection molding machine is the most important equipment for injection molding; plastics injection molding accounts for nearly 50% of all plastic processing methods. Finally, the moulded part, known typically as moulding, is extracted from the mould. injection moulding. Plastic Injection Molding Machine Definition.

From www.sourceint.com

Plastic Injection Molded Products Source International Plastic Injection Molding Machine Definition using a specialized hydraulic or electric machine, the process melts, injects and sets plastic into the shape of a. simply put, an injection molding machine is an intricate piece of equipment that produces plastic parts by. This marvel of modern engineering melds heat and pressure to morph plastics into shapes and sizes ranging from simple bottle caps to. Plastic Injection Molding Machine Definition.

From total-manufacturing.com

Plastic Injection Molding The Injection Molding Machine Plastic Injection Molding Machine Definition using a specialized hydraulic or electric machine, the process melts, injects and sets plastic into the shape of a. That transforms raw plastic pellets into a myriad of products. simply put, an injection molding machine is an intricate piece of equipment that produces plastic parts by. Finally, the moulded part, known typically as moulding, is extracted from the. Plastic Injection Molding Machine Definition.