Endless Round Sling Inspection Checklist . Remove your synthetic round sling for service if these conditions are present: Make periodic inspections of synthetic round slings at intervals no greater than 12 months. Items to look for include: Holes, tears, cuts, abrasive wear or snags that expose the core yarns. Inspect sling for damage regularly, if the sling is sling under tension. This checklist has been developed by pelican & slingspector. All personnel should be alert to damaged, remove it from service. A good guide to follow includes: Melting or charring of any part of the. Weld splatter that exposes core yarns. Ensure this checklist is suitable for your particular sling, sling user, and the. Danger of falling and/or uncontrolled load, sling tension. Missing or illegible sling identification. Missing or illegible sling identification. Make a thorough inspection of slings and attachments.

from www.scribd.com

Holes, tears, cuts, abrasive wear or snags that expose the core yarns. Remove your synthetic round sling for service if these conditions are present: Broken or damaged core yarns. Melting or charring of any part of the. Danger of falling and/or uncontrolled load, sling tension. A good guide to follow includes: This checklist has been developed by pelican & slingspector. Ensure this checklist is suitable for your particular sling, sling user, and the. Items to look for include: Make periodic inspections of synthetic round slings at intervals no greater than 12 months.

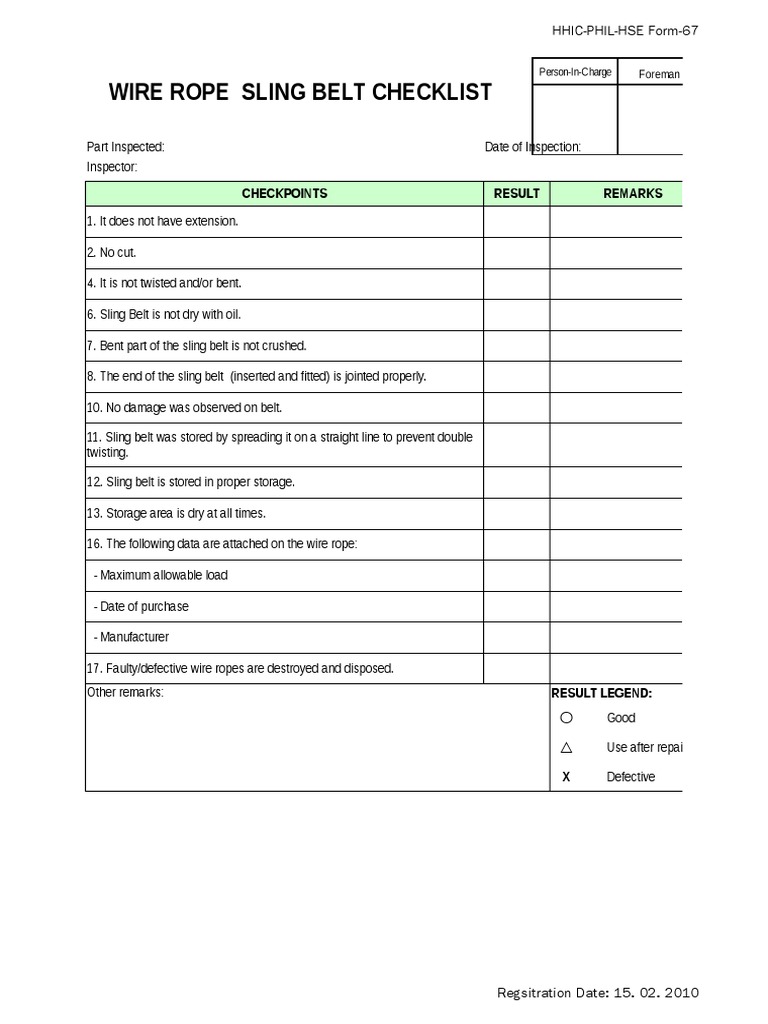

Sling Belt & Wire Rope Inspection Checklist

Endless Round Sling Inspection Checklist All personnel should be alert to damaged, remove it from service. Broken or damaged core yarns. Melting or charring of any part of the. Make a thorough inspection of slings and attachments. Missing or illegible sling identification. Ensure this checklist is suitable for your particular sling, sling user, and the. Danger of falling and/or uncontrolled load, sling tension. Items to look for include: All personnel should be alert to damaged, remove it from service. Remove your synthetic round sling for service if these conditions are present: Make periodic inspections of synthetic round slings at intervals no greater than 12 months. This checklist has been developed by pelican & slingspector. Weld splatter that exposes core yarns. Inspect sling for damage regularly, if the sling is sling under tension. Holes, tears, cuts, abrasive wear or snags that expose the core yarns. A good guide to follow includes:

From www.asaka-lifting.com

WholesaleQuality Inspection for High Strength 8t Round Endless Slings Endless Round Sling Inspection Checklist Melting or charring of any part of the. Broken or damaged core yarns. Make a thorough inspection of slings and attachments. Missing or illegible sling identification. All personnel should be alert to damaged, remove it from service. Holes, tears, cuts, abrasive wear or snags that expose the core yarns. Inspect sling for damage regularly, if the sling is sling under. Endless Round Sling Inspection Checklist.

From www.scribd.com

MANM300000GH00FOR000151 Rev 0 Shackles and Chain Sling Endless Round Sling Inspection Checklist Make periodic inspections of synthetic round slings at intervals no greater than 12 months. Remove your synthetic round sling for service if these conditions are present: All personnel should be alert to damaged, remove it from service. Danger of falling and/or uncontrolled load, sling tension. Missing or illegible sling identification. This checklist has been developed by pelican & slingspector. Inspect. Endless Round Sling Inspection Checklist.

From securelift.net

ROUND SLINGS ENDLESS SecureLift Endless Round Sling Inspection Checklist This checklist has been developed by pelican & slingspector. Inspect sling for damage regularly, if the sling is sling under tension. Weld splatter that exposes core yarns. Make a thorough inspection of slings and attachments. Items to look for include: Melting or charring of any part of the. Remove your synthetic round sling for service if these conditions are present:. Endless Round Sling Inspection Checklist.

From www.hsedocuments.com

Sling Inspection Checklist HSE Documents Endless Round Sling Inspection Checklist Inspect sling for damage regularly, if the sling is sling under tension. A good guide to follow includes: Broken or damaged core yarns. Ensure this checklist is suitable for your particular sling, sling user, and the. Danger of falling and/or uncontrolled load, sling tension. Missing or illegible sling identification. Missing or illegible sling identification. Make periodic inspections of synthetic round. Endless Round Sling Inspection Checklist.

From sling-inspection-form-template.com

Sling Inspection Form Template Nocode Form Builder Endless Round Sling Inspection Checklist Broken or damaged core yarns. Ensure this checklist is suitable for your particular sling, sling user, and the. A good guide to follow includes: Items to look for include: Melting or charring of any part of the. Weld splatter that exposes core yarns. Holes, tears, cuts, abrasive wear or snags that expose the core yarns. Make periodic inspections of synthetic. Endless Round Sling Inspection Checklist.

From www.studypool.com

SOLUTION Sling inspection checklist Studypool Endless Round Sling Inspection Checklist Make a thorough inspection of slings and attachments. Inspect sling for damage regularly, if the sling is sling under tension. Weld splatter that exposes core yarns. This checklist has been developed by pelican & slingspector. A good guide to follow includes: Holes, tears, cuts, abrasive wear or snags that expose the core yarns. Danger of falling and/or uncontrolled load, sling. Endless Round Sling Inspection Checklist.

From resources.herculesslr.com

Round Sling Inspection Hercules SLR Endless Round Sling Inspection Checklist All personnel should be alert to damaged, remove it from service. Holes, tears, cuts, abrasive wear or snags that expose the core yarns. Danger of falling and/or uncontrolled load, sling tension. Make periodic inspections of synthetic round slings at intervals no greater than 12 months. A good guide to follow includes: Items to look for include: Make a thorough inspection. Endless Round Sling Inspection Checklist.

From www.scribd.com

Sling Belt & Wire Rope Inspection Checklist Endless Round Sling Inspection Checklist Make a thorough inspection of slings and attachments. Missing or illegible sling identification. Ensure this checklist is suitable for your particular sling, sling user, and the. Make periodic inspections of synthetic round slings at intervals no greater than 12 months. This checklist has been developed by pelican & slingspector. Weld splatter that exposes core yarns. Items to look for include:. Endless Round Sling Inspection Checklist.

From www.mazzellacompanies.com

How to Inspect a Synthetic Roundsling to ASME B30.9 Standards Endless Round Sling Inspection Checklist Missing or illegible sling identification. Missing or illegible sling identification. A good guide to follow includes: Ensure this checklist is suitable for your particular sling, sling user, and the. Holes, tears, cuts, abrasive wear or snags that expose the core yarns. Inspect sling for damage regularly, if the sling is sling under tension. Weld splatter that exposes core yarns. All. Endless Round Sling Inspection Checklist.

From loeahwnir.blob.core.windows.net

Sling Inspection at Tommy William blog Endless Round Sling Inspection Checklist All personnel should be alert to damaged, remove it from service. Inspect sling for damage regularly, if the sling is sling under tension. Melting or charring of any part of the. Broken or damaged core yarns. Missing or illegible sling identification. Danger of falling and/or uncontrolled load, sling tension. Remove your synthetic round sling for service if these conditions are. Endless Round Sling Inspection Checklist.

From mavink.com

Lifting Sling Inspection Form Endless Round Sling Inspection Checklist All personnel should be alert to damaged, remove it from service. Ensure this checklist is suitable for your particular sling, sling user, and the. Inspect sling for damage regularly, if the sling is sling under tension. A good guide to follow includes: Danger of falling and/or uncontrolled load, sling tension. Missing or illegible sling identification. This checklist has been developed. Endless Round Sling Inspection Checklist.

From www.pinterest.com

Inspection of Synthetic Slings & Polyester Roundslings (Poster Endless Round Sling Inspection Checklist All personnel should be alert to damaged, remove it from service. A good guide to follow includes: Holes, tears, cuts, abrasive wear or snags that expose the core yarns. Missing or illegible sling identification. Items to look for include: Melting or charring of any part of the. Weld splatter that exposes core yarns. This checklist has been developed by pelican. Endless Round Sling Inspection Checklist.

From www.slideshare.net

Lifting Sling Safety Endless Round Sling Inspection Checklist Danger of falling and/or uncontrolled load, sling tension. Holes, tears, cuts, abrasive wear or snags that expose the core yarns. Missing or illegible sling identification. Weld splatter that exposes core yarns. A good guide to follow includes: Make a thorough inspection of slings and attachments. Remove your synthetic round sling for service if these conditions are present: Ensure this checklist. Endless Round Sling Inspection Checklist.

From www.kljack.com

Liftex 16' Endless Round Sling Green K.L. Jack Endless Round Sling Inspection Checklist Missing or illegible sling identification. This checklist has been developed by pelican & slingspector. Melting or charring of any part of the. Make periodic inspections of synthetic round slings at intervals no greater than 12 months. Make a thorough inspection of slings and attachments. Weld splatter that exposes core yarns. Remove your synthetic round sling for service if these conditions. Endless Round Sling Inspection Checklist.

From www.uscargocontrol.com

Endless SinglePath Slings CheckFast® Inspection System Endless Round Sling Inspection Checklist All personnel should be alert to damaged, remove it from service. Missing or illegible sling identification. Items to look for include: Weld splatter that exposes core yarns. Inspect sling for damage regularly, if the sling is sling under tension. Make a thorough inspection of slings and attachments. Missing or illegible sling identification. Melting or charring of any part of the.. Endless Round Sling Inspection Checklist.

From www.macmor.com

Macline Yellow (ML90) Endless Round Slings MacMor Industries Endless Round Sling Inspection Checklist Broken or damaged core yarns. Make periodic inspections of synthetic round slings at intervals no greater than 12 months. Items to look for include: A good guide to follow includes: Holes, tears, cuts, abrasive wear or snags that expose the core yarns. Ensure this checklist is suitable for your particular sling, sling user, and the. Remove your synthetic round sling. Endless Round Sling Inspection Checklist.

From www.slideshare.net

Nylon Slings Inspection Checklist Endless Round Sling Inspection Checklist Items to look for include: Holes, tears, cuts, abrasive wear or snags that expose the core yarns. Missing or illegible sling identification. Inspect sling for damage regularly, if the sling is sling under tension. Weld splatter that exposes core yarns. Melting or charring of any part of the. Make periodic inspections of synthetic round slings at intervals no greater than. Endless Round Sling Inspection Checklist.

From www.scribd.com

FC 4.1.6 Synthetic Sling Inspection Checklist Form PDF Endless Round Sling Inspection Checklist All personnel should be alert to damaged, remove it from service. Weld splatter that exposes core yarns. Ensure this checklist is suitable for your particular sling, sling user, and the. Holes, tears, cuts, abrasive wear or snags that expose the core yarns. A good guide to follow includes: Remove your synthetic round sling for service if these conditions are present:. Endless Round Sling Inspection Checklist.

From ferreterro.com

Endless Round Slings Ferreterro India Pvt. Ltd. Endless Round Sling Inspection Checklist Ensure this checklist is suitable for your particular sling, sling user, and the. Melting or charring of any part of the. Holes, tears, cuts, abrasive wear or snags that expose the core yarns. Missing or illegible sling identification. Inspect sling for damage regularly, if the sling is sling under tension. Items to look for include: Make a thorough inspection of. Endless Round Sling Inspection Checklist.

From vvmaritime.ro

Round endless slings Lifting and mooring equipment inspections Endless Round Sling Inspection Checklist A good guide to follow includes: Inspect sling for damage regularly, if the sling is sling under tension. Items to look for include: Broken or damaged core yarns. Remove your synthetic round sling for service if these conditions are present: Holes, tears, cuts, abrasive wear or snags that expose the core yarns. This checklist has been developed by pelican &. Endless Round Sling Inspection Checklist.

From www.irishironwrecker.com

Endless Round Sling Green Irish Iron Wrecker Endless Round Sling Inspection Checklist A good guide to follow includes: Items to look for include: Make periodic inspections of synthetic round slings at intervals no greater than 12 months. Ensure this checklist is suitable for your particular sling, sling user, and the. Weld splatter that exposes core yarns. Inspect sling for damage regularly, if the sling is sling under tension. Melting or charring of. Endless Round Sling Inspection Checklist.

From www.scribd.com

014Sling Inspection Checklist PDF Rope Wire Endless Round Sling Inspection Checklist Make periodic inspections of synthetic round slings at intervals no greater than 12 months. Melting or charring of any part of the. Ensure this checklist is suitable for your particular sling, sling user, and the. Broken or damaged core yarns. Missing or illegible sling identification. Holes, tears, cuts, abrasive wear or snags that expose the core yarns. Remove your synthetic. Endless Round Sling Inspection Checklist.

From www.scribd.com

Sling Inspection Checklist General Requirements and Inspection Endless Round Sling Inspection Checklist Items to look for include: Make a thorough inspection of slings and attachments. Ensure this checklist is suitable for your particular sling, sling user, and the. Inspect sling for damage regularly, if the sling is sling under tension. Holes, tears, cuts, abrasive wear or snags that expose the core yarns. Broken or damaged core yarns. A good guide to follow. Endless Round Sling Inspection Checklist.

From www.pinterest.co.uk

best sling inspection form template example Published by Michael Nardi Endless Round Sling Inspection Checklist Melting or charring of any part of the. Items to look for include: Missing or illegible sling identification. Holes, tears, cuts, abrasive wear or snags that expose the core yarns. Ensure this checklist is suitable for your particular sling, sling user, and the. Broken or damaged core yarns. Weld splatter that exposes core yarns. Make a thorough inspection of slings. Endless Round Sling Inspection Checklist.

From www.scribd.com

Round Sling Inspection Check List PDF Endless Round Sling Inspection Checklist This checklist has been developed by pelican & slingspector. Ensure this checklist is suitable for your particular sling, sling user, and the. Weld splatter that exposes core yarns. Melting or charring of any part of the. Make periodic inspections of synthetic round slings at intervals no greater than 12 months. Make a thorough inspection of slings and attachments. Missing or. Endless Round Sling Inspection Checklist.

From twaylifting.com

LiftAll® Tuflex EN60 Green Endless Round Slings Lift All Round Slings Endless Round Sling Inspection Checklist A good guide to follow includes: Melting or charring of any part of the. Danger of falling and/or uncontrolled load, sling tension. Holes, tears, cuts, abrasive wear or snags that expose the core yarns. Missing or illegible sling identification. Missing or illegible sling identification. Inspect sling for damage regularly, if the sling is sling under tension. Weld splatter that exposes. Endless Round Sling Inspection Checklist.

From www.scribd.com

FC 4.1.5 Flexible Steel Wire Rope Sling (FSWR) Inspection Checklist Endless Round Sling Inspection Checklist All personnel should be alert to damaged, remove it from service. Broken or damaged core yarns. Items to look for include: Danger of falling and/or uncontrolled load, sling tension. Inspect sling for damage regularly, if the sling is sling under tension. This checklist has been developed by pelican & slingspector. Holes, tears, cuts, abrasive wear or snags that expose the. Endless Round Sling Inspection Checklist.

From www.scribd.com

BR Lifting Sling Inspection Criteria R2 PDF Rope Knot Endless Round Sling Inspection Checklist Ensure this checklist is suitable for your particular sling, sling user, and the. A good guide to follow includes: Items to look for include: Make a thorough inspection of slings and attachments. All personnel should be alert to damaged, remove it from service. Inspect sling for damage regularly, if the sling is sling under tension. Remove your synthetic round sling. Endless Round Sling Inspection Checklist.

From www.safetymgmtstudy.com

Sling Inspection Checklist PDF/Doc Endless Round Sling Inspection Checklist Broken or damaged core yarns. Missing or illegible sling identification. Weld splatter that exposes core yarns. Ensure this checklist is suitable for your particular sling, sling user, and the. Melting or charring of any part of the. Missing or illegible sling identification. Items to look for include: Holes, tears, cuts, abrasive wear or snags that expose the core yarns. Remove. Endless Round Sling Inspection Checklist.

From www.scribd.com

Chain Sling Assembly Inspection Checklist Form PDF Endless Round Sling Inspection Checklist Danger of falling and/or uncontrolled load, sling tension. Ensure this checklist is suitable for your particular sling, sling user, and the. This checklist has been developed by pelican & slingspector. Make periodic inspections of synthetic round slings at intervals no greater than 12 months. Missing or illegible sling identification. Weld splatter that exposes core yarns. A good guide to follow. Endless Round Sling Inspection Checklist.

From www.linkedin.com

How to inspect the lifting chain slingInspection checklist Endless Round Sling Inspection Checklist This checklist has been developed by pelican & slingspector. A good guide to follow includes: Ensure this checklist is suitable for your particular sling, sling user, and the. Weld splatter that exposes core yarns. Inspect sling for damage regularly, if the sling is sling under tension. Make a thorough inspection of slings and attachments. Remove your synthetic round sling for. Endless Round Sling Inspection Checklist.

From www.lift-it.com

RoundSling Safety Information LiftIt® Manufacturing Endless Round Sling Inspection Checklist Melting or charring of any part of the. This checklist has been developed by pelican & slingspector. All personnel should be alert to damaged, remove it from service. Make a thorough inspection of slings and attachments. Missing or illegible sling identification. Make periodic inspections of synthetic round slings at intervals no greater than 12 months. Items to look for include:. Endless Round Sling Inspection Checklist.

From hollyburton.z19.web.core.windows.net

Endless Round Sling Chart Endless Round Sling Inspection Checklist Missing or illegible sling identification. This checklist has been developed by pelican & slingspector. Inspect sling for damage regularly, if the sling is sling under tension. Items to look for include: Remove your synthetic round sling for service if these conditions are present: Missing or illegible sling identification. Make a thorough inspection of slings and attachments. A good guide to. Endless Round Sling Inspection Checklist.

From nexglobal.com.sg

Round Sling Endless NEX Global Enterprises Endless Round Sling Inspection Checklist Ensure this checklist is suitable for your particular sling, sling user, and the. Melting or charring of any part of the. Danger of falling and/or uncontrolled load, sling tension. All personnel should be alert to damaged, remove it from service. Inspect sling for damage regularly, if the sling is sling under tension. Remove your synthetic round sling for service if. Endless Round Sling Inspection Checklist.

From www.scribd.com

HSE 0XXX Sling Inspection Checklist PDF Endless Round Sling Inspection Checklist Items to look for include: Missing or illegible sling identification. Ensure this checklist is suitable for your particular sling, sling user, and the. A good guide to follow includes: Melting or charring of any part of the. Make a thorough inspection of slings and attachments. Danger of falling and/or uncontrolled load, sling tension. Broken or damaged core yarns. Make periodic. Endless Round Sling Inspection Checklist.