Metallurgy Reduction Process . Refractory metals are normally made by hydrogen reduction of oxides, and the same process can be used for copper. Direct reduction ironmaking is a process that involves reducing iron ore to obtain metallic iron in a reaction vessel using gas or solid reducing. Hydrogen reduction of metal oxides has been extensively studied at laboratory scale, particularly in regard to kinetics and reaction. Metallothermic reduction is a general term for reduction reactions conducted to obtain a target metal or compound from feed material. Besides mrrs, there are a plethora of reduction methods that are widely employed in materials preparation and manufacturing.

from joirorfse.blob.core.windows.net

Besides mrrs, there are a plethora of reduction methods that are widely employed in materials preparation and manufacturing. Hydrogen reduction of metal oxides has been extensively studied at laboratory scale, particularly in regard to kinetics and reaction. Direct reduction ironmaking is a process that involves reducing iron ore to obtain metallic iron in a reaction vessel using gas or solid reducing. Refractory metals are normally made by hydrogen reduction of oxides, and the same process can be used for copper. Metallothermic reduction is a general term for reduction reactions conducted to obtain a target metal or compound from feed material.

Process Metallurgy And Electrolysis at Amie Lachapelle blog

Metallurgy Reduction Process Besides mrrs, there are a plethora of reduction methods that are widely employed in materials preparation and manufacturing. Hydrogen reduction of metal oxides has been extensively studied at laboratory scale, particularly in regard to kinetics and reaction. Besides mrrs, there are a plethora of reduction methods that are widely employed in materials preparation and manufacturing. Refractory metals are normally made by hydrogen reduction of oxides, and the same process can be used for copper. Metallothermic reduction is a general term for reduction reactions conducted to obtain a target metal or compound from feed material. Direct reduction ironmaking is a process that involves reducing iron ore to obtain metallic iron in a reaction vessel using gas or solid reducing.

From saylordotorg.github.io

Metallurgy Metallurgy Reduction Process Refractory metals are normally made by hydrogen reduction of oxides, and the same process can be used for copper. Direct reduction ironmaking is a process that involves reducing iron ore to obtain metallic iron in a reaction vessel using gas or solid reducing. Besides mrrs, there are a plethora of reduction methods that are widely employed in materials preparation and. Metallurgy Reduction Process.

From www.researchgate.net

Powder metallurgy process Download Scientific Diagram Metallurgy Reduction Process Refractory metals are normally made by hydrogen reduction of oxides, and the same process can be used for copper. Hydrogen reduction of metal oxides has been extensively studied at laboratory scale, particularly in regard to kinetics and reaction. Metallothermic reduction is a general term for reduction reactions conducted to obtain a target metal or compound from feed material. Direct reduction. Metallurgy Reduction Process.

From www.youtube.com

METALLURGY / CHAPTER 1 / CLASS 12 / Part 3 (Reduction of metal oxides Metallurgy Reduction Process Besides mrrs, there are a plethora of reduction methods that are widely employed in materials preparation and manufacturing. Hydrogen reduction of metal oxides has been extensively studied at laboratory scale, particularly in regard to kinetics and reaction. Refractory metals are normally made by hydrogen reduction of oxides, and the same process can be used for copper. Metallothermic reduction is a. Metallurgy Reduction Process.

From www.youtube.com

+2 Chemistry Unit 1 Metallurgy Reduction of metal oxides Metallurgy Reduction Process Hydrogen reduction of metal oxides has been extensively studied at laboratory scale, particularly in regard to kinetics and reaction. Besides mrrs, there are a plethora of reduction methods that are widely employed in materials preparation and manufacturing. Metallothermic reduction is a general term for reduction reactions conducted to obtain a target metal or compound from feed material. Refractory metals are. Metallurgy Reduction Process.

From www.researchgate.net

A schematic illustration of the powder metallurgy route to prepare Metallurgy Reduction Process Refractory metals are normally made by hydrogen reduction of oxides, and the same process can be used for copper. Besides mrrs, there are a plethora of reduction methods that are widely employed in materials preparation and manufacturing. Direct reduction ironmaking is a process that involves reducing iron ore to obtain metallic iron in a reaction vessel using gas or solid. Metallurgy Reduction Process.

From chem.libretexts.org

23.3 Metallurgy of Iron and Steel Chemistry LibreTexts Metallurgy Reduction Process Metallothermic reduction is a general term for reduction reactions conducted to obtain a target metal or compound from feed material. Besides mrrs, there are a plethora of reduction methods that are widely employed in materials preparation and manufacturing. Refractory metals are normally made by hydrogen reduction of oxides, and the same process can be used for copper. Hydrogen reduction of. Metallurgy Reduction Process.

From www.iqsdirectory.com

Powder Metallurgy What Is It? Processes, Parts, Metals Used Metallurgy Reduction Process Refractory metals are normally made by hydrogen reduction of oxides, and the same process can be used for copper. Metallothermic reduction is a general term for reduction reactions conducted to obtain a target metal or compound from feed material. Besides mrrs, there are a plethora of reduction methods that are widely employed in materials preparation and manufacturing. Hydrogen reduction of. Metallurgy Reduction Process.

From www.youtube.com

Steps involved in Metallurgy YouTube Metallurgy Reduction Process Besides mrrs, there are a plethora of reduction methods that are widely employed in materials preparation and manufacturing. Metallothermic reduction is a general term for reduction reactions conducted to obtain a target metal or compound from feed material. Direct reduction ironmaking is a process that involves reducing iron ore to obtain metallic iron in a reaction vessel using gas or. Metallurgy Reduction Process.

From www.pw.live

Metallurgy Use, Type, Definition, Formuals, Examples Physics Wallah Metallurgy Reduction Process Refractory metals are normally made by hydrogen reduction of oxides, and the same process can be used for copper. Hydrogen reduction of metal oxides has been extensively studied at laboratory scale, particularly in regard to kinetics and reaction. Direct reduction ironmaking is a process that involves reducing iron ore to obtain metallic iron in a reaction vessel using gas or. Metallurgy Reduction Process.

From ijmmm.ustb.edu.cn

Development and progress on hydrogen metallurgy Metallurgy Reduction Process Metallothermic reduction is a general term for reduction reactions conducted to obtain a target metal or compound from feed material. Hydrogen reduction of metal oxides has been extensively studied at laboratory scale, particularly in regard to kinetics and reaction. Refractory metals are normally made by hydrogen reduction of oxides, and the same process can be used for copper. Direct reduction. Metallurgy Reduction Process.

From www.youtube.com

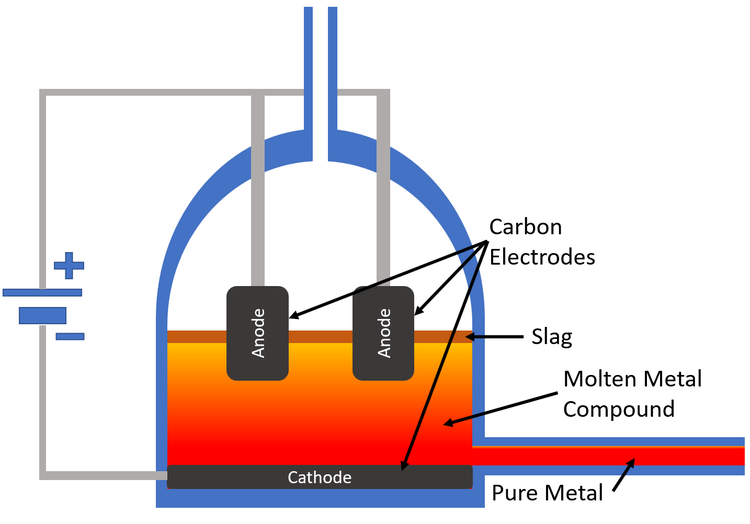

Electrolytic reduction of alumina metallurgy science with sachin Metallurgy Reduction Process Direct reduction ironmaking is a process that involves reducing iron ore to obtain metallic iron in a reaction vessel using gas or solid reducing. Hydrogen reduction of metal oxides has been extensively studied at laboratory scale, particularly in regard to kinetics and reaction. Besides mrrs, there are a plethora of reduction methods that are widely employed in materials preparation and. Metallurgy Reduction Process.

From overallscience.com

Extraction of Metals (Metallurgy) Overall Science Metallurgy Reduction Process Besides mrrs, there are a plethora of reduction methods that are widely employed in materials preparation and manufacturing. Hydrogen reduction of metal oxides has been extensively studied at laboratory scale, particularly in regard to kinetics and reaction. Direct reduction ironmaking is a process that involves reducing iron ore to obtain metallic iron in a reaction vessel using gas or solid. Metallurgy Reduction Process.

From mechcontentduet.blogspot.com

Metallurgy & Heat Treatment of Metal (MCQ) Tuhin Engineering Academy Metallurgy Reduction Process Metallothermic reduction is a general term for reduction reactions conducted to obtain a target metal or compound from feed material. Refractory metals are normally made by hydrogen reduction of oxides, and the same process can be used for copper. Direct reduction ironmaking is a process that involves reducing iron ore to obtain metallic iron in a reaction vessel using gas. Metallurgy Reduction Process.

From www.mech4study.com

Powder Metallurgy Process with its Advantages and Disadvantages Metallurgy Reduction Process Direct reduction ironmaking is a process that involves reducing iron ore to obtain metallic iron in a reaction vessel using gas or solid reducing. Hydrogen reduction of metal oxides has been extensively studied at laboratory scale, particularly in regard to kinetics and reaction. Besides mrrs, there are a plethora of reduction methods that are widely employed in materials preparation and. Metallurgy Reduction Process.

From learnmechanical.com

Powder Metallurgy Process Definition, Application, Advantages, PDF Metallurgy Reduction Process Hydrogen reduction of metal oxides has been extensively studied at laboratory scale, particularly in regard to kinetics and reaction. Besides mrrs, there are a plethora of reduction methods that are widely employed in materials preparation and manufacturing. Direct reduction ironmaking is a process that involves reducing iron ore to obtain metallic iron in a reaction vessel using gas or solid. Metallurgy Reduction Process.

From www.tec-science.com

Direct reduced iron process tecscience Metallurgy Reduction Process Metallothermic reduction is a general term for reduction reactions conducted to obtain a target metal or compound from feed material. Direct reduction ironmaking is a process that involves reducing iron ore to obtain metallic iron in a reaction vessel using gas or solid reducing. Refractory metals are normally made by hydrogen reduction of oxides, and the same process can be. Metallurgy Reduction Process.

From www.youtube.com

Smelting process Metallurgy Reduction process of Metallic oxide Metallurgy Reduction Process Refractory metals are normally made by hydrogen reduction of oxides, and the same process can be used for copper. Besides mrrs, there are a plethora of reduction methods that are widely employed in materials preparation and manufacturing. Direct reduction ironmaking is a process that involves reducing iron ore to obtain metallic iron in a reaction vessel using gas or solid. Metallurgy Reduction Process.

From www.iqsdirectory.com

Powder Metallurgy What Is It? Processes, Parts, Metals Used Metallurgy Reduction Process Metallothermic reduction is a general term for reduction reactions conducted to obtain a target metal or compound from feed material. Refractory metals are normally made by hydrogen reduction of oxides, and the same process can be used for copper. Besides mrrs, there are a plethora of reduction methods that are widely employed in materials preparation and manufacturing. Direct reduction ironmaking. Metallurgy Reduction Process.

From www.youtube.com

Metallurgy Reduction of metal oxides into metals /Smelting class 12 Metallurgy Reduction Process Direct reduction ironmaking is a process that involves reducing iron ore to obtain metallic iron in a reaction vessel using gas or solid reducing. Refractory metals are normally made by hydrogen reduction of oxides, and the same process can be used for copper. Hydrogen reduction of metal oxides has been extensively studied at laboratory scale, particularly in regard to kinetics. Metallurgy Reduction Process.

From www.youtube.com

HallHeroult Process Electrolytic Reduction of Fused Alumina Metallurgy Reduction Process Refractory metals are normally made by hydrogen reduction of oxides, and the same process can be used for copper. Besides mrrs, there are a plethora of reduction methods that are widely employed in materials preparation and manufacturing. Direct reduction ironmaking is a process that involves reducing iron ore to obtain metallic iron in a reaction vessel using gas or solid. Metallurgy Reduction Process.

From www.researchgate.net

Powder metallurgy process procedure Download Scientific Diagram Metallurgy Reduction Process Direct reduction ironmaking is a process that involves reducing iron ore to obtain metallic iron in a reaction vessel using gas or solid reducing. Refractory metals are normally made by hydrogen reduction of oxides, and the same process can be used for copper. Metallothermic reduction is a general term for reduction reactions conducted to obtain a target metal or compound. Metallurgy Reduction Process.

From www.slideserve.com

PPT METALLURGY PowerPoint Presentation, free download ID5812711 Metallurgy Reduction Process Refractory metals are normally made by hydrogen reduction of oxides, and the same process can be used for copper. Hydrogen reduction of metal oxides has been extensively studied at laboratory scale, particularly in regard to kinetics and reaction. Metallothermic reduction is a general term for reduction reactions conducted to obtain a target metal or compound from feed material. Besides mrrs,. Metallurgy Reduction Process.

From www.researchgate.net

Technical characteristics of the PbZn metallurgical reduction process Metallurgy Reduction Process Refractory metals are normally made by hydrogen reduction of oxides, and the same process can be used for copper. Hydrogen reduction of metal oxides has been extensively studied at laboratory scale, particularly in regard to kinetics and reaction. Direct reduction ironmaking is a process that involves reducing iron ore to obtain metallic iron in a reaction vessel using gas or. Metallurgy Reduction Process.

From www.slideserve.com

PPT Chapter 23 Metals and Metallurgy PowerPoint Presentation, free Metallurgy Reduction Process Hydrogen reduction of metal oxides has been extensively studied at laboratory scale, particularly in regard to kinetics and reaction. Direct reduction ironmaking is a process that involves reducing iron ore to obtain metallic iron in a reaction vessel using gas or solid reducing. Besides mrrs, there are a plethora of reduction methods that are widely employed in materials preparation and. Metallurgy Reduction Process.

From www.iqsdirectory.com

Powder Metallurgy What Is It? Processes, Parts, Metals Used Metallurgy Reduction Process Refractory metals are normally made by hydrogen reduction of oxides, and the same process can be used for copper. Metallothermic reduction is a general term for reduction reactions conducted to obtain a target metal or compound from feed material. Hydrogen reduction of metal oxides has been extensively studied at laboratory scale, particularly in regard to kinetics and reaction. Direct reduction. Metallurgy Reduction Process.

From www.iqsdirectory.com

Powder Metallurgy What Is It? Processes, Parts, Metals Used Metallurgy Reduction Process Metallothermic reduction is a general term for reduction reactions conducted to obtain a target metal or compound from feed material. Besides mrrs, there are a plethora of reduction methods that are widely employed in materials preparation and manufacturing. Refractory metals are normally made by hydrogen reduction of oxides, and the same process can be used for copper. Hydrogen reduction of. Metallurgy Reduction Process.

From joirorfse.blob.core.windows.net

Process Metallurgy And Electrolysis at Amie Lachapelle blog Metallurgy Reduction Process Direct reduction ironmaking is a process that involves reducing iron ore to obtain metallic iron in a reaction vessel using gas or solid reducing. Refractory metals are normally made by hydrogen reduction of oxides, and the same process can be used for copper. Metallothermic reduction is a general term for reduction reactions conducted to obtain a target metal or compound. Metallurgy Reduction Process.

From www.researchgate.net

Conventional powder metallurgy process from metal powder to finished Metallurgy Reduction Process Refractory metals are normally made by hydrogen reduction of oxides, and the same process can be used for copper. Direct reduction ironmaking is a process that involves reducing iron ore to obtain metallic iron in a reaction vessel using gas or solid reducing. Hydrogen reduction of metal oxides has been extensively studied at laboratory scale, particularly in regard to kinetics. Metallurgy Reduction Process.

From byjus.com

Flowchart of Extraction of Metals Metallurgy Reduction Process Refractory metals are normally made by hydrogen reduction of oxides, and the same process can be used for copper. Hydrogen reduction of metal oxides has been extensively studied at laboratory scale, particularly in regard to kinetics and reaction. Besides mrrs, there are a plethora of reduction methods that are widely employed in materials preparation and manufacturing. Metallothermic reduction is a. Metallurgy Reduction Process.

From kleanindustries.com

Can industry decarbonize steelmaking? Klean Industries Metallurgy Reduction Process Hydrogen reduction of metal oxides has been extensively studied at laboratory scale, particularly in regard to kinetics and reaction. Direct reduction ironmaking is a process that involves reducing iron ore to obtain metallic iron in a reaction vessel using gas or solid reducing. Metallothermic reduction is a general term for reduction reactions conducted to obtain a target metal or compound. Metallurgy Reduction Process.

From www.alliedsinterings.com

Understanding the Powdered Metallurgy Process Allied Sinterings, Inc. Metallurgy Reduction Process Direct reduction ironmaking is a process that involves reducing iron ore to obtain metallic iron in a reaction vessel using gas or solid reducing. Besides mrrs, there are a plethora of reduction methods that are widely employed in materials preparation and manufacturing. Refractory metals are normally made by hydrogen reduction of oxides, and the same process can be used for. Metallurgy Reduction Process.

From cd-us.struers.com

Metallography of powder metallurgy parts Metallurgy Reduction Process Metallothermic reduction is a general term for reduction reactions conducted to obtain a target metal or compound from feed material. Refractory metals are normally made by hydrogen reduction of oxides, and the same process can be used for copper. Hydrogen reduction of metal oxides has been extensively studied at laboratory scale, particularly in regard to kinetics and reaction. Besides mrrs,. Metallurgy Reduction Process.

From www.youtube.com

powder metallurgy \ POWDER METALLURGY PROCESS ATOMIZATION Metallurgy Reduction Process Besides mrrs, there are a plethora of reduction methods that are widely employed in materials preparation and manufacturing. Metallothermic reduction is a general term for reduction reactions conducted to obtain a target metal or compound from feed material. Hydrogen reduction of metal oxides has been extensively studied at laboratory scale, particularly in regard to kinetics and reaction. Direct reduction ironmaking. Metallurgy Reduction Process.

From www.mdpi.com

Metals Free FullText Carbon Impact Mitigation of the Iron Ore Metallurgy Reduction Process Metallothermic reduction is a general term for reduction reactions conducted to obtain a target metal or compound from feed material. Direct reduction ironmaking is a process that involves reducing iron ore to obtain metallic iron in a reaction vessel using gas or solid reducing. Besides mrrs, there are a plethora of reduction methods that are widely employed in materials preparation. Metallurgy Reduction Process.

From chem.libretexts.org

Chapter 21.3 Metallurgy Chemistry LibreTexts Metallurgy Reduction Process Direct reduction ironmaking is a process that involves reducing iron ore to obtain metallic iron in a reaction vessel using gas or solid reducing. Hydrogen reduction of metal oxides has been extensively studied at laboratory scale, particularly in regard to kinetics and reaction. Besides mrrs, there are a plethora of reduction methods that are widely employed in materials preparation and. Metallurgy Reduction Process.