What Drives Hydraulic Pump . In a lobe pump, both lobes are driven through suitable drives gears outside of the pump casing chamber. Here’s a look at each drive type. In a gear pump, one gear drive the other; This system consists of several key components, including a pump, motor, and actuator. In some cases, the motor and pump are set up in a direct drive configuration. Pumps are positioned on the drive housing. At its core, a hydraulic drive system utilizes fluids to transmit power. Gears or other equipment generate the power. The pump is responsible for. Pump drives take power from an input rotational source and send it to a hydraulic pump. Engineers and designers commonly use electric motors to power hydraulic pumps. Hydraulic pump drives are found in various applications, with the most common being marine, cranes, drilling rigs, construction equipment, and agricultural. A hydraulic pump is a mechanical device that transforms the mechanical energy of the hydraulic fluid into hydraulic power (hydraulic power such as pressure or flow).

from www.animalia-life.club

In a gear pump, one gear drive the other; In some cases, the motor and pump are set up in a direct drive configuration. Pump drives take power from an input rotational source and send it to a hydraulic pump. Hydraulic pump drives are found in various applications, with the most common being marine, cranes, drilling rigs, construction equipment, and agricultural. The pump is responsible for. Here’s a look at each drive type. At its core, a hydraulic drive system utilizes fluids to transmit power. This system consists of several key components, including a pump, motor, and actuator. Engineers and designers commonly use electric motors to power hydraulic pumps. In a lobe pump, both lobes are driven through suitable drives gears outside of the pump casing chamber.

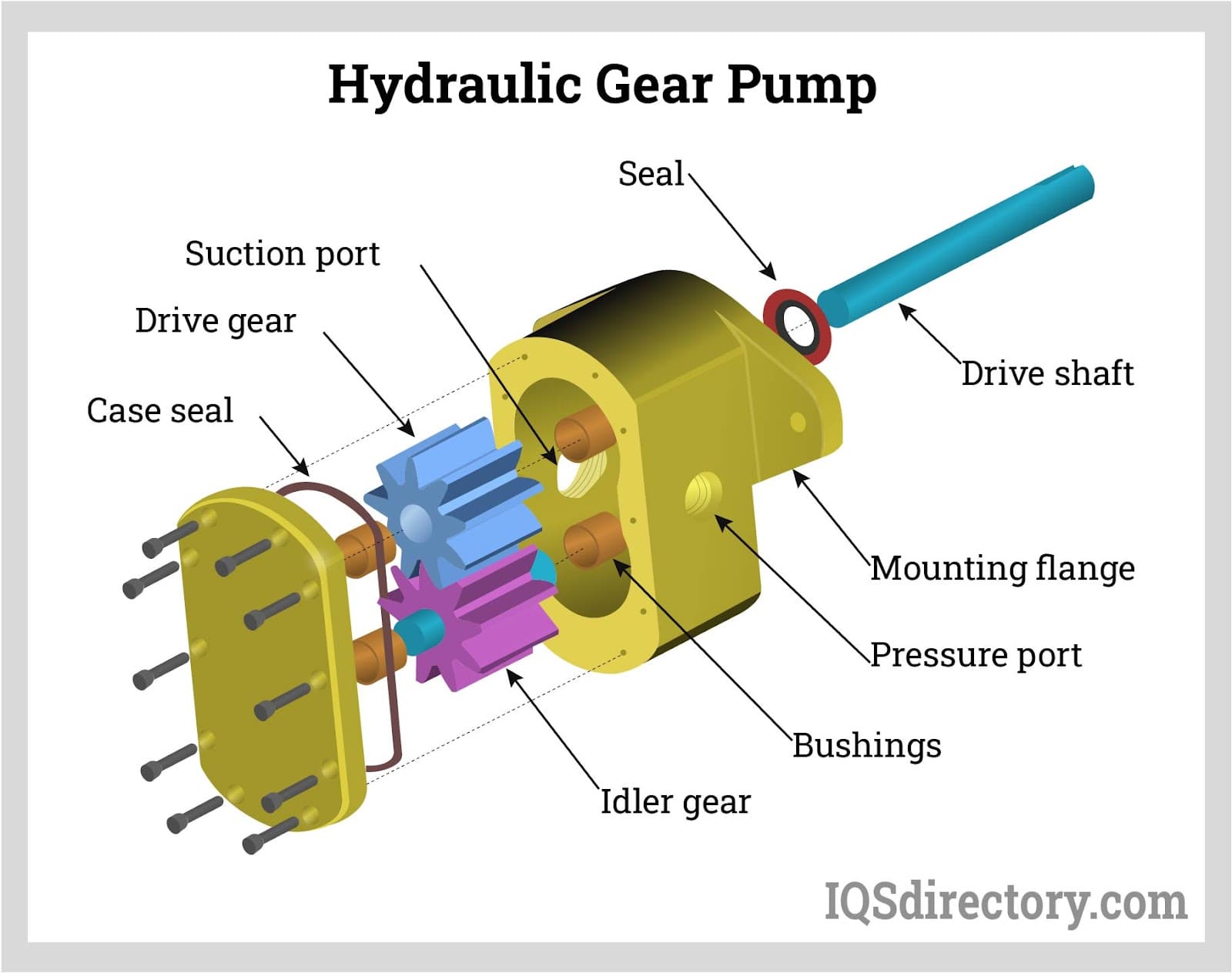

Hydraulic Gear Pump Diagram

What Drives Hydraulic Pump This system consists of several key components, including a pump, motor, and actuator. This system consists of several key components, including a pump, motor, and actuator. The pump is responsible for. Engineers and designers commonly use electric motors to power hydraulic pumps. A hydraulic pump is a mechanical device that transforms the mechanical energy of the hydraulic fluid into hydraulic power (hydraulic power such as pressure or flow). Here’s a look at each drive type. In a lobe pump, both lobes are driven through suitable drives gears outside of the pump casing chamber. In some cases, the motor and pump are set up in a direct drive configuration. Pumps are positioned on the drive housing. Gears or other equipment generate the power. Pump drives take power from an input rotational source and send it to a hydraulic pump. Hydraulic pump drives are found in various applications, with the most common being marine, cranes, drilling rigs, construction equipment, and agricultural. In a gear pump, one gear drive the other; At its core, a hydraulic drive system utilizes fluids to transmit power.

From www.highpressure.com

How Sprague Air Driven Hydraulic Pumps Work High Pressure Company What Drives Hydraulic Pump Here’s a look at each drive type. In a lobe pump, both lobes are driven through suitable drives gears outside of the pump casing chamber. In some cases, the motor and pump are set up in a direct drive configuration. Pumps are positioned on the drive housing. The pump is responsible for. Pump drives take power from an input rotational. What Drives Hydraulic Pump.

From www.directindustry.com

Hydraulic pump drive system AM 450 Twin Disc modular What Drives Hydraulic Pump In a gear pump, one gear drive the other; Hydraulic pump drives are found in various applications, with the most common being marine, cranes, drilling rigs, construction equipment, and agricultural. A hydraulic pump is a mechanical device that transforms the mechanical energy of the hydraulic fluid into hydraulic power (hydraulic power such as pressure or flow). This system consists of. What Drives Hydraulic Pump.

From www.researchgate.net

Hydraulic pump drives with one and two degrees of freedom to vary What Drives Hydraulic Pump Pumps are positioned on the drive housing. Gears or other equipment generate the power. Hydraulic pump drives are found in various applications, with the most common being marine, cranes, drilling rigs, construction equipment, and agricultural. In some cases, the motor and pump are set up in a direct drive configuration. Here’s a look at each drive type. A hydraulic pump. What Drives Hydraulic Pump.

From shandongkuangan.en.made-in-china.com

Multiple Pump Drives with Dual Drive Input for 2 Hydraulic Pumps What Drives Hydraulic Pump Pumps are positioned on the drive housing. Hydraulic pump drives are found in various applications, with the most common being marine, cranes, drilling rigs, construction equipment, and agricultural. In a lobe pump, both lobes are driven through suitable drives gears outside of the pump casing chamber. Here’s a look at each drive type. Gears or other equipment generate the power.. What Drives Hydraulic Pump.

From www.munciepower.com

MB050 Low Speed High Torque Motor (Spreader Applications) What Drives Hydraulic Pump Pumps are positioned on the drive housing. At its core, a hydraulic drive system utilizes fluids to transmit power. Here’s a look at each drive type. This system consists of several key components, including a pump, motor, and actuator. In a gear pump, one gear drive the other; Engineers and designers commonly use electric motors to power hydraulic pumps. The. What Drives Hydraulic Pump.

From www.pjpower.com

Beginner's Guide to Hydraulic Pump Drives Palmer Johnson Power Systems What Drives Hydraulic Pump Pump drives take power from an input rotational source and send it to a hydraulic pump. Engineers and designers commonly use electric motors to power hydraulic pumps. In a gear pump, one gear drive the other; In some cases, the motor and pump are set up in a direct drive configuration. Hydraulic pump drives are found in various applications, with. What Drives Hydraulic Pump.

From www.marcoglobal.com

MARCO HPDs Hydraulic Pump Drives from Smith Berger Marine." What Drives Hydraulic Pump This system consists of several key components, including a pump, motor, and actuator. In a gear pump, one gear drive the other; A hydraulic pump is a mechanical device that transforms the mechanical energy of the hydraulic fluid into hydraulic power (hydraulic power such as pressure or flow). Here’s a look at each drive type. Pump drives take power from. What Drives Hydraulic Pump.

From www.marcoglobal.com

MARCO HPDs Hydraulic Pump Drives from Smith Berger Marine." What Drives Hydraulic Pump At its core, a hydraulic drive system utilizes fluids to transmit power. Pumps are positioned on the drive housing. The pump is responsible for. Pump drives take power from an input rotational source and send it to a hydraulic pump. Hydraulic pump drives are found in various applications, with the most common being marine, cranes, drilling rigs, construction equipment, and. What Drives Hydraulic Pump.

From www.northerntool.com

Concentric Hydraulic Pump — 22 GPM, 2Stage, Model 1080035 Northern What Drives Hydraulic Pump Hydraulic pump drives are found in various applications, with the most common being marine, cranes, drilling rigs, construction equipment, and agricultural. Gears or other equipment generate the power. The pump is responsible for. A hydraulic pump is a mechanical device that transforms the mechanical energy of the hydraulic fluid into hydraulic power (hydraulic power such as pressure or flow). In. What Drives Hydraulic Pump.

From mavink.com

Hydraulic Piston Pump Diagram What Drives Hydraulic Pump Pump drives take power from an input rotational source and send it to a hydraulic pump. Engineers and designers commonly use electric motors to power hydraulic pumps. The pump is responsible for. In a gear pump, one gear drive the other; In a lobe pump, both lobes are driven through suitable drives gears outside of the pump casing chamber. Gears. What Drives Hydraulic Pump.

From www.animalia-life.club

Hydraulic Gear Pump Diagram What Drives Hydraulic Pump Pumps are positioned on the drive housing. Here’s a look at each drive type. In some cases, the motor and pump are set up in a direct drive configuration. Pump drives take power from an input rotational source and send it to a hydraulic pump. Engineers and designers commonly use electric motors to power hydraulic pumps. In a gear pump,. What Drives Hydraulic Pump.

From flinthyd.blogspot.com

Flint Hydraulics, Inc. Prime Movers in Hydraulic Systems What Drives Hydraulic Pump Here’s a look at each drive type. Engineers and designers commonly use electric motors to power hydraulic pumps. At its core, a hydraulic drive system utilizes fluids to transmit power. Pump drives take power from an input rotational source and send it to a hydraulic pump. In some cases, the motor and pump are set up in a direct drive. What Drives Hydraulic Pump.

From blogs.bu.edu

How many different hydraulic pumps are there? Kawasaki Hydraulic Pump What Drives Hydraulic Pump In a gear pump, one gear drive the other; This system consists of several key components, including a pump, motor, and actuator. At its core, a hydraulic drive system utilizes fluids to transmit power. In some cases, the motor and pump are set up in a direct drive configuration. Pump drives take power from an input rotational source and send. What Drives Hydraulic Pump.

From insights.globalspec.com

How does a electric motordriven axial piston What Drives Hydraulic Pump Pumps are positioned on the drive housing. Here’s a look at each drive type. In some cases, the motor and pump are set up in a direct drive configuration. Gears or other equipment generate the power. In a lobe pump, both lobes are driven through suitable drives gears outside of the pump casing chamber. Pump drives take power from an. What Drives Hydraulic Pump.

From www.aircraftsystemstech.com

Aircraft Hydraulic System Pumps What Drives Hydraulic Pump Engineers and designers commonly use electric motors to power hydraulic pumps. Hydraulic pump drives are found in various applications, with the most common being marine, cranes, drilling rigs, construction equipment, and agricultural. This system consists of several key components, including a pump, motor, and actuator. Here’s a look at each drive type. Gears or other equipment generate the power. In. What Drives Hydraulic Pump.

From www.youtube.com

Hydraulic Motor Types and how are they work? hydraulic motors and pumps What Drives Hydraulic Pump In a lobe pump, both lobes are driven through suitable drives gears outside of the pump casing chamber. This system consists of several key components, including a pump, motor, and actuator. A hydraulic pump is a mechanical device that transforms the mechanical energy of the hydraulic fluid into hydraulic power (hydraulic power such as pressure or flow). Gears or other. What Drives Hydraulic Pump.

From www.directindustry.com

Hydraulic pump drive system AM 216 Twin Disc modular What Drives Hydraulic Pump In a gear pump, one gear drive the other; Engineers and designers commonly use electric motors to power hydraulic pumps. Pump drives take power from an input rotational source and send it to a hydraulic pump. Pumps are positioned on the drive housing. In some cases, the motor and pump are set up in a direct drive configuration. Here’s a. What Drives Hydraulic Pump.

From www.uphyd.com

PTO Hydraulic Pump Uphyd What Drives Hydraulic Pump This system consists of several key components, including a pump, motor, and actuator. A hydraulic pump is a mechanical device that transforms the mechanical energy of the hydraulic fluid into hydraulic power (hydraulic power such as pressure or flow). Pump drives take power from an input rotational source and send it to a hydraulic pump. Gears or other equipment generate. What Drives Hydraulic Pump.

From www.youtube.com

Types of Hydraulic Pumps and Hydraulic Oil YouTube What Drives Hydraulic Pump In a gear pump, one gear drive the other; Hydraulic pump drives are found in various applications, with the most common being marine, cranes, drilling rigs, construction equipment, and agricultural. In a lobe pump, both lobes are driven through suitable drives gears outside of the pump casing chamber. In some cases, the motor and pump are set up in a. What Drives Hydraulic Pump.

From www.youtube.com

HYDRAULIC HAND PUMP WORKING YouTube What Drives Hydraulic Pump The pump is responsible for. At its core, a hydraulic drive system utilizes fluids to transmit power. This system consists of several key components, including a pump, motor, and actuator. In a gear pump, one gear drive the other; Engineers and designers commonly use electric motors to power hydraulic pumps. Here’s a look at each drive type. In a lobe. What Drives Hydraulic Pump.

From buffalohydraulic.com

Enerpac ZE3220MB Electric Hydraulic Pump Buffalo Hydraulic What Drives Hydraulic Pump The pump is responsible for. In a gear pump, one gear drive the other; At its core, a hydraulic drive system utilizes fluids to transmit power. Pump drives take power from an input rotational source and send it to a hydraulic pump. Gears or other equipment generate the power. In a lobe pump, both lobes are driven through suitable drives. What Drives Hydraulic Pump.

From www.machinedesign.com

What’s the Difference Between Direct and Indirect Drives for Hydraulic What Drives Hydraulic Pump In a gear pump, one gear drive the other; Engineers and designers commonly use electric motors to power hydraulic pumps. The pump is responsible for. Gears or other equipment generate the power. At its core, a hydraulic drive system utilizes fluids to transmit power. Here’s a look at each drive type. Pumps are positioned on the drive housing. Hydraulic pump. What Drives Hydraulic Pump.

From okigihan.blogspot.kr

Aircraft systems Hydraulic pumps What Drives Hydraulic Pump Engineers and designers commonly use electric motors to power hydraulic pumps. At its core, a hydraulic drive system utilizes fluids to transmit power. Gears or other equipment generate the power. In a lobe pump, both lobes are driven through suitable drives gears outside of the pump casing chamber. A hydraulic pump is a mechanical device that transforms the mechanical energy. What Drives Hydraulic Pump.

From www.argo-hytos.com

Hydraulic Drives ARGOHYTOS What Drives Hydraulic Pump The pump is responsible for. Pumps are positioned on the drive housing. At its core, a hydraulic drive system utilizes fluids to transmit power. Gears or other equipment generate the power. Engineers and designers commonly use electric motors to power hydraulic pumps. In a lobe pump, both lobes are driven through suitable drives gears outside of the pump casing chamber.. What Drives Hydraulic Pump.

From www.machinedesign.com

What’s the Difference Between Direct and Indirect Drives for Hydraulic What Drives Hydraulic Pump Engineers and designers commonly use electric motors to power hydraulic pumps. Pump drives take power from an input rotational source and send it to a hydraulic pump. At its core, a hydraulic drive system utilizes fluids to transmit power. Hydraulic pump drives are found in various applications, with the most common being marine, cranes, drilling rigs, construction equipment, and agricultural.. What Drives Hydraulic Pump.

From www.northerntool.com

Concentric Hydraulic Pump — 11 GPM, 2Stage, Model 1001689 Northern Tool What Drives Hydraulic Pump Pump drives take power from an input rotational source and send it to a hydraulic pump. Hydraulic pump drives are found in various applications, with the most common being marine, cranes, drilling rigs, construction equipment, and agricultural. Pumps are positioned on the drive housing. This system consists of several key components, including a pump, motor, and actuator. A hydraulic pump. What Drives Hydraulic Pump.

From www.researchgate.net

Pump and hydromotors of the hydrostatic drives (a) variable What Drives Hydraulic Pump In a lobe pump, both lobes are driven through suitable drives gears outside of the pump casing chamber. At its core, a hydraulic drive system utilizes fluids to transmit power. Gears or other equipment generate the power. This system consists of several key components, including a pump, motor, and actuator. Pump drives take power from an input rotational source and. What Drives Hydraulic Pump.

From avsmanual.com

M312, M315, M318 and M320 Excavators Hydraulic System Caterpillar What Drives Hydraulic Pump A hydraulic pump is a mechanical device that transforms the mechanical energy of the hydraulic fluid into hydraulic power (hydraulic power such as pressure or flow). In some cases, the motor and pump are set up in a direct drive configuration. In a lobe pump, both lobes are driven through suitable drives gears outside of the pump casing chamber. Engineers. What Drives Hydraulic Pump.

From www.hydraulic-pumps.org

RG Group Hydraulic Pump What Drives Hydraulic Pump A hydraulic pump is a mechanical device that transforms the mechanical energy of the hydraulic fluid into hydraulic power (hydraulic power such as pressure or flow). The pump is responsible for. Here’s a look at each drive type. Engineers and designers commonly use electric motors to power hydraulic pumps. Gears or other equipment generate the power. In a gear pump,. What Drives Hydraulic Pump.

From www.linquip.com

Working Principles of Hydraulic Pump (With Videos) Linquip What Drives Hydraulic Pump Engineers and designers commonly use electric motors to power hydraulic pumps. Gears or other equipment generate the power. This system consists of several key components, including a pump, motor, and actuator. The pump is responsible for. At its core, a hydraulic drive system utilizes fluids to transmit power. In a lobe pump, both lobes are driven through suitable drives gears. What Drives Hydraulic Pump.

From www.directindustry.com

Hydraulic pump drive system AM 320 Twin Disc modular What Drives Hydraulic Pump In some cases, the motor and pump are set up in a direct drive configuration. The pump is responsible for. Pumps are positioned on the drive housing. Here’s a look at each drive type. A hydraulic pump is a mechanical device that transforms the mechanical energy of the hydraulic fluid into hydraulic power (hydraulic power such as pressure or flow).. What Drives Hydraulic Pump.

From www.youtube.com

Eaton Hydraulic Drive Motor YouTube What Drives Hydraulic Pump Hydraulic pump drives are found in various applications, with the most common being marine, cranes, drilling rigs, construction equipment, and agricultural. A hydraulic pump is a mechanical device that transforms the mechanical energy of the hydraulic fluid into hydraulic power (hydraulic power such as pressure or flow). Engineers and designers commonly use electric motors to power hydraulic pumps. Pump drives. What Drives Hydraulic Pump.

From www.mechaface.com

Tractor PTO Hydraulic Pump Drive MechaFace What Drives Hydraulic Pump In some cases, the motor and pump are set up in a direct drive configuration. Gears or other equipment generate the power. A hydraulic pump is a mechanical device that transforms the mechanical energy of the hydraulic fluid into hydraulic power (hydraulic power such as pressure or flow). Pump drives take power from an input rotational source and send it. What Drives Hydraulic Pump.

From www.youtube.com

Dual Pump Hydraulic Circuit YouTube What Drives Hydraulic Pump This system consists of several key components, including a pump, motor, and actuator. At its core, a hydraulic drive system utilizes fluids to transmit power. In some cases, the motor and pump are set up in a direct drive configuration. Pumps are positioned on the drive housing. In a lobe pump, both lobes are driven through suitable drives gears outside. What Drives Hydraulic Pump.

From www.insanehydraulics.com

Hydraulic motors barrels and shafts Do you know what drives what? What Drives Hydraulic Pump Here’s a look at each drive type. The pump is responsible for. Pump drives take power from an input rotational source and send it to a hydraulic pump. At its core, a hydraulic drive system utilizes fluids to transmit power. In a lobe pump, both lobes are driven through suitable drives gears outside of the pump casing chamber. Gears or. What Drives Hydraulic Pump.