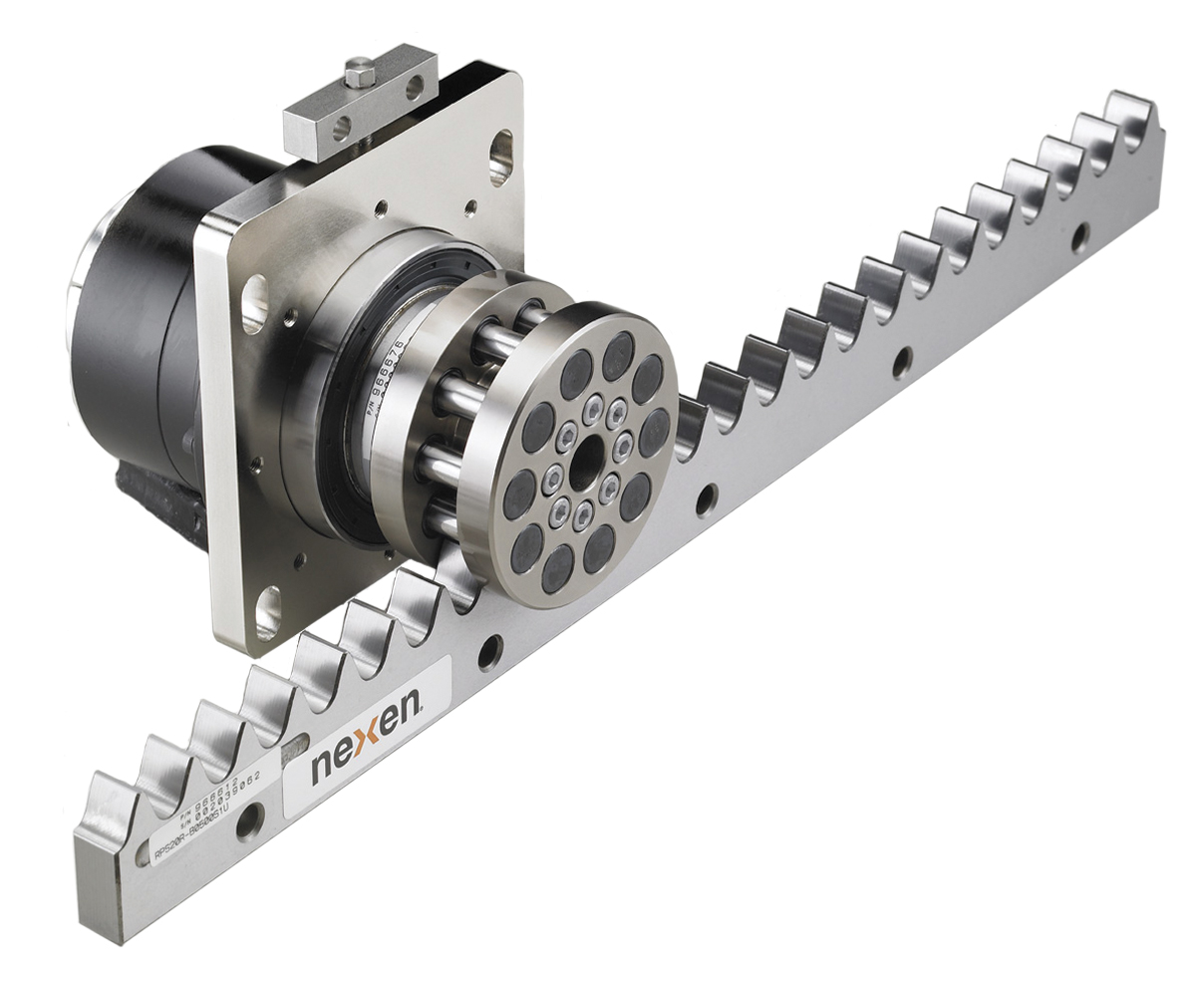

Cnc Rack And Pinion Vs Lead Screw . Straight racks and helical (angled) racks merge to drive. Let us analyze the application of rack & pinion and ball screw in the cnc router machine industry. Learn about the pros and cons of each option for your application. Techno recommends helical rack and pinion drives for better long term performance and easier maintenance. Compare rack and pinion, belt drive, and ballscrew systems for cnc machining. As the name suggests, there are two key components to a rack and pinion drive system the rack and the pinion. As the pinion turns, the machine moves. There is a rack that is bolted onto the sides of the machines and pinion, or cog/gear, that meshes with the rack. Both systems are engineered to translate rotary motion into precise linear movements, yet each comes with its unique set of advantages and limitations. Two prominent contenders in the realm of cnc router mechanisms are the rack and pinion system and the ball screw system. Here is a closer look at how rack and pinion drive systems work, their advantages and shortcomings, and how they compare to ball screw technology. If a pinion wears out it is much easier, and less. How a rack and pinion drive system works. A rack and pinion drive system is just what it sounds like.

from www.motioncontroltips.com

A rack and pinion drive system is just what it sounds like. There is a rack that is bolted onto the sides of the machines and pinion, or cog/gear, that meshes with the rack. Straight racks and helical (angled) racks merge to drive. Let us analyze the application of rack & pinion and ball screw in the cnc router machine industry. As the name suggests, there are two key components to a rack and pinion drive system the rack and the pinion. Here is a closer look at how rack and pinion drive systems work, their advantages and shortcomings, and how they compare to ball screw technology. Learn about the pros and cons of each option for your application. If a pinion wears out it is much easier, and less. Compare rack and pinion, belt drive, and ballscrew systems for cnc machining. Two prominent contenders in the realm of cnc router mechanisms are the rack and pinion system and the ball screw system.

What are rackandpinion sets? Technical summary

Cnc Rack And Pinion Vs Lead Screw Straight racks and helical (angled) racks merge to drive. How a rack and pinion drive system works. Learn about the pros and cons of each option for your application. Both systems are engineered to translate rotary motion into precise linear movements, yet each comes with its unique set of advantages and limitations. A rack and pinion drive system is just what it sounds like. There is a rack that is bolted onto the sides of the machines and pinion, or cog/gear, that meshes with the rack. Techno recommends helical rack and pinion drives for better long term performance and easier maintenance. As the pinion turns, the machine moves. As the name suggests, there are two key components to a rack and pinion drive system the rack and the pinion. Compare rack and pinion, belt drive, and ballscrew systems for cnc machining. Here is a closer look at how rack and pinion drive systems work, their advantages and shortcomings, and how they compare to ball screw technology. Let us analyze the application of rack & pinion and ball screw in the cnc router machine industry. Straight racks and helical (angled) racks merge to drive. Two prominent contenders in the realm of cnc router mechanisms are the rack and pinion system and the ball screw system. If a pinion wears out it is much easier, and less.

From www.motioncontroltips.com

What are rackandpinion sets? Technical summary Cnc Rack And Pinion Vs Lead Screw Two prominent contenders in the realm of cnc router mechanisms are the rack and pinion system and the ball screw system. How a rack and pinion drive system works. A rack and pinion drive system is just what it sounds like. Let us analyze the application of rack & pinion and ball screw in the cnc router machine industry. As. Cnc Rack And Pinion Vs Lead Screw.

From www.youtube.com

Identifying Your Ball Screw Assembly. And Lead vs pitch YouTube Cnc Rack And Pinion Vs Lead Screw Straight racks and helical (angled) racks merge to drive. A rack and pinion drive system is just what it sounds like. Compare rack and pinion, belt drive, and ballscrew systems for cnc machining. As the pinion turns, the machine moves. Two prominent contenders in the realm of cnc router mechanisms are the rack and pinion system and the ball screw. Cnc Rack And Pinion Vs Lead Screw.

From www.baiweilaser.com

Cnc Rack and Pinion Vs Ball screw Cnc Rack And Pinion Vs Lead Screw There is a rack that is bolted onto the sides of the machines and pinion, or cog/gear, that meshes with the rack. Learn about the pros and cons of each option for your application. Compare rack and pinion, belt drive, and ballscrew systems for cnc machining. A rack and pinion drive system is just what it sounds like. Straight racks. Cnc Rack And Pinion Vs Lead Screw.

From grabcad.com

Lead Screw in Solidworks Solidworks Tutorials GrabCAD Tutorials Cnc Rack And Pinion Vs Lead Screw As the pinion turns, the machine moves. Let us analyze the application of rack & pinion and ball screw in the cnc router machine industry. Here is a closer look at how rack and pinion drive systems work, their advantages and shortcomings, and how they compare to ball screw technology. As the name suggests, there are two key components to. Cnc Rack And Pinion Vs Lead Screw.

From www.shopsabre.com

The truth about rack and pinion drive systems in CNC ShopSabre CNC Cnc Rack And Pinion Vs Lead Screw As the pinion turns, the machine moves. If a pinion wears out it is much easier, and less. As the name suggests, there are two key components to a rack and pinion drive system the rack and the pinion. Here is a closer look at how rack and pinion drive systems work, their advantages and shortcomings, and how they compare. Cnc Rack And Pinion Vs Lead Screw.

From www.iqsdirectory.com

Lead Screw What Is It? How Is It Used? Types, Threads Cnc Rack And Pinion Vs Lead Screw As the name suggests, there are two key components to a rack and pinion drive system the rack and the pinion. A rack and pinion drive system is just what it sounds like. If a pinion wears out it is much easier, and less. Techno recommends helical rack and pinion drives for better long term performance and easier maintenance. Both. Cnc Rack And Pinion Vs Lead Screw.

From www.pinterest.com

Ball screw Wikipedia, the free encyclopedia Cnc, Bandsaw projects Cnc Rack And Pinion Vs Lead Screw There is a rack that is bolted onto the sides of the machines and pinion, or cog/gear, that meshes with the rack. Learn about the pros and cons of each option for your application. A rack and pinion drive system is just what it sounds like. If a pinion wears out it is much easier, and less. Techno recommends helical. Cnc Rack And Pinion Vs Lead Screw.

From www.stylecnc.com

A comparision of CNC router ballscrew transmission and rackpinion Cnc Rack And Pinion Vs Lead Screw As the pinion turns, the machine moves. A rack and pinion drive system is just what it sounds like. Techno recommends helical rack and pinion drives for better long term performance and easier maintenance. Learn about the pros and cons of each option for your application. Let us analyze the application of rack & pinion and ball screw in the. Cnc Rack And Pinion Vs Lead Screw.

From www.stylecnc.com

Ball Screw Transmission VS RackPinion Transmission Cnc Rack And Pinion Vs Lead Screw Techno recommends helical rack and pinion drives for better long term performance and easier maintenance. Both systems are engineered to translate rotary motion into precise linear movements, yet each comes with its unique set of advantages and limitations. Let us analyze the application of rack & pinion and ball screw in the cnc router machine industry. As the name suggests,. Cnc Rack And Pinion Vs Lead Screw.

From www.parkindustries.com

TITAN® CNC Router for Stone Countertop Polishing, Edging, Finishing Cnc Rack And Pinion Vs Lead Screw If a pinion wears out it is much easier, and less. Techno recommends helical rack and pinion drives for better long term performance and easier maintenance. Here is a closer look at how rack and pinion drive systems work, their advantages and shortcomings, and how they compare to ball screw technology. As the pinion turns, the machine moves. Compare rack. Cnc Rack And Pinion Vs Lead Screw.

From forsuncnc.com

What’s Better, RackAndPinion Or Ball Screw? FORSUN Cnc Rack And Pinion Vs Lead Screw Straight racks and helical (angled) racks merge to drive. If a pinion wears out it is much easier, and less. Both systems are engineered to translate rotary motion into precise linear movements, yet each comes with its unique set of advantages and limitations. Two prominent contenders in the realm of cnc router mechanisms are the rack and pinion system and. Cnc Rack And Pinion Vs Lead Screw.

From www.youtube.com

Beefing up my DIY CNC Leadscrew VS. Ballscrew Learned whole lot Cnc Rack And Pinion Vs Lead Screw There is a rack that is bolted onto the sides of the machines and pinion, or cog/gear, that meshes with the rack. Two prominent contenders in the realm of cnc router mechanisms are the rack and pinion system and the ball screw system. As the name suggests, there are two key components to a rack and pinion drive system the. Cnc Rack And Pinion Vs Lead Screw.

From www.cncyangsen.com

Ball Screw vs. Lead Screw in CNC Machines Cnc Rack And Pinion Vs Lead Screw Let us analyze the application of rack & pinion and ball screw in the cnc router machine industry. Straight racks and helical (angled) racks merge to drive. Techno recommends helical rack and pinion drives for better long term performance and easier maintenance. Learn about the pros and cons of each option for your application. A rack and pinion drive system. Cnc Rack And Pinion Vs Lead Screw.

From www.rovercnc.com

Straight Rack and Pinion Kit Modula 1.0, 17x17x1500MM RoverCNC Cnc Rack And Pinion Vs Lead Screw As the name suggests, there are two key components to a rack and pinion drive system the rack and the pinion. Here is a closer look at how rack and pinion drive systems work, their advantages and shortcomings, and how they compare to ball screw technology. A rack and pinion drive system is just what it sounds like. As the. Cnc Rack And Pinion Vs Lead Screw.

From www.iqsdirectory.com

Lead Screw What Is It? How Is It Used? Types, Threads Cnc Rack And Pinion Vs Lead Screw As the name suggests, there are two key components to a rack and pinion drive system the rack and the pinion. Let us analyze the application of rack & pinion and ball screw in the cnc router machine industry. Learn about the pros and cons of each option for your application. Here is a closer look at how rack and. Cnc Rack And Pinion Vs Lead Screw.

From www.apexdyna.nl

Linear drives 8 advantages of rack and pinion by Apex Dynamics Cnc Rack And Pinion Vs Lead Screw Compare rack and pinion, belt drive, and ballscrew systems for cnc machining. As the pinion turns, the machine moves. Both systems are engineered to translate rotary motion into precise linear movements, yet each comes with its unique set of advantages and limitations. Two prominent contenders in the realm of cnc router mechanisms are the rack and pinion system and the. Cnc Rack And Pinion Vs Lead Screw.

From www.makerstore.com.au

DIY CNC Machines and Components Maker Store PTY LTD Cnc Rack And Pinion Vs Lead Screw Compare rack and pinion, belt drive, and ballscrew systems for cnc machining. As the pinion turns, the machine moves. Straight racks and helical (angled) racks merge to drive. Two prominent contenders in the realm of cnc router mechanisms are the rack and pinion system and the ball screw system. How a rack and pinion drive system works. As the name. Cnc Rack And Pinion Vs Lead Screw.

From technocnc.com

Helical Rack and Pinion vs. Ball Screws Cnc Rack And Pinion Vs Lead Screw As the name suggests, there are two key components to a rack and pinion drive system the rack and the pinion. Learn about the pros and cons of each option for your application. Compare rack and pinion, belt drive, and ballscrew systems for cnc machining. Here is a closer look at how rack and pinion drive systems work, their advantages. Cnc Rack And Pinion Vs Lead Screw.

From mellowpine.com

Ball screw vs Lead Screw Which is Better? MellowPine Cnc Rack And Pinion Vs Lead Screw Techno recommends helical rack and pinion drives for better long term performance and easier maintenance. If a pinion wears out it is much easier, and less. Straight racks and helical (angled) racks merge to drive. Compare rack and pinion, belt drive, and ballscrew systems for cnc machining. A rack and pinion drive system is just what it sounds like. Both. Cnc Rack And Pinion Vs Lead Screw.

From www.cnclathing.com

Ball Screw vs Lead Screw, What's the Difference Between Them Cnc Rack And Pinion Vs Lead Screw As the pinion turns, the machine moves. There is a rack that is bolted onto the sides of the machines and pinion, or cog/gear, that meshes with the rack. Two prominent contenders in the realm of cnc router mechanisms are the rack and pinion system and the ball screw system. Here is a closer look at how rack and pinion. Cnc Rack And Pinion Vs Lead Screw.

From www.youtube.com

Rack & Pinion or Leadscrew? CNCnutz Episode 221 YouTube Cnc Rack And Pinion Vs Lead Screw As the name suggests, there are two key components to a rack and pinion drive system the rack and the pinion. Compare rack and pinion, belt drive, and ballscrew systems for cnc machining. Straight racks and helical (angled) racks merge to drive. Learn about the pros and cons of each option for your application. Techno recommends helical rack and pinion. Cnc Rack And Pinion Vs Lead Screw.

From theedgecutter.com

Rack And Pinion Vs Ball Screw Which system is more accurate for a CNC Cnc Rack And Pinion Vs Lead Screw Let us analyze the application of rack & pinion and ball screw in the cnc router machine industry. There is a rack that is bolted onto the sides of the machines and pinion, or cog/gear, that meshes with the rack. If a pinion wears out it is much easier, and less. Two prominent contenders in the realm of cnc router. Cnc Rack And Pinion Vs Lead Screw.

From us.misumi-ec.com

Lead Screws vs Ball Screws Differences, Benefits & Accuracy MISUMI Cnc Rack And Pinion Vs Lead Screw As the pinion turns, the machine moves. Straight racks and helical (angled) racks merge to drive. Two prominent contenders in the realm of cnc router mechanisms are the rack and pinion system and the ball screw system. There is a rack that is bolted onto the sides of the machines and pinion, or cog/gear, that meshes with the rack. How. Cnc Rack And Pinion Vs Lead Screw.

From www.cncrouterparts.com

PRO Rack and Pinion Assembly Instructions Avid CNC Cnc Rack And Pinion Vs Lead Screw Here is a closer look at how rack and pinion drive systems work, their advantages and shortcomings, and how they compare to ball screw technology. Techno recommends helical rack and pinion drives for better long term performance and easier maintenance. A rack and pinion drive system is just what it sounds like. Two prominent contenders in the realm of cnc. Cnc Rack And Pinion Vs Lead Screw.

From info.lagunatools.com

Rack and Pinion VS Ball Screw Cnc Rack And Pinion Vs Lead Screw Here is a closer look at how rack and pinion drive systems work, their advantages and shortcomings, and how they compare to ball screw technology. A rack and pinion drive system is just what it sounds like. Two prominent contenders in the realm of cnc router mechanisms are the rack and pinion system and the ball screw system. As the. Cnc Rack And Pinion Vs Lead Screw.

From www.shopsabre.com

BallScrew vs. Rack & Pinion ShopSabre CNC Cnc Rack And Pinion Vs Lead Screw Techno recommends helical rack and pinion drives for better long term performance and easier maintenance. There is a rack that is bolted onto the sides of the machines and pinion, or cog/gear, that meshes with the rack. If a pinion wears out it is much easier, and less. Learn about the pros and cons of each option for your application.. Cnc Rack And Pinion Vs Lead Screw.

From mkmra2.blogspot.com

Digital Fabrication for Designers CNC Router Build Cnc Rack And Pinion Vs Lead Screw There is a rack that is bolted onto the sides of the machines and pinion, or cog/gear, that meshes with the rack. Let us analyze the application of rack & pinion and ball screw in the cnc router machine industry. As the name suggests, there are two key components to a rack and pinion drive system the rack and the. Cnc Rack And Pinion Vs Lead Screw.

From www.shopsabre.com

The truth about ball screw technology in CNC routers ShopSabre CNC Cnc Rack And Pinion Vs Lead Screw Straight racks and helical (angled) racks merge to drive. Both systems are engineered to translate rotary motion into precise linear movements, yet each comes with its unique set of advantages and limitations. Learn about the pros and cons of each option for your application. Compare rack and pinion, belt drive, and ballscrew systems for cnc machining. There is a rack. Cnc Rack And Pinion Vs Lead Screw.

From acctekcnc.com

CNC Router Rack And Pinion System VS Ball Screw System AccTek CNC Cnc Rack And Pinion Vs Lead Screw Techno recommends helical rack and pinion drives for better long term performance and easier maintenance. There is a rack that is bolted onto the sides of the machines and pinion, or cog/gear, that meshes with the rack. How a rack and pinion drive system works. Learn about the pros and cons of each option for your application. As the pinion. Cnc Rack And Pinion Vs Lead Screw.

From www.youtube.com

CNC Router Part's Pro Rack & Pinion Drive YouTube Cnc Rack And Pinion Vs Lead Screw Let us analyze the application of rack & pinion and ball screw in the cnc router machine industry. How a rack and pinion drive system works. Compare rack and pinion, belt drive, and ballscrew systems for cnc machining. There is a rack that is bolted onto the sides of the machines and pinion, or cog/gear, that meshes with the rack.. Cnc Rack And Pinion Vs Lead Screw.

From jakmachinery.com

RACK AND PINION VS BALL SCREW JAK Machinery Cnc Rack And Pinion Vs Lead Screw Let us analyze the application of rack & pinion and ball screw in the cnc router machine industry. As the name suggests, there are two key components to a rack and pinion drive system the rack and the pinion. Both systems are engineered to translate rotary motion into precise linear movements, yet each comes with its unique set of advantages. Cnc Rack And Pinion Vs Lead Screw.

From www.stylecnc.com

Ball Screw Transmission VS RackPinion Transmission Cnc Rack And Pinion Vs Lead Screw Compare rack and pinion, belt drive, and ballscrew systems for cnc machining. Let us analyze the application of rack & pinion and ball screw in the cnc router machine industry. How a rack and pinion drive system works. There is a rack that is bolted onto the sides of the machines and pinion, or cog/gear, that meshes with the rack.. Cnc Rack And Pinion Vs Lead Screw.

From blog.thepipingmart.com

Lead Screw vs Ball Screw What's the Difference Cnc Rack And Pinion Vs Lead Screw Two prominent contenders in the realm of cnc router mechanisms are the rack and pinion system and the ball screw system. There is a rack that is bolted onto the sides of the machines and pinion, or cog/gear, that meshes with the rack. If a pinion wears out it is much easier, and less. Techno recommends helical rack and pinion. Cnc Rack And Pinion Vs Lead Screw.

From ar.inspiredpencil.com

Rack And Pinion Gear Design Cnc Rack And Pinion Vs Lead Screw Both systems are engineered to translate rotary motion into precise linear movements, yet each comes with its unique set of advantages and limitations. Compare rack and pinion, belt drive, and ballscrew systems for cnc machining. As the pinion turns, the machine moves. If a pinion wears out it is much easier, and less. As the name suggests, there are two. Cnc Rack And Pinion Vs Lead Screw.

From learnmech.com

Lead Screw Mechanism Types , Advantages, Applications Cnc Rack And Pinion Vs Lead Screw Here is a closer look at how rack and pinion drive systems work, their advantages and shortcomings, and how they compare to ball screw technology. Compare rack and pinion, belt drive, and ballscrew systems for cnc machining. If a pinion wears out it is much easier, and less. A rack and pinion drive system is just what it sounds like.. Cnc Rack And Pinion Vs Lead Screw.