Hydraulic Pump Running But No Pressure . Repair or replace faulty parts and ensure that the pump is properly calibrated to maintain the required pressure levels. Verify that the pump is not drawing in air or vapor. Conduct a thorough inspection of the hydraulic system to identify the source of pressure loss. Ensure all connections are tight and the seals are intact. Lack of flow or system pressure is the most common hydraulic pump problem. When the pump does not receive adequate oil volume at its suction port, high vacuum pressure occurs. Hydraulic pumps often stop working. Ensure the suction line is free of blockages and has an adequate fluid level. This dissolved air is pulled out of the oil on the suction side and then collapses or. Pump delivering too little or no flow. Shaft turning in wrong direction. Check for air leaks in the suction line or fittings. Some typical culprits behind low hydraulic system pressure are: Check for leaks, damaged seals, or worn components that may be causing the pressure drop.

from www.anbaohydraulic.com

Some typical culprits behind low hydraulic system pressure are: Check for air leaks in the suction line or fittings. Ensure all connections are tight and the seals are intact. Shaft turning in wrong direction. Conduct a thorough inspection of the hydraulic system to identify the source of pressure loss. Lack of flow or system pressure is the most common hydraulic pump problem. Check for leaks, damaged seals, or worn components that may be causing the pressure drop. Verify that the pump is not drawing in air or vapor. When the pump does not receive adequate oil volume at its suction port, high vacuum pressure occurs. Repair or replace faulty parts and ensure that the pump is properly calibrated to maintain the required pressure levels.

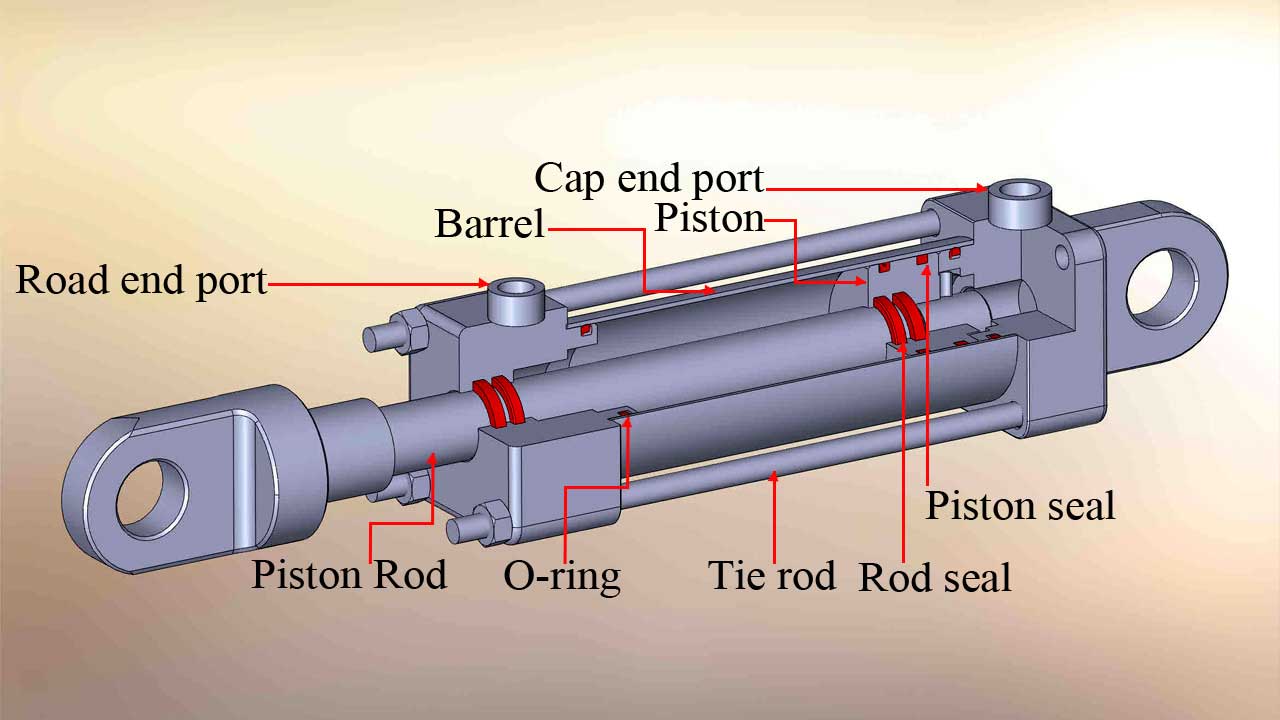

What Are The Parts Of A Hydraulic Cylinder? Anbao Hydraulic

Hydraulic Pump Running But No Pressure When the pump does not receive adequate oil volume at its suction port, high vacuum pressure occurs. Conduct a thorough inspection of the hydraulic system to identify the source of pressure loss. Pump delivering too little or no flow. Check for air leaks in the suction line or fittings. This dissolved air is pulled out of the oil on the suction side and then collapses or. Ensure the suction line is free of blockages and has an adequate fluid level. Repair or replace faulty parts and ensure that the pump is properly calibrated to maintain the required pressure levels. When the pump does not receive adequate oil volume at its suction port, high vacuum pressure occurs. Check for leaks, damaged seals, or worn components that may be causing the pressure drop. Shaft turning in wrong direction. Ensure all connections are tight and the seals are intact. Some typical culprits behind low hydraulic system pressure are: Verify that the pump is not drawing in air or vapor. Hydraulic pumps often stop working. Lack of flow or system pressure is the most common hydraulic pump problem.

From www.slideshare.net

Understanding a basic hydraulic circuit 01 Hydraulic Pump Running But No Pressure Hydraulic pumps often stop working. Verify that the pump is not drawing in air or vapor. Repair or replace faulty parts and ensure that the pump is properly calibrated to maintain the required pressure levels. Ensure the suction line is free of blockages and has an adequate fluid level. This dissolved air is pulled out of the oil on the. Hydraulic Pump Running But No Pressure.

From hydraulicpumptsumasui.blogspot.com

Hydraulic Pump Hydraulic Pump Not Working Hydraulic Pump Running But No Pressure Ensure all connections are tight and the seals are intact. Some typical culprits behind low hydraulic system pressure are: Check for air leaks in the suction line or fittings. Repair or replace faulty parts and ensure that the pump is properly calibrated to maintain the required pressure levels. Shaft turning in wrong direction. Check for leaks, damaged seals, or worn. Hydraulic Pump Running But No Pressure.

From pumpingpies.com

Well Pump Running But Not Building Pressure How To Fix It? PUMPING PIES Hydraulic Pump Running But No Pressure Some typical culprits behind low hydraulic system pressure are: Shaft turning in wrong direction. Pump delivering too little or no flow. Repair or replace faulty parts and ensure that the pump is properly calibrated to maintain the required pressure levels. Hydraulic pumps often stop working. Ensure the suction line is free of blockages and has an adequate fluid level. Check. Hydraulic Pump Running But No Pressure.

From blog.berendsen.com.au

Hydraulic pump not building pressure? Here’s what to check. Hydraulic Pump Running But No Pressure Hydraulic pumps often stop working. Lack of flow or system pressure is the most common hydraulic pump problem. Shaft turning in wrong direction. Conduct a thorough inspection of the hydraulic system to identify the source of pressure loss. This dissolved air is pulled out of the oil on the suction side and then collapses or. Ensure the suction line is. Hydraulic Pump Running But No Pressure.

From blog.berendsen.com.au

Hydraulic pump not building pressure? Here’s what to check. Hydraulic Pump Running But No Pressure Repair or replace faulty parts and ensure that the pump is properly calibrated to maintain the required pressure levels. Some typical culprits behind low hydraulic system pressure are: Ensure all connections are tight and the seals are intact. Check for air leaks in the suction line or fittings. Hydraulic pumps often stop working. Ensure the suction line is free of. Hydraulic Pump Running But No Pressure.

From blogs.bu.edu

How do you check pressure in a hydraulic pump? Kawasaki Hydraulic Pump Hydraulic Pump Running But No Pressure Some typical culprits behind low hydraulic system pressure are: Hydraulic pumps often stop working. Check for air leaks in the suction line or fittings. Ensure the suction line is free of blockages and has an adequate fluid level. Check for leaks, damaged seals, or worn components that may be causing the pressure drop. Shaft turning in wrong direction. Verify that. Hydraulic Pump Running But No Pressure.

From gesrepair.com

Types of Hydraulic Pumps How to Repair Hydraulic pump Hydraulic Pump Running But No Pressure Ensure all connections are tight and the seals are intact. Shaft turning in wrong direction. Ensure the suction line is free of blockages and has an adequate fluid level. Hydraulic pumps often stop working. Check for leaks, damaged seals, or worn components that may be causing the pressure drop. Some typical culprits behind low hydraulic system pressure are: Repair or. Hydraulic Pump Running But No Pressure.

From hxeijtlow.blob.core.windows.net

Pump Running But No Water Coming Out at Olga Richards blog Hydraulic Pump Running But No Pressure This dissolved air is pulled out of the oil on the suction side and then collapses or. Lack of flow or system pressure is the most common hydraulic pump problem. Ensure the suction line is free of blockages and has an adequate fluid level. Verify that the pump is not drawing in air or vapor. Pump delivering too little or. Hydraulic Pump Running But No Pressure.

From www.youtube.com

single acting hydraulic pump system EXPLAINED and WIRING DIAGRAM lift Hydraulic Pump Running But No Pressure Repair or replace faulty parts and ensure that the pump is properly calibrated to maintain the required pressure levels. Pump delivering too little or no flow. Verify that the pump is not drawing in air or vapor. This dissolved air is pulled out of the oil on the suction side and then collapses or. Ensure the suction line is free. Hydraulic Pump Running But No Pressure.

From store.intellaliftparts.com

Forklift Hydraulic Pump Failure Intella Parts Company, LLC Hydraulic Pump Running But No Pressure Conduct a thorough inspection of the hydraulic system to identify the source of pressure loss. Check for leaks, damaged seals, or worn components that may be causing the pressure drop. This dissolved air is pulled out of the oil on the suction side and then collapses or. Lack of flow or system pressure is the most common hydraulic pump problem.. Hydraulic Pump Running But No Pressure.

From topkitparts.com

Hydraulic Pump Repair Manual Hydraulic pumpSwing MotorHydraulic Hydraulic Pump Running But No Pressure Ensure all connections are tight and the seals are intact. Some typical culprits behind low hydraulic system pressure are: This dissolved air is pulled out of the oil on the suction side and then collapses or. Hydraulic pumps often stop working. Repair or replace faulty parts and ensure that the pump is properly calibrated to maintain the required pressure levels.. Hydraulic Pump Running But No Pressure.

From www.iqsdirectory.com

Hydraulic Pump Manufacturers Suppliers IQS Directory Hydraulic Pump Running But No Pressure This dissolved air is pulled out of the oil on the suction side and then collapses or. Hydraulic pumps often stop working. Some typical culprits behind low hydraulic system pressure are: Conduct a thorough inspection of the hydraulic system to identify the source of pressure loss. Ensure all connections are tight and the seals are intact. When the pump does. Hydraulic Pump Running But No Pressure.

From www.hytelpump.com

Hydromax HGP3AF11R Hydraulic Pump Hydraulic Pump Zuosen Hydraulic Pump Running But No Pressure Verify that the pump is not drawing in air or vapor. Hydraulic pumps often stop working. Check for air leaks in the suction line or fittings. Some typical culprits behind low hydraulic system pressure are: Ensure all connections are tight and the seals are intact. Check for leaks, damaged seals, or worn components that may be causing the pressure drop.. Hydraulic Pump Running But No Pressure.

From topkitparts.com

kti hydraulic pump troubleshooting(Symptoms and Solutions) Hydraulic Pump Running But No Pressure Lack of flow or system pressure is the most common hydraulic pump problem. Pump delivering too little or no flow. Ensure all connections are tight and the seals are intact. Repair or replace faulty parts and ensure that the pump is properly calibrated to maintain the required pressure levels. Shaft turning in wrong direction. When the pump does not receive. Hydraulic Pump Running But No Pressure.

From www.aerospacengineering.net

Aircraft Hydraulic System Hydraulic Pump Running But No Pressure Some typical culprits behind low hydraulic system pressure are: Check for leaks, damaged seals, or worn components that may be causing the pressure drop. Verify that the pump is not drawing in air or vapor. This dissolved air is pulled out of the oil on the suction side and then collapses or. Pump delivering too little or no flow. Repair. Hydraulic Pump Running But No Pressure.

From waterfiltercast.com

Well Pump Runs But No Water Pressure (Well Pumps Troubleshooting Guide) Hydraulic Pump Running But No Pressure Lack of flow or system pressure is the most common hydraulic pump problem. Ensure the suction line is free of blockages and has an adequate fluid level. Ensure all connections are tight and the seals are intact. Verify that the pump is not drawing in air or vapor. Repair or replace faulty parts and ensure that the pump is properly. Hydraulic Pump Running But No Pressure.

From www.youtube.com

Homemade Hydraulic Gear Pump Pressure testing and repair YouTube Hydraulic Pump Running But No Pressure Check for air leaks in the suction line or fittings. Ensure the suction line is free of blockages and has an adequate fluid level. Verify that the pump is not drawing in air or vapor. Conduct a thorough inspection of the hydraulic system to identify the source of pressure loss. Shaft turning in wrong direction. Ensure all connections are tight. Hydraulic Pump Running But No Pressure.

From www.youtube.com

How a two speed, manual, hydraulic pump operates YouTube Hydraulic Pump Running But No Pressure Verify that the pump is not drawing in air or vapor. Check for leaks, damaged seals, or worn components that may be causing the pressure drop. Lack of flow or system pressure is the most common hydraulic pump problem. Pump delivering too little or no flow. Check for air leaks in the suction line or fittings. When the pump does. Hydraulic Pump Running But No Pressure.

From www.machinerylubrication.com

Troubleshooting Hydraulic Pumps Machinery Lubrication Hydraulic Pump Running But No Pressure Some typical culprits behind low hydraulic system pressure are: Shaft turning in wrong direction. Repair or replace faulty parts and ensure that the pump is properly calibrated to maintain the required pressure levels. Lack of flow or system pressure is the most common hydraulic pump problem. Hydraulic pumps often stop working. This dissolved air is pulled out of the oil. Hydraulic Pump Running But No Pressure.

From topkitparts.com

kti hydraulic pump troubleshooting(Symptoms and Solutions) Hydraulic Pump Running But No Pressure Conduct a thorough inspection of the hydraulic system to identify the source of pressure loss. Ensure the suction line is free of blockages and has an adequate fluid level. Hydraulic pumps often stop working. Lack of flow or system pressure is the most common hydraulic pump problem. Some typical culprits behind low hydraulic system pressure are: Check for leaks, damaged. Hydraulic Pump Running But No Pressure.

From waterseer.org

Water Filtration & Purification Expert Hydraulic Pump Running But No Pressure Check for air leaks in the suction line or fittings. Ensure the suction line is free of blockages and has an adequate fluid level. Lack of flow or system pressure is the most common hydraulic pump problem. Pump delivering too little or no flow. Ensure all connections are tight and the seals are intact. When the pump does not receive. Hydraulic Pump Running But No Pressure.

From www.mchhydraulics.co.uk

How To Repair A Hydraulic Pump Full Repair Guide MCH Hydraulics Hydraulic Pump Running But No Pressure When the pump does not receive adequate oil volume at its suction port, high vacuum pressure occurs. Conduct a thorough inspection of the hydraulic system to identify the source of pressure loss. This dissolved air is pulled out of the oil on the suction side and then collapses or. Ensure all connections are tight and the seals are intact. Verify. Hydraulic Pump Running But No Pressure.

From www.anbaohydraulic.com

What Are The Parts Of A Hydraulic Cylinder? Anbao Hydraulic Hydraulic Pump Running But No Pressure Some typical culprits behind low hydraulic system pressure are: Hydraulic pumps often stop working. Pump delivering too little or no flow. Check for leaks, damaged seals, or worn components that may be causing the pressure drop. Ensure all connections are tight and the seals are intact. Shaft turning in wrong direction. Check for air leaks in the suction line or. Hydraulic Pump Running But No Pressure.

From www.hkdivedi.com

HYDRAULIC SYSTEM FOR BEGINNERS Mechanical Engineering Professionals Hydraulic Pump Running But No Pressure Check for air leaks in the suction line or fittings. Hydraulic pumps often stop working. Some typical culprits behind low hydraulic system pressure are: Verify that the pump is not drawing in air or vapor. Ensure all connections are tight and the seals are intact. Shaft turning in wrong direction. Conduct a thorough inspection of the hydraulic system to identify. Hydraulic Pump Running But No Pressure.

From blogs.bu.edu

Optimizing Your Hydraulic System Tips for Rexroth Hydraulic Pump Hydraulic Pump Running But No Pressure Hydraulic pumps often stop working. When the pump does not receive adequate oil volume at its suction port, high vacuum pressure occurs. Check for leaks, damaged seals, or worn components that may be causing the pressure drop. Repair or replace faulty parts and ensure that the pump is properly calibrated to maintain the required pressure levels. Verify that the pump. Hydraulic Pump Running But No Pressure.

From ar.inspiredpencil.com

Hydraulic Piston Pump Diagram Hydraulic Pump Running But No Pressure Check for leaks, damaged seals, or worn components that may be causing the pressure drop. Shaft turning in wrong direction. Verify that the pump is not drawing in air or vapor. When the pump does not receive adequate oil volume at its suction port, high vacuum pressure occurs. Repair or replace faulty parts and ensure that the pump is properly. Hydraulic Pump Running But No Pressure.

From www.linquip.com

Hydraulic Pump Working Principles Linquip Hydraulic Pump Running But No Pressure Some typical culprits behind low hydraulic system pressure are: Ensure all connections are tight and the seals are intact. Shaft turning in wrong direction. This dissolved air is pulled out of the oil on the suction side and then collapses or. Pump delivering too little or no flow. Check for leaks, damaged seals, or worn components that may be causing. Hydraulic Pump Running But No Pressure.

From blog.hydra-star.co.uk

Gates Hose, Festo Valves and tec Products from Hydrastar Ltd, UK Hydraulic Pump Running But No Pressure Ensure the suction line is free of blockages and has an adequate fluid level. Check for air leaks in the suction line or fittings. Hydraulic pumps often stop working. Ensure all connections are tight and the seals are intact. Some typical culprits behind low hydraulic system pressure are: Verify that the pump is not drawing in air or vapor. Pump. Hydraulic Pump Running But No Pressure.

From www.northerntool.com

Concentric Hydraulic Pump — 28 GPM, 2Stage, Model 1080036 Northern Hydraulic Pump Running But No Pressure Hydraulic pumps often stop working. Repair or replace faulty parts and ensure that the pump is properly calibrated to maintain the required pressure levels. When the pump does not receive adequate oil volume at its suction port, high vacuum pressure occurs. This dissolved air is pulled out of the oil on the suction side and then collapses or. Some typical. Hydraulic Pump Running But No Pressure.

From topkitparts.com

monarch hydraulic pump troubleshooting(guide &solutions) Hydraulic Pump Running But No Pressure Ensure all connections are tight and the seals are intact. Pump delivering too little or no flow. Conduct a thorough inspection of the hydraulic system to identify the source of pressure loss. Hydraulic pumps often stop working. Verify that the pump is not drawing in air or vapor. Shaft turning in wrong direction. Repair or replace faulty parts and ensure. Hydraulic Pump Running But No Pressure.

From www.hydraulic.online

Tractor Speed Increase PTO and Hydraulic Pump Kit Buyer's Guide Hydraulic Pump Running But No Pressure Verify that the pump is not drawing in air or vapor. When the pump does not receive adequate oil volume at its suction port, high vacuum pressure occurs. Lack of flow or system pressure is the most common hydraulic pump problem. Repair or replace faulty parts and ensure that the pump is properly calibrated to maintain the required pressure levels.. Hydraulic Pump Running But No Pressure.

From birminghamseals.co.uk

Increasing The Working Life Of Your Hydraulic Pump! BSCL Hydraulic Pump Running But No Pressure Ensure all connections are tight and the seals are intact. When the pump does not receive adequate oil volume at its suction port, high vacuum pressure occurs. Check for leaks, damaged seals, or worn components that may be causing the pressure drop. Ensure the suction line is free of blockages and has an adequate fluid level. Some typical culprits behind. Hydraulic Pump Running But No Pressure.

From www.youtube.com

Engineering Science N4 Hydraulics Hydraulic Pump Exam 3 Hydraulic Pump Running But No Pressure Some typical culprits behind low hydraulic system pressure are: Shaft turning in wrong direction. Hydraulic pumps often stop working. Verify that the pump is not drawing in air or vapor. This dissolved air is pulled out of the oil on the suction side and then collapses or. Conduct a thorough inspection of the hydraulic system to identify the source of. Hydraulic Pump Running But No Pressure.

From www.anglo-agriparts.com

Massey Ferguson 135 Hydraulic Pump 10 Spline, Less Pressure Control Hydraulic Pump Running But No Pressure Check for leaks, damaged seals, or worn components that may be causing the pressure drop. When the pump does not receive adequate oil volume at its suction port, high vacuum pressure occurs. Lack of flow or system pressure is the most common hydraulic pump problem. Pump delivering too little or no flow. Repair or replace faulty parts and ensure that. Hydraulic Pump Running But No Pressure.

From www.newproductreport.com

Fuel pump runs but no pressure Hydraulic Pump Running But No Pressure Lack of flow or system pressure is the most common hydraulic pump problem. Conduct a thorough inspection of the hydraulic system to identify the source of pressure loss. This dissolved air is pulled out of the oil on the suction side and then collapses or. Ensure the suction line is free of blockages and has an adequate fluid level. Shaft. Hydraulic Pump Running But No Pressure.