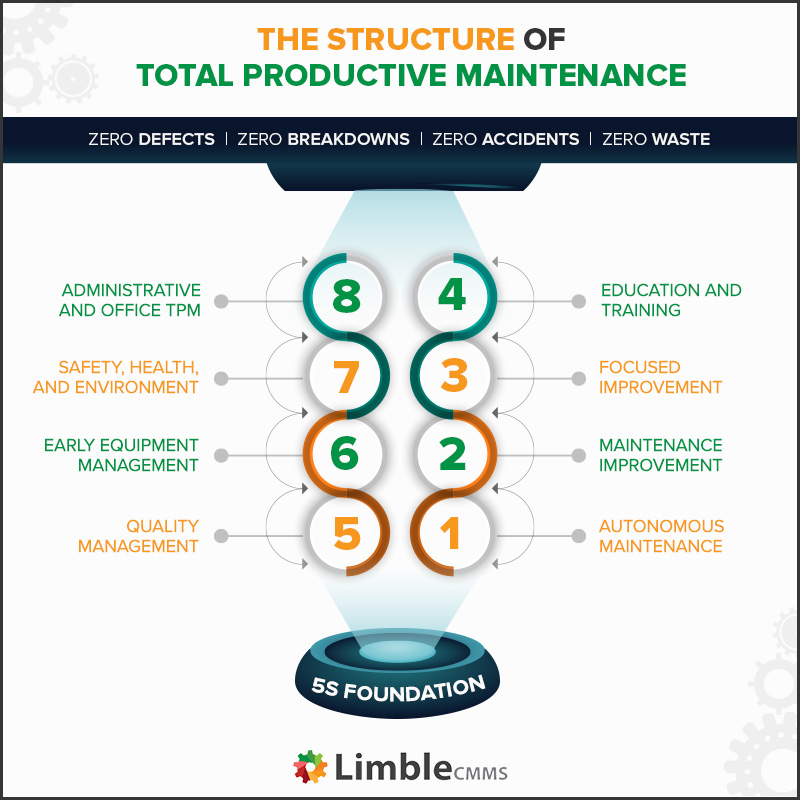

What Is Tpm Lean . Learn about the 5s foundation,. Total productive maintenance (tpm) is a maintenance management method that allows for increased productivity and efficiency in production by eliminating. Learn what tpm is, how it works, and why it is important for achieving perfect production and operational efficiency. Learn about the eight pillars of tpm, a system for maintenance of equipment that aims at achieving an optimal production environment devoid of defects, downtime, stoppages and accidents. Tpm is a lean maintenance strategy that aims for zero breakdowns, zero defects and zero work accidents. The pillars include 5s, autonomous maintenance, planned maintenance, quality maintenance and more. Learn how tpm relates to lean manufacturing and its 8 pillars of support, such as autonomous maintenance, quality maintenance, and focused improvement. Explore the core principles, pillars, and benefits of tpm with examples and tools. What is tpm, total productive maintenance and how does it compare or integrate with other maintenance programs such as predictive and preventive maintenance? Tpm stands for total productive maintenance, a japanese method to prevent errors and failures in industrial processes. Learn about the 8 pillars of tpm, or the 8 basic principles of tpm, and how to implement them in your industry. Tpm is a methodology that engages operators in cleaning, maintaining, and improving their workstations to ensure safety and quality during production cycles.

from limblecmms.com

Tpm is a lean maintenance strategy that aims for zero breakdowns, zero defects and zero work accidents. Learn how tpm relates to lean manufacturing and its 8 pillars of support, such as autonomous maintenance, quality maintenance, and focused improvement. Total productive maintenance (tpm) is a maintenance management method that allows for increased productivity and efficiency in production by eliminating. Learn about the eight pillars of tpm, a system for maintenance of equipment that aims at achieving an optimal production environment devoid of defects, downtime, stoppages and accidents. Explore the core principles, pillars, and benefits of tpm with examples and tools. Learn about the 8 pillars of tpm, or the 8 basic principles of tpm, and how to implement them in your industry. Learn about the 5s foundation,. Learn what tpm is, how it works, and why it is important for achieving perfect production and operational efficiency. Tpm stands for total productive maintenance, a japanese method to prevent errors and failures in industrial processes. The pillars include 5s, autonomous maintenance, planned maintenance, quality maintenance and more.

Ultimate Guide To Lean Manufacturing And Lean Production

What Is Tpm Lean Total productive maintenance (tpm) is a maintenance management method that allows for increased productivity and efficiency in production by eliminating. The pillars include 5s, autonomous maintenance, planned maintenance, quality maintenance and more. Tpm is a lean maintenance strategy that aims for zero breakdowns, zero defects and zero work accidents. Total productive maintenance (tpm) is a maintenance management method that allows for increased productivity and efficiency in production by eliminating. Tpm is a methodology that engages operators in cleaning, maintaining, and improving their workstations to ensure safety and quality during production cycles. Learn what tpm is, how it works, and why it is important for achieving perfect production and operational efficiency. Learn about the eight pillars of tpm, a system for maintenance of equipment that aims at achieving an optimal production environment devoid of defects, downtime, stoppages and accidents. Learn how tpm relates to lean manufacturing and its 8 pillars of support, such as autonomous maintenance, quality maintenance, and focused improvement. Explore the core principles, pillars, and benefits of tpm with examples and tools. What is tpm, total productive maintenance and how does it compare or integrate with other maintenance programs such as predictive and preventive maintenance? Tpm stands for total productive maintenance, a japanese method to prevent errors and failures in industrial processes. Learn about the 8 pillars of tpm, or the 8 basic principles of tpm, and how to implement them in your industry. Learn about the 5s foundation,.

From www.creativesafetysupply.com

What is the difference between TPM and TQM? Creative Safety Supply What Is Tpm Lean Learn about the 5s foundation,. Learn how tpm relates to lean manufacturing and its 8 pillars of support, such as autonomous maintenance, quality maintenance, and focused improvement. Learn what tpm is, how it works, and why it is important for achieving perfect production and operational efficiency. Total productive maintenance (tpm) is a maintenance management method that allows for increased productivity. What Is Tpm Lean.

From www.kaizen-coach.com

TPM® Basics "Lean Training" What Is Tpm Lean The pillars include 5s, autonomous maintenance, planned maintenance, quality maintenance and more. Tpm stands for total productive maintenance, a japanese method to prevent errors and failures in industrial processes. Learn about the eight pillars of tpm, a system for maintenance of equipment that aims at achieving an optimal production environment devoid of defects, downtime, stoppages and accidents. Total productive maintenance. What Is Tpm Lean.

From www.pinterest.dk

TPM Overall Equipment Effectiveness OEE Lean manufacturing, Lean six What Is Tpm Lean Total productive maintenance (tpm) is a maintenance management method that allows for increased productivity and efficiency in production by eliminating. Tpm stands for total productive maintenance, a japanese method to prevent errors and failures in industrial processes. Learn how tpm relates to lean manufacturing and its 8 pillars of support, such as autonomous maintenance, quality maintenance, and focused improvement. What. What Is Tpm Lean.

From www.lucidchart.com

What Is Total Productive Maintenance (TPM)? Lucidchart Blog What Is Tpm Lean Explore the core principles, pillars, and benefits of tpm with examples and tools. Total productive maintenance (tpm) is a maintenance management method that allows for increased productivity and efficiency in production by eliminating. Tpm stands for total productive maintenance, a japanese method to prevent errors and failures in industrial processes. Learn about the 5s foundation,. What is tpm, total productive. What Is Tpm Lean.

From www.linkedin.com

Lean Manufacturing & Six Sigma Worldwide on LinkedIn What is TPM What Is Tpm Lean Tpm is a lean maintenance strategy that aims for zero breakdowns, zero defects and zero work accidents. Learn about the eight pillars of tpm, a system for maintenance of equipment that aims at achieving an optimal production environment devoid of defects, downtime, stoppages and accidents. Tpm stands for total productive maintenance, a japanese method to prevent errors and failures in. What Is Tpm Lean.

From arrowheadco.net

TPM Lean Six Sigma Consulting Services ARROWHEAD What Is Tpm Lean Learn about the 5s foundation,. Tpm is a lean maintenance strategy that aims for zero breakdowns, zero defects and zero work accidents. Learn about the eight pillars of tpm, a system for maintenance of equipment that aims at achieving an optimal production environment devoid of defects, downtime, stoppages and accidents. Explore the core principles, pillars, and benefits of tpm with. What Is Tpm Lean.

From techqualitypedia.com

TPM Pillars TPM full form Meaning and Benefits What Is Tpm Lean The pillars include 5s, autonomous maintenance, planned maintenance, quality maintenance and more. Explore the core principles, pillars, and benefits of tpm with examples and tools. What is tpm, total productive maintenance and how does it compare or integrate with other maintenance programs such as predictive and preventive maintenance? Learn what tpm is, how it works, and why it is important. What Is Tpm Lean.

From www.beyondlean.com

TPM Total Productive Maintenance What Is Tpm Lean Learn about the 8 pillars of tpm, or the 8 basic principles of tpm, and how to implement them in your industry. Tpm is a lean maintenance strategy that aims for zero breakdowns, zero defects and zero work accidents. Learn what tpm is, how it works, and why it is important for achieving perfect production and operational efficiency. Learn about. What Is Tpm Lean.

From www.zlepsito.eu

TOTAL PRODUCTIVE MAINTENANCE (TPM) LEANpropagace implementace What Is Tpm Lean Learn what tpm is, how it works, and why it is important for achieving perfect production and operational efficiency. Learn about the eight pillars of tpm, a system for maintenance of equipment that aims at achieving an optimal production environment devoid of defects, downtime, stoppages and accidents. What is tpm, total productive maintenance and how does it compare or integrate. What Is Tpm Lean.

From www.creativesafetysupply.com

How are TPM and Lean related? Creative Safety Supply What Is Tpm Lean Explore the core principles, pillars, and benefits of tpm with examples and tools. The pillars include 5s, autonomous maintenance, planned maintenance, quality maintenance and more. Tpm is a methodology that engages operators in cleaning, maintaining, and improving their workstations to ensure safety and quality during production cycles. Learn how tpm relates to lean manufacturing and its 8 pillars of support,. What Is Tpm Lean.

From www.slideshare.net

Lean TPM Autonomous Maintenance 2 What Is Tpm Lean Learn about the 8 pillars of tpm, or the 8 basic principles of tpm, and how to implement them in your industry. Total productive maintenance (tpm) is a maintenance management method that allows for increased productivity and efficiency in production by eliminating. Learn about the eight pillars of tpm, a system for maintenance of equipment that aims at achieving an. What Is Tpm Lean.

From limblecmms.com

Ultimate Guide To Lean Manufacturing And Lean Production What Is Tpm Lean Explore the core principles, pillars, and benefits of tpm with examples and tools. Total productive maintenance (tpm) is a maintenance management method that allows for increased productivity and efficiency in production by eliminating. Learn how tpm relates to lean manufacturing and its 8 pillars of support, such as autonomous maintenance, quality maintenance, and focused improvement. Learn about the eight pillars. What Is Tpm Lean.

From operationsinsider.com

TPM Productive Maintenance — Operations Insider What Is Tpm Lean What is tpm, total productive maintenance and how does it compare or integrate with other maintenance programs such as predictive and preventive maintenance? Learn what tpm is, how it works, and why it is important for achieving perfect production and operational efficiency. Learn about the 5s foundation,. Tpm stands for total productive maintenance, a japanese method to prevent errors and. What Is Tpm Lean.

From www.tpslean.com

TPM Total Productive Maintenance > Lean Manufacturing TPM Video What Is Tpm Lean Learn about the eight pillars of tpm, a system for maintenance of equipment that aims at achieving an optimal production environment devoid of defects, downtime, stoppages and accidents. Tpm stands for total productive maintenance, a japanese method to prevent errors and failures in industrial processes. Learn what tpm is, how it works, and why it is important for achieving perfect. What Is Tpm Lean.

From mavink.com

Tpm Lean Manufacturing What Is Tpm Lean Tpm is a lean maintenance strategy that aims for zero breakdowns, zero defects and zero work accidents. Learn what tpm is, how it works, and why it is important for achieving perfect production and operational efficiency. Learn how tpm relates to lean manufacturing and its 8 pillars of support, such as autonomous maintenance, quality maintenance, and focused improvement. What is. What Is Tpm Lean.

From razhanco.com

Lean Total Productive maintenance and repair (Lean TPM) What Is Tpm Lean Learn how tpm relates to lean manufacturing and its 8 pillars of support, such as autonomous maintenance, quality maintenance, and focused improvement. Tpm is a methodology that engages operators in cleaning, maintaining, and improving their workstations to ensure safety and quality during production cycles. Learn what tpm is, how it works, and why it is important for achieving perfect production. What Is Tpm Lean.

From techqualitypedia.com

TPM Pillars TPM full form Meaning and Benefits What Is Tpm Lean Tpm is a methodology that engages operators in cleaning, maintaining, and improving their workstations to ensure safety and quality during production cycles. Total productive maintenance (tpm) is a maintenance management method that allows for increased productivity and efficiency in production by eliminating. Learn about the eight pillars of tpm, a system for maintenance of equipment that aims at achieving an. What Is Tpm Lean.

From leanmanufacturing.online

Lean and TPM as Equal Partners in Ratcheting Up Performance Enhancing What Is Tpm Lean Total productive maintenance (tpm) is a maintenance management method that allows for increased productivity and efficiency in production by eliminating. Tpm stands for total productive maintenance, a japanese method to prevent errors and failures in industrial processes. Learn about the 8 pillars of tpm, or the 8 basic principles of tpm, and how to implement them in your industry. Learn. What Is Tpm Lean.

From www.leansixsigmadefinition.com

TPM Lean Manufacturing and Six Sigma Definitions What Is Tpm Lean Learn about the eight pillars of tpm, a system for maintenance of equipment that aims at achieving an optimal production environment devoid of defects, downtime, stoppages and accidents. Learn about the 8 pillars of tpm, or the 8 basic principles of tpm, and how to implement them in your industry. Total productive maintenance (tpm) is a maintenance management method that. What Is Tpm Lean.

From www.allaboutlean.com

An Overview of the Eight Pillars of Total Productive Maintenance What Is Tpm Lean Learn how tpm relates to lean manufacturing and its 8 pillars of support, such as autonomous maintenance, quality maintenance, and focused improvement. What is tpm, total productive maintenance and how does it compare or integrate with other maintenance programs such as predictive and preventive maintenance? Explore the core principles, pillars, and benefits of tpm with examples and tools. Tpm is. What Is Tpm Lean.

From www.youtube.com

Four Principles Lean Manufacturing & TPM YouTube What Is Tpm Lean What is tpm, total productive maintenance and how does it compare or integrate with other maintenance programs such as predictive and preventive maintenance? Learn about the 5s foundation,. Total productive maintenance (tpm) is a maintenance management method that allows for increased productivity and efficiency in production by eliminating. Learn about the eight pillars of tpm, a system for maintenance of. What Is Tpm Lean.

From leanmanu.com

TPM Qué es y Cómo implementarlo【 2023 What Is Tpm Lean Total productive maintenance (tpm) is a maintenance management method that allows for increased productivity and efficiency in production by eliminating. Learn about the 5s foundation,. Learn how tpm relates to lean manufacturing and its 8 pillars of support, such as autonomous maintenance, quality maintenance, and focused improvement. Tpm is a lean maintenance strategy that aims for zero breakdowns, zero defects. What Is Tpm Lean.

From www.pinterest.com

We provide training in Lean Manufacturing and TPM Related courses such What Is Tpm Lean Learn about the 8 pillars of tpm, or the 8 basic principles of tpm, and how to implement them in your industry. Learn about the eight pillars of tpm, a system for maintenance of equipment that aims at achieving an optimal production environment devoid of defects, downtime, stoppages and accidents. What is tpm, total productive maintenance and how does it. What Is Tpm Lean.

From www.sesa-systems.co.uk

TPM method The day of a machine What Is Tpm Lean Learn about the 5s foundation,. Learn how tpm relates to lean manufacturing and its 8 pillars of support, such as autonomous maintenance, quality maintenance, and focused improvement. What is tpm, total productive maintenance and how does it compare or integrate with other maintenance programs such as predictive and preventive maintenance? Total productive maintenance (tpm) is a maintenance management method that. What Is Tpm Lean.

From mungfali.com

TPM Lean Manufacturing What Is Tpm Lean Learn what tpm is, how it works, and why it is important for achieving perfect production and operational efficiency. Learn how tpm relates to lean manufacturing and its 8 pillars of support, such as autonomous maintenance, quality maintenance, and focused improvement. Tpm is a methodology that engages operators in cleaning, maintaining, and improving their workstations to ensure safety and quality. What Is Tpm Lean.

From www.bharatagritech.com

Total Productive Maintenance TPM All Pillars Explained In, 40 OFF What Is Tpm Lean Learn how tpm relates to lean manufacturing and its 8 pillars of support, such as autonomous maintenance, quality maintenance, and focused improvement. Total productive maintenance (tpm) is a maintenance management method that allows for increased productivity and efficiency in production by eliminating. Tpm stands for total productive maintenance, a japanese method to prevent errors and failures in industrial processes. Learn. What Is Tpm Lean.

From www.latestquality.com

What Are the 7 Pillars of TPM Used in Lean Latest Quality What Is Tpm Lean Tpm is a methodology that engages operators in cleaning, maintaining, and improving their workstations to ensure safety and quality during production cycles. What is tpm, total productive maintenance and how does it compare or integrate with other maintenance programs such as predictive and preventive maintenance? Tpm is a lean maintenance strategy that aims for zero breakdowns, zero defects and zero. What Is Tpm Lean.

From www.reddit.com

12 Steps of TPM Implementation How to Implement TPM What Is Tpm Lean Explore the core principles, pillars, and benefits of tpm with examples and tools. Learn how tpm relates to lean manufacturing and its 8 pillars of support, such as autonomous maintenance, quality maintenance, and focused improvement. The pillars include 5s, autonomous maintenance, planned maintenance, quality maintenance and more. Total productive maintenance (tpm) is a maintenance management method that allows for increased. What Is Tpm Lean.

From wiki4ever2.blogspot.com

wiki4ever What Is Tpm Lean Learn about the 8 pillars of tpm, or the 8 basic principles of tpm, and how to implement them in your industry. Tpm stands for total productive maintenance, a japanese method to prevent errors and failures in industrial processes. Learn how tpm relates to lean manufacturing and its 8 pillars of support, such as autonomous maintenance, quality maintenance, and focused. What Is Tpm Lean.

From www.alfraconsulting.eu

TPM in field Training What Is Tpm Lean Learn about the 8 pillars of tpm, or the 8 basic principles of tpm, and how to implement them in your industry. Tpm stands for total productive maintenance, a japanese method to prevent errors and failures in industrial processes. Learn how tpm relates to lean manufacturing and its 8 pillars of support, such as autonomous maintenance, quality maintenance, and focused. What Is Tpm Lean.

From gbu-taganskij.ru

Total Productive Maintenance [Ultimate Guide On TPM], 58 OFF What Is Tpm Lean Learn how tpm relates to lean manufacturing and its 8 pillars of support, such as autonomous maintenance, quality maintenance, and focused improvement. Learn what tpm is, how it works, and why it is important for achieving perfect production and operational efficiency. Tpm is a methodology that engages operators in cleaning, maintaining, and improving their workstations to ensure safety and quality. What Is Tpm Lean.

From leanmanufacturing.online

TPM Pillars Enhancing Your Business Performance What Is Tpm Lean Tpm is a methodology that engages operators in cleaning, maintaining, and improving their workstations to ensure safety and quality during production cycles. Learn about the 5s foundation,. Learn about the eight pillars of tpm, a system for maintenance of equipment that aims at achieving an optimal production environment devoid of defects, downtime, stoppages and accidents. Learn what tpm is, how. What Is Tpm Lean.

From learntransformation.com

What is Total Productive Maintenance(TPM)? And Its 8 Pillars Learn What Is Tpm Lean Learn what tpm is, how it works, and why it is important for achieving perfect production and operational efficiency. Explore the core principles, pillars, and benefits of tpm with examples and tools. The pillars include 5s, autonomous maintenance, planned maintenance, quality maintenance and more. Learn how tpm relates to lean manufacturing and its 8 pillars of support, such as autonomous. What Is Tpm Lean.

From learntransformation.com

What is Total Productive Maintenance(TPM)? And Its 8 Pillars Learn What Is Tpm Lean Learn what tpm is, how it works, and why it is important for achieving perfect production and operational efficiency. What is tpm, total productive maintenance and how does it compare or integrate with other maintenance programs such as predictive and preventive maintenance? Total productive maintenance (tpm) is a maintenance management method that allows for increased productivity and efficiency in production. What Is Tpm Lean.

From leanfactories.com

TPM and Six Sigma Basics Lean Factories What Is Tpm Lean Tpm is a lean maintenance strategy that aims for zero breakdowns, zero defects and zero work accidents. Learn how tpm relates to lean manufacturing and its 8 pillars of support, such as autonomous maintenance, quality maintenance, and focused improvement. Learn what tpm is, how it works, and why it is important for achieving perfect production and operational efficiency. Tpm is. What Is Tpm Lean.