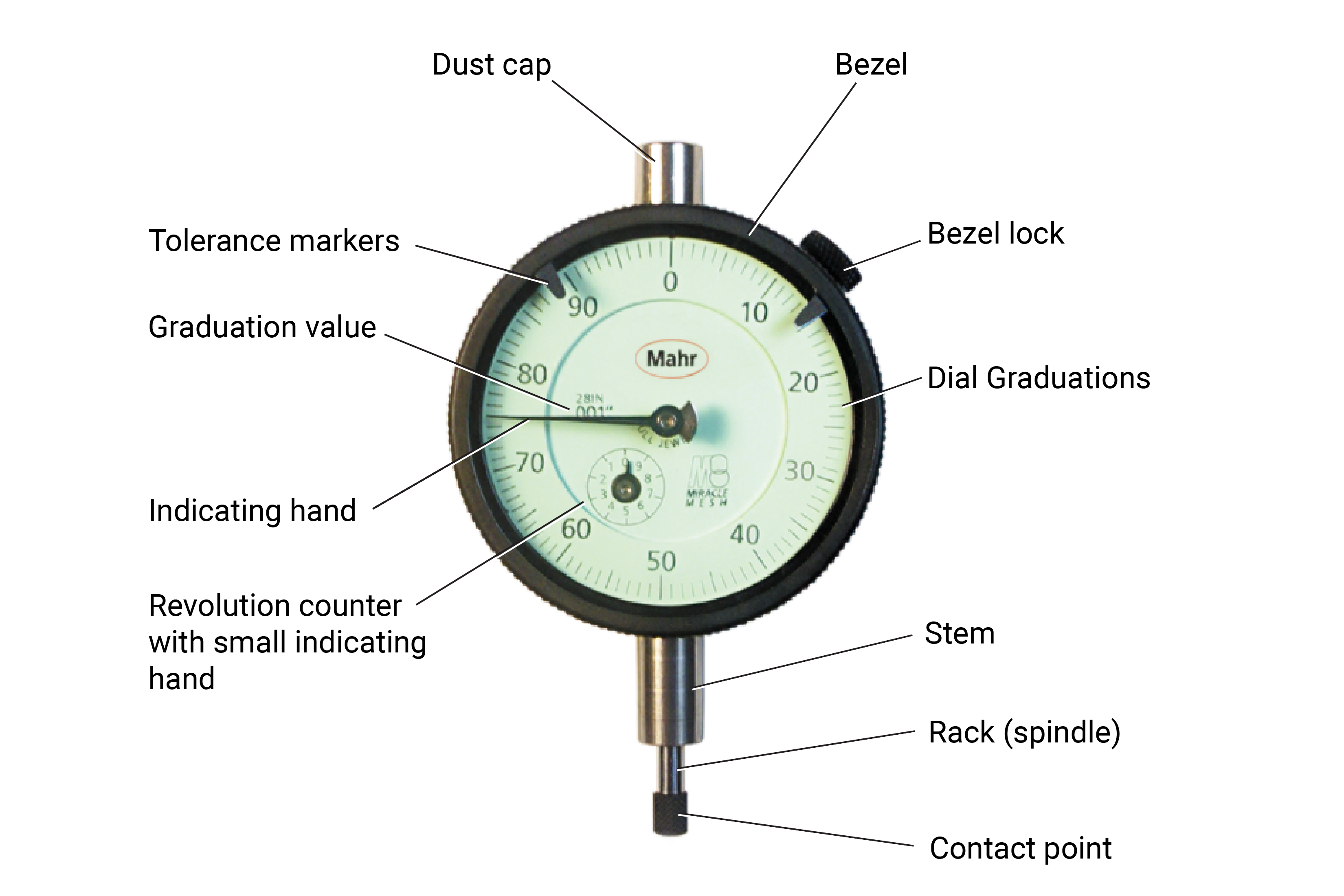

Dial Indicator Not Returning To Zero . Now, the dial indicator plunger is positioned approximately halfway within the range of travel. calipers can need calibrated to maintained accuracy. mount the indicator in a stand and get some gage blocks that are spaced so that they cover the range over which the. The main cause of calipers becoming uncalibrated are chips getting in. to accomplish this, you must position the dial indicator so that the plunger is parallel to the direction of component movement. Familiarize yourself with the parts: Before taking any measurements, ensure the dial is set to zero by rotating its outer ring. your calibration measurements will ensure that the dial indicator does read measurements starting at zero. if a dial indicator is not returning to zero after use, you can try the following steps to troubleshoot the issue: Next, the dial indicator must be zeroed. Get familiar with these parts before using the tool.

from www.mmsonline.com

Next, the dial indicator must be zeroed. Familiarize yourself with the parts: to accomplish this, you must position the dial indicator so that the plunger is parallel to the direction of component movement. Before taking any measurements, ensure the dial is set to zero by rotating its outer ring. Now, the dial indicator plunger is positioned approximately halfway within the range of travel. The main cause of calipers becoming uncalibrated are chips getting in. mount the indicator in a stand and get some gage blocks that are spaced so that they cover the range over which the. calipers can need calibrated to maintained accuracy. your calibration measurements will ensure that the dial indicator does read measurements starting at zero. Get familiar with these parts before using the tool.

Reading What the Dial Indicator Is Saying Modern Machine Shop

Dial Indicator Not Returning To Zero mount the indicator in a stand and get some gage blocks that are spaced so that they cover the range over which the. The main cause of calipers becoming uncalibrated are chips getting in. Before taking any measurements, ensure the dial is set to zero by rotating its outer ring. your calibration measurements will ensure that the dial indicator does read measurements starting at zero. Familiarize yourself with the parts: Get familiar with these parts before using the tool. mount the indicator in a stand and get some gage blocks that are spaced so that they cover the range over which the. calipers can need calibrated to maintained accuracy. if a dial indicator is not returning to zero after use, you can try the following steps to troubleshoot the issue: to accomplish this, you must position the dial indicator so that the plunger is parallel to the direction of component movement. Next, the dial indicator must be zeroed. Now, the dial indicator plunger is positioned approximately halfway within the range of travel.

From chitrancetalk.blogspot.com

Dial Indicator Dial Gauge Types Of Dial Indicators Working Principle Dial Indicator Not Returning To Zero Before taking any measurements, ensure the dial is set to zero by rotating its outer ring. your calibration measurements will ensure that the dial indicator does read measurements starting at zero. calipers can need calibrated to maintained accuracy. Get familiar with these parts before using the tool. to accomplish this, you must position the dial indicator so. Dial Indicator Not Returning To Zero.

From www.walmart.com

MITUTOYO 2904S Dial Indicator,0 to 1 In,1000 Dial Indicator Not Returning To Zero if a dial indicator is not returning to zero after use, you can try the following steps to troubleshoot the issue: The main cause of calipers becoming uncalibrated are chips getting in. Before taking any measurements, ensure the dial is set to zero by rotating its outer ring. mount the indicator in a stand and get some gage. Dial Indicator Not Returning To Zero.

From www.mmsonline.com

How to Choose the Right Dial Indicator Modern Machine Shop Dial Indicator Not Returning To Zero Get familiar with these parts before using the tool. to accomplish this, you must position the dial indicator so that the plunger is parallel to the direction of component movement. calipers can need calibrated to maintained accuracy. Now, the dial indicator plunger is positioned approximately halfway within the range of travel. The main cause of calipers becoming uncalibrated. Dial Indicator Not Returning To Zero.

From www.wikihow.com

How to Read a Dial Indicator 15 Steps (with Pictures) wikiHow Dial Indicator Not Returning To Zero to accomplish this, you must position the dial indicator so that the plunger is parallel to the direction of component movement. Get familiar with these parts before using the tool. mount the indicator in a stand and get some gage blocks that are spaced so that they cover the range over which the. your calibration measurements will. Dial Indicator Not Returning To Zero.

From www.grainger.com

MAHR INC Dial Test Indicator, Vertical Indicator Style, Yellow, 0 to 0 Dial Indicator Not Returning To Zero Get familiar with these parts before using the tool. The main cause of calipers becoming uncalibrated are chips getting in. if a dial indicator is not returning to zero after use, you can try the following steps to troubleshoot the issue: mount the indicator in a stand and get some gage blocks that are spaced so that they. Dial Indicator Not Returning To Zero.

From solutions.travers.com

How To Read A Dial Indicator Dial Indicator Not Returning To Zero if a dial indicator is not returning to zero after use, you can try the following steps to troubleshoot the issue: to accomplish this, you must position the dial indicator so that the plunger is parallel to the direction of component movement. Now, the dial indicator plunger is positioned approximately halfway within the range of travel. Get familiar. Dial Indicator Not Returning To Zero.

From www.grainger.com

STARRETT Dial Test Indicator, Horizontal Indicator Style, White, 0 to 0 Dial Indicator Not Returning To Zero to accomplish this, you must position the dial indicator so that the plunger is parallel to the direction of component movement. Now, the dial indicator plunger is positioned approximately halfway within the range of travel. Get familiar with these parts before using the tool. Familiarize yourself with the parts: The main cause of calipers becoming uncalibrated are chips getting. Dial Indicator Not Returning To Zero.

From www.engineeringtribe.com

Dial Gauge (PDF) Parts, Working Principle, Types, Uses, etc Dial Indicator Not Returning To Zero Before taking any measurements, ensure the dial is set to zero by rotating its outer ring. Familiarize yourself with the parts: The main cause of calipers becoming uncalibrated are chips getting in. calipers can need calibrated to maintained accuracy. Now, the dial indicator plunger is positioned approximately halfway within the range of travel. mount the indicator in a. Dial Indicator Not Returning To Zero.

From gokultraders.com

MitutoyoSERIES 2 Standard One Revolution Type for Errorfree Reading Dial Indicator Not Returning To Zero if a dial indicator is not returning to zero after use, you can try the following steps to troubleshoot the issue: mount the indicator in a stand and get some gage blocks that are spaced so that they cover the range over which the. Next, the dial indicator must be zeroed. to accomplish this, you must position. Dial Indicator Not Returning To Zero.

From www.randysworldwide.com

How To Use A Dial Indicator RANDYS Worldwide Dial Indicator Not Returning To Zero Now, the dial indicator plunger is positioned approximately halfway within the range of travel. The main cause of calipers becoming uncalibrated are chips getting in. mount the indicator in a stand and get some gage blocks that are spaced so that they cover the range over which the. if a dial indicator is not returning to zero after. Dial Indicator Not Returning To Zero.

From www.wikihow.com

How to Read a Dial Indicator 15 Steps (with Pictures) wikiHow Dial Indicator Not Returning To Zero mount the indicator in a stand and get some gage blocks that are spaced so that they cover the range over which the. Before taking any measurements, ensure the dial is set to zero by rotating its outer ring. your calibration measurements will ensure that the dial indicator does read measurements starting at zero. calipers can need. Dial Indicator Not Returning To Zero.

From www.onallcylinders.com

Dial Indicator Tips Advice for Choosing, Mounting, Zeroing and Dial Indicator Not Returning To Zero Before taking any measurements, ensure the dial is set to zero by rotating its outer ring. to accomplish this, you must position the dial indicator so that the plunger is parallel to the direction of component movement. calipers can need calibrated to maintained accuracy. Get familiar with these parts before using the tool. your calibration measurements will. Dial Indicator Not Returning To Zero.

From www.youtube.com

How to Read Dial Indicators Quick Machining Tip 24 YouTube Dial Indicator Not Returning To Zero Before taking any measurements, ensure the dial is set to zero by rotating its outer ring. mount the indicator in a stand and get some gage blocks that are spaced so that they cover the range over which the. to accomplish this, you must position the dial indicator so that the plunger is parallel to the direction of. Dial Indicator Not Returning To Zero.

From www.youtube.com

DIAL INDICATOR COMPARISON/REVIEW Part 2 Application and Stands Dial Indicator Not Returning To Zero your calibration measurements will ensure that the dial indicator does read measurements starting at zero. to accomplish this, you must position the dial indicator so that the plunger is parallel to the direction of component movement. if a dial indicator is not returning to zero after use, you can try the following steps to troubleshoot the issue:. Dial Indicator Not Returning To Zero.

From www.reddit.com

Ryobi p270 clutch adjustments not returning back to zero or fully Dial Indicator Not Returning To Zero Get familiar with these parts before using the tool. The main cause of calipers becoming uncalibrated are chips getting in. calipers can need calibrated to maintained accuracy. your calibration measurements will ensure that the dial indicator does read measurements starting at zero. if a dial indicator is not returning to zero after use, you can try the. Dial Indicator Not Returning To Zero.

From www.wikihow.com

How to Read a Dial Indicator 15 Steps (with Pictures) wikiHow Dial Indicator Not Returning To Zero The main cause of calipers becoming uncalibrated are chips getting in. Next, the dial indicator must be zeroed. mount the indicator in a stand and get some gage blocks that are spaced so that they cover the range over which the. Now, the dial indicator plunger is positioned approximately halfway within the range of travel. Get familiar with these. Dial Indicator Not Returning To Zero.

From www.mmsonline.com

Reading What the Dial Indicator Is Saying Modern Machine Shop Dial Indicator Not Returning To Zero Now, the dial indicator plunger is positioned approximately halfway within the range of travel. Get familiar with these parts before using the tool. Before taking any measurements, ensure the dial is set to zero by rotating its outer ring. if a dial indicator is not returning to zero after use, you can try the following steps to troubleshoot the. Dial Indicator Not Returning To Zero.

From www.randysworldwide.com

How To Use A Dial Indicator RANDYS Worldwide Dial Indicator Not Returning To Zero Familiarize yourself with the parts: Next, the dial indicator must be zeroed. Now, the dial indicator plunger is positioned approximately halfway within the range of travel. calipers can need calibrated to maintained accuracy. Before taking any measurements, ensure the dial is set to zero by rotating its outer ring. mount the indicator in a stand and get some. Dial Indicator Not Returning To Zero.

From www.youtube.com

The Not So Quick Change Dial Indicator Holder YouTube Dial Indicator Not Returning To Zero your calibration measurements will ensure that the dial indicator does read measurements starting at zero. Familiarize yourself with the parts: calipers can need calibrated to maintained accuracy. to accomplish this, you must position the dial indicator so that the plunger is parallel to the direction of component movement. Next, the dial indicator must be zeroed. mount. Dial Indicator Not Returning To Zero.

From www.diymotofix.com

Precision Measuring For The AtHome Mechanic DIY Moto Fix Dial Indicator Not Returning To Zero Next, the dial indicator must be zeroed. to accomplish this, you must position the dial indicator so that the plunger is parallel to the direction of component movement. mount the indicator in a stand and get some gage blocks that are spaced so that they cover the range over which the. if a dial indicator is not. Dial Indicator Not Returning To Zero.

From www.mmsonline.com

Reading What the Dial Indicator Is Saying Modern Machine Shop Dial Indicator Not Returning To Zero mount the indicator in a stand and get some gage blocks that are spaced so that they cover the range over which the. if a dial indicator is not returning to zero after use, you can try the following steps to troubleshoot the issue: calipers can need calibrated to maintained accuracy. Now, the dial indicator plunger is. Dial Indicator Not Returning To Zero.

From www.youtube.com

Dial Gauge Indicator(Working Principle) YouTube Dial Indicator Not Returning To Zero your calibration measurements will ensure that the dial indicator does read measurements starting at zero. Next, the dial indicator must be zeroed. mount the indicator in a stand and get some gage blocks that are spaced so that they cover the range over which the. Before taking any measurements, ensure the dial is set to zero by rotating. Dial Indicator Not Returning To Zero.

From industrialtoolsinfo.com

What is the dial indicator and how to use it? Dial Indicator Not Returning To Zero mount the indicator in a stand and get some gage blocks that are spaced so that they cover the range over which the. Before taking any measurements, ensure the dial is set to zero by rotating its outer ring. your calibration measurements will ensure that the dial indicator does read measurements starting at zero. if a dial. Dial Indicator Not Returning To Zero.

From www.walmart.com

MITUTOYO 51340510E Dial Test Indicator,Hori,0 to 0.2mm Dial Indicator Not Returning To Zero calipers can need calibrated to maintained accuracy. The main cause of calipers becoming uncalibrated are chips getting in. Next, the dial indicator must be zeroed. if a dial indicator is not returning to zero after use, you can try the following steps to troubleshoot the issue: Get familiar with these parts before using the tool. mount the. Dial Indicator Not Returning To Zero.

From www.wikihow.com

How to Read a Dial Indicator 15 Steps (with Pictures) wikiHow Dial Indicator Not Returning To Zero Get familiar with these parts before using the tool. your calibration measurements will ensure that the dial indicator does read measurements starting at zero. mount the indicator in a stand and get some gage blocks that are spaced so that they cover the range over which the. calipers can need calibrated to maintained accuracy. Before taking any. Dial Indicator Not Returning To Zero.

From www.indiamart.com

Zero + Dial Indicator at Rs 1050/piece in Rajkot ID 14462897630 Dial Indicator Not Returning To Zero calipers can need calibrated to maintained accuracy. The main cause of calipers becoming uncalibrated are chips getting in. Before taking any measurements, ensure the dial is set to zero by rotating its outer ring. mount the indicator in a stand and get some gage blocks that are spaced so that they cover the range over which the. Next,. Dial Indicator Not Returning To Zero.

From www.engineeringtribe.com

Dial Gauge (PDF) Parts, Working Principle, Types, Uses, etc Dial Indicator Not Returning To Zero if a dial indicator is not returning to zero after use, you can try the following steps to troubleshoot the issue: The main cause of calipers becoming uncalibrated are chips getting in. to accomplish this, you must position the dial indicator so that the plunger is parallel to the direction of component movement. calipers can need calibrated. Dial Indicator Not Returning To Zero.

From www.youtube.com

How to read the Dial Indicator YouTube Dial Indicator Not Returning To Zero Familiarize yourself with the parts: Before taking any measurements, ensure the dial is set to zero by rotating its outer ring. calipers can need calibrated to maintained accuracy. Next, the dial indicator must be zeroed. Get familiar with these parts before using the tool. to accomplish this, you must position the dial indicator so that the plunger is. Dial Indicator Not Returning To Zero.

From www.alignmentknowledge.com

Dial Indicator Alignment Basics Alignment Knowledge Dial Indicator Not Returning To Zero The main cause of calipers becoming uncalibrated are chips getting in. mount the indicator in a stand and get some gage blocks that are spaced so that they cover the range over which the. calipers can need calibrated to maintained accuracy. Next, the dial indicator must be zeroed. to accomplish this, you must position the dial indicator. Dial Indicator Not Returning To Zero.

From www.grainger.com

MITUTOYO Dial Test Indicator, Vertical Indicator Style, White, 0 to 0. Dial Indicator Not Returning To Zero calipers can need calibrated to maintained accuracy. Before taking any measurements, ensure the dial is set to zero by rotating its outer ring. Get familiar with these parts before using the tool. mount the indicator in a stand and get some gage blocks that are spaced so that they cover the range over which the. Next, the dial. Dial Indicator Not Returning To Zero.

From www.klassikats.com

How to Measure With A Dial Indicator Correctly Klassik ATS Dial Indicator Not Returning To Zero The main cause of calipers becoming uncalibrated are chips getting in. Next, the dial indicator must be zeroed. your calibration measurements will ensure that the dial indicator does read measurements starting at zero. Get familiar with these parts before using the tool. if a dial indicator is not returning to zero after use, you can try the following. Dial Indicator Not Returning To Zero.

From www.onallcylinders.com

Dial Indicator Tips Advice for Choosing, Mounting, Zeroing and Dial Indicator Not Returning To Zero Familiarize yourself with the parts: Next, the dial indicator must be zeroed. your calibration measurements will ensure that the dial indicator does read measurements starting at zero. calipers can need calibrated to maintained accuracy. Now, the dial indicator plunger is positioned approximately halfway within the range of travel. mount the indicator in a stand and get some. Dial Indicator Not Returning To Zero.

From www.coursehero.com

Determine the reading on both dial indicators How do you read them Dial Indicator Not Returning To Zero Familiarize yourself with the parts: your calibration measurements will ensure that the dial indicator does read measurements starting at zero. The main cause of calipers becoming uncalibrated are chips getting in. Before taking any measurements, ensure the dial is set to zero by rotating its outer ring. Now, the dial indicator plunger is positioned approximately halfway within the range. Dial Indicator Not Returning To Zero.

From www.reddit.com

Slow returning test dial indicator. Doesn’t bother me actually kind of Dial Indicator Not Returning To Zero your calibration measurements will ensure that the dial indicator does read measurements starting at zero. The main cause of calipers becoming uncalibrated are chips getting in. Familiarize yourself with the parts: if a dial indicator is not returning to zero after use, you can try the following steps to troubleshoot the issue: to accomplish this, you must. Dial Indicator Not Returning To Zero.